|

|

Forum Index : Electronics : a new way to balance lithium ion battery

| Author | Message | ||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

After observing my lifepo4 bank cell voltages during the charge cycle, there is only a limited time window to actually measure any great difference in individual cell voltages. This only occurs when they are in the knee of the sharp voltage rise starting around 3.45 and up to 3.5 volts or greater, we are only talking 30 minutes or less here, all other times the cell voltages are virtually identical, especially when inverter loads are running, injecting noise into the bank. So any hopping balance process isnt going to measure any difference between the cells except in this small window, thus wih big AHr cells, I feel little bursts of current are not going to achieve very much. Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That is the reason why I want my video display of cell voltages to record the maximum and minimum peak cell voltages reached during normal operation. That will not only give a better indication of overall balance, but of any relative cell amp hour capacity differences. I can then do any individual cell charging or discharging manually if required. The hopper is not expected to balance the system, only to tend to keep it in balance over a very long period. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

I am not over confident the cells divided by bank voltage idea would do much either, but the logic seems sound, and I think it is worth a try. Warpspeed wants to measure voltage, but it has nothing to do with function other then data knowledge. This doesn't measure any difference between cells as a concept, it just acts on each with an average of the bank. But it also averages variations. There would not seem to be any thermal issues with this approach. Things working as intended, you would not damage cells. So we have a balance reference 1/17th, or bank voltage divided by cells which is following any changes. A cell is connected, it is either lower and takes additional charge, or higher and clipped to the new equilibrium, which is something between the bank division and cells series supply. The cell equal with the bank division remain unaffected. The current requirement could be guesstimated with known PSOC measurements. EG: GBS 3.2v Lifepo4 Cells Capacity between 3.5v and 3.65v is around 1-2 Amp. This doesn't give us a clear understanding of whats required, but I have more info that might take us closer. Cheers Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

It seems there can be two extremes here. People running relatively few large Ah cells, and people running large series strings of relatively low Ah cells. The BMS situation is rather different. The big cell guys are going to have far fewer balance problems, and its more easy to manage, and its going to take more grunt to shift the balance if/when required. Us small cell people (30 x 60Ah) have many more cells to watch over, and much less power needs to be shunted around to do the trick. So its really a rather different problem. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

Image problems, try later Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes the Forum image gremlin has returned. I have to use Photobucket whenever that happens. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

I was reading something on PSOC that might be helpful, but it is mislaid for a while. The balance requirements as relates to bank size should be linear. The capacity per Milli-volt is not, but as long as it is only going in one direction. Low Discharge of reasonably good quality cells might respond. This is voltage vrs capacity for 100Ah GBS Cells: Charging and Discharging. Also A 50Ah GEB Cell. http://imgur.com/a/H1ZL6 Here I have Boxed the approximate Capacity of 77Ah between 3.35 and 3.45v. Not very scientific but about 7.7 Amp per .01v. http://imgur.com/hcOSky8 Most of the Voltage to Capacity Graphs for reasonable quality cells are evenly declining or ascending, which suggests it should work? Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I will wait until my cells arrive, then complete the voltage monitoring system first. Then see what they actually do. Those curves suggest a battery mid point working voltage of around 3.3 volts under fairly light charge and discharge conditions, all in the flat portion of the curve. That's about where I plan to begin. Thirty cells and 100 volts nominal with only a few volts of variation in either direction up and down from there. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

The question is the capacity extracted from bank each cycle that determines voltage envelope. The graphs are all different and are only an indicator. In discussion with GBS regarding 100Ah Lifepo4 cell, The remaining capacity for our 3.2V100Ah is only 1-2Ah with 3.5 cut-off charge and 2.5 cut-off discharge. When the battery is discharged to 2.5V, there is only 1-2Ah left. When it is 2.8V, there is around 4Ah left. So you get a big initial increase in cycle life for very little in lost capacity. With another cell, lost capacity could be quite a lot. Take into consideration the Specified End of Discharge, were it is 2v the cell curve can be very different. Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

It appears that the number of discharge cycles before the battery is stuffed has a lot to do with depth of charge/discharge. Over sizing the battery and staying right in the middle of the operating envelope can greatly increase battery life. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

It has nearly everything to do with charge and discharge level. High temperatures have a negative impact on the stored or physical age of cells, as opposed to the capacity being more about the total passage of energy in and out. The problem is the cell characteristics, not many sellers provide good details because the cell are that close to specification, any variation on use results in large loss of capacity. That seems to be the gist of it, although I am a bit lazy with learning. From my recent experience I suggest: Study and buy cells to suit your application, not the other way around. I started with a daily Capacity requirement and minimum of 2000 cycles. From there it was looking for cells that fit Charge and Discharge requirements. This is important because there are price breaks at various levels, the sellers know their Market. So the batteries meeting the requirement are looked at more closely for cycle life and PSOC if you know the cell. When the Manufacturer makes banks with preset PSOC levels you can have some confidence. My personal opinion before even testing it, would be that any cell that is not already used in PSOC situation may not be good candidates. If a seller has a usable feature in their cell, they are going to capitalize on it. There would be exceptions, given some Chinese companies with genuine communication problems, but as in western society, many act dumb if it suits. Cheers Gary |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

FYI, I used a 100 FARAD capacitor which, I think comes close to the "enormous" rating. But it was doing piddly all with 200Ah cells. As Downwind so succinctly pointed out: I was using a thimble full when I should use a bucket full per connect time. You might get a better mileage with your 60Ah cells but I stay with my comments that supercaps are an inefficient way to do this. And they can be fearsome if your test probe accidentally shorts some PCB tracks. If you replace the cap with voltage injection, as I suggested above, your relays can cycle up to their one million (or whatever) operations life span. I could still use what I have for cell monitoring as the cell voltage changes very slowly until they are all equal. Hi cell voltages are up to 3.65V as observed during the absorption period. Low cell voltages are around 3.35V. I have not yet observed the lowest voltage in the morning just after I used the kettle but before any significant charge came in from the panels. I set the low voltage alarm to 3.2V, well above the 3.0V of a flat cell. Gazz, I read your posts from end to end and my head is spinning now. I'm afraid I'm too old to cope with so many questions in a row. Besides, other than balancing your cells I do not know what you are trying to do, you tend to lose me with frequent thought diversions. Sorry. Klaus |

||||

| busman Newbie Joined: 30/10/2016 Location: AustraliaPosts: 21 |

And I come back to my earlier post, why, why why. Because I (or you in this case) can it seems. People seem to want to soooo overcomplicate looking after a Liths bank, it ain't rocket science until you make it so. I am sure that you guys, once you have a few years and a few different attempts will be asking why the f%$k I spent so much time, money and energy on something I simply do not need. That is where I am at with my 2 Liths banks. Good luck, BTW the wheel is round you know. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

not sure if this is any help Tony. the rule of thumb convention has been to pretend LiFePo4 cells are a nominal 3 volts each. so the old lead acid naming convention converted to LFP 12v 4 cells 24v 8 cells 48v 16 cells 72 volt 24 cells 96 volt 32 cells 120 volt 40 cells it seems to work quite well with the max and min battery voltage specs for most off the shelf parts. I'm confused, no wait... maybe I'm not... |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

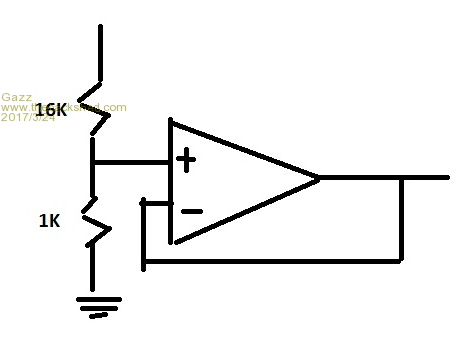

Hello Klaus, "frequent thought diversions"? I'm no spring chicken either, but we try. People are going to use and charge cells in many ways, often different to you or me. The usable charge and discharge voltage for the same cells from different Manufactures is all over the shop, so don't worry about the numbers. It is just an example. Lets say you have 8x 200Ah cells. EG: Charge Voltage = 24v (3v per cell) The voltage across bank will change a little with charging time and increased capacity. Some Cells will be slightly higher and some lower. To balance 8 cells you can connect them in parallel. Lets say we have 2 cells: One is 3v, the other is 3.2v. Connect the two cells in parallel they are both about 3.1v ----------------- Not done any complex electronics in over 40years. I am asking: if anybody wants to help with component choice and circuit design. We start by connecting a simple 2 resister "voltage divider" across the bank. The voltage between resistors = bank voltage divided by cells as below.  Shown are (16KΩ + 1KΩ) resistor values for a 17 cell Bank. You see here the voltage divider is connected to a (Opp Amp) voltage follower. A Voltage Follower replicates the voltage on its input to its output. I need a voltage follower capable of at least 1 amp. I have been looking for a power supply that can replicate a reference voltage. Hope there is someone in forum who can offer suggestions. Cheers. Add: I have options for commercial solutions, but there is always room for a better mouse trap. Just depends on the interest. Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

|

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Algorithm could be: Measure the battery voltage at the beginning of the 6 second period. If its the lowest voltage cell, feed it some charging current for the remainder of the period. Is that how you did it ? Cheers, Tony. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Measure the battery voltage at the beginning of the 6 second period. If its the lowest voltage cell, feed it some charging current for the remainder of the period. Is that how you did it ? No Tony, I do *not* measure cell voltages for balancing purposes. It is not required as the method lets each cell choose how much (or little) current it requires to charge up to a theoretical voltage of 3.8V. How is it done? I have a picaxe chip create a binary code. From this the relays are stepped through 1 - 10, repeat, in sequence. the picaxe lets me program how long the relays are on and how long they are off. I use 3 seconds on and 0.5 second off. I found during my supercap experiments that there *must* be a period when all relays are off before the next set turns on (two relays per cell, to isolate each terminal). You'd do well to incorporate that off period, despite your clever relay arrangement. If you cannot find changeover contact relays suitable you can always use N/O contact relays. I could post the relay schematic if that helps. So, to continue, as each relay connects a cell in turn to a positive & a negative 'bus' all that's required to have the bus at the above mentioned 3.8V. That voltage *must* be supplied from an isolated supply. I use a little transformer DC power pack off the inverter, then a DC/DC converter from Ebay. 12V in and 3.8V out. When set to 3.8V the most top up charge each cell gets is about 0.5A. It would get less if that voltage was set lower. The cells *never* charge up to 3.8V - which is still in the 'safe' region BTW - as the equalising stops at sunset. By the time the cells are equal at 3.45V each the current to the bank from the MPPT charge controller is 1-2A or off altogether (into 200AH)and the equalising current around 0.4A per cell. You will have to experiment with your smaller Ah cells to get the equalising charge right. Now, while I do not log (other than looking at a DPM) the cell voltages, it would be easy to incorporate with the picaxe (or other microprocessor)to log it during the relay ON times. The 'bus' jumps to 3.8V during the relay OFF period, naturally. Klaus |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Some Cells will be slightly higher and some lower. To balance 8 cells you can connect them in parallel. Lets say we have 2 cells: One is 3v, the other is 3.2v. Connect the two cells in parallel they are both about 3.1v ----------------- Paralleling cells to equalise? Bad idea IMO unless you *only* have two cells to play with. If you read my posts you will know I have 16 lithium cells of 200Ah, each connected in series to form a battery bank of nominal 48V. The cells are interconnected with heavy copper links, these links must carry the full load or charge current. So there is no way to connect any different just for balancing daily, without shutting down the battery bank. If you wish to connect your cells differently you are on your own, I cannot advise you as I have no experience nor wish to experiment with that. Klaus |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

Hello Klaus, "frequent thought diversions"? I'm no spring chicken either, but we try. People are going to use and charge cells in many ways, often different to you or me. The usable charge and discharge voltage for the same cells from different Manufactures is all over the shop, so don't worry about the numbers. It is just an example. Lets say you have 8x 200Ah cells. EG: Charge Voltage = 24v (3v per cell) The voltage across bank will change a little with charging time and increased capacity. Some Cells will be slightly higher and some lower. To balance 8 cells you can connect them in parallel. Lets say we have 2 cells: One is 3v, the other is 3.2v. Connect the two cells in parallel they are both about 3.1v ----------------- You are deliberately taking me out of context, and fabricating your own version of what I am saying. I'm done with you and this post, but I have offered some valuable information. Perhaps when you get over the paranoid delusion of Americans coming to steal your ideas. Smell the roses Gary |

||||