|

|

Forum Index : Other Stuff : Making my own CNC plotter

| Author | Message | ||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

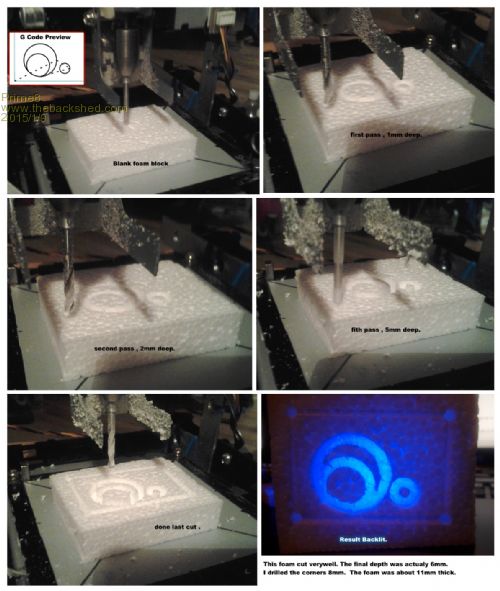

hmm , i put a small 5v hobby motor on it for fun . ok the plotter is now a Mini Mill !! Now that Z is under stepper control , i figured i would strap a motor and a drill bit to see if it could mill a small piece of foam . well it worked! i think i cooked the lil' 1$ hobby motor by driving it with 9.6v . LOL you could smell the brushes cooking ! LOL i need to find one of my 9v rc plane brushed motors of about the same size and make bit holder . If that proves even better i will use one of my brushless R/C motors , as they have PWM (servo like ) speed controls the arduino could drive as if it was a servo.

hope those pics show . Old coder, and bodger of things that may spark. |

||||

| plasma Guru Joined: 08/04/2012 Location: GermanyPosts: 437 |

drill plotter

looks like this will work. |

||||

| powerednut Senior Member Joined: 09/12/2009 Location: AustraliaPosts: 221 |

Nice work. You'll probably find you get better results if you use a cheap router bit. It should be easier on your bearings too. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

well the cheapo hobby 5V motor is hanging on . Im running it on 9.6v pack via a old mechanical speed control. you can smell its brushes burning . LOL . after switching to dremmel bit that has side cutting edges , and using some ID Alu tube to shore it up , there is almost no run-out . before using the white foam i tested this on some more pink foam . the drill bit actually heated form friction , and then started melting its way . LOL so i had some white packing foam left from some x-mas stuff. usually this stuff is hard to cut and shape vs FFF . at 8x micro-stepping the feed rate looked perfect . I only cut 1mm deep per pass. 6 passes. ending with 6mm deep . The cut edges were very sharp and way cleaner than i had hoped to get from foam like this. i then did some drills and light lines. and finished by back-lighting test with a blue LED!

hope those images work . I'll attach a copy of teh first here localy . local copy :

Old coder, and bodger of things that may spark. |

||||

| powerednut Senior Member Joined: 09/12/2009 Location: AustraliaPosts: 221 |

Very nice. are you intending to use it to make a bigger cnc mill, or are you just using it to experiment with? |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

both . but yeah i will be making a bigger one , i never expected to get milling working at this scale. lol ~sort of nuts that way . I plan to make the G code sender app , and make it as a plugin for my 3d editor. that way simple shapes can be depth tested and milled. Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

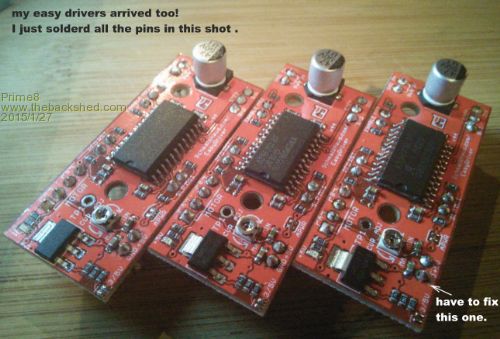

when/if some other things that are coming in the main get here i will try making a GBRL build on a Nano v3 clone . but that needs some easy drivers for what i want that for . other wise i can keep using my custom firmware . I do need to add X axis movement in my line code, that way I can support proper 3D lines. then i can work on having my firmware work with my own 3d editor P3D editor v1 Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

well having play , i used a bit bigger chunk of foam . i made a small Gcode sketch for the wife . ( home made stuff wins big points , even if it was bench top or work shop made ) LOL i did 5 passes 5mm deep . the foam is 10mm thick . i did 2 tight circles to 5mm to make sure they kept their shape and the center bit. i put in her initials at 0.8mm deep. ( IIRC) then i removed them from the gcode cycle. I use solvespace parametric CAD to make my Gcode. i then clean it up in note pad , mainly I change the cut depts . when i get my own control app build that will no longer be necessary as it will have some cycle and gcode processing tools built in for 2.5D milling. i will be trying to get 3d milling sorted soon. Then i will try to let it carve a face . I may just cave and use GBRL for that .

thats it for now . I'll try and get a new video with my HD cam and better lighting this weekend. Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

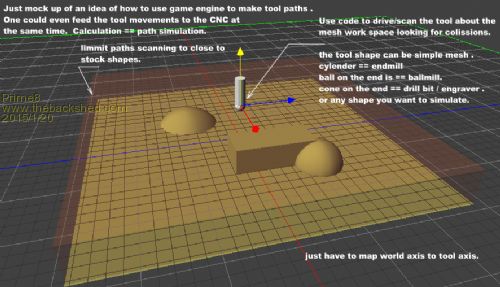

has been a rough few days . but i have though i need to make a generic CNC sim in software . where you can set tools and tool shapes . its can the test tool paths and look for collisions . ~ I have some code (c++) that can convert height maps to position (3d) funny enough it was not for CNC i used it in a terrain generating tool for game making . i can do virtual scans of most 3d mesh formats . so i could actually use the physics to test tool depth across a mesh . have it save the valid paths , and then convert to G code. Hmm. possibly even make the g code as it goes. hmm maybe i should make a virtual CNC simulation , that can be setup to look like what ever setup a user has . it is way to easy to pass G code to 3D sim objects as it is no doff that a fancy camera path . the only diff is a in sim i can use teh physics libs to check for tool and armature collisions . should not be too hard to add that to my 3D editing tool now . ~ possibly edit my 3d tool or have it as a plugin for it .. hmm  Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

ok i had some good light and my tablet was charged so i could record some video of it moving and doing a single 1mm cut pass. http://youtu.be/8arHJMQ4i6E the first pass is supposed to be 0.2mm to 0.5mm for the text to show but here this was more about t he motion so I ran it at 1.1mm when i checked the Gcode. that is at 8x micro stepping . My driver lets me change the micro stepping on the fly . as long as the rig is homed , then the targets are good . I pass a custom code to my firmware and it will change the step mode. can be done in G code comments. Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

i coudl like to link my rig to my own sender app soon . and have it display intended tool position . I could use the same engine as my current 3D editor , and even have it scan for tool paths against a mesh . I just need to link it to my arduino via USB . that 'should' be easy. LOL ( uses D3D ( directx 9c ) but i knwo it has run in wine on some linux distros. )

Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

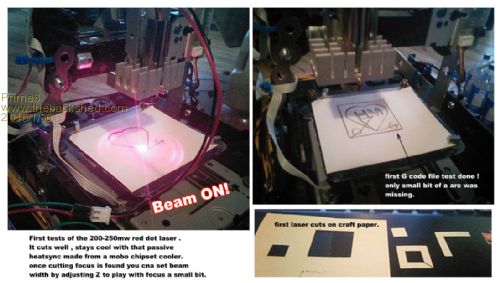

my lasers arrived. both are red , both have built in drivers & protective circuits. the small one is 5mw , the diode emits a line but the lens is a standard dot type. the longer one is 250mw , the diode emits a dot, and has a standard lens.

when I power up the big one , I only had it rough focused and it started to burn the black coroplast i mount my Arduinos and such on . oops! the glasses made it hard to see the smoke. the line diode will be used off my round surface mirror , to make a perfect line for webcam 3D scanner . i can automate the scan motions with steppers or servos. some other things arrived too.. loads to play with .

Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

Beam ON! first g code run / test ! >> to do , make it so motor and beam can be hot swapped . possibly solder or jb-weld some ID guide tubes and then have magnets hold them on .

Video http://youtu.be/MB_HNfeuJ1I once I get this sorted , and a client project , i will upscale the rig and start on a primitive 2.5D and 3D CAM tool . I have been testing some CAM tools (free ones) . Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

some more testing . I will begin work on a gcode sender & path previewer for 2d, 2.5d , 3d gcode. and then i will try to use a CSG lib to simulate tool cuts and start a min CAM tool project . but lets burn stuff.. lol

Link to bigger pic Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

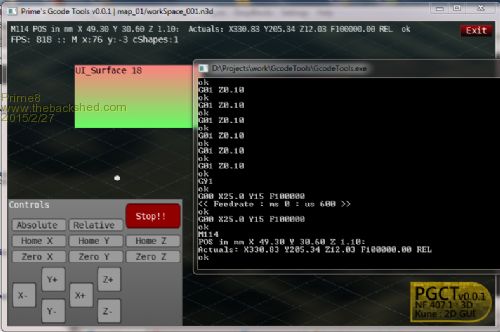

ok I did some testing with my 250mw laser on some things and fixed some bugs in my firmware. now i'm working on getting my own code to drive the rig and preview render the Gcode. my wife loved this set vs the paper i did before.

I need to speed up the laser on black foam , it melts the under side wider than the top face , like a gunshot exit . /\ , if i speed it up it will be more || one of the bugs fixed , corrected my control of federates. with a true Arduino UNO i get insane baud rate . in this pic the 3D window is not showing anything yet , and the text dumped is nit reflecting what is in my firmware and all it capabilities.

Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

http://youtu.be/gy2O9NWfnAI Old coder, and bodger of things that may spark. |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

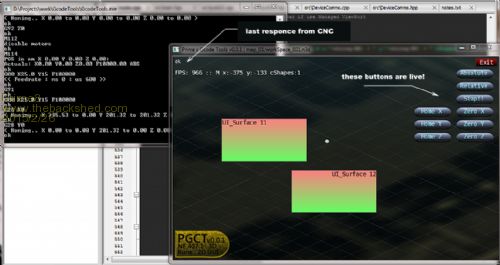

i have my c++ app talking perfectly over a custom serial lib to Arduinos. i have started putting some Gcode commands in. nothing to wild yet . things that will be easy to do not to long form now . direct machine control via mouse. Ie you will be able to right click on the work space in viewer and the tool will go there ( at pre defined depth ) . on screen preview of gcode paths . testing tool for collisions along paths. ( requires making a small tool editing thingy , but not hard ) modeling the work area/volume . 3D transforms of gcode files, then save/send to CNC . ( rotate any axis* , translation , scale ) * not too sure about rotations on all 3 axis , but vertical for sure . nothing crazy yet , but the buttons on the right are live and i have bound some simple gcode commands to the 2 test buttons . i have not had to edit my UI class much . once i have the parts of a Gcode sender UI up ,( ie a serial terminal and such) I will start the previwer code. Eventually a very simple CAM using 3D collisions of Bullet Physics.

Old coder, and bodger of things that may spark. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Thanks for your progress reports prime8. I'm positive I would have thrown the towel in before this point. I'm confused, no wait... maybe I'm not... |

||||

Prime_8 Regular Member Joined: 07/12/2014 Location: CanadaPosts: 51 |

its fun , and learning process. I will probably fold to just using GRBL , but i will make sure my control app can run my custom firmware and GBRL of some version . sorry for small pic (gets re-sized here ) , but i have not found a good pic posting site all butons work . I'm not as far as i want to be but what i have works.

Old coder, and bodger of things that may spark. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I generally resize jpg files before I upload. if I want to go bigger than 500 wide I save it as a gif that will go to 1000. I'm confused, no wait... maybe I'm not... |

||||