|

|

Forum Index : Windmills : BLDC DD 3-Phase AC Induction Generator Build

| Author | Message | ||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

I installed a 3 phase VFD (variable frequency drive) on my drill press. Thats why I was able to get so many accurate data points for my graph. It has a lot of params, and settings. It might actually have current, voltage, maybe even torque already calculated. I was thinking about this the other day. I've never played around with it much. I'll have to read up on the manuals. Edited 2021-04-28 13:52 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Yeah shorting across the neutral and winding, through the Ammeter, (no resistor in series) gives a 2.8A max production. The resistor I got is just too low of resistance to measure any power production across it. I assume this because it is lower resistance than the windings. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

And one other thing. The stock magnets, I believe, are not powerful enough to produce more power. And most likely the laminate core of the stator, will or already is magnetically saturated. People have reported that they can get more power out of these DD BLDC-generator conversions, so I'll assume there's a little more wiggle room for power gain. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

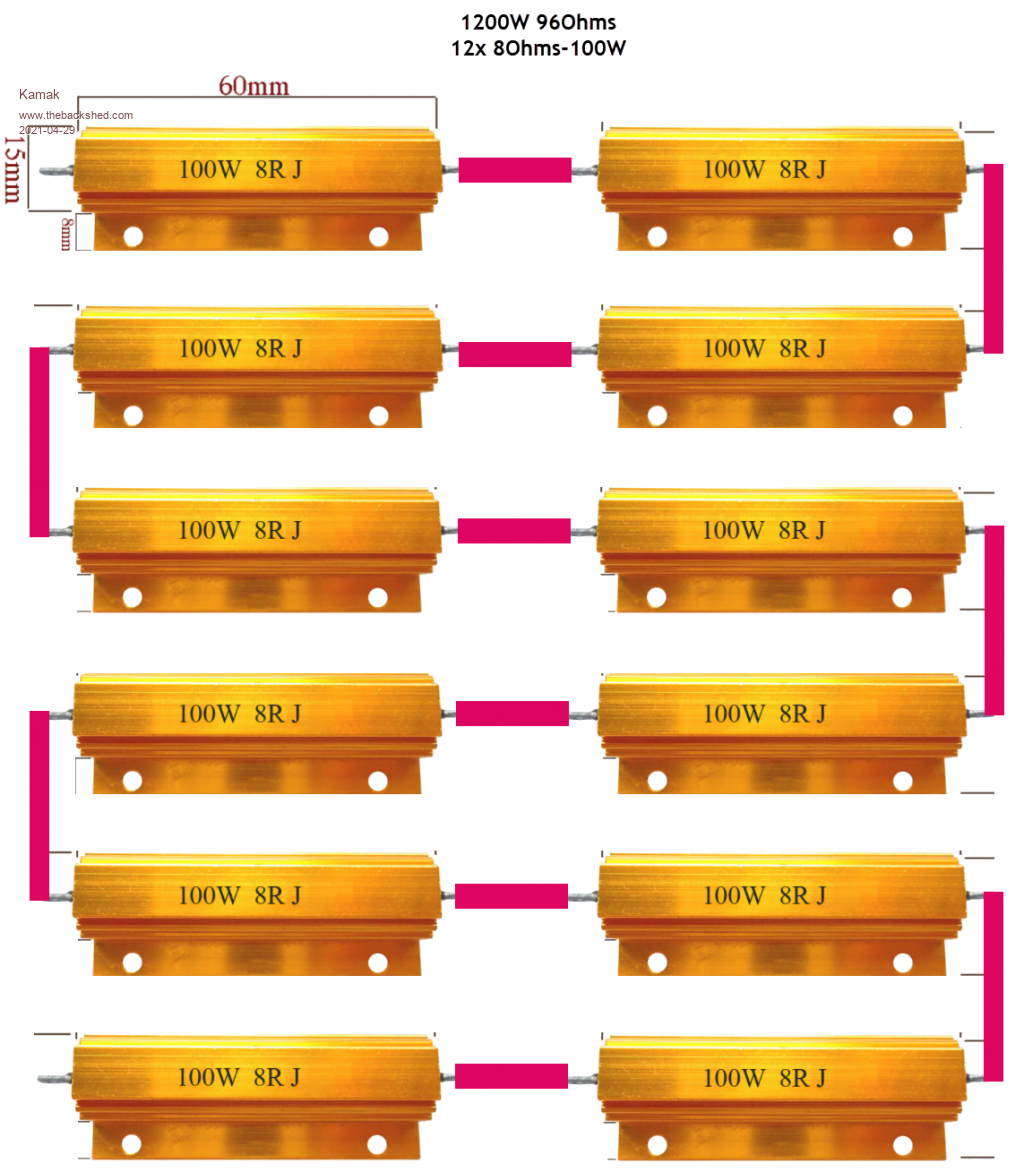

http://www.thebackshed.com/forum/ViewTopic.php?TID=13699&P=2#167620 "10ohm loads(100W incandescent bulbs)" 10ohm load at room temperature, it climbs to 120ohms at 110W. 120V x 0.919A = 110.28W, R = 120/0.919 = 120ohms. This time I'll put two bulbs in series on one winding. 405Hz 240V 914mA 405/24x60 = 1012.5rpm 240x0.914 = 219.36W, 219.36W/2 = approx 110W per bulb. R total @ 219.36W was: 240/0.914 = 262.58ohms So R total starts out at 20ohms @ 0W and climbs to 262.58 @220W For reference, At room temp, zero voltage, R total = 6.2(winding) x 20(x2 bulbs)/(6.2 + 20) = 4.7328ohms. R total with 2.7ohm load resistor = 6.2x2.7/(6.2+2.7) = 1.8808ohms. Without having plotted the current vs rpm graph, I noticed that the current curve is quite different with a dynamic resistive load (temperature dependant bulbs) as opposed to a static load of 2.7ohms. I will expect a static load of 88ohms to behave more like the 2.7ohm load.  Edited 2021-04-29 06:31 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

To be continued.....Waiting for parts... |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

For sh*ts and giggles, I threw a 900W capable (3x 300W incandescent light bulbs in series) load on the rectifier. The torque requirement was quickly discovered to be too much for my 1Hp 230V/2.8A drill press, motor with VFD. So I have to get a smaller motor pulley to increase the torque to a ratio of 3.357:1 (pulley#1 5.875" pulley#2 1.75"). The motor at full speed will be 3490rpm and the output at the chuck will be approx 1040rpm, just above my max design parameter. The torque of the motor will be multiplied by 3.357 at the chuck. Hopefully, that's enough not to trip an overload from the VFD. Aside from all the mechanical friction between the motor and the drill chuck, I hope there's enough left over to ramp up the rpm from dead stop to full speed and produce the generator's max output capability, at stock. It's only going to get tougher with more powerful magnets. Watts in > Watts out, through a rotating mechanical linkage. Due to electrical losses, mechanical friction, and moments of inertia, the output power will always be less than the input power. The most I would ever be able to produce at the chuck of the drill press would be < 600W. Edited 2021-05-05 00:58 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

At this point, I feel this "wind turbine" pursuit has drawn to a conclusion for me. The original pursuit was to make a DIY generator out of a Samsung DD BLDC motor, enhance its output, and hand it over to a relative, living in an area with the greatest opportunity for wind power generation. That has been discovered to not be adequate enough to justify any further development of a wind turbine. Though I am going to pursue the generator project and the detailing of developments of this BLDC conversion. I will continue documenting my developments here as originally planned, but probably will copy and paste the details and clear and concise development of the enhanced BLDC/generator conversion, to the electrical topics section, in the end. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Though I've always had the itch to work with carbon fiber, mold making, and create "Plugs" I would love to design a beautiful mold for an ultra stiff lightweight carbon fiber wind turbine rotor blade. That and the design of a practical, functional, and simplistic proportional applied eddy current rotational speed controller. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

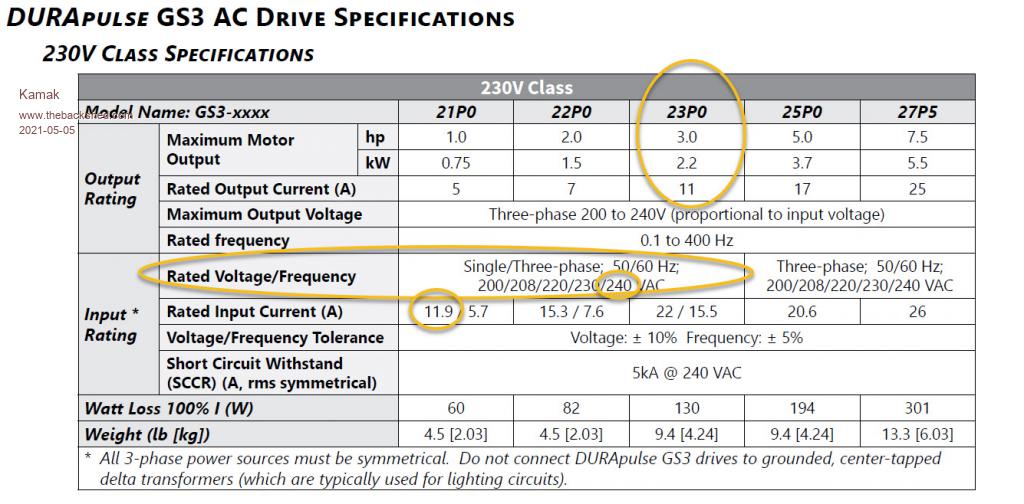

One of the first things I need to do is increase the Hp of a testbed to spin up a generator under load. My 1Hp drill press motor/controller has been discovered to be too light to achieve 500W and above, for a generator's torque requirements, I need a 3Hp Inverter duty 3ph motor and a new 3Hp VFD. Instead of mounting this to my drill press, I would weld up a stand-alone test gig. Though I have increased the torque a little bit, with a new pulley ratio (coming), so windup might not trip a thermal overload anymore, plus I've been playing around with the VFD's voltage/Freq ratio curve also, to help reduce startup current control. A direct drive testbed is really the way to go, going forward. 3Hp VFD 3Hp/3ph Motor  Edited 2021-05-05 04:00 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

This would create approx 2.8KW of work, at the motor shaft. With a direct drive, it would reduce mechanical losses. There is also no way I would even be able to produce half this power/wattage out of this generator design, so having at least double that power requirement, to test it, would be wise. Edited 2021-05-06 05:00 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

A good source of information, when sizing a power source (motor) to test an inductive load, like these BLDC/Generator conversions. https://www.engineeringtoolbox.com (PF) Power Factor for a Three-Phase Motor Benefits of Power Factor Corrections Power Factor Correction with Capacitor Suggested Capacitor Ratings for T-Frame NEMA Class B Motors motor-calculator Example: Assumption: BLDC/Generator predicted power: 1200W, not calculating for its Reactive power (the power consumed by itself generating its internal emf). This would only be the assumed Apparent Power. 1200W = 1.61HP In order to produce 1.6HP output at the shaft of the test "Driving" motor, including efficiency loss and PF, it would require a sizing of approx: P = 1200W = X(consumed test motor power) x 90%eff x 85%PF X = 1570W Consumed power to the test driving motor. 1570W = 2.1HP With a conservative safety factor of approx, 1.5 = approx a 3HP motor. Edited 2021-05-08 03:16 by Kamak |

||||