|

|

Forum Index : Microcontroller and PC projects : Generic PIC32 mini board and MM "Shield"

| Author | Message | ||||

| boss Senior Member Joined: 19/08/2011 Location: CanadaPosts: 268 |

Ji JohnS, good point, you are right. But still, there are lot of transformers, light bulbs and this means a few dollars (ponds) more for the local Hydro. Regards |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

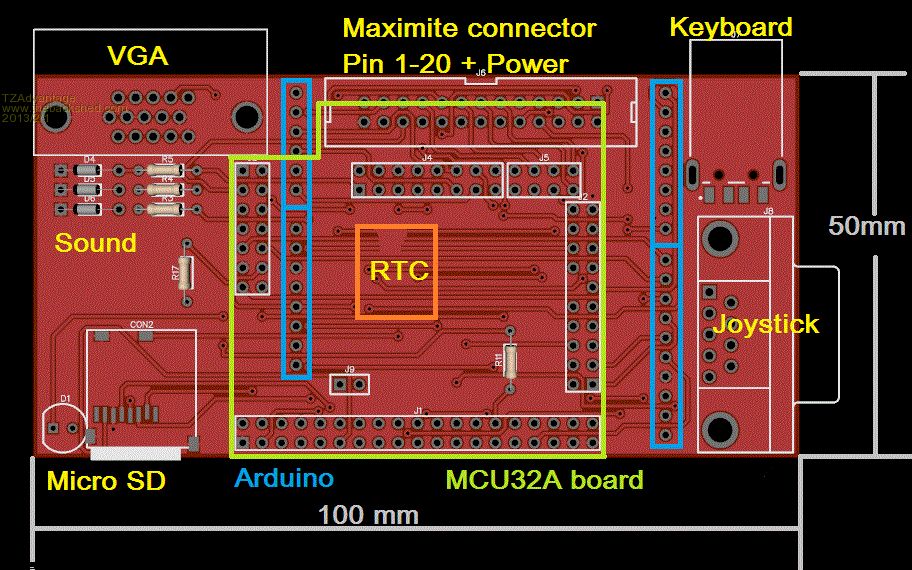

The idea for a 110/240v power supply on the board is gone. Good points were made and for safety it is important to leave it out and just use an external adapter. I have made some progress for the carrier board. It measures 50x100mm. Still to be placed are the rtc, sound and a power connector and a 7805 or better regulator. If space permits i can but some support circuitry for 1-wire, CAN and RS-232/245 on the board. The joystick is not wired yet, as i am not sure what kind of joystick it will be. I put in a 9-pin dsub as a placeholder for a Atari style joystick. The routing is done by an autorouter, just to see if the placement of the parts is ok. The board will be fully routed by hand as that gives the best results, especially with ground planes and other sensitive lines like the i2C and SPI. Here is a render of the board until now.

I found a nice solution for the arduino connector. I placed it on the bottom side of the board. This will allow easy access to both sides and keeps the 'Maximite' and 'Arduino' separate. Microblocks. Build with logic. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

Hi TZ, That is workable, It has the advantage that it wont foul with any connectors (VGA etc) but it makes the VGA sockets upside down if access is needed to say an LCD or switches on the ARduino, Not too bad a compromise and keeps the PCB still small. regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| JohnS Guru Joined: 18/11/2011 Location: United KingdomPosts: 3802 |

Have a look at Olimex boards - they're open hardware. They use some interesting power supplies. Much better and more efficient than 7805. Schematics are on their site. John |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

I am looking for a dc-dc converter so that the input range can have a large range. They are very efficient and in a small package. Also they not generate much heat. If someone has a good suggestion/experience for a specific type please let me know. Microblocks. Build with logic. |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

The challenge will be to have a good enclosure that allows it to be used in two ways. I am designing one that has a center ring like piece of around 3-4 cm high and goes all around. Then a bottom and cover that can interchange. The ring can then be extended when necerssary by stacking on another one, i will make them 1, 2, 3, and 4 cm. So any hieght can be made. Only one "ring" will have the necessary cutouts. The others are solid and can be used to put in your own mounting holes. Microblocks. Build with logic. |

||||

| paceman Guru Joined: 07/10/2011 Location: AustraliaPosts: 1329 |

The challenge will be to have a good enclosure that allows it to be used in two ways. I am designing one that has a center ring like piece of around 3-4 cm high and goes all around. Then a bottom and cover that can interchange. The ring can then be extended when necerssary by stacking on another one, i will make them 1, 2, 3, and 4 cm. So any hieght can be made. Only one "ring" will have the necessary cutouts. The others are solid and can be used to put in your own mounting holes. Circular - sounds a bit radical TZ - I'm not sure I understand what you're saying here. What if people just want to put it in a normal box, that wouldn't stop the underside connector being accessible if standoffs were used. You'd need to consider mounting holes too though, also how to get it in the box if connectors are on both sides. Usually with the connectors at the back they're flush with the outside surface and the board is angled in to get them in position, then the front drops in. Would the underneath connector be on the edge of the board or further in i.e. the external cable socket on the board or chassis mounted via a ribbon cable? Re the power supply - Jebzs suggestion here: http://www.ledsales.com.au/catalog/index.php?main_page=produ ct_info&cPath=142_146&products_id=840 might be an option - high efficiency, wide range input. |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

Circular is not what i meant. I works like a spacer. Using one of more spacer you could vary the height of the box. Circular is actually pretty easy to make. Lots of PVC pipe available. Might be an novel design for a computer. :) Connectors are placed so that only the backside have protruding ones, namely the VGA and keyboard connector. Also a still to be placed power jack. The rest is with board dimension. I will make a 3d design in a few days. I am going on a small holiday to Laos. Everyone a good weekend! Microblocks. Build with logic. |

||||

| JohnS Guru Joined: 18/11/2011 Location: United KingdomPosts: 3802 |

See the ones in the Olimex schematics such as for the Pinguino32 & Duinomite. If you want more interesting still see their A13 Olinuxino. John |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

I am considering dropping the VGA connector as it is huge. A small header in its place will save a lot of pcb area and will lower costs. Would this be acceptable or is it a complete no-no? I was thinking if you need a connector, you just mount it where you want and connect a few wires. It would be easy enough to solder as the header will be on a 0.1" grid and the connector is also not too small. Thoughts? Microblocks. Build with logic. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

A small header in its place will save a lot of pcb area and will lower costs. Would this be acceptable or is it a complete no-no? Personally I think it would be a mistake, many people cant solder very well and to a DB15-HD connector it would be difficult for them. You could always make a pinout to suit an existing cable like used to be supplied with PC m/b for VGA before they started mounting it on the rear panel. or you can save a lot more space by designing an I/O board similar to this Dontronics/Olimex module which gives all of the PC type I/O on the one PCB, (ie. VGA, Composite, Audio & K/B) You could make the header compatible with this board but the CMM is Stereo AUDIO and this is designed as MONO I/O so you may wish to do a redesign. See Pic 2013-02-07_203710_DM_IO.pdf Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Nick Guru Joined: 09/06/2011 Location: AustraliaPosts: 512 |

VGA connector must stay. The Maximite market needs a ready made "plug-n-play" and ready to go design. This will attract people who are not skilled with an iron or can put together electronic kits. It will attract people who are programmers and those wanting to learn programming and this means more software. More software is the key to success else you're making another niche product for a smaller market share. It will allow those learning about electronics to get straight into experimenting with electronics without having to know about electronics assembly to build the computer in the first place. I'd like to see a CMM with the minimum components required to get it up and running and offer a plug in daughter board that includes all the extras for "pro" use. The important criteria is low cost and pre-assembled... like the Rasberry Pi. If we keep thinking about about trying to cram in every concievable hardware interface then we will price ourselves out of the market. Nick |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

I was actually trying to find ways to lower costs. The pcb can be smaller which will lower price because more of the same layout can be fit on a standard size board. This will also minimize cost when you need to assemble. You can wave solder or reflow more of them in one time. Cables with connectors can be ordered for good prices, so no hand soldering is needed. You can have connectors on top of each other instead of all of them next to each other. This will again make the pcb smaller, it will also enable putting all the connector on the back, allowing a nicer enclosure design. This then will make the enclosure small which can make a huge difference in the final price. It is not uncommon for small series that the enclosure is as expensive as the electronics. It will be the first place to start looking for cost savings. When you choose to make enclosures using a cnc, 3d printer or lasercutter you would minimize time to make them and for assembly. It is not so much the material costs, but the time needed to make it. With injection molding prices are significantly higher for larger molds, so much so that injection molds only start to get interesting when you order 100.000 pieces or more! Using existing boxes will make it ugly and unsaleable. Only if it is in kit form people have to solder. Otherwise it is just a ready to use products. Microblocks. Build with logic. |

||||

| paceman Guru Joined: 07/10/2011 Location: AustraliaPosts: 1329 |

What would be the best choice for an enclosure? As small as possible, or one that has some room to include your own piece of hardware? What would be an acceptable size? My personal preference for a 'desktop' version would be a size of around 150x100x30mm. This will have lots of spare room and lowers the need for yet another enclosure for your own project. I agree, the VGA connector should stay. If necessary make the board slightly bigger because its "official" box will likely be considerably bigger and if it's a separate board in another box of electronics there will be plenty of room. The 150x100 above sounds good but I'd make it higher, about 40mm just to make it possible to add custom switches, sockets etc above the other connectors if people want them. The original Maximite is 30mm high and I added a sub-mini power switch and audio socket to that (above the I/O connector) but it was a difficult squeeze. CG's standard CGCOLORMAX is 50mm high to allow Arduino shields and it's easy to install extra switches, sockets etc. on the back - I've added three, power select, audio and F/W upgrade. The 50mm is more than necessary though if you're not "proto-ing" and less tall looks better. Stacked connectors are handy but they need good support because of extra leverage on the board and tracks which is trickier in a normal enclosure. Wired magazine came out with a story the other day on a company in the USA Protomold that now does fast-turnaround, short-run, reasonable price injection molding that might be of interest. Greg |

||||

| Nick Guru Joined: 09/06/2011 Location: AustraliaPosts: 512 |

I personally use the backward approach. I work out the case I want to use then design the PCB to suit. Also, Maybe a 2 tier case design may be an idea. A slim model for the standard unit with an option to replace the top for a taller version for upward expansion. Nick |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

PCB's are a lot cheaper when you can panelise (spelling?) them. For that you need parts to be somewhat similar in size, at least on one edge. The enclosure i have in mind uses four part/maybe six. a top and bottom with in between on each side 'layers'. Depending on how high you want it, maybe after including an arduino shield you add more layers. Each side can have special spacers to connect D9 for joystick, d15 for vga, and other stuff like audio connector, power etc. If you want a wider or deeper box, you use longer parts. I will probably lasercut those. The 'TZBlox' idea is to have a modular system to build your own embedded system and enclosures. I was planning to start with blocks that have a single function, ideal for prototyping, then be able to combine them in an enclosure or even on a pcb. But the maximite has so much to offer that it would be a much wiser choice to start with that. Add-ons can be compatible with the maximite connectors. I rerally like to have 2 joystick connectors because those can be very good to attach not only joysticks but all other kinds of stuff. Particular motors with or without feedback. All those connectors use a lot of room, and i would like to stack them. This will mean that some of them have to be wired with a connector. Paceman, thanks for the protomold link. I already send them an email for info and prices. I would prefer though to buy locally. Microblocks. Build with logic. |

||||

| JohnS Guru Joined: 18/11/2011 Location: United KingdomPosts: 3802 |

Interesting. A big gripe with the RPi is its tiny size and that has meant it's missing various things, all making for problems. (Things like 5V-only power, not enough USB ports, no 5V-tolerant IOs, no prototype area, hardly any GPIOs. Without the hype it would never had sold.) John |

||||

CircuitGizmos Guru Joined: 08/09/2011 Location: United StatesPosts: 1425 |

A big gripe with the RPi is its tiny size and that has meant it's missing various things, all making for problems. (Things like 5V-only power, not enough USB ports, no 5V-tolerant IOs, no prototype area, hardly any GPIOs. Without the hype it would never had sold.) John It is frustrating to compare the Maximite with the rPi, since the rPi has some serious peripherals built in. They just are not meant to go head to head. I hope each will be judged separately as filling their own niche. Having said that, the CGCOLORMAX has a ton of ports, some 5V tolerant, prototyping area... The Maximite needs a way to generate the hype for the class of machine that it is. Micromites and Maximites! - Beginning Maximite |

||||

| JohnS Guru Joined: 18/11/2011 Location: United KingdomPosts: 3802 |

As you can see, I'm not comparing their features, but pointing out that small can be negative. The smaller a 'mite is the less useful, is my feeling (at the risk of over-stressing it). John |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

My search to find parts that combine connectors is not getting any results. I am looking for something similar to this:

The picture is from the parallax website and this connector with print is 12US$, way to expensive! VGA + USB A would be even better. They are used on PC motherboards but getting them separate is difficult as first i need to find a manufacturer or seller. Did some of you come across a connector like that? Microblocks. Build with logic. |

||||