|

|

Forum Index : Electronics : Time for a new Warpinverter build

| Author | Message | ||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

So this is the issue we are hoping to resolve by ... 1) putting some distance between the secondary winding and the core ... say 5mm spacer 2) putting some distance between the secondary and primary windings 3) fitting a copper or aluminium shield winding between prim and sec Yes/No? If I remember rightly, Mark wound his primary winding first before the secondary, to see how that worked ... but I don't think he's had a chance to try it out. And Klaus fitted plywood spacers top and bottom of the core ... but I don't recall if there was any spacer around the inner hole or outer face of the core. Were there any measurements taken to see how dramatic the spikes are on his main tx? I'm assuming you recommend turning off all AC loads before doing that (to give the DC switch contacts an easier life) ... or is that not necessary? Cheers, Roger |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 423 |

Having floating gates while powering up the main DC rail (or powering down) may cause issues. I would definitely turn off the load first when shutting down. Given that I have experienced capacitive coupling from the collector to gate, I will be going further and using 3 relays. One to control the main contactor, one to control the precharge contactor, and another to control the logic circuitry. That way, the gates are never floating or capacitively driven on/off when the main DC line goes live. Finally, in an overload trip condition, there is still the possibility of the gate drivers dying before the main DC rail hits zero. For that, I'll add some capacitors to the warpverter logic board and gate drive circuitry, so that it is powered up while the main DC rail fully discharges. That's adding to the complexity, but it rules out certain fault states, and stops at least some of the head scratching when it (if it) goes bang. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes, to reduce the capacitance across the high voltage secondary. This becomes increasingly important where the secondary voltage is high, and the voltage step up ratio also very high. Its a judgement call really. Yes, as above Not really necessary for a Warpverter as there are no high frequencies to capacitively couple between primary and secondary. That was mainly applicable to early PWM inverters that had no series choke. An efficient non saturating choke will reduce the high frequency ripple in the primary to such an extent that a screen isn't really required anymore. Usual to wind thinnest wire on first to produce flattest winding, then wind the lumpy fat wire over the top. It creates a much neater result. Thinnest wire could be either the primary or the secondary, depending if the transformer is voltage step down or voltage step up. Klaus used thin wooden "washers" top and bottom with a nicely radiused outside corners, which eliminated the sharp right angle bend in the wire when trying to wind around a steel core with very sharp right angle corners. Its a good idea, and it places far less stress on the wire and its insulation, which might possibly fracture at a later date. The reasons were purely mechanical, not electrical. Its typical of the thought and care Klaus puts into everything he does. Don't know the answer to that. Its only recently he has bought a good quality digital oscilloscope. I'm assuming you recommend turning off all AC loads before doing that (to give the DC switch contacts an easier life) ... or is that not necessary? Edited 2021-02-06 15:58 by Warpspeed Cheers, Tony. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

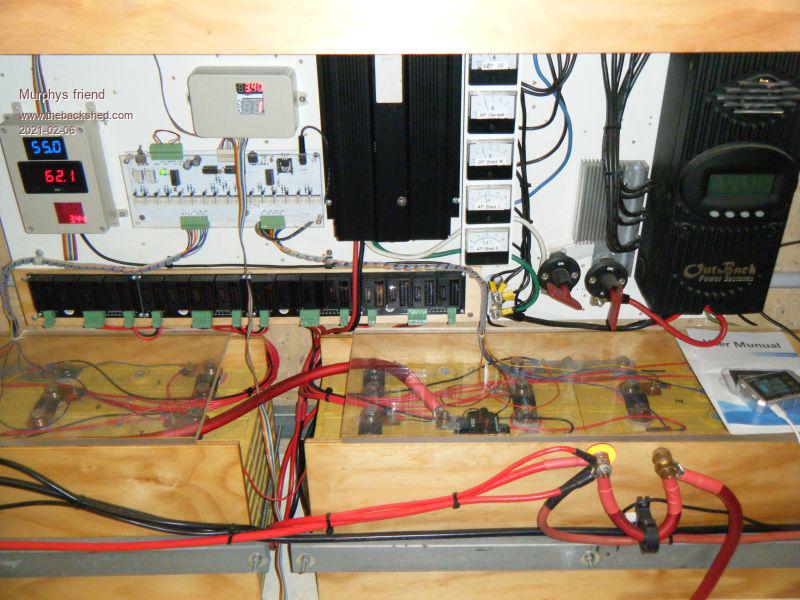

OK, that incident was last year after the warpverter ran for about 2-3 months (can't remember exactly). Initial blowups due crystal & startup problems. Never had it running reliably after chainsaw incident. I tested it since then with a bench power supply that easily powers a 100W floodlight from a good inverter. Re the battery: 16 x 200Ah Winston LYP cells (now about 50% capacity). See picture below  Re the oscilloscope buying, budget not ready for that just now as I recently upgraded my battery set up to include these 16 x 200Ah LiFePO battery cells:  Re the gap between secondary & primary winding in a torodial transformer. I wish you luck with that, I distinctly remember having to cut off a nearly completed multi layer secondary as it turned out there was nowhere near enough space left for the primary. I used the Aerosharp cores with the standard hole. If you can increase the hole size by at least 10mm diameter then you *might* include a primary/secondary winding gap. Forget that otherwise, especially if you use a primary 'cable' type wire, you can see from the pictures I posted last year how that hole shrinks on a fully wound transformer. Re the rounded washers at each core cheek, they were made from 6mm plywood and I consider them *essential* if you wind that core by hand. There was no spacing other than Mylar tape insulation inside the hole for space reasons. I think I included a 1mm ABS plastic layer and circumferential placed tape on the outside. Also consider the winding technique, you can *never* pull that wire as tight as a winding machine by hand. So the wire will bulge out in the center of the hole where it matters. I used a 25mm dowel to push it in but that works only so far, you *will* lose space there. That suggested 6 turns less per layer only works for a winding machine IMO, by hand its at least 10 turns less, especially with second hand wire and with the uneven base of subsequent layers. Then consider the winding method. If you use re cycled wire and then transfer the straightened wire onto a tightly wound spool that fits through the hole, as some builders do, you really waste all the straightening effort by kinking the wire again with tight turns around the spool. You could try the shuttle method you probably used for unwinding the original core but that also kinks the wire. I used the 'hoop' method (shown in my pictures) which is kindest to the wire. It takes a bit to get the hang of but then is easy to use and it even worked with the twisted strand enameled wire I used for the primaries. Lastly with epoxy impregnated winding layers one gets a much firmer base for subsequent layers. I'm not sure that applies with that silastic stuff Mark used. You *will* need a firm base under the primary as it may require a soft faced hammer to get on tight. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

Been watching with interest for a while. Just thinking, would it be worth (one of you) trying an appropriate size E I Type transformer to try in place where one of the toroids keeps blowing fets? Only if one can be found handy, winding the coil on to a former is strait forward (easy) practically reel to reel winding. The worst and most difficult part is dealing with the lamination's, depending on how they have be configured, or put together. It might help show what the difference is if any, and perhaps narrow down where the problems might be. Cheers Aaron Off The Grid |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

I may have misunderstood the sequence ... but I believe Mark built his #1 transformer in the usual way, but about that time you all discovered that capacitive issue with Andrew's device ... ... so Mark built a second version with the primary wound first ... 14 layers of 25 turns ... and then the secondary turns on top ... see here https://www.thebackshed.com/forum/ViewTopic.php?TID=11385&P=12 And Klaus fitted plywood spacers top and bottom of the core ... but I don't recall if there was any spacer around the inner hole or outer face of the core. Klaus used thin wooden "washers" top and bottom with a nicely radiused outside corners, which eliminated the sharp right angle bend in the wire when trying to wind around a steel core with very sharp right angle corners. Its a good idea, and it places far less stress on the wire and its insulation, which might possibly fracture at a later date. The reasons were purely mechanical, not electrical. Its typical of the thought and care Klaus puts into everything he does. I stand corrected there. I certainly like the method he used and plan to do the same thing. I'll make mine perhaps 5-6mm all round bigger than the core to allow for the wrapping/spacer I put between the core and the first winding. That way if I use coreflute like Mark did ... the overhanging plywood washer will prevent the wire from crushing it and cutting through. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

OK, that incident was last year after the warpverter ran for about 2-3 months (can't remember exactly). Initial blowups due crystal & startup problems. Never had it running reliably after chainsaw incident. I tested it since then with a bench power supply that easily powers a 100W floodlight from a good inverter. Small consolation I suppose ... but having run for 2 -3 months points to it being able to function ok. Now of course, to work out why it keeps blowing. Thanks for the great photos and the additional detail ... a picture is worth a thousand words. I used the Aerosharp cores with the standard hole. If you can increase the hole size by at least 10mm diameter then you *might* include a primary/secondary winding gap. Forget that otherwise, especially if you use a primary 'cable' type wire, you can see from the pictures I posted last year how that hole shrinks on a fully wound transformer. Yeah, I'd got that loud and clear. That's why I've sent off for a quote on a core with 120mm ID. Hopefully I can then add 5-6mm of spacer around the ID and OD ... along with the plywood washers. Then consider the winding method. If you use re cycled wire and then transfer the straightened wire onto a tightly wound spool that fits through the hole, as some builders do, you really waste all the straightening effort by kinking the wire again with tight turns around the spool. You could try the shuttle method you probably used for unwinding the original core but that also kinks the wire. I used the 'hoop' method (shown in my pictures) which is kindest to the wire. It takes a bit to get the hang of but then is easy to use and it even worked with the twisted strand enameled wire I used for the primaries. I am hoping to get each secondary winding on just one layer and the figures Tony has helped me work out look promising. Will find out soon enough.  I also plan on using new wire ... at least for the main transformer, to help keep it neat and tight ... and I also plan on following your method of using a hoop. I keep watching the videos by 'frackers' who also used a hoop (bike rim) to see if I can pick up a better understanding of the process. https://www.youtube.com/watch?v=kYtudDVucUo https://www.youtube.com/watch?v=RbuXQ005wE8&feature=emb_logo Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

I also plan on using new wire ... at least for the main transformer, to help keep it neat and tight ... and I also plan on following your method of using a hoop. I keep watching the videos by 'frackers' who also used a hoop (bike rim) to see if I can pick up a better understanding of the process. https://www.youtube.com/watch?v=kYtudDVucUo https://www.youtube.com/watch?v=RbuXQ005wE8&feature=emb_logo I looked into that bike rim idea, perhaps OK for a very large core with little height. It won't work for a double stack as the rim's curvature is too big and its not flexible. The bike wheel rim also needs smoothing where the spoke holes are as they would damage the enamel on the wire already wound on the core. The 19mm slit black poly pipe I use was perfect and cheap. Its rather floppy at first until the first turn of wire is loaded into it, then it handles nice an does no damage to the wire. The ends were held together with gaffa tape, this wears after each layer is wound onto the core but is easily replaced. There was a video clip around back then, of a commercial toroid winding machine, very educational to watch. That also shows they use a much smaller diameter split rim than a bike wheel. I also used a large plastic fishing hand casting reel, worked OK initially until the hole got too small for it. The Poly tube gets through a 25mm hole. |

||||

| nickskethisniks Guru Joined: 17/10/2017 Location: BelgiumPosts: 458 |

It can be interesting to find out which material is best to use as spacer, maybe there are better materials to use. So it can be less thick. I'm planning to build my own warpverter, I've got all the materials for a 48V version but I need to strip about 5 "potted" transformers before I can even start with the transformers, other projects have higher priority. I hope to start with it next year. I'm still thinking/searching for the best Half-bridge design to implement, I think Mackoffgrid did a good job. When hearing all those stories about the difficulties, I would choose for a series inductor from the start. If it can't harm, It would cost less then a batch of destroyed mosfets. One would think that that current peak thru that big toroid is already "soft started" because there is already current flowing thru it's secondary. All transformers are connected in series, and the big toroid is not the first one started. Although at some point in can be energized in the opposite direction, because at a given time you subtract the voltages, that is probably the hardest point for the mosfets. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That six turn per layer figure is a purely a theoretical number that comes from the mathematical properties of circles. Any planning of what will actually fit requires a very large dose of pessimism ! The safest approach is to work out the circumference at 70% of the original hole starting diameter, because that last layer is going to be the tightest fit. And as Klaus says, the layers will never sit dead flat no matter how hard you try. You will very likely reach that 70% point at least a layer or two layers before you expect, but at least the expected number of turns should still go on at that circumference. I must confess, after years of designing and winding transformers, I wimped out, and asked a friend that has a transformer winding business to wind mine. He even used the large winding machine I built, and eventually gave him (for free) many years ago. So I escaped all the drama, and more by luck than anything else avoided the startup and current spike issues as well. Anyhow, Klaus's warpverter has run successfully for at least a couple of months which suggests its basically sound, but the chainsaw incident has probably damaged something somewhere that is still not quite right. Its the smaller inverters that are randomly blowing up, and not from overloading. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

I looked into that bike rim idea, perhaps OK for a very large core with little height. It won't work for a double stack as the rim's curvature is too big and its not flexible. The bike wheel rim also needs smoothing where the spoke holes are as they would damage the enamel on the wire already wound on the core. The 19mm slit black poly pipe I use was perfect and cheap. Its rather floppy at first until the first turn of wire is loaded into it, then it handles nice an does no damage to the wire. The ends were held together with gaffa tape, this wears after each layer is wound onto the core but is easily replaced. Yes, I had come to that conclusion too. I've been looking for materials similar to your poly pipe but stiffer and had been wondering about a kids plastic hoop ... but depending on how many turns of wire are needed, it may not be big enough inside diameter. ... and I do recall you saying you would go bigger with your hoop if you did it again ... up to about 900mm?? I did wonder about using a piece of stormwater pipe or even electrical conduit .... although that might be a bit thick at that diameter. That should take care of the centre hole. Should be able to cut a strip out of an oversize piece and slide it in. Could also 3D print a tube to slide in ... that has grooves printed in to help locate and space the first layer of windings. But then that would probably turn into a gooey, corrosive mess after some time or overheating depending on the material it was printed from. Anyone know if that is feasible? Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

That six turn per layer figure is a purely a theoretical number that comes from the mathematical properties of circles. Any planning of what will actually fit requires a very large dose of pessimism ! The safest approach is to work out the circumference at 70% of the original hole starting diameter, because that last layer is going to be the tightest fit. And as Klaus says, the layers will never sit dead flat no matter how hard you try. You will very likely reach that 70% point at least a layer or two layers before you expect, but at least the expected number of turns should still go on at that circumference. How critical is that 70% mark Tony. If you add another layer after, it cuts into the area needed for the primary ... but if there is still physically room for that ... it wouldn't affect things too much? I agree that the fact it had run for some months means that it is basically sound, which is a lot better than considering the alternatives. I assume Klaus could test it by running just the largest two transformers into a basic safe load ... like a couple 500 watt halogen globes or something like that ... leave it run for a few hours to gain confidence that they still work ... and then try and fault find the smaller inverters ... assuming that it is one of them causing the issues. Either way, it would be a step towards finding out. Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

How critical is that 70% mark Tony. If you add another layer after, it cuts into the area needed for the primary ... but if there is still physically room for that ... it wouldn't affect things too much? Its a theoretical thing.... The most efficient transformer will have roughly equal copper losses in the primary and secondary. If one winding is just about on fire, and the other is running stone cold, its the hot winding that ultimately limits the safe power level. So a good starting point might be to split the available winding area into two equal volumes, and fill each with as much copper as will fit. Its not super critical, but a theoretical ideal to aim for. If you are deciding if one more layer will be o/k, jump ahead and work out your primary wire size and turns and see how tight its going to be. If it looks super tight, better maybe not to risk that extra layer on the first winding. If your estimated thick second winding is going to be a fairly loose fit, an extra layer is not going to hurt. With a PWM inverter, not being able to get the last final turn or two on is not going to be a disaster. With a Warpverter, the exact turns ratios are much more important if all the small steps are going to end up being even. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Its a theoretical thing.... The most efficient transformer will have roughly equal copper losses in the primary and secondary. If one winding is just about on fire, and the other is running stone cold, its the hot winding that ultimately limits the safe power level. So a good starting point might be to split the available winding area into two equal volumes, and fill each with as much copper as will fit. Its not super critical, but a theoretical ideal to aim for. If you are deciding if one more layer will be o/k, jump ahead and work out your primary wire size and turns and see how tight its going to be. If it looks super tight, better maybe not to risk that extra layer on the first winding. If your estimated thick second winding is going to be a fairly loose fit, an extra layer is not going to hurt. With a PWM inverter, not being able to get the last final turn or two on is not going to be a disaster. With a Warpverter, the exact turns ratios are much more important if all the small steps are going to end up being even. That's very helpful thanks Tony. Hopefully I can recall all this as I get to that stage. More notes needed.  Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Roger, re the hoop diameter. Think about this way, its a sitting down job if you value your back. A 900mm hoop might get tricky to wiggle past your knees. The diameter is a compromise of how many meters of copper wire you can fit into it. Obviously enough to complete one layer unless you are happy to have wire joins along the layer - this goes against my way of doing it so I have no such joins. I believe Mark has lots   . .Tony, while the transformers are discussed here can you confirm a testing method for all four that came to my mind recently. All 4 transformer secondaries are connected in series and the primaries left open. Now, I should be able to power the connected secondaries from 230V AC as that is their combined voltage. Correct? (I'll do that with a variac). I then read the idle current for the interconnected transformers. Then I parallel two of the primaries (via a resistor), if I got the phasing right (and number of turns) the idle current at the powered secondaries should not change. Correct? Then I add another transformer's primary and check the idle current again. Finally connecting the 4th transformer primary. This way I can confirm the phasing of my windings. I wound them with red start tails and black end tails anyway but for peace of mind I will re check the *everything* in that warpverter. But I thought it be better to ask a transformer expert first. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If you connect all the secondaries in series, its the inductance of each secondary that will determine how the voltages split, and that is an unknown and unknowable variable. Now we have designed all four transformers to have the primaries driven with a 44v 50Hz sine wave, which creates around one Tesla of design flux density in each core. In fact that is a complete fiction ! The largest transformer is driven by a 44v peak square wave at minimum dc input, and the smaller transformers by some very odd looking waveforms that contain a whole series of ever changing duty cycles and frequencies. At maximum dc input, all the transformers could be driven from an 88v peak square wave ! But by designing for 44v 50Hz sine wave, it hugely simplifies things, and everything falls into place for all of the four transformers. Its complex enough for most people the way it is now !! The smaller transformers operate at much higher frequencies so the ACTUAL flux swing will be a lot lower than 1 Tesla, by an amount that guarantees eddy current losses in the cores will be quite low and completely acceptable. Trying to visualise all this in operation is a mind bending exercise. Best not to even try to think about it. Just know that if the transformers are all designed for 44v 50Hz sine wave input it will work fine mate, "no worries". If you want a sneak preview of what the final idling power of the whole inverter will be, it should come pretty close to what just the largest transformer measures when the secondary is connected to the 230v to 240v grid, plus about six watts. That six watts is for the control board and the sixteen opto isolators, eight of which will be on and eight off, plus the sixteen gate driver circuits. Anything extra like digital LED voltmeter readouts, or fans, will be on top of that. Most of the 5Kw to 7.5Kw warpvertes seem to end up around 20 to 35 watts idling power which is about the same as a good PWM inverter of similar power. Don't be concerned about transformer phasing. It can all be wrong and nothing bad will happen, except the output waveform will look rather peculiar. That is easy to fix once its up and running. Edited 2021-02-07 19:56 by Warpspeed Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

. .That makes sense. I've been trying to work out how the process might work, though usually when I do decide on a method, once I actually attempt to carry it out, I end up doing it a completely different way. Sounds like I'm from your mould ... I will certainly be aiming to do each winding without joins. I don't suppose there's anything wrong with having joins ... but I just couldn't do it. Something about me being ocd or worse I suppose.  Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Trying to visualise all this in operation is a mind bending exercise. Best not to even try to think about it. Just know that if the transformers are all designed for 44v 50Hz sine wave input it will work fine mate, "no worries". Thanks Tony, it looks I have been doing too much thinking on my morning exercise walks  . .OK, I will rule out any transformer problems. Once I redo all the power & driver PCB's to have the same arrangement I shall see if that fixes it. The reason why just the two small transformer drive mosfets blow could be that they are on a separate, rather compact, heat sink assembly and perhaps in too close proximity to each other. Tried replacing everything on that PCB.... Roger, it may be wise to lay in a good supply of mosfets, my warpverter uses 40  but then I may have an answer about my malfunctions by the time you get to test yours. but then I may have an answer about my malfunctions by the time you get to test yours. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

That makes sense. I've been trying to work out how the process might work, though usually when I do decide on a method, once I actually attempt to carry it out, I end up doing it a completely different way. OK, to start you have to pre load the hoop with wire. So you place it through the hole and fix the ends together so they form a circle. You need the copper wire on a spool located so the wire unravels in the direction your hoop can turn around the toroid. You need a little hole in the hoop where the wire anchors on, I tape that end (it sticks out) to stop it catching in the toroid hole. Now you load the hoop, I do that in the direction from the spool towards me over the core before entering the hole. Just rotate the hoop towards you and feed the wire on (in the slot in my case). You know the hoop circumference which lets you calculate how many turns you need to load, always allow extra, calculations are not very exact I found. Cut the wire from the spool and this end is the start of your winding. The trick is to figure out which direction to wind it around the core. The wire should pull straight from the hoop and not do a U turn. Pull enough wire out for one turn and a bit, do that turn, pull out some more wire and keep doing that until all the turns are wound on. This is where I found the advantage of a split tube that holds the wire captive invaluable. Just imagine a few turns slipping off an open rim... I made a paper disk with radial space marks at each ten turns and wound over that, makes it easier to keep track. Make sure the wire goes radially around (closely spaced in the hole and widely spaced on the outside) Oztules came up with a method of winding two turns side by side (touching) all around and then have the wide outside space. What this does is create a 'space' on the outside where you wind the next layer into in the same fashion. And so on for the third layer. This makes it much easier to keep track of the turns number on the next layer and also gives a neat finish. You obviously can't do that trick wit thick primary cable  . .You'll have fun and very sore fingers  |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

It is like nike just do it The smaller wire is easier to wind I would not recommend over 2mm on the high side The smaller the mm the tighter it will be around the core and easier to wind I use a shuttle about 1 1/2 to 2 foot long I don't wind wire tight on the shuttle The bigger the hole in your core the better You can put more copper on a smaller core for a higher wattage Your core may heat up after a while after using that higher wattage But all appliances kick on and off and are not on 24/7 You want the very most possible copper on your core as possible Your leftover hole size makes no difference as long as you can get a bolt through it I step down one from the standard wire Gage amperage guide so a 12 gauge wire would be good for 15 amps instead of 20 Remember that is for the absolutely Max amperage in my figures I over build every core not to need a fan so if I'm needing 5000 Watts I build it for 7500 Watts The best way to wind your core if it's a larger core start with around a hundred turns Once you get a hundred turns wound on your first layer use the light bulb and a switch trick and a current clamp and check the idle plug straight into your wall outlet Write that number down add another 10 turns see what that number is keep winding until it doesn't make enough difference for the extra turns If you do it this way you will get the perfect amount of turns for your core Doing it this way and if you get a pretty tight wind your Transformer will be completely silent It will also have the very least possible Idol current when put into your inverter You never know how much wire you're going to be able to fit on your core So go off amperage if you're able to get enough copper for 50 amps on your high side then do the math and see how many amps at the lower voltage low side it would take to put out that 50 amps on your high side Then use that size or amount of layerers to make the low match your high side It is critical that you test your high side at every layer you do not want to be off not 1 volt between your two legs of 120 or between the layers that make up each leg of 120 So check it often using the light bulb and switch trick Think about what the voltage difference is between each wire that's going to be side by side or on top of each other if the voltage difference is very high at all then add a layer or two of tranny tape So every layer should get tranny tape and if you have to add a few extra turns on to the next layer then make sure it has a layer of tranny tape below and above it As long as you have windings that have different voltages insulated well then I would not worry about it too much you're going to find out that you're not going to get each layer perfect and using only one layer Those are the secrets to getting a Transformer with the lowest as possible idle current that is silent And remember what I said about wattage of the core the magnetic link is there for a higher wattage and if that higher wattage is not going to be ran for long periods of time a smaller core May dissipate enough heat for that time when the higher wattage will be used I like to over do my Transformers some of the ones I call 5000w will do 10,000 Watts with lots of cooling So basically it all comes down to how much wire you can fit on a core how much heat well that core dissipate and do you want to use a crazy amount of fans I mean you could put a leaf blower on that bad boy get that wattage pretty high on a small core but then you might as well just go out and buy a factory made inverter Now in my opinion if you want to be really smart about it build your inverter to go in a oil field case In my opinion that is the future of inverters there is one or two people that are ahead of the curb that's already done this on this site and they are more than willing to share what they have found out Edited 2021-02-08 06:12 by BenandAmber be warned i am good parrot but Dumber than a box of rocks |

||||