|

|

Forum Index : Electronics : a new way to balance lithium ion battery

| Author | Message | ||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

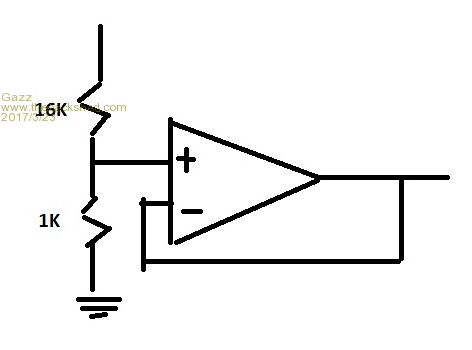

Yes, with two resistors, one exactly sixteen times the other. And that is a very easy ratio to do (1K 16K for example). Slow sequencing of relays can be done with a timer chip (555) and a digital counter that resets after 17 counts. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

I am getting my head around your idea, other things are priority! So you are discharging high cells to this flyback doda, and it then discharges to the bank. Seems like a closed loop, when charged it can not exceed the bank to enter with any efficiency. I would need to see a logic diagram to get my head around it. Still reading up on things, Thanks for sharing your idea, I am interested to learn how it works. Gary |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

A voltage divider, so you think the idea could work? So if we have a on period of 8 minutes, all cells are covered each hour of charge. I have not done any electronics for a long time, so not over confident yet. Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I have yet to get this working, I do not even have a battery yet, although one has now been ordered. I was thinking more like six seconds per cell (I will have thirty cells) cycling through every three minutes. That six seconds charges or discharges the "hopping capacitor" and a fully floating voltmeter records the voltage right at the end of the six second settling period for data logging and display. That may change, but is the grand plan for now. The same thirty relays both balance, and measure the voltage on each cell for six seconds every three minutes. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

I was making consideration for the relay lifespan going out to 8 minutes, also the time required for good stabilization between charge voltage past the equalization of load, not sure if this is right or even makes sense? Do you apply other logic other then cycles per hr for 6 seconds? Curious because I have to move on plans now, so cells can be connected on receiving. Not like you want to leave these things in a shed with out understanding the characteristics. I guess you might be talking about the data logging aspect with the relays measuring voltage, my mind is focused on the idea of no user interaction once set. Not interested in logging or measuring other then the design stage, I hate making work. I want to use my time on other things, so building to turn key design. Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Each relay operates for six seconds each three minutes which I estimate will give excellent relay life and still be fast enough to log peak voltage excursions of individual cells at high rates of either charge and discharge. If this scanning system also drives the battery disconnect system, you want it to be reasonably fast to monitor each cell. I have never seen a relay actually wear out. They usually fail either because the coil goes open circuit, or the contacts burn. Coils going open is usually because either its a five cent Chinese relay, or it has a very high voltage coil wound with incredibly fine wire. Or both. If you use high quality relays of suitable coil voltage the coils themselves will be pretty reliable. Contact failure is a result of either using a cheap relay with unsuitable contact material, or the circuit designer very badly screwed up. Both are avoidable. If you have a bunch of cycling relays that can present a pair of electrical connections directly across each individual cell, you can use it to monitor the cells voltage, or as part of a balancing system. I hope to use it for both. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

I see what you are saying now. You are using the relay to close contacts between each cell and measuring the voltage in the 6 second period for each cell to monitor Low Voltage Disconnect. My plan is to balance cells and measure the bank voltage for LVD. The idea to measure each cell for LVD is also a possibility, but I can not think how it would matter with the different route I am taking? It will take a while to think through. Appreciate your explanation, cheers Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

When the relay initially closes, some charge distribution will be going on, and the voltage measured will not initially be a good indicator. But after a few seconds the dust should have settled, and we can take a snapshot of cell voltage an instant before the next relay can react. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

Gotcha, so has the time thing been tested? On the relays, I have built a relay using heavy 3 phase contacts and a 24v DC solenoid out of Murton Bus door activator, used the relay to operate a refrigeration system fashioned when I was growing apricots. The lower switch rate is no good for your application. My thinking is along the lines of efficient choice of components. Are there any low impedance throughput options, I remember reading about such cmos gates but not up with higher current options. If the reference is a division of the bank charge, the discharge into cells would be very low. Which makes me think the current requirements might not be high. You mention inductor in series with the capacitor, how would this be chosen? Could the relays be replaced with something more efficient like n channel mosfet Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

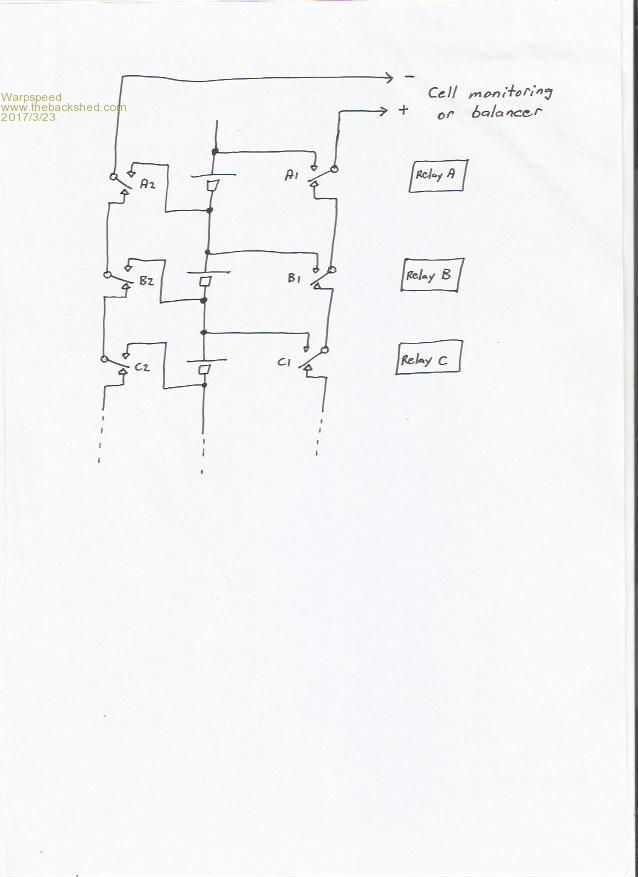

The mosfet option is interesting, but it has one serious disadvantage. Mosfets can degrade (from electrostatic damage) or fail completely. A shorted out mosfet would be absolutely catastrophic to the whole system. It would be a horrible job individually removing, testing, and replacing maybe a hundred and twenty mosfets because there was a major explosion. And even a momentary electrical spike could spuriously turn on the wrong mosfet potentially blowing up the entire system. Relays may be ancient, primitive and robust, but there are very few catastrophic failure modes if you use quality parts. The way I plan to do this, you can turn on any number of relays randomly, without the slightest chance any destructive failure. There is no way that I can see of doing that with electronic switching. This is the proposed hazard free relay switching idea:  Ah! the forum is now fixed, I can post pictures again. The IT guy deserves a special treat. Cheers, Tony. |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

Thinking timers Ok, Cells in the relays. On the Mosfet characteristics it rings a bell, I remember looking into something like this before. And now remember the similar issues? Gary |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

For individual cell monitoring I am going to use these LAA127 dual opto mos switches, they have a very high voltage rating. My intention is to use one per cell driven by a shift register. Simply turn each pair of switches on to charge a small capacitor, then isolate them all and transfer the cap via another mos switch to the voltage measuring pic processor. These can switch quickly, my aim was to measure the whole bank every second. Any cell out of tolerance can this be detected, high voltage cells would have their flyback charge circuit turned on and discharge that cell into the bank. Cheers Mike |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

These opto mos switches, do they copy input to output, or are external components required for such application. Can the two switches in IC be paralleled for double current per package?. thanks Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Good choice Mike, I plan to use something very similar for the actual fully floating voltage monitoring, International Rectifier PVA3354. Just in the last couple of weeks these devices have been listed as obsolete. http://www.irf.com/product-info/datasheets/data/pva33.pdf But I chickened out using them for switching between actual cells. If one blows up, it will cause a cascading failure of all the others. I will stick with relays. Relays are arguably more suitable for shuffling power around. Those mosfet switches really have too much on resistance for that. But for fully floating voltage measurement, I only need four of these mosfet switches, and if one blows up, changing out only four is not such a big drama. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

They act just like an electronic relay, but with a 10 ohm resistor in series with the "contact". Pretty neat, fast acting, and small. But the mosfet reliability issue is still a worry. Cheers, Tony. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Oh my, you guys are thinking way to complicated and are likely to get bogged down with this, like I did when I came up with the idea  . .For a start, the voltage difference between the cells is at worst a few tens of millivolts. If it is more you have a serious problem and need to individually charge each cell to exactly the same level before connecting any balancer. Now Tony, the six seconds you quote above is in my experience far too long. Almost all of the useful charge transfer happens in the first second, the reminding time just a trifle more. I used 3 seconds connect time BTW. But, as I mentioned before, I do *not* use this capacitor charge shuffling method any more. It only can maintain reasonable close matched cell voltages, its way too slow to make up large differences. Also, the first few milliseconds connect time might see a high current across the relay contacts, putting inductance there only adds complication, especially when multiplied by 16 cells and the relays are taking already up a lot of PCB space. The method I use now is similar with the relays but they encounter a steady current (<0.5A usually) during the *WHOLE* relay connect time (3 seconds). Much more charge gets transferred this way and the method is very satisfactory with my 48V/200Ah battery bank. So, how is it done? Simple, really. Find a small DC/DC converter with an adjustable output voltage in the range of 3.6 - 3.8V. Mine can supply up to 4A but half that much is plenty. Power this from a power supply (this *MUST* be isolated). I just use an old computer supply plugged into the 230V output of my inverter. Set the DC/DC converter output to 3.8V and connect it to the relays *INSTEAD* of the capacitor. Now each cell grabs whatever extra charge it requires to get level with any other. The lowest cell has the biggest voltage difference to 3.8V and so grabs more charge than the high cell which has less voltage difference. I fitted a small analog Ampmeter in series with the DC/DC converter output and its interesting to watch the different equalization currents. As the equalisiton period nears its end the currents become very similar as are the cell voltages. As this only runs after the solar panels reached 80V, indicating my Outback MPPT solar controller is throttling back, there is no chance overcharging my battery bank with the 3 seconds of 3.8V imposed on each cell in turn. All stops after charging has completed (the panel voltage drops below 80V). This saves relay wear. The cycle resumes the next time the battery cells are getting to the equalisation stage. Think about it, simple = reliable. I learned that the hard way. Klaus |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

You are spot on here Tinker, at full charge my cells differ by < 30mV or so, but they have to be carefully balanced prior to joining in series to make the pack. To do this I used a 50 amp variable 3.3 to 4 volt supply and set it to 3.48 volts, then in turn charged every cell individually until the current dropped to < 0.5 amps, then paralled all cells and charged them to 3.55 volts, once the current dropped to 0.1 amp I considered them top balanced; then place in series. The solar charger finishes at a series voltage of 3.47v * 16, so in practice they never over charge, the amount of energy to charge the whole pack to 100% from this voltage is about 1 amp Hr, so its not worth attempting. Of course the optomos switches would have a 500 ohm series resistor to each cell, no way can they short out the pack. The use of a 3.8V isolated PS is a very novel idea. It is important to have under voltage cell protection also, to trip off the main load (inverter) should they ever get down to near 2.8 volts per cell, as being top balanced means not so at the lower end, especially when you have invested enough in batteries to buy a new car. Cheers Mike |

||||

Gazz Newbie Joined: 22/03/2017 Location: AustraliaPosts: 20 |

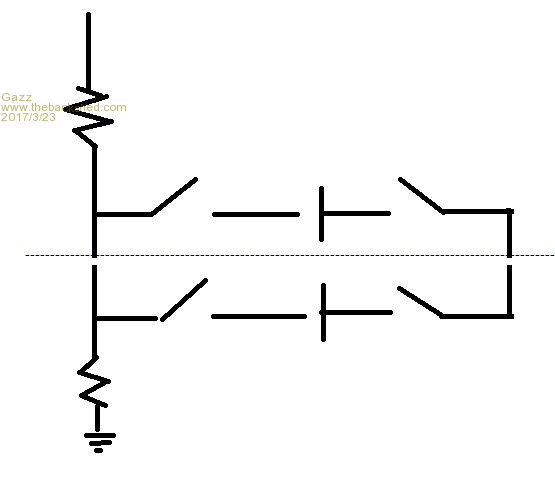

Hi Klaus, I have been thinking about your relay balance method, hence 3AM in the morning. Hoped you would visit, I would really appreciate your help to make 17S version. My system is DC only, charge voltage set by solar controller, separate LVD. Having a separate balance system without visual monitors, suits the application. My thinking has been towards what you have described tonight. Ultimately, you could use a comparator to gate counter and skip high cells. Perhaps this is over complicating things with more to go wrong, but just an idea! This is the basic logic diagram. Not literally correct. The balance voltage is a divisional, adjusted follower of bank voltage. -   - I am surprised the useful charge is only in 3 seconds. Exactly what happens when the contacts connect on cell, is it just the inrush you are using without looking at the continued equalisation process, or am I not getting something? My thinking is based on equalization taking place between the cells individual voltage in series, and the divisional balance voltage. Similar to what happens when connecting cells together in parallel to balance them. Given my application uses PSOC, I am wondering what you think of the Balance voltage being a divisional follower of the bank voltage. Is your DC/DC converter adjustable from a reference voltage. Perhaps there is an adjustable DC/DC input follower available. --- You have suggested 250ma balance current might do, but it seems low compared to the equalization effect between reference and the cells series supply. You could well be right as the task is not to correct balance in new cell assemblies. But? What if the voltage was a direct division of bank and current were higher. Commercial Active Balance systems start at 3A and transfer in both directions. A 1.5A referenced balance supply for single direction might be needed for 100Ah? Open to your thoughts. --- Lifepo4 Cells have very little voltage variation outside of the cliff each end, which is why many balance outside about 20 and 80% SOC, so it is sound from this prospective. Obviously there is the difference between you equalizing at end of charge compared to all stages of cell use, but is there any other reason other then designing the system for your particular use? There doesn't seem to be an obvious reason, why balancer shouldn't be engaged through charging if it follows bank voltage. This could be seen as voltage correcting where lower cells would gain more. The mythology is very different to a precise voltage measure for guessing cell Capacity. Might work during lower charge levels, as a result of this difference? --- What extent this would work with partial state of charge is questionable, but cell imbalance would also be less of an issue. The system would hopefully prevent cell runaway with PSOC, in a pre balanced bank with normal cell variance? Hope you don't mind helping me out. Thanks, Gary |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

|

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That is a very ingenious idea, I really like it ! It solves the problem of having a different voltage sensing circuit fitted to each and every cell that needs to be accurately preset. Use the original idea of comparing the average cell voltage with each cell, but use only the one single cell sensor and discharge load cycled across all cells via relay contacts. The big problem with a hopping capacitor is the initial very violent initial current flow through the closing contact, which is going to eat relay contacts. Placing an inductor in series will cause the current to ramp up relatively slowly on contact closure, then a ringing oscillatory current will be set up once the contact has closed. The ringing will quickly die away without any serious loss of total energy as would occur if a series resistance was added. So its much more efficient. It needs to be efficient, because as Klaus quite rightly points out, the voltage difference between cells should hopefully be only millivolts, and there is not going to be a very large charge transfer unless the capacitor is enormous. From what I have read, batteries that are not thrashed stay in pretty good balance anyway, and it takes almost nothing to keep them that way. So I am not looking at trying to quickly fix a serious unbalance problem. Just have a continuously cycling cell monitoring system system that tends towards improving balance rather than upsetting it. And something that does not need frequent maintenance, testing, or adjustment to work. Cheers, Tony. |

||||