|

|

Forum Index : Windmills : Yet another axial

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Today I made a coil winder. Printed out the cad drawing and glued to some 9mm MDF.

Cut out and holes drilled in the coil formers.

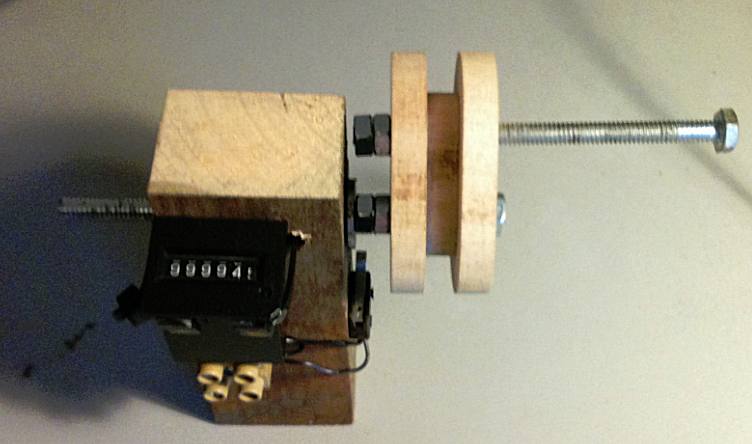

And this is my throw together coil winding jig with counter.

The counted was from a photo copier I junked years ago, its trigged by a microswitch as the coil former rotates around. I intend to apply epoxy to the coils as I wind them, so ideally I should make 12 formers, one for each coil, so I can wind them all in one hit and then give them time to set. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hmm, looks like the automatic image resizing code is broken after transfering the web site. Better fix that.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thats better. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| shawn Senior Member Joined: 30/03/2010 Location: New ZealandPosts: 210 |

Glen even after lots of relese wax or grease whatever you use, the set coil is hard to take off the centre part of your winder what I found worked best was about 4 turns of electric tape the cheap stuff around it first, this gave me the movement after it was set and it came off easy without distorting or wreaking my winder centre. I replaced the tape for each coil. Hope this makes sence. shawn |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thats a good tip Shawn, I'll use that. Thanks. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Glen, Everything is looking very professional from the start,don't feel the pressure,but we are exspecting great results!All the best Rastus see Rastus graduate advise generously |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Today I picked up the lasercut steel bits. Pretty happy with the quality and price. Using the magnet template I made earlier, I fitted the magnets to the steel plates. I think the magnet template is a good idea. It was just like putting round pegs into round holes. Add a drop of superglue and drop the magnet in, I didn't have to worry about positioning the magnets, the only thing I had to think about was which pole, N or S. The template was about 8mm above the steel plates, so I could blow down each hole to clear out any dist or wood fibres before dropping in the magnet. Next up I need to make the bearing. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| shawn Senior Member Joined: 30/03/2010 Location: New ZealandPosts: 210 |

That looks like it will cool very well almost a fan going around the stattor it will be interesting how hard you could run it before it heats up,got a tractor pto handy or ??? |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

More progress today. Bought a couple of 6205 bearings to make up the bearing hub. Machined the center tube, fitted and welded the flanges, and put back in the lathe to bore out the bearing holes and true up the face where the magnet plates bolts on. It was a struggle for the little lathe, but it got there in the end.

Finished and painted. Paint is good for hiding bad welding

Then a mock assembly. It drew blood, the magnets might be ceramic but they can still pinch

Tomorrow I'll wind up a test coil and see if I can get some figures. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Nice work Glenn, interesting to see your 'adaption' of a drill chuck to serve as a live center  Klaus |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Glenn, Just noticed I've been mis-spelling your name,my mistake  Your mill is progressing very nicely and like Murphy Law no job is complete without a little "Blood sweat and Tears".You're right I can't see the welding at all,but my guess is that the paint isn't the only thing holding it together!Cheers Rastus Your mill is progressing very nicely and like Murphy Law no job is complete without a little "Blood sweat and Tears".You're right I can't see the welding at all,but my guess is that the paint isn't the only thing holding it together!Cheers Rastussee Rastus graduate advise generously |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Glenn "it drew blood"...potential there ...

very few axial builds with ferrites out there ...sounds interesting the mags look much bigger when installed "in the flesh" niall |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn Looking good nice job, should be plenty of cooling with the open design. If you need a bigger lathe to do anything I am just a coffee stop away, you are welcome any time. All the best Bob Foolin Around |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Hi Glenn Just wanted to let you know...Looks very profesional, perfect fit on the flanges to the bearings, was that bore already cut for you or did you have to use you'r lathe for the final bore size? I am very interested with this project. Thanks for shareing this. ...Mac46 I'm just a farmer |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Made a test coil yesterday. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Dont you hate it when you click Post instead of Preview

Anyway, made a test coil. 25 turns on a former. Fitted a waterpump pulley to the front of the alternator, then rigged up my little lathe and a loop of rubber cut from a old bike inner tube to drive the alternator. Took a heap of measurements at different magnet gaps, from 9mm to 27mm. Interesting results, will post once I do all the maths, and get a little help from the guru. One thing I noticed was the test coil position is important, I get very different readings when the coil is closer to one side, or in the middle. The photo below shows the coil close to the front magnet plate, 18mm magnet spacing. In this postion I was reading 1.54Vp-p, and when it was mounted in the middle, I read 1.39Vp-p Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Hi Glenn,, just Curious whether this would effect Inductance? (from page 2). Try it with a single Mag, would be interesting to see how much effect the 2 mags have on the field pattern. Good looking work Glenn. -----Cheers, Roe Edit; If the're not glued permanently Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Hi Glen, I was looking through you'r posts and I see that you bored the inner pipe, sorry for bothering you with a repeat. Why does it have unequaled output when you tighten the clearance to one side? and how much does this effect the sine wave pattern? Most exellant work Glen, ...Mac46 I'm just a farmer |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Hi Glen, or maybe place a second coil next to the existing one.The same positive effect might occur in it also and if so pot two separate coils side by side all the way around and configure connections for best output. Anthony "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Jarbar. Sounds like an Idea ! Maybe a longer coil with fewer layers to take up the space. Glenn After reviewing your photos it may have more to do with flux path than distortion It is possible that the forward magnet plate having more steel ,(Hub etc.) is a better magnetic path.----- Cheers, Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||