| |

Page 5 of 9 Page 5 of 9   |

| Author |

Message |

GWatPE

Senior Member

Joined: 01/09/2006

Location: AustraliaPosts: 2127 |

| Posted: 12:44pm 14 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Bob,

The furling is all a balancing act with the forces, and furling should still be achievable.

I think that the constant chord and non twisted nature of the blade is contributing to the reluctance to furl. You may find that the rotor at high rpm is also contributing to the inability to furl. There is considerable stored energy in the high speed spinning rotor. This is an ideal oportunity to also rewire the mill for star. This will keep the rpm more in check and reduce the inertial energy. You might even get away with furling geometry close to the current settings. This should be the simplest option, before getting out with the saw. If this is not a solution, then I would make a significant change to the tail boom angles, and get the mill to furl at the 5-6m/s windspeeds reproducibly. I would then make some adjustments to the side angles and see the changes. Do the same for the back angles.

There has to be a reason why so much effort was spent designing tapered twisted blades. I do not see the problems with furling on my windmill, even with a 3m rotor, but the blades are tapered and twisted.

Gordon.

become more energy aware |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 12:53pm 14 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

I didnt realize Vawts had furling systems.

Just wondering if the furling is to the wrong direction to suit the mill.

I cannot help feeling it also has something to do with blade weight and centrifugal force. (then i have been wrong before)

How do your theory become effected with higher rpm, as it would appear the mill furled well at low rpm but poorly with high rpm.

No expert here, just an observer of facts.

Pete.

Sometimes it just works |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 01:06pm 14 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Gordon

Thanks for that, I can see the balancing act in motion here, I am wondering though about the star connection, as that would help at the lower speed but tend to unload at higher rpm allowing the unit to spin faster, at the moment in the wind like today the new mill blades where only doing about half the speed of the old mill which has tapered and twisted blades with furling locked up, it produces its power at higher revs to the new mill. old mill 2.5 m new mill 2.8 meter dia.

The blade in combination with the offset is what creates the force to furl, opposed somewhat by the tail lift moment, it is then the force of the tail lift that unfurls the mill or opposes the furling I think, so I might go ahead and fit the lighter tail and see if that reduces the speed of furling to a useful level. I would like to do one thing at a time to study the cause and effect of each action.

Thinking about the next step is to pull it down and increase the offset on the head and try the star connection at the same time.

All the best

Bob

Foolin Around |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 01:45pm 14 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Pete

Sorry about the typo on the VAWT instead of HAWT, by the time I realized it I couldn't get back in to edit it.

On the gyroscopic action problem it is my understanding that the gyroscopic force acts at 90 degrees to the change of the plane of rotation, so I assumed that was the back and forward nodding in the mast head, whereas the lift induced imbalance acts in the same plane as the furling.

The furling is, as was originally, in the mill, the only thing changed was the lift angle of the tail vane.

In the previous lot of wind I didn't see the initial high speed blast as I witnessed today, and the wind speed I watched then was less than half of what I watched today, it even ripped a sheet of tin of the roof that had been there for years. So the furling was having a good effort then, but didn't stand a chance today.

The blade weight is the same as before as all I did was move the blades further out on the spindles, and this would make a small change to the CG of the blade and for the given RPM an increase in gyroscopic force, bit due to the larger diameter of the blades they turn slower and that reduces the gyroscopic force so the overall gyroscopic force should be slightly lower than original.

According to Alton the 2.2 m blades would do 836 RPM @ 15 ms

According to Alton the 2.8 m blades would do 704 RPM @ 15 ms

Old mill 2.5 meter blades 955 Rpm @ 15 ms Speed different due to different blade design, it is designed to run faster.

I think there is more to this than meets the eye, and I am just thankful thet the mill is tough enough to stand up to the abuse I have given it without blowing to bits.

All the best

Bob

Foolin Around |

| |

isaiah

Guru

Joined: 25/12/2009

Location: United StatesPosts: 303 |

| Posted: 03:51pm 14 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Pete

It was so cold last night that I took leek out side and I froze to the ground before I got done and had to have the Wife come out and break me loose. Bub couldn't make it over because he's on a handicap scooter and wouldnt make it through the snow!javascript:' ' ' ' ' ' '

URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 10:49pm 14 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Isaiah

At least you wont waste much power running a deep freezer, and next time you need to attract some attention from your wife , there are easier ways than that.

They tell me that all this cold weather in the northern hemisphere is due to global warming according to the work of the eminent Irish professorial Paddy O'Murphy.

All the best

Bob

Foolin Around |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 10:58pm 15 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi All

Another storm front on Wednesday afternoon gave some medium power winds to 7.5 ms resulting in good power conversion along the same outputs indicated by Gordons Graph a few listings ago, the furling wasn't a problem as the wind was only gusting to 8 ms however the same lock into the wind situation was observed.

It would seem that by my increasing the diameter of the blades to 2.8 meters I have exceeded the amount of furling power for the standard offset on the mill, Phill warned me of this initially, but in my quest for low end power I tried it any way, Fool Fool.

I now have the issue of lowering the furling speed and loosing a bit of top end power, that isn't a real issue anyway as these high power events are a rare occurrence and short duration so add little to the long term power collection, as Gordon says, it is the wind that is there most times to aim to catch.

As my usual winds are from 1.5 ms to 3 ms I have to look at optimizing at these speeds, unfortunately that means leaving the blades at 2.8 meters and lowering the furl speed, thereby loosing the high speed high power we all like to see.

First step is a larger and lighter tail vane, I will post pictures when I finnish it.

The second step is a boost converter to try to get a few extra watts at rpm up to 150. as at 75 rpm it starts to make power, this indicates the low speed efficiency of the alloy blades at the moment this is lost as the cap doubler requires 14 volts to start and the GTI requires 13 volts to start. A lot of times the prop is turning and making 10 to 12 volts that isn't enough to synchronize the GTI, this is in the 1.5 t0 2.5 ms bracket so not much power but every little bit helps.

I will keep you posted as to progress on the boost converter, it is rated to boost from 7 volts, so should recover the low speed energy, Hope Hope. By going this way I can leave the unit in delta.

Furling first though, as it is overheating the battery feed wires with to many amps when it gets wound up.

All the best

Bob

PS

Wind Speed Table base on Altons

MS ----mph ---Tn ----TKg ----RPM ---W@B ---ST Kg/m

0.5-----1.1-----0.9-----0.1-----27------0------ 0

1-------2.2-----3.4-----0.3-----54------2-------0

1.5---- 3.4---- 7.7---- 0.8-----80----- 7------ 0.01

2------ 4.5---- 13.6--- 1.4-----107---- 16----- 0.02

2.5---- 5.6---- 21.3--- 2.2-----134---- 31----- 0.03

This is the region I am aiming to recover energy from, with these blades at 2.8 meter diameter the power output is a bit higher than with Alton due to the high torque of the blades in contrast to a small tip size that is used as a standard in Alton calculator. The wide cord constant width blades generate more torque for the given airspeed. Edited by VK4AYQ 2010-12-17

Foolin Around |

| |

Bub73

Senior Member

Joined: 10/12/2009

Location: United StatesPosts: 116 |

| Posted: 01:47am 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Bob,

This is Isaiah on Bub's laptop but we have some pic's for you!

I had some help and the weather wasnt too real bad so we stuck it up or we may have taken more pictures.

The mill is a ECM 180 volt 10 amp rewired JERRY.

AND YES when it went up the blades lopped over a couple of times and quit so we wont have wind for 5 days now!! ' ' '

At this time 8:38 pm yesterday the temp is 5 deg f. and for once a nice blue sky.

We had a great solar day but my gloves froze to the shed roof while we were putting the mill up!

When we get a breeze we will see if the mill still puts out!

The second picture is with the zoom and looks like the blades may hit the tower but this is not the case,just camera angle and camera operator.

Isaiah ' ' '

|

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 03:37am 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Isaiah

Thats Murphy law of wind section 2.

Looks good though and very visible no plane will run into it.

Will be interesting to see how much power it makes.

You did a good job with the photos, its no to hard once you get the hang of it.

I am in town today getting some bits and pieces and there is another big storm happening, not much wind here but will be interesting to see if the mill survives today as I am not there to hold its hand.

Don't hang onto the roof so long, and dont try to lick off the ice.

All the best

Bob

Foolin Around |

| |

isaiah

Guru

Joined: 25/12/2009

Location: United StatesPosts: 303 |

| Posted: 05:23am 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi All

That is a piece of galvanized stove pipe I made into a weather shield.

It covers the ECM Motor and the pivot area and back to the tail support.

It is held on with large hose type clamps.

That is snow froze to the tower half way up in the first picture.

My other mill I used a piece of 10" pvc to make the weather shield and that gives around 2'' a side clearance this worked good except the birds started building nests in it!! The birds would land on the tail and go in to the shield from the back side weather the motor was running or not!

The next project is to pull that mill down as it sometimes make a non funny noise!

It is either debris in the cooling fan or a bearing going bad It has been up over a year in several heavy storms.

This motor (DAYTON 180 VOLT @1710 RPM4.5 AMP.) has the two big horse shoe magnets and the wires are on the armature.

Dose any one know of a way to get more output out of it without hacking into the armature?

URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 08:13am 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

It bothers me somewhat with how you have your tail and yaw bearing setup.

To me it looks like an accident waiting to happen.

Or is this mill not meant to furl??

Pete.

Sometimes it just works |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 01:06pm 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Isaiah

I am wondering where your location is in the States. Your 5 deg temperature is real close to the temperature I have here.

What diameter is your blades and at what RPM dose she cut in or begin to produce usable power??

I would love to get my hands on a lattice tower like yours.

Jim

Jim |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 01:33pm 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Jim and Charlie

It is a neat tower room for expansion in the mill size in the future.

All the best

Bob

Foolin Around |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 01:45pm 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi All

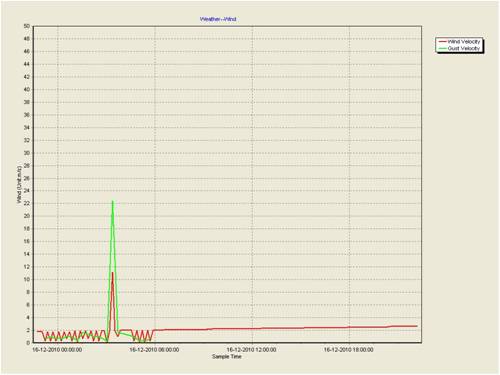

This is a capture of the front coming through today, disregard the reading to the right of the frontal peak as the memory filled up and as a result it didn't catch the second front later in the day. Mill survived OK so far even not furling properly.

All the best

Bob

Foolin Around |

| |

isaiah

Guru

Joined: 25/12/2009

Location: United StatesPosts: 303 |

| Posted: 03:34pm 16 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi

Pete, Bub said the ECM you don't have to worry about furl!

So that is a non furling tail.It is though offset to one side.

Jim I'm in southwest Michigan25 miles n of the Indiana line.

The blades come from Richard Mail in England and this set has a 51 1/2 inch swept area.

The tower I found along side some lake property for $20.00

the mill cuts in around 260 rpm and dosent take too much with those blades to do that.

URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 05:10pm 17 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

isaiah

Yup thats what I thought where in the same neck of the words so to speak. I am on the west side of Lake about 30 miles south west of Chicago. Just wondering where you were located.

Jim |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 12:29am 18 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Jim and Charlie

You guys shore chose a cool place to live, at least you don't have to worry to much about generators overheating.

Last time I was over there I left Australia in 30 deg C heat and got off the plane in Chicago it was - 9 degrees C, I nearly froze, Had to go to Rockford to look at a project, ice and snow everywhere. I was glad to get out of the place.

Very good area for wind though, I didn't see any mills then but maybe it's changed a bit now. Sounds like you are out near Rockford Jim as that is near where I went.

Very good potential for wind harvesting in that area, and the possibility of heating using VAWT instead of heating oil of wood fires, as I noticed that the trees are depleted right across the middle of USA.

All the best

Bob

Foolin Around |

| |

JimBo911

Senior Member

Joined: 26/03/2009

Location: United StatesPosts: 262 |

| Posted: 02:55pm 18 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

VK4AYQ

I am about 40 miles/64.37Km from Rockford. Yes the state of Illinois has many wind farms which means lots of wind is available. Illinois is mostly flat with lots of food farms. Here in the states the Midwest is called the bread basket of the world farms for miles and miles unfortunately the average person knows little about small wind. I've always said (as soon as electricity get more expensive only then do people start to look for alternatives. )

Our weather can go from -17.78C in the winter to 35C in the summer kind of crazy I know, seems just as soon as your body gets use to one temp it changes and you start all over again. Summers are pretty nice. Chicago does has some really HOT women and that helps.

Jim |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 03:44pm 18 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Jim

Our weather is more stable temp wise daytime temp in the winter is about 20 C up to 40 C in the summer in heat wave condition, I am only about 40 miles inland so that helps.

The wind here isnt that good as I am between two mountain ranges, sea breeze in the afternoon, storm fronts and the occasional cyclone edge wind in the summer.

My next project is a 3.6 meter dia mill to try and catch some more energy from the lighter breeze, will be a high voltage mill to give a wider useful band.

the women in Chicago may be hot but the weather is not, and its more fun to warm a cool one than cool a hot one, getting to old for that.

All the best

Bob

Foolin Around |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 12:39am 22 Dec 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi All

To carry on with the effort to get the mill to track the wind and furl better I have fitted a larger area but slightly shorter tail vane, in the light winds thismorning it was tracking better and more stable with the wind direction, so that side is a positive.

How the furling will go remains to be seen when a bit of wind comes along, the new tail is a piece of 1.4 mm marine alloy so is quite stiff and reduces the tail weight by 1.8 kilo. I am hoping this will reduce the furling moment to get it to furl by 12.5 ms as thats full power + a bit total amperage 50 amps.

The new tail Vane.

Compared to the other vane extension.

As you can see it is quite a bit larger and higher to get it out of the turbulent air in the middle of the disk, time will tell if it is an improvement.

All the best

Bob

Foolin Around |

| |

| |

Page 5 of 9 Page 5 of 9   |