|

|

Forum Index : Windmills : My new mill

| Author | Message | ||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

isaiah This: http://www.motherearthnews.com/Renewable-Energy/1973-11-01/T he-Plowboy-Interview.aspx Becomes a "hot link" like this: Plowboy Interview

. . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Charlie This man was way ahead of the times and what he was doing years ago is what we will need to do in the future if we want to maintain a reasonable standard of living without the financial stress of ever increasing energy costs, it is a real worthwhile read for all of us trying to achieve what he has already done 70 years ago. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All Just a little report on my little mill, it is alive and well and weathered several big blows without damage.

It is the one in the middle of the roof. Old photo most trees are now trimmed to below wind flow area. However the intent of this report is to let you know that for several days now I have had a steady south east breeze at between 1.5 and 2 MS, this has given me the opportunity to monitor the bottom end performance of the mill that Gordon so often mentions as the most important.

The old 500 watt mill isn't turning in this breeze so no output but the new mill is turning consistently and producing between 1 and 2 amps at 28 volts or an output of 25 to 50 watts, on slight gusts it was peaking at 4 amps, this isn't a lot to be sure to be sure, but as the old lady said every little bit helps. This shows the efficiency of the GEO 222 blades, and the basic design of the little mill. I know that problems where had from overdriving the mill but in it's forte role as a slow MS producer it is the best I have ever found Thanks Phill. Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All For those who live in Australia, you may have noted we have had some winds up the east coast, and thank goodness I live far enough north to have missed the destructive winds the good side is it has given a few days of wind in the 3 to 6 MS with some gusts reaching 12 MS. This has given me the opportunity to try a few mods to my hay wired controllers and tidy things up a bit in the electrical department. I have settled on a good compromise with my new mil the little wonder OEM machine, it is recovering more power from the wind than it should so I have to look at the wind indications on my weather station as being a bit pessimistic. I think it is the blades but nobody agrees with me on that. However it has given me the opportunity to play with different combinations of boost devices, The one that is working the best in these low speed winds is a 3 amp boost module cutting in at 5 volts and .5 amps this increases up to 3 amps at 14 volts. Then I have re installed the boost capacitors as per Phills design for the mill, they cut in at 14 volts and 1 amp increasing up to 4.5 amps at 25 volts when the main rectifier cuts in and I have seen 10 amps on many occasions as the wind gusts up a bit, but at a steady 5 MS it sits on 6 amps. On some high speed gusts the mill was totaling over 50 amps before furl set in then it dropped back to around 15 amps until the blades accelerated again. This is metered on three separate meters totaling 13.5 amps equals 405 watts at an output voltage of 30 volts. The wind mill voltage is read from the 3 phase bridge running the boost module. as it is lightly loaded it gives a fair indication of the actual voltage produced, DC of course. The mill is still connected in Delta as it gives better drive that way, I tried star and it cut in a bit quicker but still not as slow as with the 3 amp boost module. On the 3 amp module, I had one on there that cut in a 3 volts but it loaded the blades a bit and made the mill grumble at lower revs, the one I have got now cuts in at 5 volts and has a ramp on the loading so it doesn't just drop on, it seems to take a second or so to ramp up and works smoother, but it does the same job as the other one. For some reason and I am not sure what, the cap doubler brings in the main rectifier earlier than the mid range boost module I was using before, both work well but the mill cuts in smoother with the caps than the boost module. I have some pictures to up load when all is back to normal. Also did the controller for the old Chinese mill along the same lines and will give a description of that as well if you all are interested. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

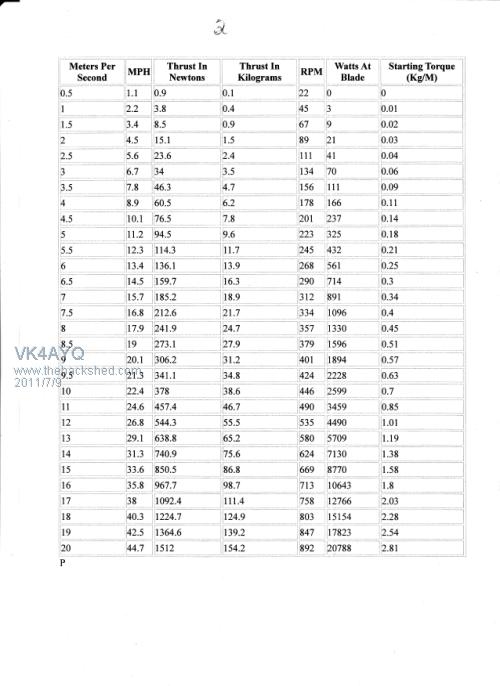

Hi All Now we are back on line I have some photos of my controller and a table from Altons that reflects the performance of the mill. The Altons chart has been back engineered to suit the mill outputs, based on the 3 meter diameter blades GEO222 with an angle of attack of 8 degrees and a CLMax of 2 TSR of 7 and efficiency of 50% The actual CL Max of the Geo 222 blades is 2.4 so My estimates are a bit conservative to cover any other things I missed. The blades run very quiet and are barley audible over the wind noise, a sound recording level meter couldn't pick up the sound at 20 meters but it can be heard by ear, the wind noise on the microphone wind muff drowned out the mill noise. Allowing for a bit of losses the figures of watts out match the chart profile.

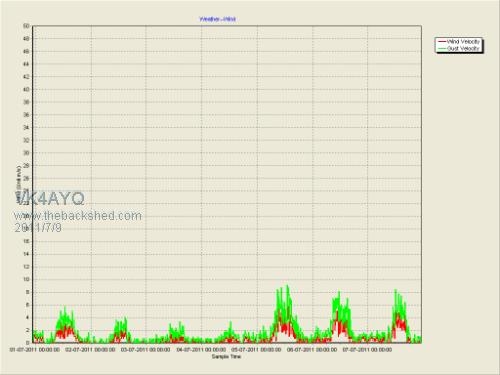

. This is with the 3 meter diameter blades in wind that is a reasonable indication of present winter conditions. The green is the gusts and red is the wind average speed unfortunately due to the reaction time of the weather station some of the top information is lost, and as Gordon pointed out it is not a true calibrated instrument so there is a margin for error.

The controller This is the controller with the 3 amp module boosting, the lower meter is the boost module and the top meter is the main rectifier. As the wind speed increases the main rectifier starts to conduct and the boost module is still working. This is the cut in of the boost module at 2.5 MS Just over 1 amp output. The lower cut in module 3.5 volts loaded the bottom end a bit more than I liked but recovered a bit more power cutting in at 2 MS. Not shown in the photos is the Cap doubler that Phill gave me the circuit of, it works very smooth and cuts in at 15 volts DC on the mill and puts in another 4.5 amps across the board. I have a 30 amp meter metal shunt model on the controller at the moment and it pegs out on gusts so all in all a successful little controller. When the mill furls the meter drops back to 15 amps on the main rectifier, then as the blades unfurl it comes up to between 20 and 25 amps depending on turbulence in the wind.Mill out put holds steady at 30 volts for 28 volts at the battery reflecting a bit of loss in the cable to the battery, about 20 meters of 6mm cable. I tried the mid range boost converter as well it cuts in at 10 volts and does 10 amps but for the moment the caps seem to work the output smoother, and what I lost on the mid range boost unit I picked up on the main rectifier. All the best Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Bob, That is a picture of Efficiency, Storing Watts in a 2-Mile wind!!!, WoW!. Good looking Meter, and Box also. One puzzling thing about your Chart is the Starting torque. I don't know much about windmill data values but why would the Starting torque change with a wind change if the bearings are good? There is something I'm Missing Here. -----Cheers, Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Roe I think that is the starting torque available for a stopped blade at the indicated wind speed. Mine starts between 1.4 and 1.5 MS with the geo 222 blades but the other mill had high speed blades and it doesn't start before 3.5 MS once it is going it will keep going in lower wind speed, this indicates the 222 blade section is far more efficient at slow wind speeds, as when it gets to 10 MS they generate the same output in relation to their capacity, the old Chinese mill has 2.4 meter diameter blade as to the OEM mill at 3 Meters. All the best Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

OK Bob, For a Cogging Situation this data would be desirable, I knew I wasn't seeing the whole picture. That 3 amp booster device you are using? On average How much time in one day is this active and how much extra power is produced that you would not get without it? What I'm getting at is, with Gordons Caps and this booster how much more power is collected than would be available without them, say an average month. ----Cheers, Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bob, I have been doing a bit of experimenting with the 60V boost module on my system , the reason you are noticing that the Cap/dblr cuts in through the main rectifier earlier than the boost converter is because the B/Cvtr clamps the DC voltage at its min input untill it reaches its max output amps and then the DC volts start to rise where as the C/DBLR still alows the voltage to increase with RPMS smoothly untill the main rectifier cuts in. This can easily be seen with a DMM on the dc to the B/Cvtr. So far the use of the B/converter on my AX/FX was dismal as it instantly loads the blades at 50-60Rpm and clamps the volts @ 10VDC and the output in low wind was much less than the Cap/doubler. The mill is severly overloaded and the output falls below the 500w mill. I have not tried it on the 500W Kit as yet but I can see it would probably work a little better on that mill because of the higher actual cut-in Rpm . I have been trialing a Cap/Quadrupler with 680uF Caps instead of the 1600uF and the results are very good with the 500W only 20% less in output than the AX-FX in very low wind of 5 to 9klm (1.5m/s to 3m/s), which is on the mark as the blade dia is 2.8m compared to he AX @ 3.1m and taking into consideration the iorn loss and slight cogging of the 500W. I still beleive a correctly matched Cap/Doubler will track the available wind power and keep the blades at their optium TSR better than most other forms of tracking. This is also Gordons opinion after he perfected his Wind MPPT controller he then went back to the caps because of their simplicity and the way they JUST WORK without all the electronic gizmos. But if you go for low wind performance there is always a trade off with heavier loading in medium wind , I will be putting a post together with all the data from the loggers that confirms what I have been saying all along that it is better to run a mill slightly underloaded and it will give more power in the long run. Blade caculators and wind tunnel testing do not take into account the mill not tracking the wind perfectly and an overloaded blade will take a lot longer to recover from any wind shifts or wind speed changes which happen many times in a given period. I still believe you would get the same if not better low wind output running the mill in star and a lesser uF Cap/dblr , without seeing the high 50A+ spurts that usually only end up causing damage for the 1 or so days a year which the recovery time can be costly in lost power and blown components. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Phill I agree that simpler is better and the caps is a simpler way to go even if a bit more expensive due to the cost of caps. I did try the star connection with and without the booster and it worked well but at a higher cut in speed than the booster, I suppose the booster had the advantage of collecting 1 to 2 amps in delta or star at very low wind speed which is the norm at my place whereas at the same speed the caps didn't do anything till the voltage reached 15 volts whereas the booster was doing 2 to 3 amps over the dead spot. Interesting was the fact that in delta it went higher in amps on the booster before the caps cut in and in delta the caps produce 4.5 amps compared to 2 amps in star. I didn't get any higher speed winds while in star to get an idea of what it would do amps wise, it was just coming onto the main rectifier and the response to gusts was more feeble than in delta, where it really has a noticeable extra output on any gusts, it sits at 8 to 10 amps but when a bit of a gust comes it goes up to 25 to 30 amps very positively. I tried the 60 volt booster in delta and the results where disappointing maxing out 2 amps and loading the mill more than the lower voltage booster. I didn't try the 60 volt booster in star as it came after I tried the star exercise. The caps went to 1.5 amps in star but due to the higher cut in voltage needed more wind to work, but that's normal. The voltage comparison from star to delta was 1.5 to 1, about what I expected. If I was using a 48 volt battery I would use star for sure, with the booster but with the 24 volt system I feel it works better in delta, but needs the booster for the low end as the caps cut in a bit high 15 volts. I think the main difference in our results is the output voltage matching. One day when I can afford to get a proper data logger ready made I will have a more accurate reading. The blades at 3 meter diameter seem to be about ideal and do not look like stalling or overloading, but did slow a bit with the lower cut in module. When I do the next one I will set it up in star so can swap from one to the other with a logger without doing a balancing act to remove the front cover to connect in star. My wife has a pink fit when she sees me on top of the ladder hanging onto the mast removing and replacing the cover, she has no sense of adventure, or is more sensible than me, one or the other. All the best Bob PS: On the lower voltage booster it does not clamp the mill voltage as I can watch it go up and down with the rpm of the mill, it may be different on the 60 volt booster but I didn't notice when I have tried it, but that is delta again. Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Roe The modules I am using at the moment: Ebay item numbers 1:- Item number: 200607221396 This is lower voltage unit 2:- Item number: 110711024540 This is the higher current higher voltage unit. As for an estimate of extra power without a logger it is only a guess. With the mill in standard condition Star it cuts in at 24 volt 5.5 to 6 MS With the mill in delta rewire it cuts in at 6 to 6.5 MS With Caps only in star it cuts in at 4.5 MS 2 amps max With caps only in delta it cuts in 5.5 MS 5 amps max With the low voltage booster in star it cuts in at 1.5 MS but grumbles a bit 3 amps With the low voltage booster in delta it cuts in at 2.2 MS runs smoother as more blade speed smooths out the mill a bit. 3 amps With the 10 volt booster it cuts in at 3 MS in star. 1 amp to max 6 amps With the 10 volt booster it cuts in at 3.8 MS in delta. 1 amp to max 9 amps Main rectifier cuts in at approx 6.5 to 7.2 MS start charging at 5 amps and goes to 30 at 12 MS approx as it is starting to furl there, it is a bit hard to be accurate, on 15 MS gusts before furling it goes to approx 50 amps but then drops to 15 to 25 amps once it furls due to tree induced turbulence. All the readings are additive as they are on 3 separate meters so yield is around 8 to 10 amps at 5,5 to 6 MS this is power it wouldn't be doing without enhancement, so say 250 watts while the wind is there and is reasonable. The boost modules keep charging until battery voltage reaches 28 volts than cut out but the main rectifier keeps charging and the excess is dumped into GTI. My place is a low wind area so would not expect to get more than 2500 watts a day on overage. I am doing the LG to try for a lower speed machine but that is a work in progress. All the best Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Bob, Thanks for the breakdown on the mill performance. About 13-1/2 MPH 18 KPH makes 250 watts for you. I've been watching your posts on the LG, Things are moving along, Sure like that Lathe, Especially the Chuck and swing Capacity. nice method of controlling the resin while it set up. I saw Oztules Panel creation on Fieldlines a few days ago when this Forum was closed. "What a Guy". ----Cheers, Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Roe I will do some voltage and current testing once the resin sets right off it is a bit slow in this cold weather. All the best Bob Foolin Around |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Hi Bob, Can you help me understand this? When you say your mill puts out 2500 watts a day, what does that mean? 2500 watt-hours? Averages 2500 watts of power over a 24 hrs? 2500 watt-hrs in 24 hours? I'm confused. Thanks, Perry |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Perry What I meant was 2.5 KW (2500 watts) a day on the average. in reality about 104 watts per hour, average just over 3.5 AH at 28.5 volts the charging voltage for the battery pack. It is an arbitrary figure because I do not have a logger at the moment and as you well know the wind is very fickle so it can vary between 30 amps and zero. By using the average wind speed on the weather station for a month against a known output of the mill at that wind speed I can get a rough idea of output, I do not take into account the gust speeds so it may be conservative. All the best Bob Foolin Around |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

10-4, I understand now. So what you are saying is that you make 2.5 kW-hr a day. Watts are a measure of instantaneous power, not energy. So saying you made 2500 watts a day doesn't really makes sense, kind of like saying you made 300 volts in a day. Sorry if this sounds nit-picky and I know you know the difference between the two but I see these accidentally interchanged a lot around the net. 2.5 kWh/day is a pretty decent figure. I hear you on the wind measurement as well. That's an art form in itself. Perry |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Perry I was trying to simplify the concept and caused confusion sorry about that, the whole point of the observation was to show that little bits do add up over time and with the little boost modules it harnesses the bottom end power that would otherwise not be there, I know now that when I look at the mill and the blades are turning it is making power that wasn't there before, and at my place that low wind is the norm. By the way it take me all day to make 300 + volts on LG so that may be a bit true, I crept it up slowly to lookout for magic smoke. All the best Bob Foolin Around |

||||