|

|

Forum Index : Windmills : Requesting selecting wire size for stator

| Author | Message | ||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

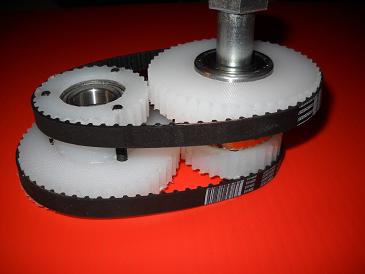

Hi, I completed the gear drive. It is very noisy. As I added more gears the noise increased. It makes to much noise for my application. Because the increased RPM is needed for the project I am going to use the same technique with belts and pulleys. Comments welcome.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

What about chain? I've used chain drives for a lot of projects, its pretty reliable and tollerant. Belts need tension to stop them slipping, and that soaks up power. Chain is very efficient. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, because it is for a vertical application I do not how I could keep it lubricated. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Govertical, The pic' may give an optical illusion,the gears don't appear to be perfectly flat,which stops them running true and will add to the noise.The gear material possibly flex's at contact surfaces and the bearing,if they are roller will also add to chatter noise.Alluminium machined gears with dry lubricated close tolerance bush bearings will keep the weight down and reduce vibration is a guess I'd make. Adding to Glenn's suggestion you could gravity drip feed oil,sparingly drop by drop onto the chain.A sump/well and guards would be needed.Also motor bike chain lube could be sprade on occassionally and is an excellent "dryish" chain lube.Cheers Rastus see Rastus graduate advise generously |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi govertical, I hope you don't mind a couple of after thoughts.Try spraying silicon lubricant on the gear train to improve performance and reduce noise.Also, there are chains made with teflon bushing between the chain links and pins and are maintenance and lubrication free,if you go that direction.Cheers Rastus see Rastus graduate advise generously |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

If your going to go with a chain drive then try and source some 'tsubarki'(sp) SS self lubing chain. At work we had a big problem with chain drives due to the water so I changed out every chain drive with that and we have no more problems with chain rusting or grease flying off and going into the product (fruit). The the small extra expense it will be the way to go for your project. Cheers Bryan |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I found a source for small timing belts. I can cut the pulleys I need. I believe this will work well and keep the cost down. Thank you for the additional ideas. http://www.mcmaster.com/#6484k145/=e0b137 just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

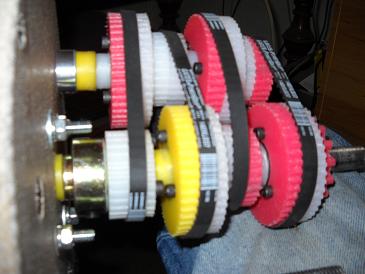

Project update: I am able to fabricate the cogged pulleys that are required. Adding idler pulleys will be challenging. I have to order larger diameter timing belts so the pulleys can be a larger diameter to allow better bolt hole placement. Comments welcomes.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Interesting that you went to the trouble to machine your own timing belt pulleys. I purchased some from a company (RS components) here in Australia, they were made from aluminium and have shoulders to prevent the belt from slipping off. With your version you need to have very precise shaft alignments, especially if one pulley is very large. I would suggest that you make the shaft on one side movable to allow belt tension adjustment, I found the small belts stretched quite a bit by the load my solar tracker put on it. Klaus |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Govertical, The update looks great!Choosing the belts and cogged pulleys should absorb a lot of vibration and reduce undesireable noise levels.Do you have something in mind for idler pulley's? All the best Rastus see Rastus graduate advise generously |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Here is my set up that I posted. http://www.vawts.net/download.spark?ID=999003&aBID=125317 I am selling all the older design setups they have survived 80+ MPH in a supper cell that landed on it in MO USA still working to this day. Bob Mann |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

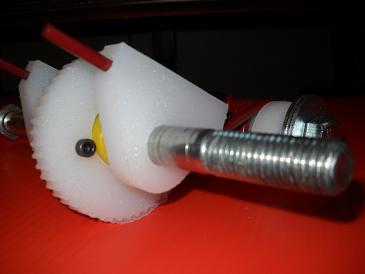

Hi, making one shaft move so all the belts tighten at the same time will require the least amount of parts and is easiest to fabricate. Thanks for the suggestion. I found a tooth rake that is used for agriculture that will function as a torsion spring to move the posts apart and provide a constant tension to the belts over time. It will a few days to fabricate all the parts. Thanks again and enjoy the day.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Greetings, just some photos of torsion spring yoke assembly. I still have to cut slide holes in the mounting plates. Enjoy the day.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Some nice work there govertical, any chance of a picture of the machine you use to cut the belt pulleys? Klaus |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Govertical, Is there any possibility that the spring can start to bounce in operation as the belts stretch,resulting in belt loss or at the least some drumming.Constant tension monitoring could become frustrating.The build quality is first class!Cheers Rastus see Rastus graduate advise generously |

||||

| rissole Newbie Joined: 10/05/2011 Location: AustraliaPosts: 15 |

As my old man used to say "there's engineers and there's Engineers". you are one of the second lot, well done, nice work! Rusty |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

http://www.youtube.com/watch?v=ZCGT6roWXw0 Requested info about CNC, enjoy the day. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

NICE  , I wish I had one of these , I wish I had one of these  Klaus |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Greetings, I still have to add spring shaft adjustment to tighten all the belts at the same time. I made the belt pulleys double the width to allow for easier belt to pulley alignment, this will also allow the belts to self track. Fabrication of the first one is going slow but so far the results appears to indicate that it will work. Enjoy the day.

just because your a GURU or forum administer does not mean your always correct :) |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Looks good. If you put metal disks on either side of the machined pulleys it would help keep the belts from jumping in case you lose alignment. One belt pops off and you have a free-wheeling rotor and no way to keep it from overspeeding. Perry |

||||