|

|

Forum Index : Microcontroller and PC projects : Good places to get PCB’s made....

| Author | Message | ||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Will check them out also. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

I have found that the Press 'n' Peel stuff works very well. Cut a piece bigger than the pcb you are doing and use cheap laser stickers to anchor it to a sheet of paper and you get a lot of boards per page. I have used it for single and double sided boards but of course plate throughs are an issue. For QFD packs I use 'Chipquik" and heat the board on the same iron I apply the Press 'n' peel with.For the plating I got some stuff from RS which last for ages. With this system you can get very good results on smd. |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

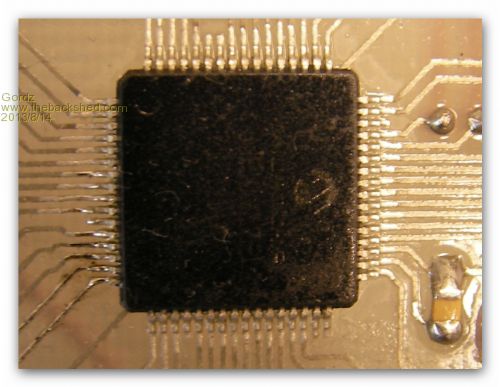

Here are a few examples

|

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

and this

|

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Yes, I must admit they do look good for homebake boards.

I am still not a fan of those clothes-iron based methods such as press-n-peel or toner-transfer, as they torture the copper laminate with the heat from the iron, and it can de-laminate if overheated. I guess it is all in your "Iron technique" and is OK, if you can make it work, and you only need a couple or a prototype. I have tried the toner-transfer method myself, but I was never able to make it work - the pattern never transferred, and all I ended up with was super heated, de-laminated(and useless) PCB, and an equally high temperature anger! I was using Brother toner, which I found out subsequently, does not work as they have no plastic component or something like that, that other brands of toner do, so it probably would have worked with a different brand of printer. What printer brand are you using, out of interest? I still prefer UV exposure/develop/rinse/etch and films of the artwork for homebake boards. But then - everyone's a critic!!!!

Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

I use a cheap Epson laser printer because I have one :) but I have used many others too with no problem. You can get amazing results with this process and I have never had an issue with delamination etc. My iron is set between nylon and polyester. Once you try this method you won't go back to photo resist. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

A bold statement.  Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

Try it just for giggles, it does not take long and then you can be sure. I also used to do the whole UV exposure/develop/rinse/etch and don't miss it at all. Maybe I am just lazy but replacing three steps with one.... |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Might just do that - for the aforementioned giggles. I will try with my Brother printer, but not expecting that to work, I will see if I can get the pattern printed on another brand printer. I am guessing that thinner paper is better. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

Don't use paper ! use Press 'n' Peel film. When this method first came out the paper of choice was glossy magazine and the result was poor to say the least. Any laser using heat transfer toner will work as the toners are pretty much all 'plastic' dust which is melted on to the paper you are printing on. This is why Press 'n' peel works so well. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Oh - OK - I hear you now. I think I can get that press-n-peel stuff from my local Jaycar - I will get some and try it out - what the Hell!

EDIT: Perhaps not. Not for $42 for five sheets of the freakin' stuff I'm not. I would have tried it, but press-n-peel is about 100% more expensive then using pre-sensitized photo-resist boards from the likes of Kinsten. Still, your results are proof that the method does seem to work, even with really fine tracks and close spacing. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

Lemmo know how it goes, Jaycar is not the cheapest but you don't use a whole sheet at a time and it will last ;) |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Where do you buy your film from? Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

I think I got a pack of E-Bay but its been a while. I print the design onto a sheet of good bond paper, then cut a piece of P 'n' P bigger than the PCB by about 20mm all round. I use laser printer labels to 'tape' the film over the print then feed the same sheet through the printer again. I never use whole sheets unless it is a PCB that size. |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Dunno how one can say glossy paper doesn't work as every iron on design I have done has been spoton. Years ago I tried that PnP and swore never to buy the crap again. Then tried the UV method only to find I had to do a double print and overlay them just to get the image dark enough. Now the glossy paper I used were bearing brochures from BSC and found they worked nicely. The printer I used was a xerox and now I have a new brother laser so might just for the hell have to try that one out. Cheers Bryan |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Yeah, I had seen on YouTube, vids of people using glossy photo paper for this - might have to try that out. Glossy paper is much cheaper then PnP for $42 for five sheets... Smoke makes things work. When the smoke gets out, it stops! |

||||

belsean21 Newbie Joined: 06/07/2013 Location: AustraliaPosts: 12 |

PnP is much cheaper if your order direct from the suppliers's website Techniks |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

Its $15 for a pack of 5 sheets. Thats $3 a sheet !!! .http://item.mobileweb.ebay.com/viewitem?itemId=160825024266 |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Wow - MUCH better prices then Jaycar - I will probably get some via eBay(only need a few sheets for now), and I will try both methods - the PnP AND the glossy photo paper. I don't have a lot of time these days for prototyping, but I will put this on my to-do pile.... Quote from the Techniks website: I would agree with that - Brother toner does not seem to work using these methods. I will make a point of using another laser printer brand for my experiments. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gordz Regular Member Joined: 10/08/2013 Location: AustraliaPosts: 55 |

I got my first pack of P 'n' P from Techniks when they were still young. They ran a small competition for projects using their film. Most of that was used in perfecting technique  Interesting point about the Brother because we can get one for about $60, won't bother with Brother. Interesting point about the Brother because we can get one for about $60, won't bother with Brother. |

||||