|

|

Forum Index : Solar : Deciding if I should build this solar heater

| Author | Message | ||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That all looks perfectly reasonable Roger. The flow with one inch back pressure is about 650 CFM, and its reasonably quiet as it runs at only 1750 rpm, and it would be very easy to control the speed. Now its 12" diameter (300mm) and generates 2 inches at zero (blocked flow) and runs at 1750 rpm. To get similar performance at 2800 rpm at the same tip speed would require a rotor diameter of 1750/2800 x 12 inches, about 7.5 inches diameter. That comes pretty close to my original guess of an eight inch rotor being the practical minimum. I suppose it comes down to how much the beast costs....... And you will have to fabricate a housing for it which will be very easy. Another way to do it would be the cooling rotor from an old air cooled VW engine fitted to a 2800 rpm induction motor. I just found some info on that here: http://offroadvw.net/tech/wes/fan.html It says the inlet diameter is 150mm so going by the picture the outside diameter must be at least eight or nine inches, so the developed pressure should be fine. According to the graph of measured airflow, at 2800 rpm flow should be around 500 CFM+ with the wider rotor. This still involves building a housing, but the motor and rotor should cost just about nothing. Cheers, Tony. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

VW Fan, just checked the one down the back, yes 150mm ID, 230mm OD and about 75mm deep.  Cheers Aaron Off The Grid |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Perfect !! Thanks Aaron. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

Your Problem will be the Diffuser Roger. That thing that fits in the ceiling that is popularly round now ( So you never have to align the bastareds and make sure the hole is cut straight and lines up) and the airflow though that. I have no idea what the airflow rate of those is ( But they probably have a rating) but I know that the sort of flow you are looking at will be too much for one. That's OK, You can put one at each end of the room and Just put a Y connection off a single damper controlling them. If you try to push too much air though a single outlet they will howl like a gale Blowing through the cracks under the doors and through the windows only much louder ( annoyingly so) with that forced air pressure Noise and will also reduce your flow rate which will push your delivered temps up. It may be that you have enough flow and temps to do opposite ends of the house. 3-4 or more KW into one large room IS going to get the temp up pretty quick so spreading the heat out may be a good idea. I did think you said you were going to pull in outside air so you may need an outlet somewhere. Maybe something like a Doggy door with a flapper so inside pressure will open it but outside air won't come in. This system may also work at night in summer. If the outside air becomes cooler than the inside air which I get a lot here, you could draw the cooler air in. Might be a lot of heat soak in the roof but should eventually drop. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That would work really well in summer with another differential temperature controller. Run the blower only when the house is hotter than outside. It would turn on after sunset, probably run all night, then turn of shortly after sunrise all automatically as the temperatures dictated. If you decide to go with the dc motor, and I can see good reasons for doing that, a different control strategy then becomes possible. We run the blower speed up to keep and hold a constant set temperature difference between the tubes and the house. In crappy cloudy weather the blower will run much more slowly, but more importantly it will not be cycling on and off, but running at some suitable speed and gracefully accelerating and decelerating. That may be much less annoying than having vast blasts of air starting and stopping. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

HA! Years ago I used to shoot for some car magazines, Street machine, one called " street and Strip" In which the Models were more the strip part than the Drag strip and... I ended up getting involved with the Vw Crowd producing a Vid of their annual Nationals Rally and doing shoots for a couple of magazines. I can honestly say I have never met a more eccentric group of people in my entire Life and that's saying something given the different interests I have had over the years. "Regular" car guys would bring the car to the shoot, give it a wipe over and tell you if there was anything you wanted them to do as far as move it or whatever, just let them know or feel free to put it where you wanted and stand back and watch. The VW guys would want to point out the tyre valve cars that were hand Crafted by Fritz Muller whom was Hitlers seconds cousin's Aunty Twice removed On his fathers uncles side and give you a 40 Minute run down on on how the ash tray was designed. Then they would go on about the engine and how that was built and made a Whopping 125 Hp. Ugggghhh! At my last place the guy that owned the place next door owned The biggest VW wreckers in Sydney and he was a nutter, a very wealthy one from what I could make out, but a nutter just the same and talk about a Tight arse and a Shonk!! Other than that, all I know is these fans are capable of keeping engines from 40 HP up to whatever they Dial them up to, 150 Hp+ cool even on hot days. Given the ambient may well be over 40o C and the engine is not supposed to go over 100, 120 Max, that tells me alone they have pretty good flow and the ability to move a LOT of heat. The tin work on a VW engine is pretty straight forward but there are some bends and deviations as well as having to push the air though the cooling fins so the gas path is not without restriction. The question in my mind is how much HP and what revs do these things run? I would be looking at a 1.5 Hp Motor at the 2800 You suggest. If the thing only needs 600W, that's what it will pull. An unloaded motor does not draw much so if the load is less than the motor rating, no harm done because the load WILL be above it's unloaded draw so I don't see that matters. If the power is needed it's there, if it's not then the motor has an easier time. Also using a large Rotor gives the opportunity to slow it down for less noise as well as power consumption. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I was going to ask If Roger was decided on a DC motor? One thing with mentioning this comes to mind.... In native application, the Fan on a VW is driven off the Generator. I don't know if later ones had alternators but shouldn't matter either way. I remember years ago playing with a generator and by connecting it to a battery and pulsing the current, It was possible to get it to run like a motor. I know with a speed controller the same can be done with alternators. I'm wondering if a fan and generator could be used in this application with a controller You would no doubt be able to cook up Tony if one does not already exist to do the job of driving the fan so it could be DC Voltage dependent? This would save having to worry about shafts and mating the fan and all that which unless Roger has a lathe or knows someone with one, could be a hassel. Don't know what a machine shop would charge to fit one up but then there is the motor to obtain. Best I know of in low Voltage DC is a48V DC scooter motor which come up to 1200W I think it is. I don't know how they would go doing big hours being Brushed and non cooled though. Looks like I'm out of touch, that one is 2 KW so no shortage of grunt and the RPM should be OK although they do tend to drop a bit with a Load. Another thing with the VW fans is if they were somehow not sufficient in pressure, what would be to stop mounting 2 Back to back with a shaft through the middle and a bearing each end of the housing and belt driving them to the motor which would allow gearing them up if required? Small industrial Timing belt or 4grove Micro V should do the trick. Easy to feed these return air as well if required. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Pretty much my own thoughts exactly Dave. Stick the rotor onto whatever motor is on hand and do some testing. If it only needs 1/4Hp that is all it needs. As I mentioned earlier an 18 inch rotor produces 17 inches at 2850 rpm. A 9 inch rotor a quarter of that or about 4.25 inches blocked pressure. So we are way ahead of our needs pressure wise, and we can slow the thing down easily enough. If I was doing this myself, I would probably use a three phase motor and a small VFD. No brushes to wear out and the motor could be driven at a higher frequency than 50Hz if required, but hopefully not ! A decent VFD these days will also very likely have some smart software in it for proportional/integral control, meaning it could do the compare the two thermistors, and control motor speed trick, all by itself without requiring anything else. Its a fairly common requirement in industry for variable frequency drives to control something such as pressure, temperature, fluid level, and compare a sensor output to a control potentiometer to correct whatever it is by adjusting motor rpm. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I was just thinking about a Mist sprayer on the Tubes but I don't think that is going to work. That said, I don't see why a Mist sprayer at the inlet wouldn't work do drop the air temps . There is going to be a LOT of surface area within the ducting and tubes to evaporate the water and I know from experience, you don't need much water to soak up a LOT of latent heat energy. Would depend on the ambient humidity of course but I think there could be a LOT of gains in temp reduction for a Little water.... that could easily be tapped off From a Down spout and pumped and sprayed with one of those little Caravan Pumps which I used for the water injection on my Truck and worked well with a garden Micro Mister. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Well I have a lathe, and pretty sure I can find an old pulley with a taper lock centre around here somewhere. Simple set it all up in the lathe, spigot the VW fan onto the pulley, bolt it in place, and then buy a suitable taper lock collet to suit the particular motor shaft diameter (either metric or imperial). A quick static balance on knife edges should be sufficient to get rid of the worst of any vibration. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

Yes, I would probably look at a PWM myself and just have it switched however there is certainly merit as you point out in ramping it. VFD's are pretty Cheap these days on Fleabay especially in the sort of low power requirement Roger would need. I have played with them setting up AC feed water pumps in Cooling towers but never really looked into much else. They are set to give the required flow with an over size pump and that's about it. They are oversized so they can be under driven and it again makes calculating restrictions in pipe diameter, length, lift and head etc superfluous. You just go for overkill and then set the things where you need them and that's it. They come out cruising along so you don't have to worry about the things for the next 10 years. Very useful little Critters that's for sure! |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

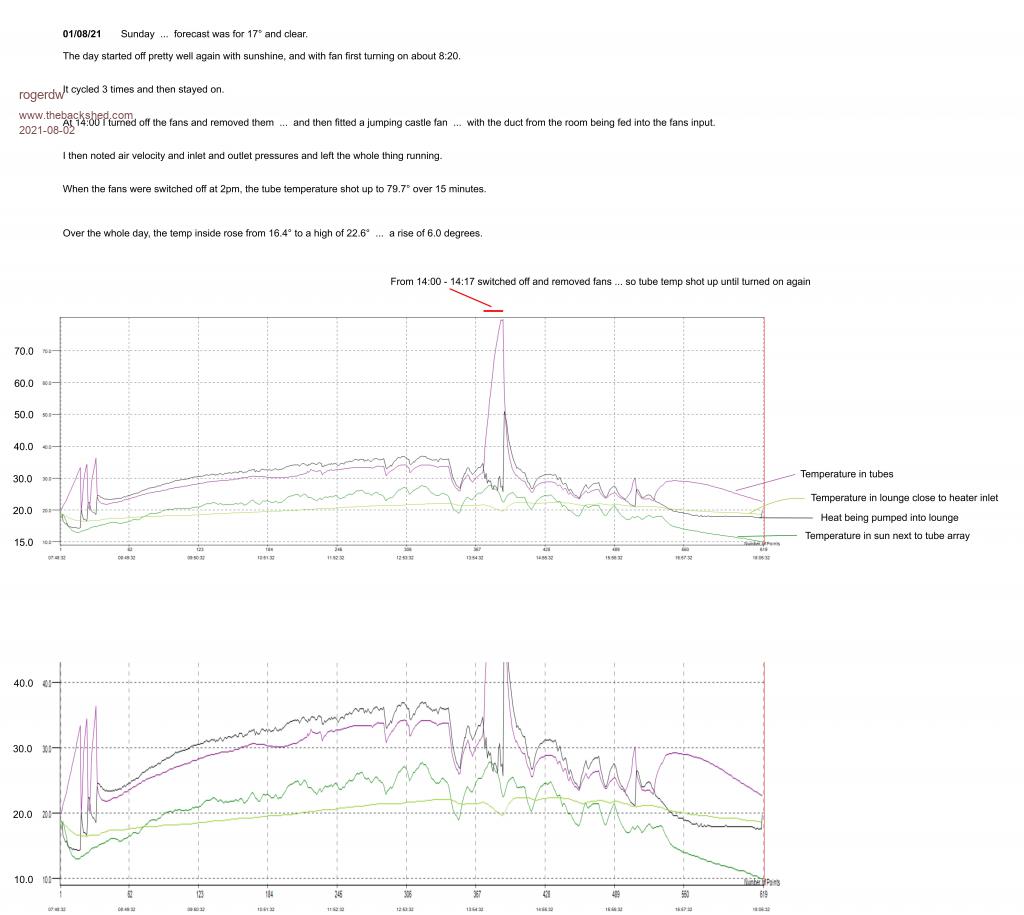

Haha, well I'm a bit of a dill. Between various things today I've come back the the computer a heap of times and pressed refresh ... and seeing no new messages have gone back to other things. Just now I discovered I'm refreshing page 25 and you guys are over here on page 26 chatting away and wondering where on earth I am I suppose!!! I do have some further news ... it's been a brilliant day for the machine today ... but at 2pm I switched it off, ripped out the inline fans and plugged a jumping castle fan directly into the end of the cold manifold. Took just over 15 mins and was back on the air. Anyway, I was able to take some readings, so hopefully they can give you guys more insight. -------------------------------- Removed all other fans and added jumping castle fan directly into cold duct ... plus fitted the duct from the room into the inlet of the fan (Specs. 430-450 W ... ?? cubic mtr/hr) Inlet Manifold = 2.1875" Outlet Manifold = .6875" Outlet Air Velocity = 28.34 ft/s Power = 363 watts (when I blocked inlet, dropped to 205 watts) --------------------------------  I had to laugh when I took the inlet pressure ... just off the scale!!!  Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Wow ! 28.34 Ft/sec x 0.1726 = 4.89 cubic feet per second = 293 CFM. A really big jump possibly more than needed, but we shall see what the tube temperatures look like in a nice clear blue sky. How about the noise level of this big orange monster ? Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Thanks, was pleased to see the result ... and Dave was right all along, it was definitely worth a try.  The fan is noisy, but being outside helps a lot ... it is the air rushing into the inlet duct in the lounge that makes the most noise from inside. But overall, much quieter than having the 8" fan running inside. I also reduced Ld from 8 degrees down to 5, which is what Tony suggested right at the start. As I've watched the system switch on and off, I've decided it is ok to have air pump in in the low 20's when the room temperature is only 16 or 17. We'll see how it goes. I want to address your other comments above, but I keep nodding off ... been a long day, sorry.   Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Very nice Roger, the tubes are now running at less than ten degrees hotter than the house and you have pretty much reached the point of diminishing returns of heat recovery. With more tubes and less flow restriction, that blower should do very well, even with extra added ducting length. A six degree rise is excellent, and pretty amazing. As the days get longer, things can only further improve. Edited 2021-08-02 08:27 by Warpspeed Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

I've had to read this a few times to finally understand how you work it out, but I appreciate your efforts, thank you. I don't think I've seen any prices, though haven't really gone looking ... more interested in the specs at the moment. I have to build fittings for the ducting anyway, so including a fan in one is no drama. That was an excellent read, thanks. Nothing beats actual experimentaion and measurements compared to all the armchair wafflers. Thanks for that Aaron, very helpful for double checking Yeah, very good point. The ceilings already full of lights, vents, ducts etc ... Maybe I could tap into the existing aircon return which has a 4ft square area. Would have to fit a damper above it so not blowing air back up the duct ... that would have to soften the gale a little. Yes, I think we will on good days, but the more I think about it the more I like the idea of it heating our main area first ... rather than the extremes. Great idea, though I think this place is leaky enough to absorb it all. If it's running and we open a door and get blown out, then maybe I need to fit one.  Had never considered it, but would be excellent if it also had a use in summer. I better get my finger out and finish this thing, otherwise it will be summer before we know it. Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If you can repurpose some or most of your air conditioning ducting in winter, by moving a few levers here and there to divert flow, that could probably all be done in such a way as not requiring a whole lot of new holes being cut in ceilings and walls. And if something does not turn out quite as you expect, it would be pretty easily restored back to the original. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Yes, makes sense. Maybe I can make a handful of manual dampers to fit in certain ducts. The outlet of this new one will be directly above the distribution box of the aircon, so wouldn't need much ducting at all then. Today's a bit of a write off. Sun started nicely this morning but just before lunch the cloud came over and the rain set in. It's freezing now ... well by SA standards anyway.  That was my intention at the beginning so I could do the soft start thing and not having it blasting away ... but I started to sway the other way once I got the differential controller and it was a matter of on or off. But I do think that variable speed would make more sense in the long term for the times when it needs to ramp up a bit or throttle back ... and like you say, would be less annoying than vast blasts of air starting and stopping. At the moment there are no complaints because we are in development mode ... but I don't think I could live with the noise of the thing at its loudest. Lucky my wife is very tolerant too. The interesting thing with the style of fan I linked to on the previous page, is that they claim to be variable speed ... Control input: 0 to 10V DC/PWM ... which takes care of quite a bit ... ... though they are of course DC motors up around 36-57V ... so needs a healthy dc supply. I will then need to have a more sophisticated control ... but that's not insurmountable. Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

It would certainly be possible to use a dc motor, and build yourself a PWM speed controller plus a PID temperature controller. A lot of messing about though to get it all going, and by the time you have bought all the parts it may end up being more expensive. How about a 2.2Kw Chinese variable frequency drive for $100 that already has the PID controller built into it ? https://www.ebay.com.au/itm/281216400406?epid=895238270&hash=item4179cdbc16:g:ieQAAOSwfmVgty92 A suitably small second hand three phase motor should be pretty easy to find. All you will need then, will be two thermistors and a potentiometer wired directly up to the VFD and nothing else. If you are eventually going off grid, or partially off grid, the ac power for the motor will come from solar anyway. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I am having a bit of trouble keeping up with what your preferred options are BUT, If you go DC, why do you need a controller at all? Admittedly my radiator fans are Tiddly winks compared with what I'm thinking you will need however, If you used a DC motor, why can't it be directly Solar panel coupled like Mine? They will proportionally track the suns power same as the tubes and should ramp up and down accordingly. I would allow an excess of panels to be sure to allow for cloudy days when you still will want some output but excepting anything I am Missing, should work fine direct connected like mine do. Other than that, I would think AC Fans would be probably easier to find something with the output required. If you can get a VFD with proportional control for $100, Wow! Couple of random thoughts... For a castle blower or any other fan, you could probably put it in the ceiling to help keep the noise down and also in an insulted box for sound suppression. Drill a hole in the blower housing to either suck hot air in or blow cool air out for motor cooling / air circulation. To splice into the existing AC vents, you would just need a Damper from The tubes as a close off when the AC is on and a damper from the AC For when the tubes are in action. Don't worry about anything mechanical, the servo Dampers are not expensive and your AC mate can probably get some used ones when he pulls out an old system ( along with the Flexible ducting) as they are usually all replaced especially if it's a bigger system/ Ductwork going in. Then you just wore it up ( think they are 24V controlled) and put another neat light switch panel on the wall somewhere, probably near the AC controls. Talented many like You roger could even make it remote control from a Key fob if you wanted and do away with the wall panel. Help prevent Thermal management interference. Reminds me of when I help my mate put a big ducted in his grandmothers house so she wouldn't keep getting sick from sitting in one room with a heater on then going somewhere else where it was freezing. Whole house was on all the time and the temp was set to 24 on Auto. We mounted the controller under the Cornice in the hall way so she couldn't fiddle with it and hit the remote in a tall kitchen Cupboard. Place was perfect temp all year round! |

||||