|

|

Forum Index : Other Stuff : GS Heat Pump

| Author | Message | ||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Bob. The Sand bed is a good idea, I'm thinking about Using pea Gravel to bed it in, this will allow the water direct contact with the pipe. In the Winter this area is saturated underground and it makes a good thermal earth link. Thanks for the Ideas. Cheers....Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Just out of curiosity, why did you choose a method that involves many joins in the poly pipe? All these look to me potential leak sources. Would it not be equally efficient to lay the pipe in a spiral fashion, like a very long coil spring, and weave that through the trenches? The trenches look deep enough to be then back filled with sand to cover the pipes before the coarse fill. I bet you'd fit even more pipe in that way. Klaus |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

I have enjoyed reading your thread and am very interested in your endeavors. I am plumbing and even more heat pump dumb. So this helps mucho. Thanks! philb |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Tinker, The following is from a previous post about 5 back. I had some ABS pipe laying around that was intended to be a part of my septic Tank system drain field (County Building Codes Require a pressure system for liquid distribution). I bought the ABS for this but County said Code specifies PVC. So now it becomes a part of my system, I realize the wall thickness will hinder the conduction of heat but it has the advantage of a large surface area. I figured the extra water (11 Gallons US.) more than the original system 91.3 pounds can store 1640 usable BTU. When the heat is turned down at night. I guess the real answer is, It was cheap. I see on the Internet lots of negative hype on PVC. and ABS pipe, I have hooked several with the teeth on the Hoe and find that they are much tougher than one would expect. You also would not expect a PVC pipe to actually bend,(Not Flex),but Bend before breaking, and when they do break it is usually at a join but it is not the cement bond that gives up, The fitting splits along its length and the pipe breaks at the point where it enters the fitting. Leaky joints are caused by moisture or bonded at low ambient temp. and old jellied Cement. I;ll take a Photo tomorrow ( Dark Now) of a couple pipes I hooked with the Hoe to show the torture they can take. I appreciate your interest. Cheers....Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

philb Thanks for the good words, I,m a Little late on this , but, Welcome to the forum. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

Hi Greenbelt. Where did you find local soil temperature maps? Google didn't work too well this time. I am in the process of building my own house now. Everything except the propane line is underground. Propane line cannot buried under the slab by code. A separate building will house all the solar and most utilities such as preheat hot water tanks and maybe cooling water as well. So I can use any refrigerant I want. If I do mess up, I can still talk about it later. There is still have a lot of latitude at this stage of the game. philb |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

plilb, Google for Ground water temp map. Here is one example of a Ground water/Soil Temperature Map Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Bent by force,not heat. PVC Pipe ripped from the ground on the teeth of a backhoe.

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

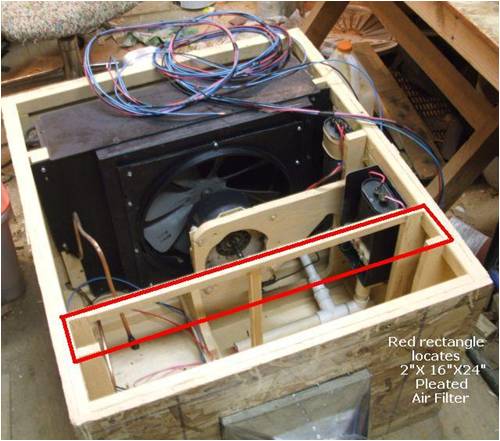

Some more Show and Tell, I have built the container box for the Condenser and Compressor, this is also the air handler and filter. A couple of Pic's now and more shortly. This is it, No Top yet, Top must be built, Bug and Spider Tight, Wife goes into orbit when a spider shows up. The 220 volt fan motor requires a running cap. so I used the double unit that came with the air conditioner. My new compressor needs a higher value than the double unit provides so I installed another salvaged from a different unit.

I mentioned this new compressor in an earlier post, It is only 14 years old, I've been moving it from place to place with the thought that I would build something, Only When was Unknown. It is not installed yet. The refrigerant is not in the Budget at this time.

Cheers---Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Whole-heartedly agree with you on the quality of PVC as a material, but glueing a joint requires both skill and practice to get it perfect. Always best to get someone to teach us the basics and have a practice with some offcuts and joiners, before tackling the first big job. HOT TIPS Don't be a tightarse use plenty of primer. Don't buy and/or use old glue (it will be too thick to spread thin and evenly). Chamfer any cut ends(I use the back of a hacksaw blade or my thumbnail). Hold the joint together until the glue grips and holds. Don't flex the join to much while it is still soft. This is the big rookie mistake, over-glueing the inside surface, you can't wipe it off inside the pipe. The glue melts the single thickness of PVC, causing a band of low strength next to the join.Although this one still lasted for 25 years at 170 PSI. "Wife goes into orbit when a spider shows up". Is your wife considering a career in space exploration? I can probably help out. This little sweetheart is just outside my front door. Tip to tip, she is the length of a beer can, that is about half adult size. No...I don't get a lot of "unwanted" visitors.

I was going to ask how much gas your heat pump will take to fill, but I may have distracted you with that last picture. yahoo I'm confused, no wait... maybe I'm not... |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

" This is the big rookie mistake, over-glueing the inside surface, you can't wipe it off inside the pipe. The glue melts the single thickness of PVC, causing a band of low strength next to the join.Although this one still lasted for 25 years at 170 PSI." yahoo2, Good advice, The swab on the cap of the cement can, is always 3 times larger than the Inside diameter of the pipe, that puts the squeeze on which causes excessive cement to be placed inside. a messy wasteful way of selling more glue. I had my wife look at your post, It should not come as a surprise to learn She doesn't like You ! The space exploration she is interested in is that which I now occupy after she throws me Out!. The system will need about 36 ounces, 2 pounds+, (about 1 kg.) Refrigerant 22 is now over $50 a pound, the R-416 is about $15 and can be ordered in quantities of Five pound containers. Cheers---Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| GreenD88 Senior Member Joined: 19/05/2009 Location: United StatesPosts: 104 |

Why not use some R-290

R-416 is not recommended for replacement of R-22 and is actually a replacement for R-12. R-290 has pretty close to the same characteristics to R-22 minus the fact it's flammable, but in a sealed system you don't have to worry about it, unless your not confident in your brazing skills. And only 2 lbs would dissipate long before it ignited I'd imagine. Their are other drop in replacements such as: R-407c, R-404a, R-417a. Licensed Master Plumber / EPA 608 Universal License / 410a Safety Certified / Medical Gas Brazer/Installer |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

GreenD88, This forum is viewed by people around the world. Some US States and Counties, also maybe other world Countries have Laws that prohibit R-290 in home appliances. Also as you mention, The brazing skills of some DIY'ers may be in the learning stage. Can you visualize this scenario, Mr. Gung ho the Whiz has finished charging his Home brew system and goes to the house for a beer, upon his return the smell of gas is strong, without thinking He flips the light switch On. No more Mr. Whiz. R-416 is a class 1 Refrigerant ,Read MSDS, Will not burn. And even though I will not endorse the use of propane it is as you say a very good sub. for many uses. I may experiment with a water heater Later on Using it. Hopefully I'll remember that light switches make a Spark. R 416 has a very low liquid pressure at 110-120 Deg.F Less pressure, Less amperes the motor Draws. good heat of vaporization (80) not as good as R22 but better than R12 at(70)something and easier to pump than either. I appreciate your Interest. Cheers---Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

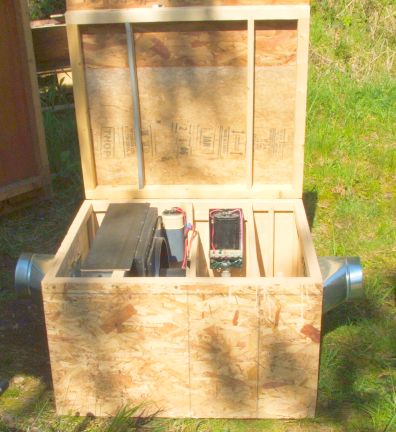

Another update; It now Has a Top, Minus the Spider Gasket. I've been thinking about using a thin foam for this very important detail. When I Bolted the timber to the concrete Footing of my house I used a condensation barrier to isolate the 2X6 wall plate I will use it to keep the bugs out.

I placed the compressor where it belongs, NOT Connected, Checked the Fan for Vibration and discovered that the rotor was bouncing against the thrust Washers Axially about Twice a second. I thought perhaps the balance adjustment may be in the Squirrel cage Wheel So I installed it for effects. It did the job, I don't know if it was more load, Flywheel effect, OR?. Moving Machinery is more Photogenic than words in a Paragraph.

With the top closed the noise level is near a whisper, when I get it all covered with Insulation I doubt we Could hear it at all in the House, Just hope the Compressor is a quiet one , it does have Rubber Motor Mounts. Cheers--- Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

I filled the Trench, bedded the pipe in Local Clay and very carefully covered the pipe with a foot of fine texture Gravel and Clay. The stony stuff was put in last. Fingers Crossed, we Had 2 Days of sun so yesterday I went to work on it. Still to wet to clean up and back drag. buts looks Better. Couple of soft spots Remain.

And its Raining again. Cheers--- Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| GreenD88 Senior Member Joined: 19/05/2009 Location: United StatesPosts: 104 |

lol Yeah I know all that  Just was a suggestion if you were looking for a something on the cheap. Let me know how the R416 works out for you. It's not really meant for High Temp use more suited for Low-Med Temperature applications. And if your Compressor is a R-22 unit it will suffer lower efficiency. It'll work and take a lot of adjustments but will be less efficient than R417a or R22 unless your using an R12 compressor. Curious since you mentioned legalities and all do you have an EPA 608 License; Type I,II,III or Universal? Just interested to see how it all turns out is all... Just was a suggestion if you were looking for a something on the cheap. Let me know how the R416 works out for you. It's not really meant for High Temp use more suited for Low-Med Temperature applications. And if your Compressor is a R-22 unit it will suffer lower efficiency. It'll work and take a lot of adjustments but will be less efficient than R417a or R22 unless your using an R12 compressor. Curious since you mentioned legalities and all do you have an EPA 608 License; Type I,II,III or Universal? Just interested to see how it all turns out is all...Licensed Master Plumber / EPA 608 Universal License / 410a Safety Certified / Medical Gas Brazer/Installer |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

GreenD88, When I get a chance I will check R-417, I'm pretty sure I looked at it but Don,t recall the details, I know that several of the HCFCs have severe glide and some have very high pressures and leak problems as well as requiring the Ester oils and I am trying to keep the Evaporator stable so that the circulating fluid (water) does not freeze while operating very close to 0, C. If I use antifreeze to operate lower, Then the ground water will freeze. I do not have enough usable land for a proper Ground Loop and the fact that this area is water logged during most of winter and spring I am counting on the water to supplement the area. It perks well so, I will have a constant renewal of water. NO, no 608 but I know how to remove and replace refrigerant. To keep the legalities legal I have enlisted my Grandson who is a licensed Tech. to save the earth and please the gods of government. I will likely change over to the poly ester Lube because this compressor has never been run and what ever R-Type I use it will be more compatible. Cheers;----- Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All I think to much worry is put into a little leak of LP gas when used as a refrigerant as we tried to blow up a fridge using it as a test years ago, the amount that leaked out, in controlled leaks (tap in line) wasn't enough to burn or explode. In a closed loop industrial situation where large quantities are used this of course is different a gas sniffer is cheap and water and detergent is OK if you are broke. In most reasonably ventilated play at home systems it dissipates faster then the leak anyway. The government is never happy so I do not worry about then to much. As for pollution, there is LPG escaping all the time naturally, not to mention the loss when filling bottles and tanks at filling stations that nobody worries about. All the best Bob Foolin Around |

||||

| GreenD88 Senior Member Joined: 19/05/2009 Location: United StatesPosts: 104 |

R-417a is advertised as a drop in replacement for R-22. It's the closest thing to R-22 if your wanting to achieve close to or same efficiency from an R-22 Compressor. On the propane subject I figured it up unless the room is smaller than 10x10x8 and you dropped 100% of a 2lb charge into the room at once it would barely be at the Lower Flammability Limit of 2% Room Volume. Licensed Master Plumber / EPA 608 Universal License / 410a Safety Certified / Medical Gas Brazer/Installer |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

To all I have a correction to make here; The post dtd; March 6, 2011 has an error. The statement in Italics is not correct. Note, " Blind to the Obvious" I discovered that some of the numbers in this Press-Temp chart for R-12 (Yellow Box) seem to have been put in the wrong box , (reversed) the vapor pressure should be lower than liquid pressure, makes one wonder if the any of the numbers are correct. Of the many errors in this post, this one came AS IS. The data I thought was intended for R-12 Vapor pressure was actually the condensing pressure data for R-134A as shown below. I apologize for my insensitive remark toward the company that markets this product.   -----Roe -----Roe

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||