|

|

Forum Index : Electronics : Winding Transformers

| Author | Message | ||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

I haven't made all my decisions about that yet. Still trying to get through the winding stage ... but need to give it more thought soon. Hi Brian, I'll send you a pm. Cheers, Roger |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

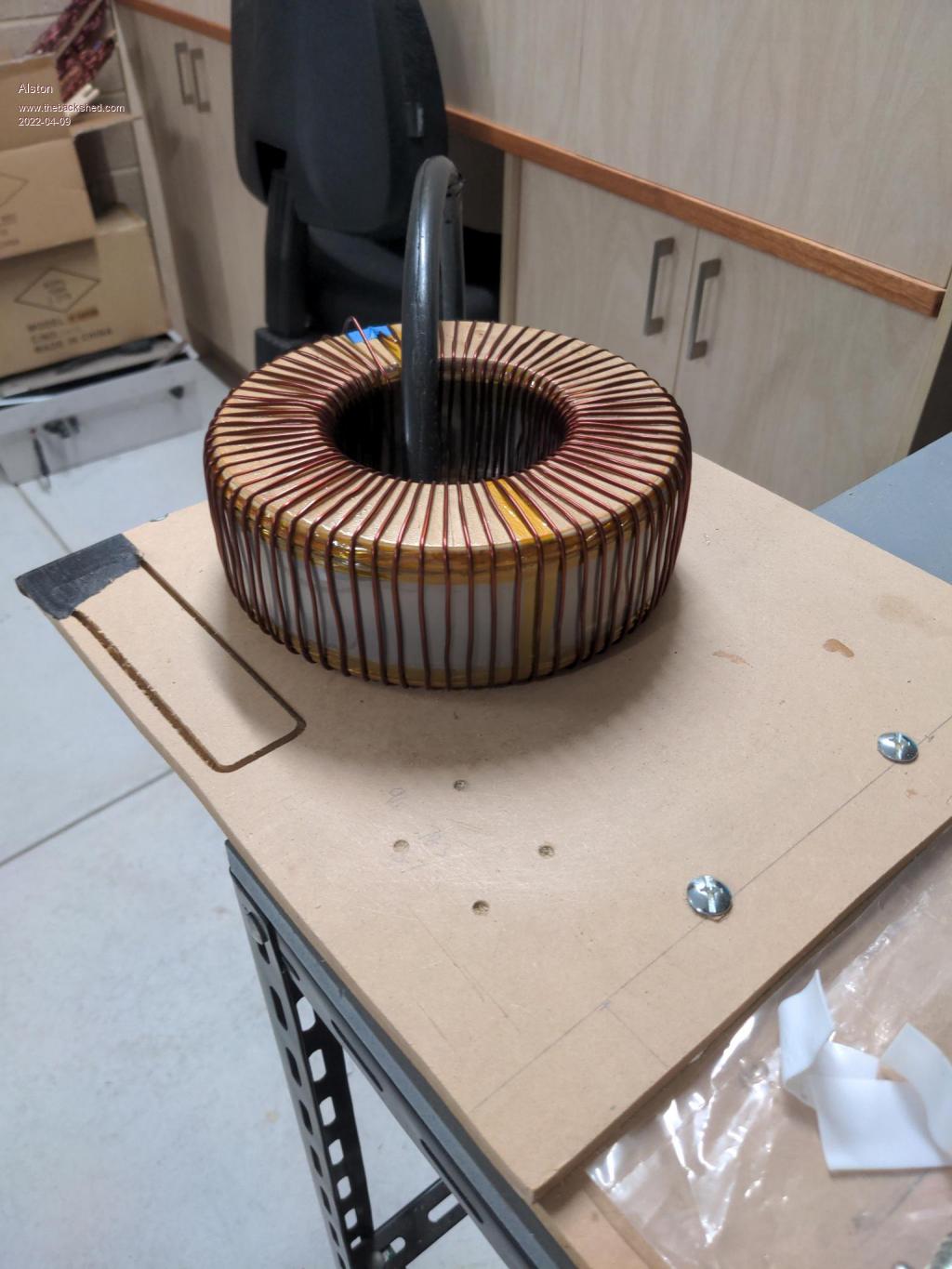

4 primary layers wound and just marked the secondaries out and ready to start winding. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Very nice Alston, good to see the progress. This is the second largest toroid? What size wire and how many turns for the primary? I've been looking for cable for my primary windings and am discovering just how expensive it is ... so wondering about using multiple strands of reclaimed wire for some of them perhaps. When I built my spot welder I managed to find some 70mm² cable at the scrap yard ... but they don't seem to have any more ... and at $23/mtr it's gunna get expensive.  Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

I used reclaimed wire for the primary on 3 of the transformers. To dop that neatly they need to be twisted as 7 strand (6 wires around a straight central one), all equal diameter wires. For the biggest transformer I used 3 of those in parallel (21 x 2.5mm sq). There is a trick how to do that, just putting the wires in a drill chuck makes a messy tangle. Look back at tinkers warpinverter build, its described there. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Here is the link: thebackshed.com/forum/ViewTopic.php?TID=11461&P=3 The edit feature did not let me update my previous post - I get an error message when trying to save it but I *can* preview it. I think there is a bug in that feature. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

I've been feeling a bit guilty having hijacked Alston's thread so much ... so I thought I'd start a seperate one to discuss the topic here ... Klaus, your link still didn't work, though I eventually found it here ... . Cheers, Roger |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

Roger this is my second biggest transformer, it has 69 primary turns and I used 1.8mm (4 layers) wire recycled from an Aerosharp. The core is from an SMA Sunny Boy that you can see me hacking out of it's potting in another thread. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Thanks Alston, that makes sense. It's hard to gauge an accurate size just from a photo ... unless there's a reference that makes it more obvious. My large transformer is 270mm in diameter and 175mm tall ... without the primary wound on it yet ... which doesn't sound all that large ... but when you see it sitting there it looks massive. And when you go to shift it, you really get an idea of its mass. Something like 46kg so far!!! Cheers, Roger |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

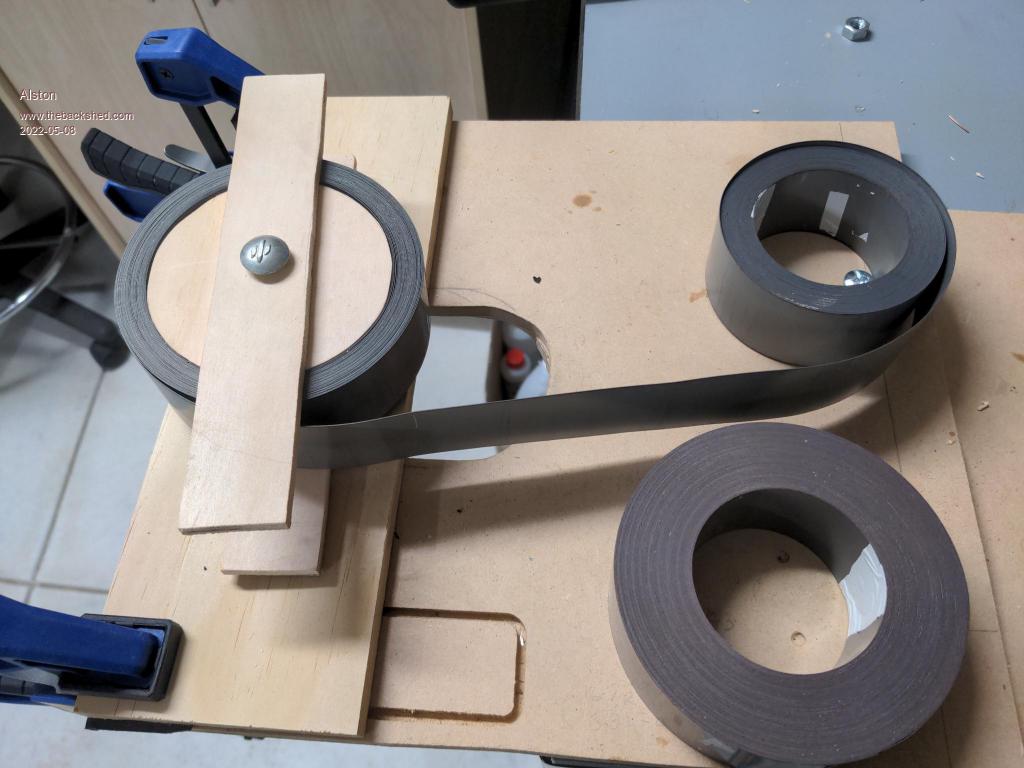

Transformer 3 is all complete and I have started on TX 2. I could not find a suitable core so I am winding one from some smaller ones I had. Here is a photo of my very crude setup that seems to be working well. I didn't go to the effort of spot welding them and instead used epoxy. By the time the endcaps are epoxied on I figured it will be pretty well all glues together.  |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

That looks great Alston, good to see you winding a core to suit. I always thought I'd use super glue to hold the first couple turns together, wait for it to set ... then wind away ... but then got carried away coz I've always wanted a spot welder. But I'm sure epoxy would be best because it has a lot more body than super glue. Even though mine seemed to wind tightly and was then spot welded ... I still ended up pouring a whole tube of superglue over the edge to soak in ... to try and make sure it doesn't rattle somewhere down the track. I've often done that in the past when trying to quieten rattly laminations in a transformer, seems to work pretty well. And if it's the windings that are rattling, I spray in a heap of coil paint. Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

I would advise the same Paul as you seem to use no tensioning method as you wind. Place some temporary fencing wire around the outside to hold the end in place, warm the core a bit (40-50 deg) so the epoxy soaks down into any lamination gap before you epoxy your endplates on. They wind those laminations on with a fair bit of tension in the factory. |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

I tried a few techniques to tension it but without a lathe or similar I would never be able to get it as tight as they were originally wound. I actually found that I could get it tight enough by hand until it would not longer slip and only the last bit wound would loosen. Thanks for the tip Klaus, I used a hot air gun and heated it up and then poured the epoxy on which seemed to soak in. This process looks to have worked really well! |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

Here is a video of how the cores are made in a factory https://www.youtube.com/watch?v=CbKhpPSDCTg Edited 2022-05-09 23:43 by Alston |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Wow, that's the modern version. This is how I did mine  ... see here ... ... see here ...Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Great find Roger  . I notice that guy still had all his toes and fingers despite a special cutting blade for them being part of the 'machine' . I notice that guy still had all his toes and fingers despite a special cutting blade for them being part of the 'machine'  . . |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

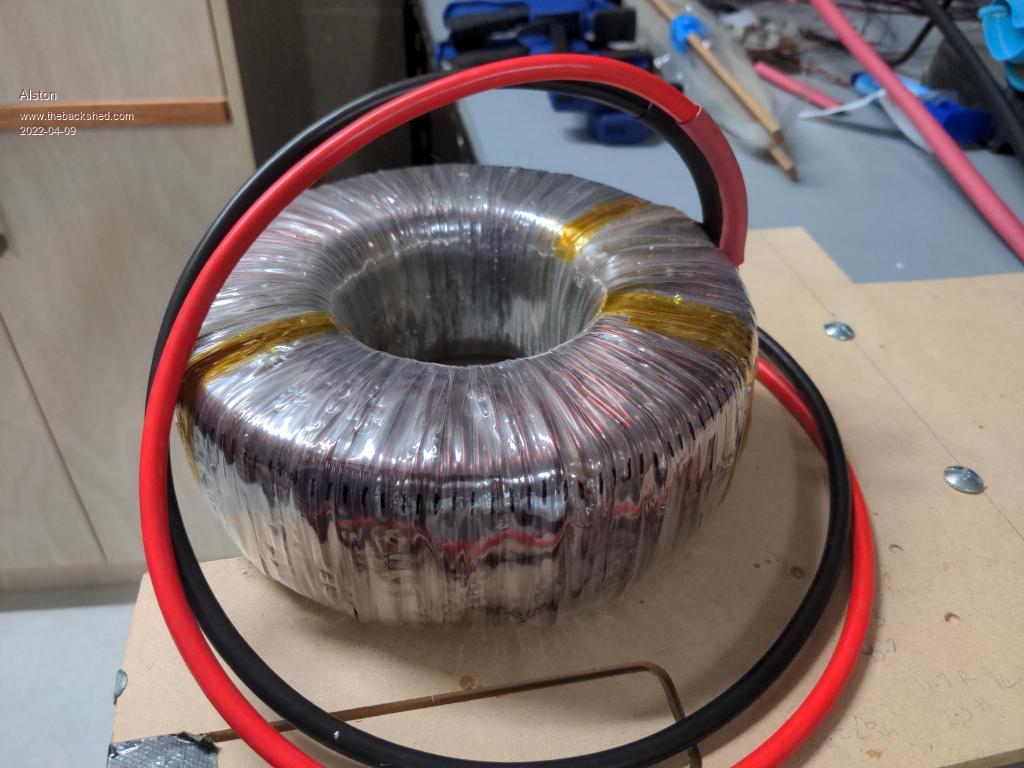

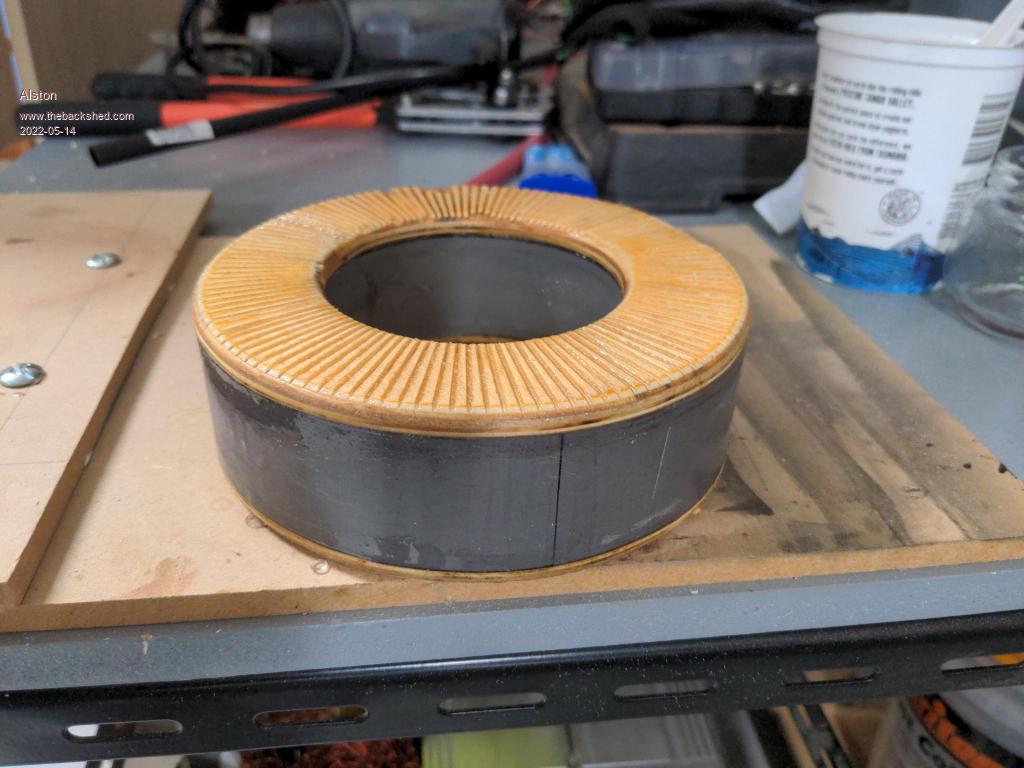

I have completed winding the core and making the end caps on the CNC. I CNC them a bit oversized, epoxy them on and once dry use a trimmer router with a flush trim bit to get them to exact before running the round over bit on them. With the smaller divisions on this transformer I had a bit of blow out near the edges but that doesn't really matter. For scale this core is OD:165mm ID:90mm and H:40mm (without endcaps)    |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 423 |

Looking good! |

||||

| oreo Regular Member Joined: 11/12/2020 Location: CanadaPosts: 49 |

Very nice work on rewinding the transformer lamination(s). Have you thrown a few windings on and measured the saturation current? What you are doing here is something I want to try, but I have been concerned about the possible work hardening of the core when rewinding. Also, the addition of epoxy or other glue will affect this as well. (I think) So I have been wondering if the actual performance of the core (per cm2) degrades much when rewinding. thanks Greg |

||||

| Alston Regular Member Joined: 04/04/2021 Location: AustraliaPosts: 63 |

I have measured it and the magnetizing power was 2.5watts. Based on the numbers Klaus gave me for his transformers this sounded fine. I should have but didn't measure the individual cores before I unwound them so not sure if I degraded their performance but the performance I have is fine. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

If you used 1 Tesla (10,000Gauss) in your calculation then your magnetizing power losses will be quite a bit less than the original winding had. I very much doubt that the above mentioned core work hardening actually occurred with your re winding method and as the epoxy is not magnetic it does nothing but silencing the layers. |

||||