|

|

Forum Index : Electronics : ozinverter improvements

| Author | Message | ||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Yes now we are older and wiser, the 393 could just be cut off and no other changes or links required, as they don't use R27 on the newer boards, and the 2110 has internal pull downs "Obviously it was necessary at that time" no I just didn't look into it further

That should put paid to the guru status... I didn't even see that till much much later ( I had stopped using the 002 by then too). Had I researched it I would have twigged to that. Tinker alluded to the r27 thing some time back..... and a two second look at the 2110 data sheet would have told the story..... sigh... I lack the credentials to be a guru so will have to stick with village idiot.... seems a better fit somehow. Will try this soon I hope... it is the last thing to winkle out to make these quite unbelievable performers. ....oztules Village idiot...or... just another hack out of his depth |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Do you guys know what you are doing to me? Downloading datasheets and reading them that is, and its a good thing one could say. So, thank you for that. Now, looking at Grogster's diagram above, nothing connected at the SD inputs of both IR2113s says "RUN" according to the info. A high on the SD line says "STOP". OK, I'm with you so far but what happens if that 'high' is removed? Does the thing soft start again? I'm assuming *nothing* was done to the EG8010 inputs in the above scenario. I need to work this out one step at a time  . .

I got a spare EGS002 board today, took the LM393 comparator off already and plan to suss out the best way to drive my big inverter with that board. Klaus |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

The SD inputs on the 2110 driver IC's are just an instant ON/OFF kind of concept. The 2110's have nothing at all to do with the soft-start, as that is handled by the 8010 controller IC. So, if the inverter is running happily, and you put a high on the SD lines, the 2110's will inhibit their output, which will instantly stop the main driver board MOSFET's in their tracks, and the inverter output will drop off. The high on the TFB pin causes the 8010 to think there is an overheating situation, so it shuts itself down, stopping the SPWM drive signals. Now, when you remove the high on the SD lines to the 2110 chips, that will re-enable their output, allowing them to drive the main power board MOSFETS. At the same time, removing the high from the TFB pin on the 8010 allows the 8010 to restart. As to how exactly it does this restart is a question perhaps better for Oz to answer, but I expect that having tripped a fake over-temperature event, removing that high on the TFB pin so that the 8010 can restart as normal, it will most likely use soft-start if that has been selected - that would be my guess anyway. If you left the 8010 running, and just switched the 2110 drivers off and on, I expect that the main power board MOSFETS would self-destruct when you re-enabled the 2110's without soft-start, so that is why the 8010 is being triggered too by the same signal as the one used to stop the 2110's if you see what I mean. That is my interpretation of things anyway. I might be wrong - Oz or other will correct me if that is the case. Smoke makes things work. When the smoke gets out, it stops! |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Thats how I see it exactly Grogster. 2110 turned off and on without 8010 soft start being triggered = poof! Both temp and 2110 turned high will work perfectly. They will be synced with the SCR. It is a no frills on or off latch. On will lock off the 2110 near instant, and we don't really know how long the temp takes to stick, but it is quicker than you will be able to reset the switch thats for sure. A reset will enable the 2110, and the temp will initiate the soft start.. job done

Providing there is no chance of noise making the 2110 jitter etc, it should all work. .........oztules Edit re read this "I'm assuming *nothing* was done to the EG8010 inputs in the above scenario. I need to work this out one step at a time . " Not sure what you meant here... the diagram does sync the 8010 and the 2110.. so *something* is done in that above scenario ( grogster pic) or not if you mean your explanation.... below that. Village idiot...or... just another hack out of his depth |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Thanks guys. What I'm trying to learn is how each chip (2110 & 8010) individually contributes to a emergency shut down. Grogster did now explain that *both* chips have to turn off with the 2110 being faster (hopefully). To soft start again I assume 8010 has to turn on last, its unlikely both (8010 &2110) can be made to turn on *exactly* at the same time even if they are 'synced'. How critical is timing here? What I find odd with the EGS002 board is it having no ON OFF circuitry. How did the designers plan to turn the thing on? Just powering it up? And how about turning it off? Surely, while the Tfb can be coaxed to do this job it surely is an odd way to do it. How would one shut the inverter down for some time then? What I mean is, the over current trips it (as you guys plan to do that) but nobody is home. How long can the Tfb be forced to keep it off, indefinitely? Klaus |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Technically speaking, when you press the "Reset" and the SCR releases things, BOTH the 2110 driver IC's AND the 8010 restart at the same time. Really the 2110 IC's are ready the instant you remove the high on their SD lines, but cos the 8010 takes time to ramp up with the soft-start, the result is that the 2110 drivers also ramp up slowly - being driven by the 8010's soft-start signal, if you see what I mean. To put it in automotive terms, imagine what happens if you slowly accelerate in 1st or drive - that is the equivalent of the soft-start. When enabled, the 2110's are "Idling", and then the 8010 pushes the accelerator pedal down. WITHOUT the soft-start being disabled, it would be like the 8010 has the accelerator pedal pressed right down, and enabling the SD lines on the 2110 driver IC's is like dropping the car into Drive(or dropping the clutch in 1st) from a stationary position with your foot flat on the gas - it's not very healthy for the car or transmission, unless it is a super strong one.  Think of how the tyres on a car scream and smoke a-lot if you do that, and that is your MOSFET's on the power board. Think of how the tyres on a car scream and smoke a-lot if you do that, and that is your MOSFET's on the power board.  If you're REALLY unlucky, you can cause your engine to throw a rod or otherwise blow itself to bits - that is the rest of your inverter. If you're REALLY unlucky, you can cause your engine to throw a rod or otherwise blow itself to bits - that is the rest of your inverter.

As to your question about the inverter tripping while you are away, as the SCR cannot reset once tripped without Human intervention, the SCR will keep the inverter in limbo and everything in the OFF state, until either you reset it, or the battery bank goes flat. Think of an SCR kind of like a latching relay. If you apply a voltage to it's anode pin, there will be no volts between it's cathode and ground until you put a small voltage on it's gate(kind of like the relay coil). Once the SCR conducts, then the cathode will be at the same voltage as the supply(give or take 0.6v or so), and it will remain in the "ON" state, even if you take away the gate voltage and never put it back on again. It will, in fact, totally ignore any further gate voltage activity from the point it has been tripped. The only way to reset the SCR is to either drop the current being drawn though it below the holding-current figure(which tends to be 0.5mA or so), or remove the input voltage on the anode. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Grogster, I am wondering now if you actually tried out that SCR circuit you posted above? I breadboarded it and found what you said below is important: " The only way to reset the SCR is to either drop the current being drawn though it below the holding-current figure(which tends to be 0.5mA or so), or remove the input voltage on the anode." I used two separate 5V supplies. One mimicked the C/T via a voltage divider (pot) to supply the gate voltage. The other 5V supply was connected as per your drawing. So when I now slowly ramp up the gate voltage the SCR (I used a C106D) triggers ON at around 0.6V on the gate. So far so good. Ramping down the gate voltage and the SCR stayed on. The RST button turned it off. Then I replaced the LED I had used from the cathode to 5V ground as an indicator with a flashing LED. The circuit no longer latched on (because the load current came off and on). So now I'm wondering if there should be some load (LED?) connected at the cathode, to make sure it works reliable as I do not know if the current into the SD input is sufficient to latch the SCR on. Unfortunately I'm tied up with family matters for a few weeks and so will have little time to more experimenting with the actual EGS002 board. Does anybody know if I *have* to connect the mosfets to my EGS002 board when I power it up with 5V? Not having them connected would allow me to bench test the shut down circuit without high current worries. Klaus |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Yes, that is an EXCELLENT point. You are 100% correct that the LED works fine, as it represents a constant load of at least a few mA to keep the SCR on. The "Off" current of a flashing LED could be micro-amps, and if not at least half a milli-amp or so, most SCR's will drop off - it will be the same as pressing the reset button. So a standard LED will work, but a flashing one might just blink ONCE, then stay off. Is that what was happening? I think it was...... NO, I had not built this circuit, I was just going on theory, but it seemed sound. In my board, I am using a flashing LED to indicate the SCR has tripped, so your experiment and feedback give us valuable information. Yes, I think we need a small load in the form of a 1k to ground or something similar. We don't need much current flow to keep the SCR on - one or two mA would do it. Nicely spotted!  Smoke makes things work. When the smoke gets out, it stops! |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

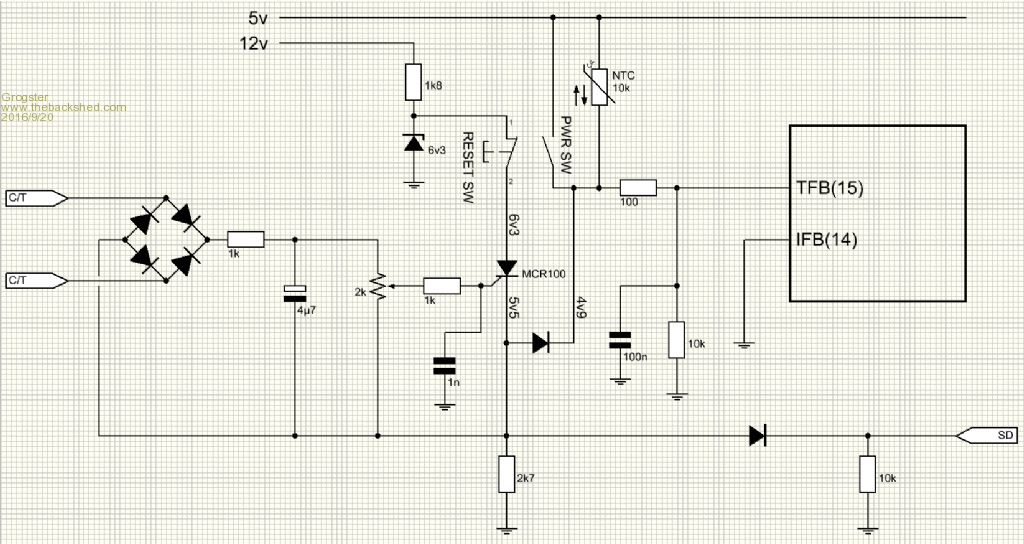

In the other thread, Oz mentions that: [Quote=Oztules]Have done some tests with the current shut off with the SCR. On a small unit works fine, BUT you will need more voltage than +5v to drive the SCR to turn the temp pin off. The SCR will drop .7v or so across it's junctions when conducting which took my 5v down to 4.3v... which is not enough to trigger the temp pin... so used a 1k8 and 6v2 zener to provide the SCR voltage... then works very fast and perfectly so far.... shorted it out dozens of times... but this is only a bench test of a single fet board, and small ( 500w) EI transformer..... looking at the scope, there is no quibble, it is instant off... so should be ok ... probably not needing to use the driver pins.. will see later when some 10000uf caps turn up [/Quote] So, I am guessing that Oz has something like this setup now then:

I've added a 2k7 resistor to ground on the cathode of the SCR, which will allow about 2mA to flow, to keep the SCR in the ON state once tripped. I assume that the series diode from the SCR cathode to the temp pin is still in position, resulting in about 4v9 on the temp pin when tripped. Without the diode, the voltage on the temp pin would be about 5v5, which is smack on the absolute maximum input voltage based on the 8010 datasheet, page 10, chart 7.1..... I don't like running things right at the max, so can Oz just confirm that he still has that series diode in there? I can see why the unit may not have wanted to work with a 5v supply to the SCR. When tripped, voltage-drop across the SCR being about 0.7v, leaves 4v3 or so on the cathode of the SCR when tripped, then you loose another 0.6v in the series pass diode, bringing the voltage that the TEMP pin sees down to 3v7 or so, which is obviously a bit on the low side to happily trip the TEMP pin. Nice spotting on that, Oz.

Smoke makes things work. When the smoke gets out, it stops! |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Instead of the 2k7, I used a led and 1k resistor to keep the current flowing, and show me what was going on. I used a 6v2, which gives 5.2v on the TFB pin when triggered.... no diodes in series, a 6v zener looks about right. TFB needs at least 4.3v, but to make sure it turns on unequivocally, I figure 5 or more is better. ( <5v5). Probably won't require the diodes and driver shut off, we'll see as we get more power and tighter transformers involved with this. More cap won't arrive till the end of the week.. so not much I can do at the moment. Yes I used the 12v line for feed voltage. Has to retire the 4u7... it stopped it triggering quickly/reliably... but I was only working with 500watts max... shorted it dozens of time

...........oztules Village idiot...or... just another hack out of his depth |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Still using the small 500w transformer and power supply instead of battery, so these results are not real life high power at the moment. There is a slight wobble in the trace sometimes and a strong wobble other times.... so used the diodes onto the SD pins of the driver chips... now there are no wobbles on shorts.. it just stops and turns on the o/temp pin of the 8010.. seems very solid. Be happy when some big caps come to populate the board so I can move on to testing with batts and proper loads. So this looks like the way to tackle this but do your own tests, as these are not conclusive yet. The 4u7 is not used at the moment... will introduce some capacitance when and if i see it needs it for stability. Sad thing is...... I got some boards done already... and now they will be second rate if this works as expected. Tinker ... TFB can be turned off indefinitely. .........oztules Village idiot...or... just another hack out of his depth |

||||

| jdevine82 Newbie Joined: 01/09/2016 Location: AustraliaPosts: 13 |

Hi all I have been thinking a little and a question has come up. Now that we are using the ct to shut off instantly, it would make sense that it would need to be adjusted so it was not trigger happy, but does that mean we are going to need to put another ct to shut down for the slow over current protection as well? Ie when I have 6 kw connected to my 5kw inverter... It would need to be slower but at a lower threshold then the high current fast shutdown using the scr... |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

I suspect a cap on the scr gate will allow for slow shut off... a spike produces a high voltage, and will trigger near instant charging a small cap.... smaller spikes would take longer to charge the cap ( rc network with sink really) to get to trigger voltage.... this will be suck it and see territory. Could also just use the CT input as was for the current shutdown, and two coils. Independent then. ...........oztules Village idiot...or... just another hack out of his depth |

||||

| jdevine82 Newbie Joined: 01/09/2016 Location: AustraliaPosts: 13 |

Hi all I have now updated my git repo with the latest as we understand it. I went with oztules suggestion of two ct transformers, 1 for slow overload and 1 for fast overload. ozinverter with ctx2 mod I think I will get some boards made like this and see where we are at with these modifications. I have left a cap in place across bridge as it easier to leave it off the board then to add it later.. Thanks Jason |

||||