|

|

Forum Index : Electronics : OzInverter OzCntrl PCB rev12 Sept2017

| Author | Message | ||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Thanks, one more question, Clockman has 1K resistor from plus pole before 6v5 Zener (supply line for SCR), but on your Gerber is 1K8 ? OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

1k will be fine, and is on my pcb file as 1k.... either will do. It is only to provide source to the scr, so makes no material difference, except for the current draw.. which will be 5ma difference. I just grab something that will do, and run with that I'm afraid. There is probably a great deal of room for optimization, but it runs so perfectly, I cant see what difference I could make if I did calculate every component. ........oztules Village idiot...or... just another hack out of his depth |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Is there any way to test ctrl board without connecting it to power board? OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

You can test the output pins of the IR2110 chips on the low side with an Oscilliscope. One chip will give a square wave output, the other is the sinewave pulse width modulation. To do this you need to put your probe on and turn on the 8010 chip, you only have a few seconds before it will shut down due to no voltage feedback. You can connect the 12v on the board to the positive side of the output of the diodes to fool it into running constantly, it may require some adjustment of the VFB pot to get the right voltage level. Then you can test the control board and power board by leaving the capacitors off the power board and put a couple 10-ohm resistors in series with the 48V input you can run the power board without risk of blowing the MOSFETs. Once you have established you are getting a decent smooth sinewave and low idle current from the transformer you can then shut it down and add capacitors. Then you can finish assembling everything and everything should be fine. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Thanks Madness. So, for the power & ctrl board test I need to desolder all the 10000 uF caps off? OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

If the capacitors are on the PCB you have a large amount of energy instantly available to the MOSFETs. For this reason, also you need the resistance on the power supply. Also it is a good idea to measure the current while doing this on a 48 volt inverter you should have around 1 amp of current. This will depend on the type of transformer you are using. With a toroid my idle current is less than 1 amp. If something is wrong you can easily blow every MOSFET without taking these precautions. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Roger, roger... will do as suggested. My Lab power supply is equipped with adjustable current limiter, so will start with lowest level ... Thanks. OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I assume you have a CRO, the waveform may be distorted a bit with the limited current but should be smooth. If you get any spikes etc something is wrong, you may get a sinewave that is wider than normal near the peaks, but as you increase the current it should look normal. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Have tested today ctrl board alone. For voltage sense I connected it to 230v home grid (Off-grid). It takes less than 30mA @ 50v. Both pulses are there, temp. protection works, current shut down and on/off switch too. Is it normal that System LED flashes in case of voltage too low/high or current shut down, regardless to position of on/off switch? Also current shut down (after triggering) is not reset until I switch supply to board Off and back On. OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

The one drawback with the 8010, is that if the voltage rises slowly, the chip will hang... and be totally unresponsive, so it needs a reset switch. I do this by a momentary switch that shorts the power to ground after the 120r input resistor.... crude but works perfectly well. This allows you to slowly charge the cap bank when installing it with say a 100r resistor.... the 8010 will hang, we reset ( short to ground after the 120r ) and we install with no brutal sparking. It also is the only way to reset the current shut down. I did this on purpose, as I want a person to reset from a current overload, in case there is a real problem on the line. Mine are always set well north of 10 kw, if you blow that there is something wrong I suspect. "Is it normal that System LED flashes in case of voltage too low/high or current shut down, regardless to position of on/off switch?"..... it is years since I looked at this or had a fault, and can't really recall what the true behavior is. I may get the heat gun out and have a look  Those scope pics are not what I remember, but it relies on where you actually measure as to the shape of the waves on the output side of the drivers, and you may need a fet attached to see it, or the high side voltage pump will not work properly. Wow you have some gear there  .........oztules Village idiot...or... just another hack out of his depth |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

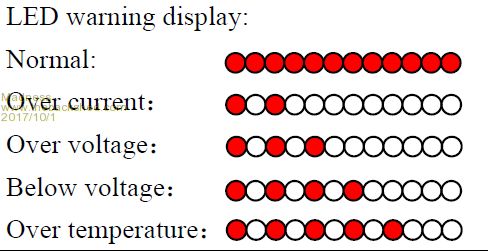

I am not sure what the first CRO photo is but the next one off the bottom IR2110 looks very good, the other IR2110 should short hi/lo similar to a square wave. Is that in the photo taken at a angle to the CRO? The other output pins on the IR2110's will not show a signal till it is connected to the power board as it requires the charge pump to drive the high side. LED will flash as per below, this is from the EG8010 manual attached.  2017-10-01_213231_EG8010.pdf There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I am still at a very early stage with my own PWM inverter, but one thing I did discover is that the voltage feedback works by sampling right at the positive peak of the cycle. It expects to see exactly +3.0 volts when it samples. If you just feed in rectified grid power into your voltage feedback, it will not be synchronous with the inverter sampling point. It really needs a +3.0v dc voltage, so it sees that at the sampling point every time it samples. Feeding in grid power is otherwise an excellent way to set up the feedback and initially selecting gain resistors, so that Vfb gets nice clean half cycles peaking at +3.0 volts with 230v input. Another thing to think about is phase shift at 50Hz in Vfb. The high frequency PWM needs to be filtered out of the Vfb signal so its a clean half sinewave without any ripple on top. But too heavy filtering can produce a phase delay so the the feedback sampling can then occur significantly after the actual peak voltage. Any noise, wobbles or phase delay at the peak of the cycle can play havoc with the sampling, and final voltage regulation can become erratic, especially with different loading on the inverter output. I am still busy with other projects at the moment, and already have a working inverter. My version of the Forum PWM inverter is not a priority project right now, but it will come... Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Connecting the 12V DC supply on the PCB to the VFB circuit works fine, you need to adjust the pot a little to find where it is happy. Once you have done that it will run happily all day. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Hi Brac321, I see you have updated the old 10aOzControl board to the 12 version, nicely done. And your testing and photos are good to see. I look forward to seeing your finished and running OzInverter. Crikey 'Oztules', these folk are sure whizzing along. Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Certainly setting a very cracking pace difficult to keep up with. Cheers, Tony. |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Oztools, thanks for all the infos. I think I will play a bit around this problem (current shut down reset), have some ideas. My scope pictures, yes Madness 2nd one is valid and should be ok, 1st one was taken with not properly set scope (AC/DC ...). Blurry pictures taken at low light with my shaking hands, sorry. "Wow you have some gear there" - hm, nothing special, older high freq. lab equipment up to 14 GHz. Some RF generators, few spectrum analyzers, modulation analyzers, video generators, etc. More than 30 years was occupied designing UHF & SHF - Microwave projects ... Warpspeed, yes I found out the same behavior of voltage feedback stage. Have used stabilized PS later on, and the voltage level must be very precisely set. Anyhow, also with home grid it can be tested well, except from time to it goes in to under voltage protection and back. Clockman, yes I've updated your board. It operates well, except problem with reset of current protection. After triggering it (with trimmer & DC source on sensors input), it stays permanently ON - until both boards were disconnected from DC source. Don't know if I missed something to rewire around SCR for rev.12? It is a bit strange to me, that diode bridge is not grounded in that part of board. I have only older Gerber files from Oztools where this protection circuit does not exists. Any link to the latest, valid Gerber files? Have tested today ctrl and spare power board without caps, with only 4 fets on. For now all ok on a 2.5kW trany, with not proper voltage ratio (230/32v). Output voltage (AC) drops while/if lowering DC input voltage below 51v. I guess I need to unwind low voltage part of trany a bit, to get rid of that behavior. Above 51v DC in, output remains rock solid. Standby current with my choke is 140mA @ 51v DC (cca 7,14w). OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

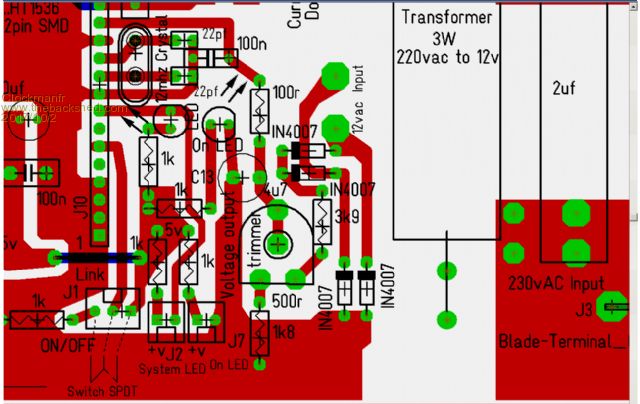

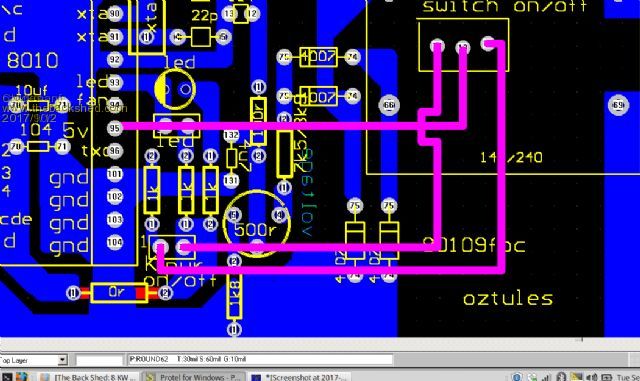

Any link to the latest, valid Gerber files? I am still updating my No12 board and have created Gerbers, but as usual I have modifications so now on 12b. I did mention that I would send you a No12 when i was happy with it. But looks like your doing great with modifiying the No10 board.  I am sure you have amended the OzCntrl board No10 to the No 12 arrangement. Just to check a couple of things brac123...... Firstly, ... I trust that you did not fit that 1k5 resistor that is shown on No10 board at Pin 6 of the 8010 chip. Board 12 has Pin 6 going straight to the centre contact on a SPDT On/Off OzInverter switch. Looking at your board a little closer, It is not clear.? I can not see that extra 1k resistor or is it under the board. Regards shutting down the DC on the power board, ..... Personally I do not see a problem with this. I think its a good safety feature especially if the overcurrent has tripped, either alter the trimmer to allow more as Oztules says 10kW is fair, or check to see where the problem is. Also if its a reset, then within 15 to 20 seconds then my BIG 250amp DC Midnite Breaker can cope. However like Oztules I add a 100r resistor when first connecting the DC to the Power board, as those Capacitors can draw horrendous amounts of amps, splat time, on DC connection even before starting the Inverter. As he says, ..... "The one drawback with the 8010, is that if the voltage rises slowly, the chip will hang... and be totally unresponsive, so it needs a reset switch. I do this by a momentary switch that shorts the power to ground after the 120r input resistor.... crude but works perfectly well. This allows you to slowly charge the cap bank when installing it with say a 100r resistor.... the 8010 will hang, we reset ( short to ground after the 120r ) and we install with no brutal sparking. It also is the only way to reset the current shut down. I did this on purpose, as I want a person to reset from a current overload, in case there is a real problem on the line. Mine are always set well north of 10 kw, if you blow that there is something wrong I suspect." This is the no 12 board. .....  or Oztules. .......  Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

The current control is a pretty blunt instrument, and is a final shut down. I intended it to shut the thing down totally... so it is behaving as I designed. The floating diodes are necessary to supply a floating voltage to make things happen there..... use of the CT as a voltage source that is isolated. I am not understanding the intense interest with the voltage control. All the conclusions i find as obscure, if you use a transformer and feedback it is clear that there is no fancy top of sine wave business going on, nor is phasing of any consequence. You can be as cavalier as you please with this part of the circuit, as it will self regulate, it is only the capacitor you use for smoothing that will have any influence on the hysteresis. It uses the RMS not the peaks, it is rectified and filtered. It is because you are trying to use a fixed voltage for regulation that you are finding things that are not relevant to it. I say again as I said before, the 8010 provides the three volts there by massaging the output, and it will always be 3 volts, as it will pwm to make that case. If you inject other voltages into this input, it loses control, and looks to be finnicky. it is not.... it is simple neg feedback.... simply don't do it, and use a little transformer ( 24v/240 or whatever), and you will get a proper picture of the wave forms, as they will be real, rather than trying to fight against a fixed wrong voltage.. it is not as hard as has been depicted, it is simple and rugged. Anyone injecting a fixed voltage into the VFB is not doing themselves justice, just muddying the waters..... use a real 24/240 tranny if you don't want to use your big one.... then the waveforms will be properly represented, and you can test for the resilience of the VFB, and interactions of the trimmer, and set the board trimmer right there and then. It will be pretty close when you fire up the big one. You do not want the big tranny hooked up if your wildly out of range, as it may go full pwm, and may blow up the fets. (Although, with the caps removed, you will not blow them up.) So current o/load is based on AT power supplies idea, that off is off until it is powered down, and don't inject 3v into the VFB unless you want nonsense results. Design a reset into it ( I short the 120r to ground with momentary on switch). .............oztules Village idiot...or... just another hack out of his depth |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Your waveform looks good brac, next step on the power board is to fully populate it except for the caps. With no load the FETs will run all day like that without a heatsink. If you get the same result add the caps and heatsink then your done with that part. Current protect would normally only be triggered well beyond 10 KW, it is intended to protect against a dead short type situation. A while ago I had a 5KW motor stall and it tripped the 20A breaker, the inverter handled that with no problem. This was without overcurrent protection but probably getting close to where it should be tripping. I only mentioned putting the 12 VDC on the VFB for initial testing of the control board. This is the only time I would do this. You can test it by turning off the switch and have your probe on the pin you want to check and turn it on. This works but you only have 3 seconds before it shuts down due to no VFB. Voltage is normally rock solid and never varies, as I see somewhere Oz wrote "the numbers are painted on the meter" Sorry for any confusion caused. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Clockman, yes the 1k5 was removed, 1k (SMD is on bottom side) on the Off position of the switch. And that switch operates without any problems. I would like to see part of the latest board around current protection (upper right corner of ctrl PCB). I know, my English is fare a way from perfect, but I do understand Oztools explanation how he solved reset of current protection, and yes it is a good idea for inverter to stay Off after over current error. What disturbs me is that it can not be reset without physically switching main power off. In past decades I've designed plenty of electronic devices, not only RF stages, but also very complex digital boards and complete devices with multiple microprocessors etc. Hardware and software, from idea to the end product. These were projects where such hangs are not allowed at any circumstances. In process of hardware design there were almost always problems with slow rising supply voltages, or short interrupts of PS, or not filtered supply lines, or unproperly blocked supply lines close to the IC's, unproperly routed lines (specially Ground planes) on PCB's, etc. I was forced to discover how to deal with each time on a new, what to do with each new processor, or each different logic board.  Therefore have some ideas to try out on incoming days on the 8010 chip... it should be safe  - can be done on a ctrl board alone without any risk. Will post here if I get any useful results. - can be done on a ctrl board alone without any risk. Will post here if I get any useful results.In two days I should get some 2nd hand heat sinks. They came larger as required and would need to shorten them a bit and partially mill down (5 cm thick) to fit on your boards. OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||