|

|

Forum Index : Windmills : Servo motor for wind turbine

| Author | Message | ||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Mike, Thanks for the link back to the 2006 era Back Shed posts. As you say, much of this has been hashed over previously, but this was a new topic for me. If you wanted to summarise the significant points to consider when using a servo as a wind generator alternator, I guess that they would be: 1 The nameplate voltage is misleading. It will not generate anything like that voltage even if spun up to its rated speed. As you indicated early in this thread, the real test is to set it up in a lathe connected via a rectifier to a battery (ie under the load that you want it to supply), and see how fast you need to spin it to get a useful charge rate. You can then select your turbine accordingly. 2 The rated continuous current is probably conservative for wind generator duty, because it will be better cooled, and because the motor losses are being supplied mechanically by the turbine. The rated current is a per winding rating, so you should be able to get a DC charging current that is at least the rated current times the number of windings. No doubt old news for you Mike, but certainly something new for me and some others following this thread. One last comment is that the encoders fitted to the servos might make a useful tacho. Regards Don B |

||||

| 97fishmt Regular Member Joined: 19/04/2010 Location: United StatesPosts: 77 |

Absolutely Don B, I've tried to figure them out but no luck for me. You can study the wire schematics or if you knew how the controllers did what they do, I'm sure it's possible. Or have it generate through its controller or make one to suit. It could provide all the data you would need about its workings. Anyhow no I'm not good at presenting my ideas or getting things down for others to read, I know. So thanks for taking interest and not coming down on me too hard. Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Mike, You have made an extremely valuable contribution to the knowledge base here at the Forum. While we here in oZ are perfecting local available low cost technology with smart drive washing machine motors, there is a whole bigger world out there, with hardware that most of us are probably completely unaware exists. So thanks for your patience, it is greatly appreciated. . Cheers, Tony. |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

Don B, thats my intent. I have some micro plc's with high seed counter function and can scale to proper readout. My next step will be testing with rectifer, I beleave that the dc voltage will be 90% of ac voltage minis small voltage drop from rectifer. But I will let you all know and be a part of my new project and hobby, thats. |

||||

| 97fishmt Regular Member Joined: 19/04/2010 Location: United StatesPosts: 77 |

Cheers Tony!

I'm just not a technical guy but I've been playing with these things for over 20 years so.. well.. thanks for being kind. |

||||

| isaiah Guru Joined: 25/12/2009 Location: United StatesPosts: 303 |

This is off subject but is related and it looks like we got some new viewers her and I thought they may be interested in the battery rescue. http://www.thebackshed.com/forum/forum_posts.asp?TID=2979&PN =1&TPN=1 URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

You should be able to do a lot better than 90% of the measured ac voltage.. When you rectify three phase with six diodes, the dc voltage is very nearly the peak of the ac voltage waveform. Look at your own Avatar, where the ABC waveform cross over right up near peak voltage. That is what you will get out of your rectifier, less a small diode voltage drop. The absolute voltage peaks are about 40% higher than the RMS voltage you measure with an ac voltmeter, so the rectified dc from a three phase six diode rectifier will be maybe about 135% not 90% of the ac voltage you are measuring now. Cheers, Tony. |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

I am going to make some new blades, the pic shows a 18 mph winds and the servo rpm is 140. |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

I don't know what happened to the pic, will try again. |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

Bub73, I took your advise about making, and weld a pivot tower. I got this old tv pole for free, all I had to do is take it down. It's almost 40' tall. It looks pretty sturdy. It uses a winch to drop it almost hafe way down and has two guy wire locations, one set at the top and the other about hafe way up. If anybody see's a problem with it, please post. |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

I don't know if anybody has posted about this, but theirs a lot of tv towers out there not being used since tv went digital and you might be able to get them just for taking them down. I did. |

||||

| Bub73 Senior Member Joined: 10/12/2009 Location: United StatesPosts: 116 |

piggweed and others; Take a look at this software Qblade. You may find it a big help with your blade design and its free. Also its available for both linux and the old windows oses. Bob |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Bob Thanks for the Q Blade link. It certainly appears to be very comprehensive indeed but. unfortunately, it seems to be pitched at professional blade design experts involved in desigining commercial wind turbines who already understand the process and jargon intimately. While I am sure that the authors did not anticipate anyone starting from scratch trying to use their software, one of my pet peeves is manuals or operating notes written by an expert who assumes that everyone else has the same level of expertise. Consequently, definitions and explanations of complex content are unnecessary, and examples of use are only needed by far lesser mortals. Anyone know of a more entry level blade design site that explains the process in words of one syllable, and includes examples of how it is used? Regards Don B |

||||

| Bub73 Senior Member Joined: 10/12/2009 Location: United StatesPosts: 116 |

Hi Don B; I'm having a hard time trying to learn how to use it also. It looks like it would take a lot of the guess work out of making a matching set of blades, if I just knew what I was doing. Perhaps some of the others here with some cad know how will help us out; there is a guide for it at the link below. Qblade Guidelines Bob |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

Warpspeed you where right, I a have the rectifer hooked up and it going to low battery. At 270rpm I get 13.5vdc and 1.5 amp. At 350rpm I get 19vdc and 5amps. I've looked on the forum for a dc input voltage regulated controller but did not find anything. I am looking for a controller with a input say 8 to 40vdc and output 12 or 24vdc rated for 160 or 80 amp. Any suggestions on the best way to regulate the controller input or is there a controller with varible input voltage? I have not yet decided on 12 or 24. I already have the 12vdc inverter, but 24vdc system sounds good. |

||||

| piggweed Newbie Joined: 09/01/2012 Location: United StatesPosts: 29 |

Does anybody know if these are any good? Flexcharge Wind Turbine Solar Hydro Charge Controller NC25A |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I have no personal knowledge of this controller, never even seen one. But the specifications look good. And the seller of these controllers on e-bay has 100% positive feedback for 900+ sales. Cheers, Tony. |

||||

| wilfor03 Newbie Joined: 22/03/2009 Location: United StatesPosts: 5 |

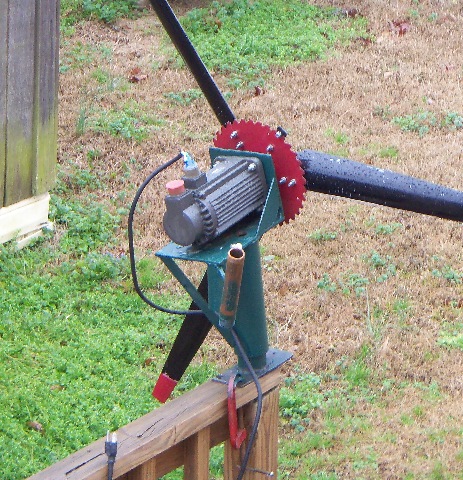

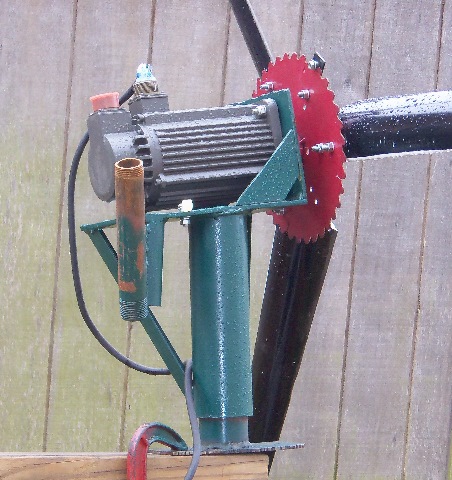

Hey guys.... Just put this on the universal mount yesterday and got it all firmed up. Put some 6 foot PVC blades on it for a test run on the 25' tower.

This is an Omron Servo Motor, 600w, 253vac, 3,000rpm, ($23. bid and 16.50 on Shipping-FleaBay)and it should start putting out 15v at about 175rpm. I can get 3-4vac (unloaded, 1 phase) by just spinning on the mount here.

We've had a storm come through this morning with some pretty heavy gusts so I didn't have to wait to put it on the tower. That sucker started spinning right there and almost sounded like an airplane revving up!! Scared the crap out of me!! Hey "97fishmt" (Mike), does that mount look familiar? I copied your mount build and have had 3 motors on this thing so far (Servo, ECM, and DC Scrubber Motor). Just trying to see what suites me best for my location here in Alabama. You guys have a great day, eh? Bill |

||||

| 97fishmt Regular Member Joined: 19/04/2010 Location: United StatesPosts: 77 |

It looks super nice Bill!

Do you have to add weight to the tail when changing out motors or blades? On my mount I haven't even bothered to change the offset on any change-outs. The bolt holes have all lined up so far. The beauty of the motor on top of the mount and the tail off the other side is it can accommodate larger and longer motors, even smaller ones and it's easy changing them over. I've made my tail vane able to accept rebar inside the boom pipe to dial in the furling. Also once and awhile a small tweak to the upward tail stop if a motor is bigger or longer to keep it into the wind without adding more to the tail. Nice job Bill! Mike |

||||

| wilfor03 Newbie Joined: 22/03/2009 Location: United StatesPosts: 5 |

Hey there, Mike I haven't really had any winds that challenge the furling yet, so can't really comment on the furling (good or bad). But, yes, I can add more weight easily if I need too. Yup, can switch out motors (and wiring-ac or dc) in about five minutes time. I've got several holes drilled in the face mount (where the genny bolts to the mount) so whatever motor pretty well matches up with the mount. Also, offset the furling rod a couple inches for adding a longer motor if needed later on. AND, put a 3-4 degree angle on the mount plate/tower pipe for more clearance if I was to use longer than 6' props (wood or PVC). Got all this great info from YOU, and I thank you for it. Just hope I can help others as you have helped me!!

Bill |

||||