|

|

Forum Index : Electronics : Various aspects of home brew inverters

| Author | Message | ||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

So how would I test which one of my collection of used cores is high quality ferrite and which are crappy powdered iron? Could you test this with a magnet or does one have to wind wire around it and do complicated measurements? Klaus |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

Im still in the dark as to why there was such an apparent current spike across the gate resistor (red trace in the last excel graph), was it a common mode spike or did it really exist? The gate drive did not seem to exhibit a corresponding +ve glitch - it was actually below ground at the time. The performance of the differential probe in the most recent pictures looks quite good with reasonable common mode rejection. For the red spike to be there it should mean only one of two things, the gate drive of the 10 ohm resistor went momentarily high or the gate side of the 10R went momentarily negative, a very fast fall of VDS coupled back by Cgd causing a neg glitch? This could happen when the top FET turns off and the choke/Toroid flux energy reverses into the bottom FETs diode. Poida when I said the spike could be a measurement technique - I really meant the circuitry within the differential probe, it was not supposed to sound like you used an improper technique, I could have worded that better. I also applaud your technique of very short connections directly to the tip & ground parts of the probe tip - its the only way to see fast signals accurately in a noisy environment. The undershoot of the bottom trace is curious. It is common to see that pattern at the choke connection (bottom FETs drain to top FETs source) at the time the top FET turns off and before the bottom fET turns on. In this dead time the lower FETs diode conducts some energy from the choke/transformer, which means that node becomes ~ 1V below ground as the energy is returned to the supply, this causes the undershoot effect on the upper gate drive that can just be seen in the dark blue trace second to last picture. The light blue trace looks very similar, I can only imagine that somehow when the bottom FETs diode conducts there is a difference between drive ground and the source of the FET (also ground) during the high current energy pulse from the choke/toroid. The drive ground I refer to is the buffer stage collector/ground connection of the PNP transistor. Differences in ground potential is purely an OHMs law issue when high currents exist causing voltage drops. Probing from the FET source in question to various points along the neqative PCB trace might reveal whats going on. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

What is required is a very high inductance per turn, and you can measure that directly by adding a few test turns onto an unknown core. Powdered iron toroids are almost always coated and have some distinctive colour code, sometimes two colours. Ferrite is almost always just bare ferrite, a dull dark grey or black without a coating. Powdered iron cores may typically have up to about 200nH for one turn, say 20uH for ten turns, often much less. High permeability ferrite might be more like 1uH for one turn or 100uH or more for ten turns. If you connect the CRO probe tip directly to the ground clip, there should be no noise seen. But if the probe ground is connected to a piece of really noisy equipment, current can flow down the probe screen and produce a voltage drop along the screen. If you then connect the probe tip to the ground clip there can be a lot of noise, and that will be superimposed on the real signal. By winding the probe lead through a suitable toroid that places a significant impedance in series with the ground which reduces the noise current. Not only that, any voltage drop along the screen is also induced into the central signal wire of the probe, and cancels out a great deal of any high frequency noise. This can be a very useful technique for really noisy high power things things like switching power supplies or inverters. Cheers, Tony. |

||||

mackoffgrid Guru Joined: 13/03/2017 Location: AustraliaPosts: 460 |

Mike, I'll look forward to when you have your setup going. Between you and Poida we'll keep gaining insights backed up with beautiful images. I have spent some time earlier this year looking at mosfets in a H-bridge. It seems to me that while on a macro level the bridge works well enough, but when you drill down to the micro (nano even) level as Poida is showing all is not so nice. Mosfets become capacitors on every leg and every dvdt event causes currents to flow where we don't want them to. So the top FET can cause unwanted turn-on of the bottom FET, but in the least there is a capacitive current spike through the source pin of the bottom FET to GND. I've shorted the gate to source, and I even tried a negative gate voltage, but you still get a current spike through the FET to ground. I can appreciate why the SMPS guys went away from hard switching. When you showed the benefit of the ferrite bead on the drain - it was a "of coarse" moment for me. It will be interesting to see how IGBT's work in a H-Bridge configuration. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Its certainly possible, the grid tie guys do it all the time with high frequency PWM at multi kilowatt levels, and usually with only with four devices. The variable speed motor drive people use IGBTs and high frequency PWM at many tens of kilowatts. Higher voltage dc with IGBTs will present far fewer problems than multiple parallel low voltage mosfets trying to switch a hundred amps or more into an incredibly low impedance transformer primary. Its o/k up to a "certain" power level, but at very high power, it all becomes really really difficult. Cheers, Tony. |

||||

mackoffgrid Guru Joined: 13/03/2017 Location: AustraliaPosts: 460 |

Gday Tony, Yes that is what I meant to imply. My next inverter (100v) will be utilising some IGBTs and I'm expecting an order less effects regarding high side - low side influences. Cheers Andrew |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

It all becomes much easier to get good reliable results. Cheers, Tony. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

I am going to cease reading and posting for a while - I need to build up my unit I already have lots to go on with - some parts will still take a couple of weeks though. I also have a project energy meter (a real paying job !!) that I cant ignore much longer. I must admit the bead effect was very dramatic on my first prototype - it caught me by surprise how effective it was - a real woah camel event  I think IGBTs have some of the best of Bipolar and FET advantages especially at high voltage applications where the higher saturation voltage is less of an issue. I am still quietly confident that I/we can make an inverter that can be tackled by semi novices that will be well behaved as long as the recipe is followed and will be much more forgiving for small deviations from the recipe. I like H FET bridges I have used many hundreds of them since ~ 1995 the main issues I really faced was trying to incorporate synchronous FET rectification now that caused much grief - here I dont have to synchronise or rectify anything on the output - how easy is that !  If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1418 |

Part 35: Further examinations of Madness' power board. Differences between driving 1x HY4008 and 3x HY4008 I now have 1x HY4008 on one half of the full bridge and 3x HY4008 on the other 1/2. All MOSFETS have the large ferrite beads on their Drain pins. The inverter runs fine. The first thing I noticed is the EMI caused by the hard switching of DC supply has been reduced to a very large degree. This now gives me unexpectedly clean signals when I attach probes (with their little ground leads too) at current sensor output, for example. The much reduced EMI is a welcome result and will help in unexpected ways, particularly on the nanoverter board. RenewableMark found his nanoverter was upset by EMI and the fix was to add ferrite beads until stable running returned. I think with these beads on the Drains, we might have sorted out this problem. Secondly, adding 2 more HY4008 to the totem pole drive outputs does not delay the switching, or degrade it in any way I can see. This is to be expected, Madness has a lot of confidence in these boards, stemming from his continual use of the board in his home inverter. Finally, I notice the high side charge pump seems to HAVE been effected by the addition of the 2 extra MOSFETS per leg. When driving one HY4008, the peak gate drive voltage is about 16V and this is maintained for the duration of the PWM pulse. But when driving 3 HY4008, the high side gate voltage exceeds 17V for a little, then drops down to about 13.5V near the end of the PWM pulse. The HY4008 specs show a maximum Gate voltage of +/- 25V to Source. This 17V is good. Not too high and not too low. Too high and we risk having a short service life due to the oxide insulation layer of the Gate wearing out. (they do, at high Vgs) Too low and we risk spending too long switching, that is too long in the resistive area of Vgs. This increases inverter power loss and adds a lot of heat. It also is responsible for poor service lifetimes. So the 17V is good. Particularly putting 17V in to get the switching done fast and then reducing it a bit, for maximum Gate oxide insulation lifetime. Below is a link to large image, comparing gate voltages of the low and high sides for (on the left) 1x HY4008 and (on the right) 3x HY4008. I have recorded these at 3 time locations in the 50Hz half wave. 5.0ms, 1.3ms and 8.7ms At each of these times, I show the entire PWM pulse first, then zoom in to the switch ON and then switch OFF events. I used different vertical attenuation settings for the 3x sadly. But you can still see enough. imagur link This work nearly completes my investigations into the suitability (for use in my home inverter) and behavior of the Madness 6x HY4008 totem pole driven power board. I think it's time to build the working inverter board, with 4x HY408 per leg and place it into service. Madness, I would like to add a feature request: A large LED, to show when the board contains significant energy I added one myself and it helps me avoid sparky "whoopies". I ensure, without fail, to only connect power when the LED is out. And I only connect the nanoverter when the LED is out too. I wonder if a nominal value pulldown resistor might be a useful protection to the power board? 10K on both low and high sides, to board ground, located either at the 10 pin connector or the T.P. drive inputs. On one occasion, I blew 1/2 the board when inserting the 10 pin plug from the nanoverter into the power board. When powering a 275W purely resistive load, the inverter draws about 297W This is about 92.5% efficient. I think this is very good for most of our needs. My house spends the vast majority of the time needing about 500W from the inverter and so it looks like I will waste about 7.5% of 500W or 37W. I can live with that. No doubt this can be improved but it would need a lot more work I am not prepared to undertake. Maybe it would get to 95%, and 25W waste. I doubt we could get it better than that no matter the build. wronger than a phone book full of wrong phone numbers |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The LED and pull down may be handy while playing around with it. Will have to think about that, my Inverter has been running at least 12 months now 24/7/365. So is it really necessary? Actually, I have never powered up a power board without a control card attached. Poida would you mind posting a picture with the Beads in place, please? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1418 |

I have seen the high side charge pump retain voltages of 16V for an hour after I remove the DC supply. I wonder if this might be part of the reason why I had the blow-up when I plugged the controller board in. The beads have a bit of shrink tubing due to their surprising resistance. The Drain will be 55V to Source, so if it touches the Gate? I just checked the bead resistance (probe points on opposite side of cyclinder) and it can be as low as 150 Ohms. The LCR meter at 10kHz thinks they are about 11uH with a wire passing once through the hole of the bead. wronger than a phone book full of wrong phone numbers |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

Wow that was awesome Poida just in time for me to build me one too already ordered the board And I'll be using four per leg also I'll be following in your footsteps if you don't mind I have no equipment for testing I would like to do as close as possible to yours Thanks for all your valuable time be warned i am good parrot but Dumber than a box of rocks |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

How much power output are you expecting from the Inverter with 16 MOSFETs? If you are not aiming for more than short periods over 6KW it will be okay, I know I can do 30 minutes at 8KW with no dramas. My Inverter also spends several hours most days running backwards at close to 6KW. Also I have had the invert trip a 20A breaker trying to start a 5KW air conditioner compressor that was stalled. This was while my wife had the washing machine on and my son was playing xbox in the house, they never new it happened. I think for the extra $10 why not put all the MOSFETs in? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

From my experiments with my small 4 Mosfet test inverters I would suggest that 1KW per 4 mosfet bridge is about the max power that could be handled by them, assuming there is a decent size heat sink and temperature controlled fan cooling in place. So, 16 Mosfets should handle 4KW loads. That is the number I use in my home power inverters. This is a one person house hold BTW. There are brief loads a fair bit higher than that but continuous loads are well below 4KW. If I had big A/c units running long hours and a battery bank big enough to keep up to it then I too would fit the other 8 Mosfets that my boards can accept. Back battery charging via GTI is up to 3KW in ideal sunny conditions, those 16 Mosfets handle that as well. Klaus |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

The little four mosfet inverter that I have does everything I need so far I don't have a refrigerator running on it right now in the future frigerator will be plugged in 24/7 and this might make a big difference I have seen over 20 amps on the AC output of this little inverter I run a couple lights small air conditioner constantly for hours at a time So most of the time well under a thousand watts Cutting a piece of plywood or two by fours usually doesn't take over a minute or two That's when the amps really crank up there my saw if in a strain can draw 13 amps by itself doing exactly what poida the Great has told me to do has been good to me I really like the mad 4 thousand watt board but it didn't have totem pole drivers If it would have had the totem pole I would have bought it instead of the 8000 watt one be warned i am good parrot but Dumber than a box of rocks |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Fantastic work, Poida. Started reading this topic about a week ago and there is so much learning on this. Thanks.  |

||||

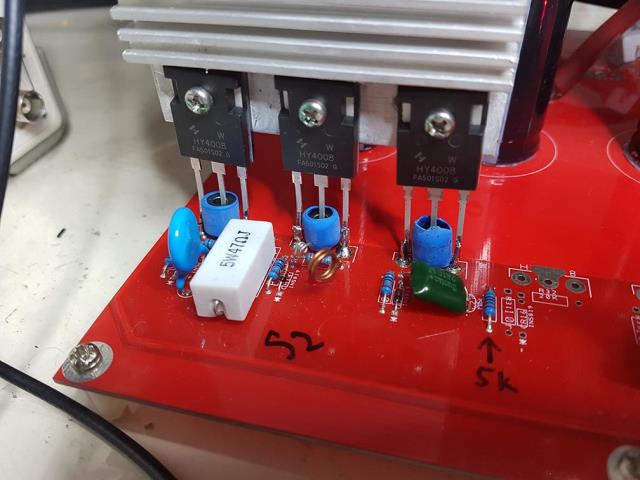

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

My 4KW power board does not have TOTEM poles as it does not need them. This Inverter runs my house just fine so long as I don't run AC or use my 240 amp MIG welder off of it.  There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

That board in the picture has 12 mosfets I like your matching control board that's pretty cool I am guessing and would be willing to bet it would run anyting I would need and more When you say AC you're probably referring to a central air unit Many of us use mini splits or E Rated window air conditioner The more wattage you use the bigger the battery Bank you need the more solar panels you need So if it all possible reduce the power you use First That was the advice I was given And it makes really good sense to me How long have you been running that inverter on your house Is this the one you referred to above that you was running for over 12 months And have ran 8 Thousand watts with That's very impressive and way above my needs One of the greats on here mentioned that a board with totem poles is better I'm not exactly sure why I don't have enough knowledge on a subject to know But the one thing I do know is when I listen to the Great's I am very happy with the outcome Not knocking your board in any way I think it is awesome love your work really like your heat sinking And you must be doing something right because all them same greats say to buy your board!!! And I appreciate the privilege of you selling me one be warned i am good parrot but Dumber than a box of rocks |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The PCB above is as follows "My 4KW power board does not have TOTEM poles as it does not need them. This Inverter runs my house just fine so long as I don't run AC or use my 240 amp MIG welder off of it." It is not capable of 8KW. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hey Buddy. Did you pushed 8kW from the 4kW board? Impressive, but looks risky for me. |

||||