|

|

Forum Index : Windmills : Airblenda 500W VAWT

| Author | Message | ||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

I was able to change when the loading kicked it, and found that it was best to have it kicking in when the VAWT was going into lift, and hence the torque was highest. If it kicked in at too low a rpm, then it generated a wobble. More design work to be done. Work is pretty hectic right now so will get onto this project more when I have some time off over x-mas. I heading in the right direction just need to increase the area of the VAWT and make the shaft stronger, and reduce the weight of the wings/wing supports.. simple when you say is quickly.

Smithy "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

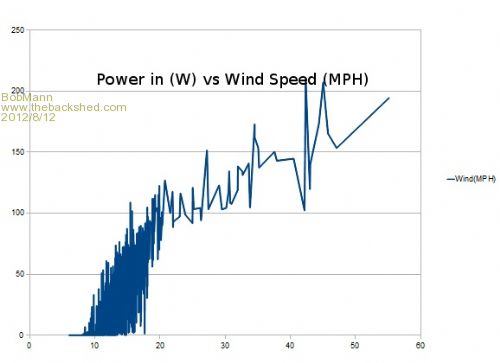

Hello every one I just wish to up date on what the Smart Controller is doing. Done and ready for prime time. Bob Mann wrote: ------------------------------------------------------------ -------------------- ------------------------------------------------------------ -------------------- MPPT post That is great Steve I know you were the guy to build some thing special. What do you think is holding it back blades size, diameter, shape, number of blades kind of blade lift??? Or do you think you should swap out to a stock F&P set up and add wire like we talked about but leave some room to group the coils. If you used a hand full of car fan relays at the turbine. You could jump coil groups remotely on the fly when you are tracking power. With some luck you may hit the magic number in short time. Bob Mann ------------------------------------------------------------ -------------------- Right now the best power curve I've found seems to max out at 200v in about 18 mph winds. At that point the controller has to leave the ideal curve, to pull more current and protect itself. (the 270 watts was seen in this condition. If it was still on the ideal curve it probably would have been much more.) It seems that if the arms were 30" long instead of 18", then in that same 18 mph wind the voltage would only be 120v. The cogging would break free in 7.2 mph winds instead of 12, and the potential power would go up by 66%. This would be a turbine better matched to that alt. [Not sure my pole would handle it, but I'm willing to try!] Steve

Using a 4 ft Lenz blade on a 36 inch circle. Bob Mann |

||||