|

|

Forum Index : Windmills : The Mannly Smart Drive hits the 1150Watt

| Author | Message | ||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Bob i,m confused here ....you can throw all kinds of tests at an alt ...put them in a lathe ,a drill press ,draw nice graphs ...whatever but at the end of the day its the fickle wind that counts ...why do tests on a Bridgeport mill when you have wind already blowing around you ....is,nt that what its actually all about ?...your potential customers will probably have the same wind conditions you have ...maybe even worse...i dont see anything in your ebay add about site (average wind conditions) i think from your web site you abandoned doing tests on your own roof mount because the available wind was so low ...correct me if i,m wrong there 1 % of people might actually be lucky enough to have a "good" wind site to make micro wind work and thats probably results from a 5 meter hawt on a 50 foot mast in ideal conditions niall |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Niall, Of some of the claims I'm too wondering if a bottle of snake oil is included in any package sold to lubricate the hidden truth's in the documents........ |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Wind Mills with out a good motor are just wirly jigs. All the testing is to build a low cost high output platform for all HAWT or VAWT and Hydro, and one that is geared to a supper high speed with a bar that is pushed or pulled to power the home or village by one person or horse or a bad stepchild. For the wind that is all up to the builder we are getting wind now at the tree tops. My water tower is working fine at 110 FT it gets from 10 MPH to 30 MPH 24/7. Here is it working you are looking at DC volts in to the Ginlong Grid Tie and about 12 to 15 MPH http://youtu.be/XjrocKrVTg4 Bob Mann Mann Smart Drive |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

interesting video Bob.....and the vawt looks really nice

now you have all the pieces of the puzzle in place you,l be able to show real world data from you tests ,which dont seem to involve roof mounting anymore (ground level) ..but are at considerable height ...(the water tower) in the video the ginlong should (i think) have been logging the watt hours produced during your 10/12mph windspeed run ....i not sure where those figures are stored but the menu section on the interface should call them up a regular tristar charge controller does this so i,d imagine the ginlong does the same this should reflect the swept area your using ....(Glens calculator link) "Wind Mills with out a good motor are just wirly jigs." interesting way of looking at it....i think i,d rather a 4m prop on an average motor ....  ...the motor costs cash ,the wind is free ...the motor costs cash ,the wind is free

looking foreward to the watt hour figures .... niall |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Hello I am testing at both sites we are working on the HAWT plate form today. so we can test the Mann Smart Drive at the water tower with the HAWT unit. The Tree Top one is shielded by the back trees I am waiting for some one to top all of them. I will test with 9 blades first this is a old pic I have add some upgrades to it. |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

Bob just one more thing to consider...... your working with very high voltage ....those Missouri wind and solar blades might run up a bit ,....but theres potential in that alt setup for using much more powerful faster blades....(everyone likes to experiment...its human nature ) if for some reason the alt got into a RUN away situation i would,nt like to be close to it trying to shut it down ...or relying on someone else (a customer ) to do so.... once you go over 24v its a completely different ball game ....... niall |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Thank you on that I do have a volt low and high adjustble limiter going to a dump on the AC 3 phase side I just need to test it and then install it . Here are some new pic of the upgrades it do has a sweep of 65 inchs Here is the adapter to bolt on my Smart Drive to a MWS unit. Here it is with the three bolt hole setup you can offset it to the left or right. Here is the Smart drive installed and locked down Here it is with the 6 blades I hope to install tomorrow at the 110 ft plateform. See I still have to pull it up by hand and assemble it by myself on a 16 inch beam. We still have 6 more blades if need to test. Bob Mann |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

i,m not sure how that works for you Bob.... here the power company insist (demand) that if your mill grid tie goes down (fails) for some reason you MUST have a certified backup over voltage cct to shut down the mill.....and they arent cheap who certifies your hv limiter Bob ? ...it is the grid after all...hv is pretty lethal...from an f&p or any other alt ps...Bob as to your claim to have the "the best pma in the world" for sale on ebay i hate to shatter your dreams but there's plenty of cheap pma,s on the net that will equal your 1k minute test on a drill press.... probably some will even exceed it but how they might survive running days on end at that power level is a different challenge...... as you seem to be cutting and pasting from forum to forum i thought you wouldnt mind me quoting you... True a windmill moving at 10 MPH is more for the buyer but some times the customer is always right niall |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

|

||||

| daveames Newbie Joined: 19/09/2009 Location: United StatesPosts: 30 |

Yikes! We know this was in good humor..Right?

Sure don't want some poor soul to think you are serious about a person or even a horse powering a home or village.

Fun and funny stuff! dave |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

There are places in the world that dream of just one night light to read with just trying to make that happen. He says he is using a 6 ft long bar with 30 LB of fource. Bob picture shows 9 100 watts lights bulbs also turned 15 100 wattt light bulbs yesterday

|

||||

| daveames Newbie Joined: 19/09/2009 Location: United StatesPosts: 30 |

Thanks Bob, I'm afraid your response has not cleared up the the real issue here. That is that the energy out of a system is ALWAYS equal to the energy into a system minus losses and no amount of arms, belts, chains, drives, elfs, fulcrums, gears, hope, inspiration, jigs, knowledge, levers, momentum, nickels, oil, plywood, quartz, ratios, sprockets, threats, ultimatums, voltage, whiskey, x-rays, youth, or zebras can change that. Just saying is all. dave |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Yeah I dont think they are 100 watt bulbs. That would be 900 watts, and the camera would close its aperture so nothing would be visible in the background. It would be near impossible to look at. Besides, a normal man is good for 100 to 150 watts for short durations. A athlete is good for 300 watts. To drive 900 watts you will need a horse. Not that it couldn't be done, but it would still take a horse to make that much power. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Glenn This is what the guy sent me after recived one of my Mann Smart Drives. He says he has a patten on the drive system. I still think a bad step child should be used to move it. Bob Mann |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

I think Lance Armstrong or a good marathon rider is good for 700w bursts , mabe it's a picture of Usain Bolt training in his back yard. Every time I read what BoB is trying to FLOG here on the forum it doesn't add up , we seem to be getting treated like Ebay Customers. Its almost degrading to the forum as well as I hear you are doing the same on multipul forums . You constantly get asked to give real data about your MANN SMART DRIVE , but fail to do so and instead show a Bridgeport Mill driving it into a grid tie inverter that would probably need the power curve set into it to load correctly, will it do the same in real conditions " SHOW US " And do you really expect poeple to believe that a the Guy has a Patent on what appeares to be a car rim supported by a couple of pieces of timber. Do you know the costs involved in Patent. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Bob. I think what Phill is trying to say is you need to listen to the people on this and other forums that are trying to point you in the right direction. There is some real expertise here and you are ignoring it. What you have built is a robust alternator that would suit a windmill of up to 500 watts, provided its coupled with a matching turbine. A set of blades 2.5 to 3 meters in diameter would work. The blades you have used above are famous for their noise and poor performance, too small and only good for 300 watts. Adding more blades wont help the peak power, it just gives better power in low winds, we're talking about under the 100 watt range of wind speeds. The peak power you achieved is very good, but not practical for several reasons as the forum members have pointed out. The RPM is too high to direct drive from a turbine big enough to drive it, so you need to use gearing. And you do need to take Naill's advise, the voltage is dangerously high and the windmill will be uncontrollable if there is a grid failure. Daves comments about the system losses are also being ignored. The fact is the person driving that device is only good for 100 watts continous duty, therefore YOU CAN NEVER GET ANY MORE THAN 100 WATTS OUT! NEVER. If he tells you he is getting 900 watts, with his patented system, he is lying to you. As I've said before, nothing personal, your workmanship is good, but you are lacking some basic scientific understanding. Listen to the forum members, they are only trying to help you. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

I think what Phill is trying to say is you need to listen to the people on this and other forums that are trying to point you in the right direction. There is some real expertise here and you are ignoring it. What you have built is a robust alternator that would suit a windmill of up to 500 watts, provided its coupled with a matching turbine. A set of blades 2.5 to 3 meters in diameter would work. I have been on the hunt for the best blade as for a VAWT and the HAWT famly The blades you have used above are famous for their noise and poor performance, too small and only good for 300 watts. Adding more blades wont help the peak power, it just gives better power in low winds, we're talking about under the 100 watt range of wind speeds. We have moved up to a 8 ft lenx2 blade by bolting 2 sets together The peak power you achieved is very good, but not practical for several reasons as the forum members have pointed out. The RPM is too high to direct drive from a turbine big enough to drive it, so you need to use gearing. And you do need to take Naill's advise, the voltage is dangerously high and the windmill will be uncontrollable if there is a grid failure.Please I have all this controlls in place. For how I tested my motor you would call it a Dyno load test. See I had my first race engine Dyno at 18 years old and ran the first Supper Flow head bench in the USA at 15 my famly was a leader in cylnder head devepment for Yamaha, Chevy, Ford and hold many world firsts in power and speed records. My late dad Dick Mann was friends with the likes of Smokey Yunick,Wood Brothers,Holman and Moody .While most were playing in your sand boxs I was handing wrencks to some of the Great race engine builders of the times Daves comments about the system losses are also being ignored. The fact is the person driving that device is only good for 100 watts continous duty, therefore YOU CAN NEVER GET ANY MORE THAN 100 WATTS OUT! NEVER. If he tells you he is getting 900 watts, with his patented system, he is lying to you. Having a closed mind is not helthie this person is running his tests I just posted the pic and what he said I do not think he is lying time will tell As I've said before, nothing personal, your workmanship is good, but you are lacking some basic scientific understanding. Listen to the forum members, they are only trying to help you. I understand alot and have learned so much here you your self said the Smart Drive would never make 500 WATTs I have showen it to go passed the 1000++ marker in real time The day we stop testing things around us and pushing forword is the day we all become sheep Glenn Bob Mann |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I have a couple of books by Smokey. I've also built a couple of Chev 350 engines and too many Datsun L series engines to count. So, to compare what you have done to the engine scene.... The guy driving 900 watts of bulbs by walking around is like dropping a bog standard Datsun 100hp motor into into a 2 ton pickup truck and telling everyone it did a 10 second quarter. Now you know from your own experience you would need closer to 1,000hp to do that, but this guys tells you he has built a special gearbox. Its just not possible. The F&P alternator peaking at 1150 watts is like a highly modified Chev running a big cam, ported heads, injection hat, that can pump out a dyno proven 800hp on methanol. Great, but you cant sell it to someone who wants to put it into his street car and use it for every day driving. Its not practical, he will never be able to use the power quoted. So yes you did manager to get 1150 watts out of a F&P, but not in a pratical RPM range or in a pratical circuit. Once you find a good set of blades, finish building the windmill, please include some form of furling, and do some field tests. That will give you an idea of how you should be rating the alternator. Remember if you over-rate it, and the buyer doesn't see the expected results, you can find yourself in deep water. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

i've read a book by Smokey Yunick, and a lot of articles from late 1960's hot rod magazines about him and his work. so far i've built/rebuilt a 55 international strait six a '65 international strait six two 1200 cc Honda civic motors a '67 Chevy 283 a 'mid 70's 350 chev with a cam and 2.02 intake heads right now i a have a Chev 350 four bolt main on my engine stand and I'm debating whether or not to destoke it down to a 327 cid with a crank from a 307chev engine. (same journal dia. as a 350) i want to mate it to an air research turbo that came from an '82 turbo transam 301 cid. the turbo has been completely rebuilt by a professional turbo rebuild company . and is sitting on my shelf. i know i will need to install a new cam with zero valve overlap in order to run with a positive manifold pressure. but i don't want to get boost pressure too early. the 350 is something very close to 16% larger than the original 301. a 327 would be very close to 8.5% larger then the original 301. the original set up on the turbo transam started getting boost at about 4000rpm. using a larger displacement engine will give me boost at a lower rpm but i'm not sure at what rpm it will start. any ideas guys? oh yea, bob, your blowing smoke at people who have been at this a lot longer than you and it's disrespectful . in your first YouTube video, you claimed that wing design was your own design and i called you on it. you are smart enough to realize we all know the design is by ed lenz and you at least acknowledge that now. i consider ed a friend and teacher. he has no problem with people using his design for private use but has stated often that anyone using the lenz2 design commercially needs to come to an arrangement with him. i will be checking with him to see it you have done that. so now you have appropriated the fisher&paykel motor as an alternator and given it your name. what ever. personaly i think that by replacing the ceramic mags with neo's your just saturating the iron,increasing the start up torque required to break it free and increasing the cogging but that's your business. i have no problem with you going into the windmill manufacturing business. good luck with it . you seem like a natural born salesman. but you are in danger of coming across like some sort of flimflam man and the wind industry is already full of those. is that what you want? |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

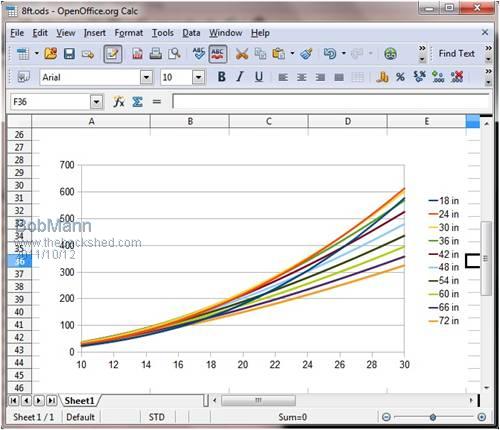

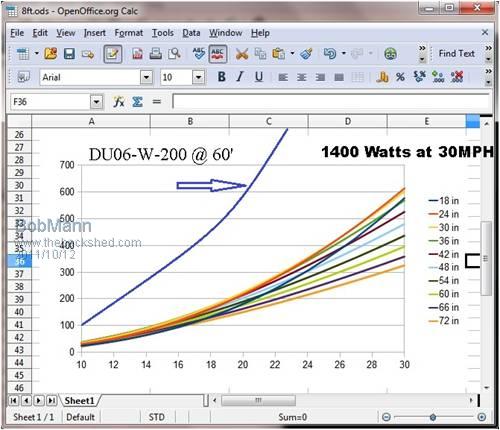

So yes you did manager to get 1150 watts out of a F&P, but not in a pratical RPM range or in a pratical circuit. Once you find a good set of blades, finish building the windmill, please include some form of furling, and do some field tests. That will give you an idea of how you should be rating the alternator. Remember if you over-rate it, and the buyer doesn't see the expected results, you can find yourself in deep water. Glenn Glenn we all now 600 RPM is not that high of a RPM. You know I still had not plotted the Ginlong so I was still leaving some on the table. All alt builders in the world test the same way. They spin them up they load them up and read the numbers. All I say to those that bitch is put your oun alt in a lathe,drill press, hook it up a gasoline motor to it and do the same test and post it. The only one was Bob from down Under. Now for price point I would like very much to know what you get for one of your 1000 Watt axle flux units and a real count on man hours to build. They are a work of art by the way. My unit was a test to see if some one could build a low cost high powered ALT that would last a life time and use unskilled workers to assemble any were in the world. I will brake down my cost here for a basic unit. 60 Stator $65 USD Drum kit $60 USD axle shaft $25 USD mounting $20 USD plate for shaft to hold stator 38 Neo Magnets $75 USD cost of parts $245 USD Time 3 HR to assemble We all know I will need big wings to get up to the full power of the Mann Smart Drive. I just assembled the 8 ft lenx setup on my tree for testing Here are our chart for a 8 ft at 36 inch Lenx blade with this ALT by the way my blades make no noise.

I feel the fix is a DU06_W_200 Lift at 8 ft 60 inchs Here is a power chart for the new blade I had to add the overlay.

These charts were done by Steve at www.vawts.net His math is as close to real world as you can get. So do I build the new test blade you said it. The F&P alternator peaking at 1150 watts is like a highly modified Chev running a big cam, ported heads, injection hat, that can pump out a dyno proven 800hp on methanol. Great with the old blades. Or run this my brother and I were hired to convert this to run on CNG to power a 1MEG WATT genarator some were in the world. I allways say go big or go home.

I will post the out come with the new blades when they are done we have not had any wind for a week. Bob Mann |

||||