|

|

Forum Index : Windmills : My new garden ornament!?!?!?

| Author | Message | ||||

| Lowerstoford Newbie Joined: 30/11/2012 Location: United KingdomPosts: 29 |

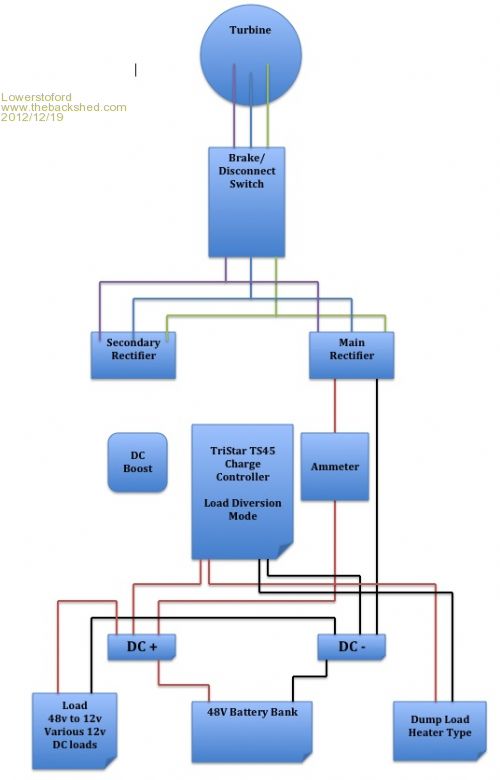

Here is a diagram of my current setup I need advice in getting the DC boost module installed My turbine outputs 30 - 48 in low wind speeds. So I am going to add the DC boost and not cap mod I have KBPC5010 diode and just need confirmation of the correct wiring on these diodes

Thanks Some Energy is Some Energy |

||||

| Lowerstoford Newbie Joined: 30/11/2012 Location: United KingdomPosts: 29 |

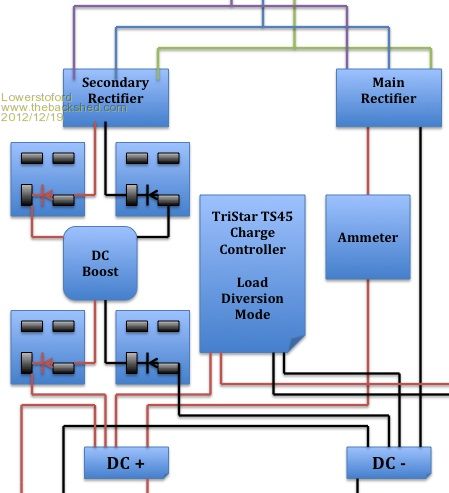

This is how I think I should wire the DC booster in

This is the booster http://www.ebay.co.uk/itm/170945298926?ssPageName=STRK:MEWNX :IT&_trksid=p3984.m1497.l2649 These are the diodes(rectifiers) http://www.ebay.co.uk/itm/260991079196?ssPageName=STRK:MEWNX :IT&_trksid=p3984.m1497.l2649 I think this is correct but would like your expert opinions....... Lee Some Energy is Some Energy |

||||

| Lowerstoford Newbie Joined: 30/11/2012 Location: United KingdomPosts: 29 |

This is why I am asking for help wiring the DC booster into my system After waiting 3 weeks for my 2 boosters to arrive from China, I jumped straight in, without much research and wired it to my secondary rectifier. This made the turbine run very slowly so I added a diode(rectifier) to the output and my DMM The wind blew, The voltage went up to battery charge levels. Wow I then added diodes to the input so both + and - where isolated and one diode on the output The wind blew, the output voltage hit battery charge levels. Then the board started making a strange buzz, so I started to move my ear to the unit to listen......... Yes, yes, its coming......... It then decided to release its magic smoke, fluff, sparks and flying metal into my face with a spectacular bang! WOOOO what a rush! (well I can say that as no damage was done to my face, just my nerves) This unit only cost a few pounds the larger one was more expensive so I must make sure it is wired correctly and does not try to modify my face. Thanks Some Energy is Some Energy |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

It looks like you might have the wrong one , some are 35V on the output and you will need the 60V ones . I think I did say it previously , they will try and hold the mill at the min input voltage which is 10.5 , so it will effectively stall the mill if it has no low down blade power which I am pretty sure yous is designed to cut-in at 150+ Rpm , This is why the mill ran slow. You would not need the diodes between the Main Rec and boost, and if the module was a 60V probably not on the other side as well , you could also AC couple with back to back DC caps to the rec to limit the current draw , then set the output V at 50 to 52 so it cuts out when the wind gets up and the main rec start kicking in. The boost module you have linked to is not the one in the pic , as the others are voltage and current adjustable but will still react in the same way. You are probably better of leaving this type right out of the system and playing with a Cap/doubler as the amount of load can be determined by the capacitance. Had a bit of a rethink here , with all the diode isolation to blow the module up like that you might have connected up the input to output V as it sure wasted the cap , you might need to double check . Is This the one you installed first HERE OR .... when it blew were you adjusting the output voltage pot to lower the output , if so the mill would have taken of and exceeded the max input V threshold ...... BANG PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Lowerstoford Newbie Joined: 30/11/2012 Location: United KingdomPosts: 29 |

OK First things First Ammeter I really need to measure the Amperage from this unit to see how much energy it is producing I thought I was being a bit premature yesterday as the wind had dropped so I thought I would check this morning as we have 6-10m/s with gusts of 13m/s The battery voltage is up from last night The dump load is running and warm The charge light is flashing on the controller The ammeter shows 0 Any ideas or pointers would be much appreciated Thanks ------ DC Booster Yes I installed the smaller one first I didn't think it though, it can only take 37v in max and the turbine will do 40 in 2.5m/s I purchased this before measuring the low speed output voltage. This is also why I'm not sure about cap doubler as the voltage would be 80 at 2.5m/s I have read many posts on this forum re dc booster, with much success Gordon has it on his hand drawn diagram The diagram I have uploaded shows how I THINK i should wire it, not how I have The first diagram is how my system is wired at the moment At first I just had a diode on the output, as it was loading the turbine down, I added on the in input. This stopped the loading down and the turbine was spinning at the normal speed, the voltage reading was normal I am sure this unit blew due to too high input voltage I also think I may have wired input to output at some point, realized what I had done and changed it quickly This would not have helped....... Some Energy is Some Energy |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I'm using three amp meters like the one you show in the link and I have no problem with any of them. Mine are on the solar inputs to the MPPT controller. There are 3 banks of solar panels (on trackers) and each bank's positive output is connected to the positive terminal of an amp meter. The negative terminals of the meters are connected together. If you had connected the meter backwards you can actually see the pointer moving to the left of zero, I would try that only with small currents as a large reverse current most likely jams the moving coil. May I suggest you approach your experimenting in a different way? Instead of connecting everything new you acquire to your life windmill circuit where unknown currents are doing their work; why not bench test each component - the Amp meter is a case in point - on an independent power supply first? Only after you have ascertained if and how it works do proceed to install it into your system. I know, one gets impatient with new things but that's one of the ways to destroy them  Klaus |

||||

| Lowerstoford Newbie Joined: 30/11/2012 Location: United KingdomPosts: 29 |

Back again! The wind dropped so I have removed the ammeter from the circuit I thought I would test it by wiring it to my 12v solar system on the load side I connected + on the load to + on the ammeter and the + on a 5m LED strip to the _ on the ammeter The light lit up The ammeter showed 0 This strip is 24W at 12V so 2A I then connected my DMM in the same way and that showed 0 in all scales and the light did not light up. I may just be using a crap DMM and a faulty ammeter..................................................... ...... Some Energy is Some Energy |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

regards the DMM, you need to shift the positive lead to the Amp socket (10A)to measure current. I am not sure I understand why you are trying to boost the volts. Step 1 is all-ways catch as much wind as you can. I am not joking about this, I have lost count of the times that I have been assured on the phone that the turbine is well up to speed and has an electrical fault that I need to urgently fix, I turn up to the job and find it surrounded by trees and sheds and barely turning  . .

Energy in the wind increases proportionally equivalent to a factor of three (cubed) of the speed. So double the wind speed, energy is multiplied by eight. anything below 5 ms with a small non furling high revving turbine has almost no energy to spin the blades, its only function is to impress or piss off the neighbours. there is not much gain to be had for a lot of effort and stress with voltage boosting IMO. There are exceptions to this, I doubt your turbine is one of them. My rule of thumb is the turbine needs to be a minimum of 15 feet above any obstacle to the wind in a 300 yard radius to reach an acceptable energy making potential. apologies if Britain has gone metric and i wasn't told. Regards Yahoo I'm confused, no wait... maybe I'm not... |

||||

| Lowerstoford Newbie Joined: 30/11/2012 Location: United KingdomPosts: 29 |

Hi Yes I had the DMM on 10A and the lead pluged into 10A I have never been able to read current with this DMM, I bought a box of 50 and sold all but 2. These both give no reading when measureing current The cost price was £1.25 I sold them for £3 You get what you pay for??

The only reason why I am trying to boost voltage is because, it can be done. Any small amount more energy I can capture via a £13 device, is more energy, so I don't want to waste it. My turbine had to go in a specific location due to materials, grazing animals, children, wife, etc It is not the best position but is pretty good. Height was limited, to get away without needing to bother the planning department, but it is 6.5m (21.5ft) to the turbine center (I could go 8m to blade tip, without planning) Open fields to the S, SW, W, NW, N, NE All other directions there are farm buildings and my house, these are 50m (165ft) away. (I have discussed moving these buildings and the house, but no one seems interested!? :-) ) The DC booster is not as important as see the amps that the turbine is producing at the moment. My plan is, the power from this turbine and solar which will be added in the future, will run my automated green house and a few other experiments. I would also like to run some of the lighting in my house which is LED. My main priority now is to see AMPS! I can hear them (PWM into a crappy dump load heater - BUZZZZZZZZZZZ) and feel them (Heat from the dump load) but I cant see them!!!! New DMM and new ammeter I imagine the ammeter must be faulty (DOA) as the needle does not move with the 24W LED Strip? what do you think? I will test it with something else later. I have some ACS712 20A Hall effect sensors that I am going to use with a Arduino and some other modules to log data from the turbine I am already logging movement and vibrations in my tower via a 3-axis accelerometer fitted to the top. These reading are great to see if the bracing I am adding, is doing what I think it should. Off to the shed I go.................. Some Energy is Some Energy |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I have 3 DMM's in the drawer that have blown the fuse in the 10Amp circuit, always said I would crack the case open and fix them, sigh ..one day. I would be lost without my DC clamp meters! The tristar has a meter panel that can be used (remote and local version) plugs in with a rj-11 cable behind the front panel, if you sniff around there are sometimes a few going cheap, I think they are worth every $, it is almost impossible to run a turbine blind, need to see the volts and amps at a glance. There is also a battery temp sensor, its pretty much a must have to avoid cooking expensive batteries. At 20 ft there will even be turbulence from the ground slowing things down on a warm day. One day you will be standing there and feel a steady cool breeze on your face from a direction with nothing in the way and the turbine will be absolutely flying. I have built a couple of guyed towers that have an extension section that can be easily fitted or taken out depending on approval. I think both of them put up stage one and got everyone used to it, then slapped it up to full height early one morning 12 months later

I know nuuu-thing herr Commandant....nuuuuuuuu-think. (Sergeant Schultz, Hogans Heroes 1965)  on the greenhouse! on the greenhouse! I'm confused, no wait... maybe I'm not... |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Lee, In all the excitement and euphoria of the turbine firing up, I forgot to mention something. I have had trouble with SOME turbines where the bolts that mount the turbine's post to the pole have come loose and fallen out or broken off. The version that has the ring that clamps around the outside of the pole is pretty good. The one that slips inside the pole and has 4 bolts that go through your tower pole will cause trouble if there is any vibration from the blades spinning. I cant suggest a fix ATM, I haven't come up with any solutions myself that I am entirely happy with. Looks like what you need now, is something to use a bit of all that power you are generating! chrissy cheers.... from the grumpy yahoo I'm confused, no wait... maybe I'm not... |

||||