|

|

Forum Index : Electronics : MAD/OZ AC/DC Charge Controller

| Author | Message | ||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

[quote]I have checked the GTI and of the 6 IGBT's and 2 diodes in it's output side 2 of the FGA40N65SMD IGBT, 80 A 650 V, are dead short. [/quote] Please note these are not 80 amp devices. The number will tell you 40N65 means 40Amps, N channel device, 650 volts. Its not a particularly remarkable device, and four dollars is probably about right. http://pdf.datasheetcatalog.com/datasheet/fairchildsemiconductor/FGA40N65SMD.pdf Something like a 60N60 for six dollars might be worth looking at maybe ? http://www.ebay.com.au/itm/5PCS-FGH60N60SFD-Encapsulation-TO-3P-600V-60A-Field-Stop-IGBT-/152474421777?hash=item23802f0a 11:g:lj8AAOSw4GVYGteM I would think trying to frequency lock a GTI to a small petrol generator might be rather risky. It should lock fine to the grid, or a stand alone off grid inverter, because the frequency it is trying to lock to never varies. A small petrol genny is going to slow down and speed up as the load changes, giving the GTI an impossible task. Its very likely to either shut down or go *BANG* I wish you luck. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I just copied that off RS components, they are stretching the truth there. FGA40N65SMD is what is already in the GTI and yes are correct Warp they are 40A although that link you provided does not work for me, surely running in pairs of 2 they should handle up to 20A easily. Been playing with Aero-sharps as the one I had setup was maxing out at 1850W and regularly shutting down with a fault. Disconnecting one set of panels from made it operate up to 1500W and the same with just the other set. I changed all the PCB's in it apart from on IGBT which had no effect. I put together another one using the PCB's I had removed from the one that was playing up. The second unit is working as it should, so that leaves the IGBT and it's PCB or the chokes, toroid and capacitor. I will get it down off the wall and swap the IGBT and see if that fixes it. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Just blew the off grid inverter again, Aerosharp was working fine. I was there when it happened, the GTI was being regulated back to about 50% and started making funny noises until the smoke escaped from the off grid inverter. This would have been similar when it failed before with the HF GTI. I don't know what I am doing that is so different to other, maybe I am just unlucky. I have had both types GTI running for a long time previously without any issue, it would seem that any issue I am having is related to the regulator chopping up the DC going into the GTI. But others are doing it with no problem so I am cunfused. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hi all, Been following this and Oz's recent thread with some interest. Sorry to hear Madness when it appeared all was going well, decided to have a coronary and took out both inverters. I thought it was the ducks nuts in controlling AC coupling. You guys are right up there when it comes to designing electronic circuits  .. Way outta my league! Hope you get to the bottom of the problem. .. Way outta my league! Hope you get to the bottom of the problem.I have been interested for some time in making a large pwm controller. Have purchased some from ebay in the past but have had a few issues with them burning out. Mainly due to me feeding it too many amps. 1kw solar from East orientation and 1kw from the West into one 60A controller, just got too much until the fets shorted out. Replaced them and is working again. Done that a few times. Works ok in the Autumn, winter and Spring but eventually I know its gonna die coming into summer when the sun is directly overhead, and, recently purchased 8 more panels with racking for just 200 bux. Bargain I thought. So cheap now! So with this extra power I will need a bigger controller So I would like to make my own! Seems these boards can carry that power! Is it ok to just run DC into these boards, purely to charge batteries without a OGI attached. If so I would like to purchase a pair. I think its a doable thing for me as I believe most of the hard work has been done... In saying that, I'm probably just jumping in the deep end. Sink or swim  I realise they are controlled by an Arduino and I purchased an 'UNO' for another project bout 6 months ago. Madness was trying to introduce me to the digital world, but alas, never got of the ground due to other commitments. Either that or I was just plain lazy! Sorry Mad!! Anyway, I've been looking latenight at plenty of Youtube tutorials on the Arduino and learning a little bout coding. Slowly getting the hang of it. Just another language really. Looking at your coding dosent appear as scary now. Marcus if it aint broke dont fix it!! |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Hi Marcus, THe PCB files above will work fine with DC only, any ripples or what ever is causing my problems would be smoothed out by your battery bank. That will work with Oztules code, just need to add drive for the second output pin. What voltage is your battery bank? 2 KW of panel should be no problem on a 48V system and a 60A charger. I am thinking the PWM must need smoothing out of the control board to a GTI, I know Oz is not doing this but things seem to work for him and not me for some reason. Previously I discussed this with Oztiles but he advised against it as he was concerned adding capacitors to the regulated may cause the GTI to be overloaded by having power stored in the caps. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hi Madness, Thanks. Nice to know its possible to create just a PWM controller with your boards and the files in this thread. Mine is a 24v system, so the current is well over 60a in peak summer when the suns high in the sky. Cooling fans on the rear of the controllers cut in and out with a temp monitor which I know helps a lot. Without them I would of cooked them all early in the peace. Next system will be 48V! So Oz's system is working ok? Is the nano better suited than the uno in this case? I couldn't imagine it would, but stranger things have happened. I see your last post things were in melt down again. Frustrating it must be!!! Keep at it and I know you'll work things out. Do you still have any boards available? Marcus if it aint broke dont fix it!! |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I went with the UNO as it gives more flexibility to add other options such as networking and data logging. If all you want to do is control your battery charging and a few SSRs for dump loads the Nano is us fine. However, there is only about $1 difference in price between the 2. Sorry no boards available, I have posted the files if you want to order some yourself. I might do more later on but right now I have other issues and not enough time to deal with them. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Mulver Senior Member Joined: 27/02/2017 Location: AustraliaPosts: 160 |

Madness, I've been pondering your issues.... and was wondering how fast is your uno cycling through the code? Is there any chance that it's so fast the pwm is adjusting up and down more like an on/off switch? As I'm assuming the battery takes some time to respond could the code have brought the pwm down to 0 and when the battery responds the pwm shoots up to 255? Dunno. Just an idea ! |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Gidday Mulver, Any input is appreciated, 2 heads are better than one! Here is the exact code I am running, there is a 10-millisecond delay on each cycle through the code and set to change if required by an increment of 5 on each cycle. Full range of the increments is 255 so it would take 50 cycles which would take 0.5 seconds. It could easily be made go slower, with an increment of 1 it would take 2.5 seconds, with a 50-millisecond delay it taking over 10 seconds to alter by full range. It does react quite quickly to changes in voltage and does not need to be fast at all. Battery voltage is what is being controlled however the GTI only sees the inverter AC voltage and that never changes. However how quickly do clouds pass over and when you have cloud edge there is a boost in sunlight intensity. Both of these failures I have had have been when there is partial cloud so you may be onto something. Another thing that can be changed is the PWM frequency, at present it is 500HZ but it can go up to 62khz, I am not suggesting going that far but it could easily be 1 or 2 KHZ. // include the library code: #include <LiquidCrystal.h> // initialize the library with the numbers of the interface pins #include <LiquidCrystal_I2C.h> // Start the LCD display library LiquidCrystal_I2C lcd(0x3F, 2, 1, 0, 4, 5, 6, 7, 3, POSITIVE); // Set the LCD I2C address int R1=0; int R2=0; // these R ints are simply for reading multiple times for averaging int R3=0; // this shows a fear of arrays and for routines int R4=0; int R5=0; int realValue=0; int inputPin=3; long fullTime=0; // timer for float stage #2 long bulkTime=0; //timer for stage 1 bulk int ledPin = 6; // fet gate connected to this pin via totem or similar driver digital pin 6 int stage1pin =4; int stage2pin =3; // led pin outputs for visual display from distance int stage3pin =2; int analogPin = 3; // divided voltage from battery or transformer if thats your go; int val = 0; // value of voltage query int count=0; // count for display timing.... stop screen jitter int pulseVal = 25; // initilise the pulse width to zero of 255.... won't help really as the thing will run for three minutes before kick off long floaTime=0; // initialise the time to zero for the absorb int floatVolts = 920; // compared to the figure of the bulk and absorb... int bulkCharge = 1004; // figured that half way ( 1000 ) would do as the set point for absorb voltage int absorbCharge =1004; // voltage equivelent for the absorb voltage.... same as bulk.... funny about that. int startAllOverAgain = 850; // probably in the 49v range long timedOut = 60000; // time delay for absorb and step rate will change this...54000=2hrs.. sort of... int increment = 5; // how much to change each pulse width for voltage control definition int weAreHereNow=0; // initialize the start stage as zero void setup() // this is where the story starts... { lcd.begin(16, 2); pinMode(ledPin, OUTPUT); // sets the pin 6 as an output for the fet drive pinMode(stage1pin, OUTPUT); pinMode(stage2pin, OUTPUT); // set led pins as outputs pinMode(stage3pin, OUTPUT); Serial.begin(9600); } void loop() // and this is where the story really starts { Serial.print("pulseVal =" ); // This display on the laptop tells us a bit about what it sees so as to calibrate Serial.print(pulseVal); // what the pulse value will mean to other parameters Serial.print(" real value ="); //show and tell time is another word for this routine Serial.print(realValue); // shows the averaged value Serial.print(" val value ="); //show and tell time is another word for this routine Serial.print(val); // shows the averaged value lcd.setCursor(8, 0); lcd.print(pulseVal/2.55); // print the PWM out //example of line ....pulseVal =240 read value =413 bulktime value =0 absorb time value =0 float time value =0 weAreHereNow =0 // pulseVal=pwm pulse output // read value is the actual value the nano sees on pin 3... so we can equate all things to this, ie voltage.. then calculate puse width etc // the rest are values of current timers in use at the time. Serial.print(" bulktime value ="); Serial.print(bulkTime); Serial.print(" absorb time value ="); //three timers Serial.print(floaTime); Serial.print(" float time value ="); Serial.print(fullTime); Serial.print(" weAreHereNow =" ); // stage number currently displaying Serial.println (weAreHereNow); delay(10); // use this to speed things up and down.... responsible for the timing number calculation //===========show the current volts with slow up routine called count.========== if (count==5) // every 10 counts, we will display only to keep screen stable { if (val<startAllOverAgain ) { lcd.setCursor(0,1); lcd.print("Pre-bulk volts"); } if (weAreHereNow==0 && val>startAllOverAgain) // if stage 1 then we do this routine { lcd.setCursor(0,1); lcd.print("Bulk = "); lcd.setCursor (8,1); lcd.print(bulkTime/450); // makes it about a minute update at 450.. ish lcd.print(" min"); } if (weAreHereNow==1) // if stage 2 then we do this screen routine { lcd.setCursor(0,1); lcd.print("Absorb "); lcd.setCursor (8,1); lcd.print(floaTime/450); // makes it about a minute update at 450.. ish lcd.print(" min "); } if (weAreHereNow==2) { lcd.setCursor(0,1); lcd.print("Float "); lcd.setCursor (8,1); lcd.print(fullTime/450); // makes it about a minute update at 450.. ish lcd.print(" min "); } lcd.setCursor(0, 0); lcd.print("V"); // print the volts out lcd.setCursor (2,0); // the if count is to slow the screen update to the value of if count=x lcd.print (val/16.99);// voltage correction.... change the number count=0; } count=(count+1); // increment the counter for printing to stop wobble //====================this section just for song and dance and twinkly lights if (weAreHereNow==0) { digitalWrite (stage1pin,1); //digital pin 8 will light up for the bulk charge bit } else { digitalWrite (stage1pin,0); } if (weAreHereNow==1) // this lights up digital pin 9 to signal stage 2 the absorb cycle { digitalWrite (stage2pin,1); // this is all to light up leds to see where we are in the cycle } else { digitalWrite (stage2pin,0); } if (weAreHereNow==2) { digitalWrite (stage3pin,1); //this lights up stage 3.. the float cycle pin 10 } else { digitalWrite (stage3pin,0); // remember if we drop below about 48v it will reset everything, the leds will show this too. } //======================================================= enough of the bull$#!+..... on with the show================================================ R1= analogRead(inputPin); // we go and read the input pin 5 times in rapid succession R2= analogRead(inputPin); R3= analogRead(inputPin); // poor mans averaging routine. probably as fast or more than normal ones. R4= analogRead(inputPin); // having read the same pin 5 times, we can go and average the result... my sort of simple averaging. R5= analogRead(inputPin); realValue=(R1+R2+R3+R4+R5)/5; // we do the average here val = realValue; // it all hinges on this value. 5 readings averaged if (val>=bulkCharge && weAreHereNow==0) // if we achieve 59v (bulk chg) AND we were in stage zero then change weAreHereNow to 1 as a flag ie absorb { weAreHereNow=1; // weAreHereNow=1 is absorb status } //=============bulk routine============== if ( weAreHereNow==0) // if in stage 1 then check voltage against bulk charge constant ... can be set in definitions { bulkTime=bulkTime+1; if (val< bulkCharge) { pulseVal=pulseVal + increment; // was not up to bulkCharge, then increase pulse width incrementally } if (val>bulkCharge) { pulseVal=pulseVal-increment; // if over the preset bulh voltage ... then back the pwm off a bit } if ( pulseVal>=255) { pulseVal=255; // if pulse width calculation exceeds 255 then just make it 255 } if ( pulseVal<=25) { pulseVal=25; //if pulse width calulation is below zero, then make it zero instead } } //==========absord routine============== if ( weAreHereNow==1 ) // if we are in absorb then do this { if (val>(absorbCharge-50)) { floaTime=floaTime+1; // check if time elapsed in absorb is up or not (timedOut constant) } if (floaTime>=timedOut) // once we reach timedOut, we have finished our absorb sequence, change status flag weAreHereNow to 2, and change the voltage now to float value { weAreHereNow=2; } if (val< absorbCharge) { pulseVal=pulseVal + increment; // was not up to bulkCharge, then increase pulse width incrementally } if (val>absorbCharge) { pulseVal=pulseVal-increment; } if ( pulseVal>=255) { pulseVal=255; // seen all this before } if ( pulseVal<=25) { pulseVal=25; } } //=========float routine======= if ( weAreHereNow==2) // are we in float charge stage { if (val>(floatVolts-50)) {fullTime=fullTime+1; } // increment float timer if (val< floatVolts) { pulseVal=pulseVal + increment; // was not up to bulkCharge, then increase pulse width incrementally } if (val>floatVolts) { pulseVal=pulseVal-increment; // keeping charge in the float band....floatVolts is the constant we use } if ( pulseVal>=255) { pulseVal=255; } if ( pulseVal<=25) { pulseVal=25; } } //==============================write the pulse to the fet====================== analogWrite (ledPin,pulseVal); // actually write the data to the fet via pin 6 ... //============================================= if (val<startAllOverAgain) // panic/reset routine when voltage drops back to 48 volts or so. { weAreHereNow=0; bulkCharge=absorbCharge; floaTime=0; bulkTime=0; fullTime=0; } } //thats all folks There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Mulver Senior Member Joined: 27/02/2017 Location: AustraliaPosts: 160 |

Id suggest you test it with a increment of 1 and longer delay time, it will react slower but your comments suggest the GTI is not enjoying the feed going into it! Also would a 10 or 16 amp breaker on the GTI better protect your inverter? The pwm frequency is out of my field of knowledge https://www.arduino.cc/en/Reference/AnalogWrite But this suggests the Uno standard is 980hz |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

It is up and running now the increment of 1, I found some salvaged FETs to repair the inverter and it got back in action early this morning. Changing one thing at a time will help narrow down the issue. Watch this space. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Mulver Senior Member Joined: 27/02/2017 Location: AustraliaPosts: 160 |

Id expect you would be able to see in your serial print if pulseVAal its fluctuating wildly! |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I have the PWM % displayed on the LCD, it does not jump around, it just counts up and down at an orderly rate it needs to. Lasted till 9:10 this morning and the inverter crapped itself. It could be the single torroid inverter is not capable of handling a 3KW GTI. Not much I can do now till my order of MOSFETs that were just picked up yesterday arrive from China. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Mulver Senior Member Joined: 27/02/2017 Location: AustraliaPosts: 160 |

But your LCD is only displaying every 5 cycles? |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

5 Cycles is 50 milliseconds or 20 times per second. I have watched on the CRO and it has always behaved in a way that matches what the LCD is telling me. With the smaller inverter it was working fine with the GTI that was maxing out at 1850, I think either the 3KW is too much for the small inverter (maybe this is why the big inverter with the 5KW HF GTI failed) or the Aerosharp GTI has some problem or my small Inverter is faulty. It had been running with the big inverter and 5KW GTI since early May, during most of this time the GTI was unregulated and I was relying on dump loads to regulate it. One option I have considered is going back to this and using PWM controlled DC dump load to give me regulation. Whatever it is I have few weeks to contemplate it till the new FETs arrive. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Mulver Senior Member Joined: 27/02/2017 Location: AustraliaPosts: 160 |

You could test it at a simple fixed PWM to see how it behaves? Also your not allowing it do drop to zero, why is that? if ( pulseVal<=25) { pulseVal=25; |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I don't let it drop to zero as I have other DC charge controllers also and sometimes it can cause the GTI regulation to drop to zero. If this happens the GTI shuts down and then restarts when the PWM lifts from zero. Then it has to go through all it's startup check and 3 minutes later reconnects. The minimum level is a little below the minimum house load. The result is the GTI drops back to a minimum but does not shutdown and restart over and over I had it do this sometimes with the hotwater element turning on and off and the cycle repeating over and over. This way it can respond to battery voltage as needed. Just spoke with Oztules about this, he is laid up with a crook back ATM. He is scratching his head ATM about this as well, however, he did agree that could be that the Inverter I am using now could be too small but this is only guessing. So I could set the PWM to not go beyond 50% with this inverter and see if any more smoke escapes. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I have dug out my old scribbled notes from some Kaco inverter work I done with a couple of selectronics units. it is pretty slim pickings. there is a minimum battery size recommended , you are well above that, although old cells act like smaller ones. ramp is set to 0% on startup. there is some adjustment on the output ramp % speed but no detail on what situations to slow the gti ramp up. max gti size is twice the offgrid inverter 30 second rating it says 5 parameters are monitored, my guess is that three are cosine numbers (power factor for L1,L2,L3 on a 3 phase setup) the others are probably inverter temperature and dropped packets on the data link. Presuming all these factors derate the inverter. They also read two DDC voltages, so that says there are probably two relays that need to be on for the output control system to start- no idea where they triggered from. I'm confused, no wait... maybe I'm not... |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

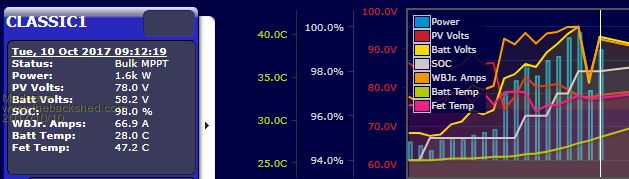

Hi Yahoo, Initial startup seems to fine, the Zeversolar and the Aero-sharps take a few minutes to do their checks and then seem to ramp up by themselves. With my setup the GTI is on all day once it kicks off in the morning. This is why I set a minimum lower limit to the PWM percentage. When it failed AC power was lost so the network also dropped out, here it shows the last bar on the chart with power at about 2/3 of maximum. This updates every 6 minutes so who knows where output went to after the failure. There was some cloud cover just before it stopped, prior to this it would have been very close to starting to reduce output looking at the voltage. Tomorrow it will get up and running again, I found some more old FETs to salvage. I have modified the code to limit it to 50% PWM. So will see if it is happy at the lower level. Need to wait for new FETs to arrive to get the big inverter operational again. Small one does not seem to be compatible with near 3KW from the GTI.  There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I am wondering out loud if what you are seeing might be a skewing of the wave from small capacitive/inductive loads and that is letting the gti wander off the 50 hz frequency and get out of sync with the off grid inverter. This would be from no load/ idle state and cause a problem as a load is applied I am thinking, OK I will use an example, A friend asked me to see if I could get his plasma cutter working on his generator, I hooked up every voltage regulator and filter I had and I could not get it to start. with no load the electronics in the cutter distorted the wave enough that it didnt like it. I plugged in a 10 inch bench grinder and the plasma cutter started fine, it didn't cut because the genset was too small but the grinder did get get us a nice clean wave. I wanted to try a power factor correction battery charger to see if that would work as well but I didn't have it with me at the time. The way I picture it, the loads should be shouldered by the off grid inverters toroid first then the GTI should slowly ramp into action that way there should be no power factor problem (unless we are driving a bank of fluro's or switchmode power supplies or something). Still only a wild theory but it has been on my mind since I saw the data node looking at cosine numbers on the kaco inverters. I figure they were doing it for a reason. I'm confused, no wait... maybe I'm not... |

||||