|

|

Forum Index : Windmills : Requesting selecting wire size for stator

| Author | Message | ||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

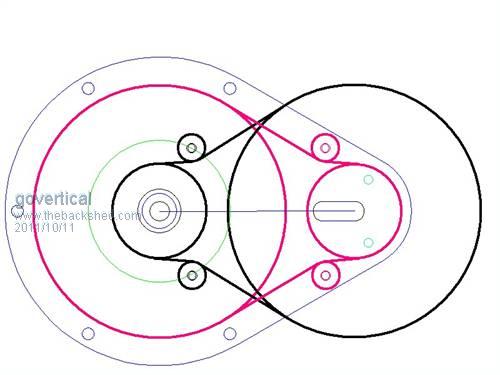

Hi, I used a CAD program to size the pulleys to fit the space where they will be mount. Then I cut round wooded disks with no teeth the size of the pulleys. I placed the belt on the wooded disks and then measure everything with a micrometer and counted the belt cogs. Then I used CAD program again to draw a .dxf file of the pulleys with teeth and I cut them with a CNC. It only took me three sixteen hour days and some trial and error to get it worked out.  I have to finish the blade rotor union then I can test to see if it works. Comments of any kind are always welcome. I feel fortunate to receive the help, thank you. I have to finish the blade rotor union then I can test to see if it works. Comments of any kind are always welcome. I feel fortunate to receive the help, thank you.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

govertical Hi

The "V" Belt will not survive long when using the soft rubber on a shear load such as a gear tooth, especially when wet. -----Cheers, Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I may resolved the belt tension issue. I plan on mounting four stationary idler pulleys, two sets, a set for each belt. The idler pulleys will position the belts to encompass more of the transmission pulley. The movable shaft can than be positioned to draw the belt snug. The grooves on the transmission pulleys provide enough traction to prevent the belt from slipping and the position of the idler pulleys will prevent the need for excessive bearing load and still allow the transmission to spin freely. Comments welcome.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi govertical, I think you can acheive the same amount of contact around the pully by just using one idler pully per belt, just bring it in a little more and increase the size so you are not bending the belt as much and wont need to spin the bearing as fast this should cut down your friction quite a bit. All the best Dean. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Dean, watching this tread I think govertical likes to do things the complicated way

Well, as long as he's also having fun, why not  Klaus |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Govertical, Impressive effort!You've thoughtfully taken account of the pitch change from a straight belt to one wrapped around the pulleys.What about the pitch variation as the belt stretches in service,will this change belt to pulley profile alignment?Just a thought,Cheers Rastus see Rastus graduate advise generously |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I completed the new pulleys. Spring loaded idler pulleys maybe the better option. It should mount directly to the top of the PMA, enjoy the day.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Two idler belt tensioners are only required if the direction of rotation changes. Since most wind mills only turn one way fit a single belt tensioning idler to the slack side of the belt. There's no need to spring load it, just locking suffices. The main purpose of the tensioner is to tighten the belt after fitting since it can't be fitted into the Vee grooves unless its loose. Do not over tighten the belt. The new belt should settle in in a very short time and further tensioning should be very infrequent unless you put way too much load on the belt. Klaus |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I completed the assembly of the movable shaft and it is a failure. I gained valuable knowledge from the experience. I am modifying the design to include one stationary idler pulley and one spring loaded idler pulley. The main belt pulley shaft will be stationary. I am including the spring loaded idler because I have no experience with what the correct belt tension should be. Thank you for all the suggestion. It should take a few days to make the modification. Thanks again and enjoy the day. just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Photo of proposed spring loaded idler pulley. I was concerned the idler would not stay perpendicular when applied to the belt but the J hook keeps it aligned. I am adding the spring loaded idler pulley because I do not know how much the belt will expand and contact and being able to adjust the belt tension will keep bearing load to a minimum. Comments welcome.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi govertical, Most big industial high speed fans usualy run about 4 belts. If you have alot of trouble with belts sliping you could always double up on your belts and pulleys. All the best Dean. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, my only experience with V belts are my car and my snow blower. This is a experiment. I am using the auto V belt a different way, I fabricated the pulleys so the belt rides on the cogged edge not the angled V sides. I do not know if the belts will slip or how much tension will be required. I have to cut new mounting plates. If this does not work I can replace the belts with high torque timing belts. Thanks for information about the multi belt technique. just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

http://www.youtube.com/watch?v=ZiC9gVNnVU8 http://www.youtube.com/watch?v=u6RcwB3XVts Hi, videos showing where the idea comes from. just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Greetings, I completed the belt and pulley fabrication. As suggested one idler does work better than the double idler configuration. The unit is very quiet, but does add drag to the system. I have to add bushings between two bearing on the double pulley fixed shaft side and design a better idler pulley assembly. The design is 90% there if I purchase the correct belts and do some fine tuning it should make my project a functioning unit. Thank you for all the help I have been receiving. I will post road test results in the near future. Enjoy the day.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

http://www.youtube.com/watch?v=ylkPilnxBco Hi, video of 1: 6.5 ratio belt drive. The pulsating sound is from a bad bearing in the test fixture. There is a small amount of noise coming from the belts and pulleys. I am surprised how easy it spins. The results justify buying the correct timing belts for the application. I think it is a viable solution to increase RPM for my project. Comments welcome Belt Drive just because your a GURU or forum administer does not mean your always correct :) |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Govertical, How about a few magnets on the pulleys with a stator under each on mounting.........just joking. We come from the land downunder. Vic |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Govertical, Overcoming the noise problem was your goal.Congratulations! you've done it!Cheers Rastus see Rastus graduate advise generously |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I completed the belt drive installation on the PMA. It is ironic that there is to much wind today for a road test.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, after I installed the belt drive I tried different manual tests and I found that the mass of magnet rotors required a higher belt tension to prevent belt slipping. I ordered a set of larger timing belts and I have to cut new pulleys. I discovered that because I offset one pulley set I have to increase the diameter of the blade rotors to allow for blade clearance during rotation. After the modifications if belt slipping is still a issue the multiple belt technique maybe the solution and I plan to add the design in the next modification to reduce bearing load, thank you for the suggestion. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi govertical, Having the bigger pullys set up the way they are may not be as compact, but I think they will run a lot easyer and you wont be losing as much power through the gearing. I might have a go at a gearing set up similar one day. Getting the right gearing set up can be the most difficult part of any build and I think most Vawts need to be geared. So keep up the good work. All the best Dean. |

||||