|

|

Forum Index : Windmills : F&P Electronic Dynamic braking

| Author | Message | ||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Attached are some photos of 2 modified F&P motor control modules set up for constant current control and constant voltage control with adjustable settings. The original circuit was designed for fixed constant voltage control of 400 VDC. They all use an IRGBC20S IGBT as the switch device with a 20 ohm 1 kW peak rated resistor which sits in the top of the heat sink as the dump load. Here is the first modified board for current control, top and bottom. Note the LM358 op amp bottom center left. This has been added to the board in place of an optocoupler that was removed as not used in the brake function. The current sense resistor is 0.22 ohms 5 W located in the middle of the board above the heat sink, below the left hand black 250 VDC capacitor. The red & blue wires are for 12 VDC supply. The feed DC into the board to be controlled is via diode kathode bottom left and the yellow wire. Next is a board modified for constant voltage control over a 40 - 460 VDC range. These last 2 photos are of an original non modified F&P board. Note the optocoupler is still in place in this non modified board. In their present configuration they're not much use in a real world application. Have put them into use recently to prove that the concept of dynamic braking can be done with simple circuitry without the need of complex microprocessor control. When I get time will scan a copy of the actual circuit diagram if it's of anyone who would like to try to build their own. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Thats really interesting Dave. A three phase induction motor also behaves as a brake if you flow a steady dc current through two of the three star windings connected in series. A schematic of what you have there would be very helpful. Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

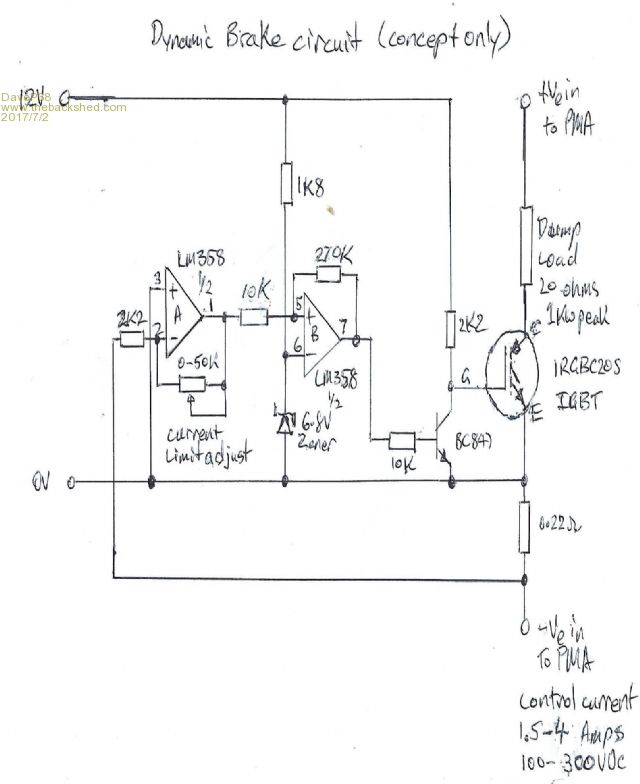

Hi Tony Once again thanks for taking interest in a topic not discussed that much, but could yield some good results in time if set up properly. Here is a scanned copy of the basic circuit as requested.  The current control has about about a 20 % drift in this set up. Setting the current to 2 amps at 60 VDC it goes up to 2.4 amps when at 200 VDC. It's good enough to prove that the concept works in principle. Will make some improvements when time permits> Having a business to run on week days, children to keep occupied on weekends burns up most of that. The resistors and IGBT switching devices can be paralleled to provide more current capability with lower voltage operating range. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

Start 'em young Dave  |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Yep will go with that about starting them young, my little boy is 4 & 1/2 and already show lots of interest in what goes on in the work shop. Wow tower climb with the young chap. Must say from photos you've posted, that's a great view from the top.  Can I ask what part of the US you're located in? Also what timber did you make those blades from? Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

We have four boys: ages 31, 12, 9 & 7. My youngest seems to be the most determined to "help". He's really into tools, jacks, things with engines and the like. I'm usually a stickler when it comes to safety gear - this is how I found on a recent day in the yard. We're in the northeast corner of VT; aptly named the "Northeast Kingdom". We're about 20 mi. to the Canadian border. We used balsam fir for our blades. If I was given a choice I'd probably use Sitka spruce, but it is not local. Balsam is locally available - we cut these logs and had them locally sawn, and air-dried - it is pretty strong for its weight, but is not as resistant to rot as say cedar. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

I thought you had sourced your supply of timber locally, good on you as that is the renewable approach for sure. We travel to the US every 2 to 3 years and have family and friends in Pittsfield, MA not that far from your state. Next visit may try to look you up to pay a visit. That's a wee bit of an age gap between the 4 boys. We only have to one at present. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hi Dave, I been following this thread with some interest as I have always been looking for a way to control the sometimes "Out of Control" fan on my mill. The furling works ok, but I am all in favor of having a secondary backup to slow things down when wild weather hits. It is scary to see those blades spinning at break neck speed. Is your controller purely based on sensing over voltage, or can the system be incorporated with the R.P.S to slow things down. This would suit in my case as the mill is fed with a 24vdc supply. Marcus if it aint broke dont fix it!! |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

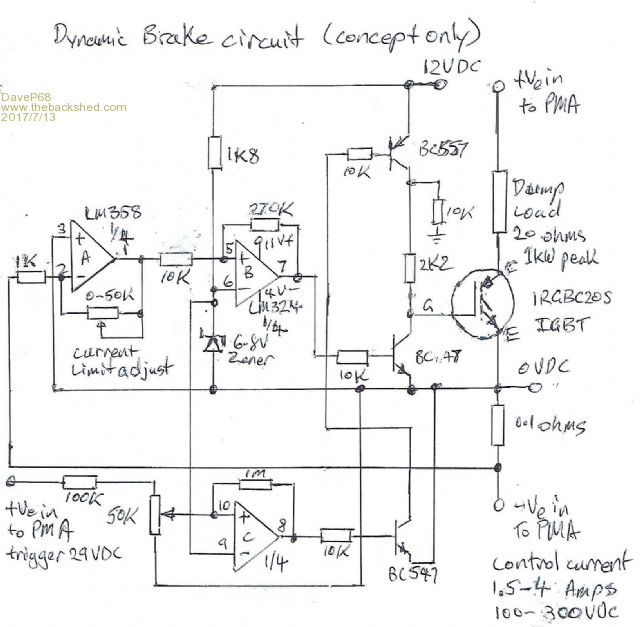

Hi Marcus Thanks for taking an interest in this topic. This dynamic brake circuit has been modified for 24 VDC operation but requires the IGBT switching device and dump load resistor to be in parallel multiples. The trip voltage is set for say 29 VDC (adjustable) and the load resistors can be reduced to 5 ohms. You would need a minimum of 5x IGBT switches and 5x 5 ohm dump load resistors set up in parallel. All feed from the same drive transistor to each IGBT gate input. This again is "Concept Only" and does not reflect an actual operational circuit!  The actual voltage trigger circuit would be some logic to trip then keep the clamp circuit on for the desired braking period. This could be minutes to say a few hours to said high winds have passed. Could also have an anemometer input to release the brake once winds have dropped to an operation level after a set period. What are your thoughts? David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| gpalterpower Senior Member Joined: 19/07/2009 Location: AustraliaPosts: 175 |

Hi Dave, Thanks for your help in adding to your original circuit diagram even though its still in the concept stage. I'm assuming there could still be a few bugs to iron out. Are you planning on testing one soon? I like your anemometer idea, but would it be possible to somehow utilise the f&p speed sensor to just slow the mill down and not come to a complete stop. More like squeezing on the brakes to a useable speed. This way it could still charge, but not be out of control. Maybe too complicated  Marcus if it aint broke dont fix it!! |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

Normally I'd say that's a bit of a haul form where we live, but in relative comparison (to NZ  ) it is quite close. By all means look us up if you can. ) it is quite close. By all means look us up if you can.Years ago I worked for a wind small manufacturer that did induction, grid-tied turbines. They employed hydraulic braking early on, and then went dynamic braking. On the larger (40-50 kW) units they used electric water heater elements in free air as the resistive load. It worked quite well, but they also used "tip brakes" on the blades which were operated by centrifugal force if the rotor exceeded its operating range. This prevented run-aways in the event that there was a gearbox failure, or malfunction of the dynamic brake. It also added another maintenance item however. I generally favor control strategies where the fail-safe mode is just that; something fails and the system shuts down. If you can incorporate that into the braking scheme it will likely work out best in the end. ~ks |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

|

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

The main reason I've been able to get good results from 'Power Factor Correction Capacitors' is due to the constant current control that this dynamic braking circuit provides. Can now get up to 2.7 W per RPM peak from a single stator between 500 & 600 RPM. When the optimum current is kept close to a constant value of 2.3 Amps from a 36 pole stator wired Delta, then the voltage can rise to the level required for maximum output power. It's an easy circuit to build if you can get hold of a scrapped F&P motor control module. Have been able to get more than a 1 kW out of my test stator using the module in the photo on the previous page. The catch is not to run the test for more than 10 seconds as the heat in the resistor gets the module VERY HOT! There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Haven't been on here for a while, so thought I'd update this topic relating to the use of this dynamic brake control circuit. Modified it to be used as a fully programmable dynamometer (enhanced VFD) to measure the efficiency of F&P stators. Having lots spare motor control modules from scrapped washing machines thought I'd re-purpose one to used as a fancy VFD. Now able to test F&P stators in different configurations or applications such as MPPT (Wind mode), how linear power curve is vs RPM constant load or as a voltage clamp to simulate battery charging. It uses 2x F&P stators connected back to back. Stator #1 is the drive motor in it's factory stock standard star mode. The second stator can easily removed and changed for another set up in a different configuration star vs delta wired 1x 12c or 2x 6c etc. Currently has an operating range of 23 to 250 RPM (most testing is in 92 - 250 RPM range) maximum input drive power is 470 W. Hope to modify the F&P motor controller to widen the operating range from 23 - 650 RPM with 3x the input drive capability up to 1400 W. The RPM measurement is done by the motor controller and shows on the display module. This can only be viewed in a special diagnostic mode hidden from your washing machine user. The dynamometer function came about by adding a fully programmable board that interfaces into the reference point of the PWM circuit comparator to make it's own adjustments. This allows full control over current 0.05 to 6 Amps DC and/or voltage from 30 to 500 VDC. Just a simple re programme to change the test mode. Won't be publishing this new circuit at this stage. Will take to much effort with most of it on bread boards and in my head not on paper. A photo of the complete setup running at 201 W continuous output at 216 RPM (note the glowing resistor in the blue module). Close up photo of the motor controller that makes it all happen. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

SparWeb Senior Member Joined: 17/04/2008 Location: CanadaPosts: 196 |

Looking good. I see you have many tricks up your sleeve, like the test mode in the F&P module. Steven T. Fahey |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Steven Yes that very useful function in the display is not in the technical manual, it requires special know how to get to. You can't just set up a system like this and hit the start button. It requires a deep understand that only the F&P design engineers have. Have a friend who designed the very same circuit board I'm using in my test rig. It's sometimes not what you know it's who you know  Here's a photo of a board covers removed for those that and are interested. David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

That's a tease, is it something that we can replicate? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Use a 3 phase brush less dc motor controller board. Thing is the board shown has a 320 VDC bus to drive the star motor in it's factory standard configuration. A bus voltage that high is "Dangerous to play with" if you don't have my back ground/knowledge of F&P smart drive product. There is no transformer on that board to provide isolation! By one of these off Ebay for $39.99 USD + Shipping 48V 1500W Electric Bicycle E-bike Scooter Brushless DC Motor Speed Controller Then rewire the stator to 6x 2c and you be able to replicate what I've. No fancy tricks here making something like this. The hard part is doing all the math with the data and turning it into graphs etc  The one thing that surprises me is no one else has tried this on here? There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I have "played with" hundreds of F&P boards, guess I will have to just see what I can workout myself. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

It's an easy set up to do if you know how the boards work. Use a Phase 7 motor controller with white RPS unit, part # for board is 420904 (most reliable one ever produced). Also need a lid lock when running in spin mode and 2x 60 ohm inlet valve coils connected or you will get a fault code 49 on start up. Once you've got it set up you will good to understand how to run in diagnostic mode when the module is driving the motor and be able to read that data. If you have another way to measure RPM, then you can skip the diagnostic mode while it is running. To run the motor in spin mode as a VFD you need to full the motor controller into thinking it has a bowl sitting on it's shaft. Start the spin mode complete a manual bowl check, once it has passed will run from 23 - 92 RPM and stay dealing there for 12 seconds. Then it will step up from 92 - 270 RPM with no load. Any other question? There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||