|

|

Forum Index : Electronics : time to build a replacement inverter

| Author | Message | ||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hi Warpspeed. I have a very important question. Maybe you (or any other friend) can help me. If i understood correctly, "excessively long output wiring" will give problems. My project consists on using two (or three) APC nobreak chassis. One chassis will have the control board + power board and the other will have the transformers. So, the wiring from Power Board to Transformers will be about 50~80 centimeters. Do you suggest to try to reduce this wiring? Thanks |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

It should be o/k, but try and put the choke up close to the mosfet bridge on the high frequency side, and run a pair of wires to the transformer primary that are closely bound together. Those precautions should go a long way to minimizing radiation from the longer than usual wiring. Cheers, Tony. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Hey Warp. Thanks for you answer.  It helps a lot. It helps a lot.So, this is correct?  To avoid radiation from the transformer wiring, you recommend putting some aluminized tape or copper tape on the wiring? Thanks. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

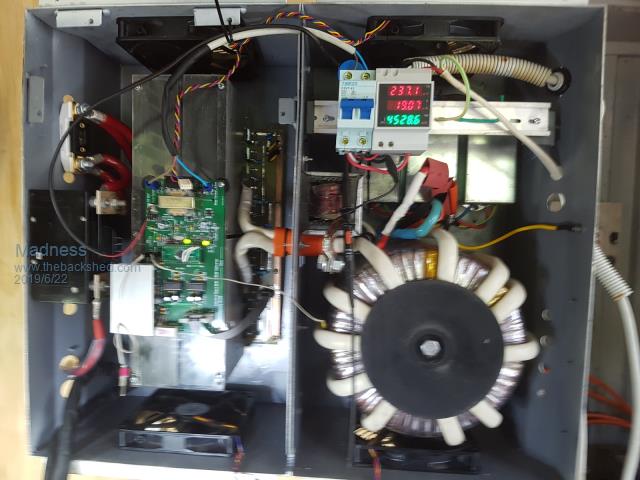

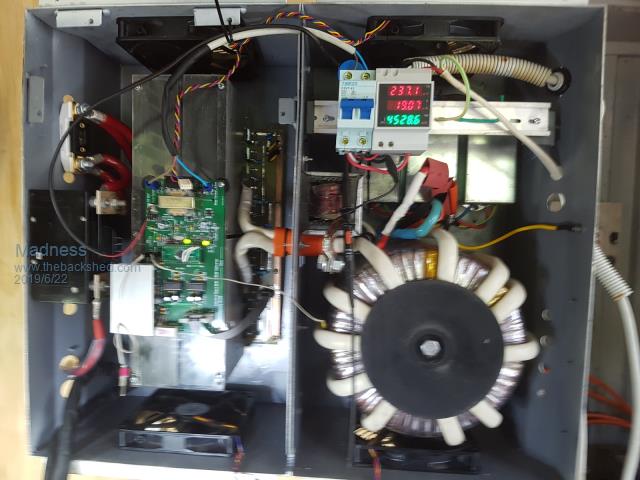

This works for me.  There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Looks like ~20cm each wire. Here i will be running about 80cm. Maybe this is a problem? I can try to reduce this size. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The way I built it was to take advantage of natural convection. There are 140mm fans top and bottom on both sides as you can see. Most of the time the fans do not run but the top of the case is noticeably warm. Doing this way also allowed me to keep the Toroid as close as possible to the power board. The cables between them though is still close to 300MM when straightened out. BTW that was the first homemade prototype of the TOTEM pole power board.  There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

I've tried to make your power board at home some months ago using silk transfer but it really went bad. Much better to have the original Mad power boards. To keep the EI transformers cool i will be using some old server fans. My cooling design is not good as yours, but is the only chassis i have at the moment. So, the better is to keep this wiring small as possible? 30CM doesn't sounds impossible here, but it will be very difficult. But i will be studing a way to keep the wiring small as possible. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

If you were told the wires have to be less than 200MM you would find a way. It is not worth trying to make the PCBs when I have them for $30AUD each, It cost nearly that much for the materials then a lot of time to etch and drill plus failures and you can never make anything anywhere near as good as the professional boards. I have few left at that price, if I get more made I won't be selling them that cheap as costs have increased. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes that is how to do it. Its mainly about keeping the wires very close together to prevent noise possibly radiating into the control system. With close spacing, the electrical and magnetic fields tend to cancel at a distance. Cheers, Tony. |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

I like that two box design for a inverter Really neat craftsmanship also I have motor controller boxes this would probably work well with I have all the big relays capacitors and surge arresters and stuff too if anybody needs them be warned i am good parrot but Dumber than a box of rocks |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

To get some scale the long side of the main PCB is 300mm long. If you take a piece of wire and bend it to the shape of the white wires going to the toroid on your screen and then straighten it and compare to the PCB it is very close to the same length. This does not take into account bends towards the front or back that are flattened out in a 2D photo. If you look at this Video of Clockmans the Toroid primary wires are quite long. So don't worry about what I have been saying about length. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1418 |

hmm, time for an update on running the Chinese inverter boards. All was well until the wfe chose to run the bar heater on the inverter. Ka-pow! Replaced 1.2 the bridge MOSFETS, in April. Yesterday I chose to run the board with the frypan, doing a nice boneless roast lamb. 1/2 hour into it. Ka-pow! I can't seem to build the modifications into a board (such as this one here My Dog, the board is $200 each now. That seems a lot of fun tickets. Am I on drugs? I recall paying $120 AU or something.) so that it can provide 2500W Not to worry, I am building a Madness power board now, driven by the nanoverter or Madness control board (not a lot of difference between the 2, maybe lower idle power) I will be including some ferrite beads on the Drains of all high and low side MOSFETS. This is for lowering the emitted electro-magnetic interference (EMI) and so providing a good situation for the control boards to work in. (no need to pictures of the gory explosions. We have all seen enough of this..) Sometimes I think I know what I am doing, other times it's clear I have idea at all. wronger than a phone book full of wrong phone numbers |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I haven't seen a blown board for long time, a picture won't hurt. :) My experience is that if you have a small enough breaker there is no bang, just a tripped breaker that won't stay on. Not trying to brag but it's been a few years now since I have seen a MOSFET with craters or a PCB with black on it. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

Looks like ~20cm each wire. Here i will be running about 80cm. Maybe this is a problem? I can try to reduce this size. To get some scale the long side of the main PCB is 300mm long. If you take a piece of wire and bend it to the shape of the white wires going to the toroid on your screen and then straighten it and compare to the PCB it is very close to the same length. This does not take into account bends towards the front or back that are flattened out in a 2D photo. If you look at this Video of Clockmans the Toroid primary wires are quite long. So don't worry about what I have been saying about length. Hey Mad. Thanks for answering. This is good to know. Was a bit afraid because of that. Thanks again for all help. |

||||

| arthur8 Regular Member Joined: 08/05/2019 Location: BrazilPosts: 69 |

All was well until the wfe chose to run the bar heater on the inverter. Ka-pow! Replaced 1.2 the bridge MOSFETS, in April. Yesterday I chose to run the board with the frypan, doing a nice boneless roast lamb. 1/2 hour into it. Ka-pow! I can't seem to build the modifications into a board (such as this one here My Dog, the board is $200 each now. That seems a lot of fun tickets. Am I on drugs? I recall paying $120 AU or something.) so that it can provide 2500W Not to worry, I am building a Madness power board now, driven by the nanoverter or Madness control board (not a lot of difference between the 2, maybe lower idle power) I will be including some ferrite beads on the Drains of all high and low side MOSFETS. This is for lowering the emitted electro-magnetic interference (EMI) and so providing a good situation for the control boards to work in. (no need to pictures of the gory explosions. We have all seen enough of this..) Sometimes I think I know what I am doing, other times it's clear I have idea at all. Poida, I would like to thank you for the boards. I will never forget this. And i owe you a beer.  You guys are fantastic! |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

Is there anything that's not recommended to run on the madness board Or does Madness just give it hell on anything and everything as long as it has a good breaker for Kicking It Off I am ready to get started on my madness board just as soon as it comes in So any tips you post will be greatly appreciated be warned i am good parrot but Dumber than a box of rocks |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The only thing I would try to avoid is short circuits. Seriously just use like it is mains power, however, I have all 24 MOSFETs installed if you want to use less for some reason I don't know the answer to your question. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

Madness I'm going to do exactly what other people tell me to do I have a hundred h hy4008 mosfets if you guys tell me to put them all in there I will I'm hoping to copycat poida the greats build He has been so good to me in the past not wanting anything in return just wanted to be a good guy I deeply appreciate him I don't have enough knowledge and don't have a lifetime to get enough knowledge to be anywhere close to all you guys on here So I'm trying to keep my foot out of my mouth and not be a pain ( maybe trying too hard) Even though you guys are the brains behind it I'm still have a lot of fun putting them together And I do learn a little bit along the way ( mainly that I don't know as much as what I think I know) This board it's pretty awesome pictures don't do it justice by the way be warned i am good parrot but Dumber than a box of rocks |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

One other caveat I will put on my previous statement. I am using my own control board, not Poidas, I am sure Poida's control board is perfectly fine but as yet I have not used it. I have tested my Inverter 8KW for 30 minutes, the Toroid was getting up around 90 degrees at the end but it did that test without any problem. Since I have started using grid tie inverters with my system I don't draw more than around 5KW at the most at night. The inverter actually works harder during the day running backwards to charge the battery. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

I guess I will be using poidas control boards unless poida decides to use your control board I do appreciate you selling me a board it is really nice board Do you use a nano style or 8010 style be warned i am good parrot but Dumber than a box of rocks |

||||