|

|

Forum Index : Other Stuff : GS Heat Pump

| Author | Message | ||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Thanks. The place is moderately large at around 8,800 sq ft (88 squares). The photos above were taken during construction back in 2004 - we've been living here for 5 years now :) There are/were some technical issues with approvals and permits and plumbing compliance etc - typical inept government types and regulations without knowledge etc. Because the two 2000 litre hot-water storage tanks were "uncontrolled heat source", nobody would touch the heatpump or solar input side, and if I did it myself I couldn't get the compliance paperwork required in order to occupy the place. The cost of the heatpump units was another major shock - a ordinary, mass-produced airconditioner with inverter-driven compressor was around $1100. Similar sized water-to-water heatpump units, without the nice inverter-drive were ten times that price, plus freight!! Talk about "price gouging"! So, I've resolved to wait until either (a) there are enough people wanting them to drive production up and prices down, or (b) I get enough time/interest to make one myself. My latest plans for world domination, are to make a heatpump unit, and to use the outside loops for heat in winter, and a second "heat exchanger" in the ceiling for summer - suck heat out of the house, condense water to reduce humidity, and create the hot water we need for showers, washing etc. Its all just time and money really. Pity I have little of either. |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

RossW You do have a summertime problem with the pipes in the floor, cold water flowing through would condense humidity for a very wet floor. As you stated, A separate system is needed for the cooling phase. If you have a central duct system for ventilation this would be best for cooling. it would eliminate the drip from cold water pipes in the attic/ceeling, even when Insulated Moisture still condenses and air seems to get inside next to the bare metal / Plastic somehow. A water to air Heat exchanger at the circulating pump, around 10 gallons per minute for your size House (Guessing )and a good size squirrel cage blower to move lots of Air. -- Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Some Trivia relative to this subject. The city of Brisbane according to a chart of world ground water temperatures is 72 deg. F. Melbourne is 59, Adelaide 64, Canberra, Perth, and Sydney at 67. This was the only cities listed for Au. For curiosity sake I looked for the coldest place on earth average that is not permafrost. Regina Saskatchewan Canada at 39 Deg. F. 4-5C. That's a cold drink of water! The warmest is Bangkok, Thailand at 85 Deg.F. This info came from the link below on page 36 of 70. A good pdf. on Ground source and Geothermal Its a big one with lots of good stuff. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi greenbelt Thanks for the link, it is very informative. All the best Bob Foolin Around |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

I've forgotten about heating -cooling is my issue. I've started painting the gal roof white and I took on an idea to use bubble wrap on windows to improve their thermal performance. Surprisingly it works well -I had a pool room which was HOT and with a shade on the outside and the bubble wrap on 3/4 of the glass i'ts now a usable room.' with temps of 35, 36, 37 tomorrow and overnight low of 25, i'm screwed its another run of 50-60KW/hrs a day for two days (1st day i get away with) Good new is nanny for the kids is on board and avoids the aircon from 11-3pm most days giving me 15KW/hrs to the grid $7 which pays for 35KW later in fact my last bill with plenty of AC i'm still in the black $400. giggling :) Luck favours the well prepared |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Time to break out the old technology. Thought about whitewash? Historically, it was applied at the start of summer. Reflects the sun, also (on windows) blocks the entry of a lot of the light, keeping homes, glasshouses and so on oh so much cooler. Come the end of summer when the rain starts, the whitewash washes off and you have the extra heat and light for winter when you need it :) |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

This was November at 16F. -9C. Its been warmer since,

-1C. expected tonight possible Snow early morning, High tomorrow Near 6C. Not Bad. Be Happy you're Warm. Keep the Beer Cold and all is well. Karl, Good Idea On The Bubble Wrap. And Ross I know The Whitewash does work, That is to Say a Good deal better than Black. Old technology is reliable because it is Time Tested. Thanks for the Comments ----Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

[Quote=Greenbelt] And Ross I know The Whitewash does work, That is to Say a Good deal better than Black. Hi, Roe. Not sure I understand what you're saying here. Is there such a thing as "blackwash"? If there is, Washington D.C could stand a dose!

. . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Pump Test, The circulating pump for my Ground Loop Was in My eyes, and others,a bit anemic for the job, I was hoping to use it because of the low power requirement (110 Watts), It's also a magnetic drive which means that the water impeller is isolated from the motor and is driven by magnetic coupling through a sealed wall. No seals to leak water into the motor. this pump should have a very long service life. the motor side is also oil filled. I paid $50,oo for it, a new one of this size is well over $200.oo . Another feature is that the motor can run against a high head without heating, Its magnetic clutch effect just slips allowing the motor to run at full speed while the impeller runs at the rated head, in this case, 14 Ft. 4M. Kind of low which was the cause of concern for suitability. It appears to be OK as the measured flow through the system was 2.3 US Gallons,8.7 liters. per minute. A couple Pic's of the test.

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

The magnetic-coupled pumps are great. I love 'em for this sort of application. As for the power requirement - it seems a lot of people don't quite understand the concept of a circulating pump. In a closed loop, with no air, you can pump water 100 metres straight up with just a sniff of power. .... as long as it comes back down again! And if it's a circulating pump, it has to come back down in order to circulate right?? Pumping water 200m down a hole, then back UP doesn't require a decent pump as long as it's all a closed loop. All the circulating pump need overcome is the friction losses, and that's a function of length of pipe, it's diameter, its internal surface, and the flow rate. If you have 3/4" pipe (looks roughly what you have in those pics, perhaps 1"), a 100W pump will move plenty of water over a few hundred metres. My circulating pump for my genset pushes water 80 metres, at up to 60 litres/minute, with a pump that takes around 60 watts. (around 13 gallons/minute) |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

DUH!! Experimenting with Refrigerant Machinery is a technical business, many times we see the pressure- temperature chart and wonder what is the meaning of this? It is clear that this is an important part of designing a refrigeration system but it becomes a fog of confusion with all the mathematics used to arrive at the solution. When the Designer has finished all the math and presents it on the page with a comment, "This shows that R-717 is best suited for this application" ???. well perhaps it does., couldn't prove it by Me. Sometimes a concept that is difficult to grasp can be explained in simple terms making the mystery disappear and a understanding of what is needed to carry on. I will try to do this here for those who are interested in working with this equipment. There are many here like myself who do not have college math to work out the formulas. We are forced to make it work first, then tune it up. Keep this in mind.,,,, Refrigerants are hazardous in many ways, some are explosive . some very toxic. Don't use the old class refrigerants such as ammonia (R-717). and sulphur based, Be careful of high pressure and the freeze burn hazards of all refrigerants. Remember also, 220 volts on a compressor or a starting capacitor is a killer.always disconnect the power and short circuit the capacitor terminals before messing with circuit boards. My reference to automobiles is the most common link with people who tinker. I would appreciate any comment about this post, like, too windy, confusing , difficult to read, informative, boring, etc.. Please no mention of my punctuation, I know its terrible. This beginning is very elementary ,,,,start of all knowledge. Warning,,, The following may not be the way it really is but this is my perspective, Hope it is useful for some of You. Be Careful. Pressure - A boiling pot on the stove is covered with a tight fitting lid, the lid is bouncing up and down letting out puffs of steam called vapor, (steam is not visible only vapor can be seen) This statement is the most important thing about the workings of a refrigerant, All documents refer to vapor pressure, not gas pressure. Something about Vapor,, Vapor is a Gas that has reached its Dew Point temperature, and appears to be fog but is not yet a liquid or a gas like air or steam, it is billions of tiny droplets in an atmosphere of refrigerant gas, at this stage the vapor can just as easily become a liquid, by chilling it a bit or a slight increase in pressure, or it can become a gas by adding heat or reducing the pressure. Now get this! At one degree cooler than boiling temperature the Vapor begins to store heat refusing to allow any further change in temperature. it will continue to store heat until its chemical nature can no longer hold any more,(Saturated Vapor), This is Called "Latent Heat"* At this point Vapor begins changing to a Gas form. (Like Air). Something about Temperature,,Heat and cold are human concepts to temperature, the elements in the universe are not tied to the way we "feel" about cold or hot., -50deg.C. is only cold to humans and animals. Cold is minus 459 deg.F anything with a higher temp. contains heat. Hydrogen itself is frozen at this temp. referred to as absolute( 0.) Propane is a Refrigerant but dangerous, a leak can cause fire and explosions. If we pour out a can of propane anywhere in the world except the polar regions it will boil away rapidly forming great clouds of vapor and disappearing as a gas.leaving a very frosted area where it boiled away. Now this brings us back to pressure. The pot lid is holding a small pressure inside the boiling pot , we know something must be done soon or the pot will boil over, We don't know why we do this but we remove the lid as if it will cool the fire or? We see the foam and high boil drop to a lower level and all is well. You have allowed the vapor to flash into steam carrying the excess heat away, The Fire can now generate steam at lower pressure allowing more evaporation that will carry off more heat than before. This is what the Compressor does, (suction side)it lowers the pressure in the pot,(evaporator) so that more refrigerant will vaporize collecting more heat as it does so. Consider the fire putting heat into the pot,it must heat the water to 212deg.F/100C. to make vapor at simmer, when more heat is added the water boils furiously but its Temperature is still 212/100 Deg. An old problem with auto's was overheating, steam pressure blowing the water out of the Radiator. well, the Radiator has been equipped with a pressure cap to increase the pressure on the water, under extra pressure the water cannot boil at 100Deg.C. its usually 230 deg.F. on the temp gauge. Today autos rarely overheat because of the loss of coolant. The fire adding heat to the evaporator is the air passing over the fins and tubes on the evaporator, In the case of a ground source heat pump operating at a temp. of 1C. /33 F. in the evaporator and the refrigerant is boiling at -30F. this is 63 deg. over the boiling point, we could say That's Hot. The flowing water from the ground loop must be adequate to collect enough ground heat to maintain the evaporator at 33 Deg.F. If it can not, the evaporator will become extremely cold, the pressure will drop, vapor will turn to a Gas, efficiency will drop, this is what happens to air to air source heat pumps when the temp nears the 7C.mark, ice forms on the evaporator and stops the air flow through the tubes and fins. No Heat, No vapor. The propane (LPG) is contained and can only boil off enough gas to keep the cylinder inside pressure at (normal for the ambient temperature,) its pressure is arround 100 psi in normal temps. This is called Vapor Pressure. When the liquid level of propane is near the bottom of the tank and the room temp. has remained the same the pressure inside will not change All we need to do to change the behavior of the propane tank is to move it to Antarctica, in winter where the outside temp is -42 deg.F./- 41C. Here we can open the valve to a full tank and nothing comes out until you tip it over and pour it out. vapor pressure is near 0, So Heat and pressure determines the boiling point of liquids. The Boiling temperature of Water, is 32deg.F., 0 deg.C. if the pressure is reduced to 0.080 pound per square inch.(absolute)( Near Vacuum,) The same as its normal freezing temperature at sea level pressure. This shows that a liquid contained cannot boil, except to replace the gas that has been removed, when the pressure matches the temperature /pressure balance, no more boiling takes place, If heat is added it will continue to heat like a piece of metal, not Latent heat, The heat will vaporize enough liquid to keep a balance of the P/T and the pressure will continue to rise. On the other hand if the tank is cooled by any means, a proportional amount of gas will condense to a liquid inside the tank which lowers the pressure to the P/T Balance, As noted above, if temp. is lowered to -42F.deg. there would be no pressure. ( there are Limits) Called Critical Limit, The Refrigerant Cycle; Visualize a system of two heat exchangers, Like Auto Radiators, connected together by a very small Tube, The tube is connected at the top of one, and to the bottom of the other. The one with the bottom connection we call the condenser, This is the one that contains the liquid refrigerant, (when the System is operating) It is a hot liquid because it has been compressed to high pressure and cannot hold the latent heat that it stored as a vapor, a fan is forcing air through the fins of the radiator removing the latent heat.* as the heat is removed the vapor begins to condense (becomes a liquid), the hot liquid continues to cool as it travels through the coils of the condenser. Cannot boil at its present contained pressure. The Compressor; The Compressor is connected to both radiators. The large tubing is the suction side connected to the Evaporator, The Compressor output goes to the condenser through a smaller tube that contains the compressed Vapor. This tube is now hot, because the vapor contains more heat than this pressure will allow so it is giving up its heat to the tubing. This is why a Heat pump should have the Tubing insulated to prevent the loss of heat until it reaches the condenser which is inside the House where the heat is needed. The small tubing that connects the bottom of the condenser to the top of the evaporator, (other Radiator), is called a capillary . or sometimes Its a pressure/Temperature sensitive valve (Expansion Valve) and is used to control the flow of liquid refrigerant to the evaporator. Once the liquid escapes this very small port, (something similar to a carburetor Jet) it is in a low pressure zone created by the suction side of the compressor, the pressure here is 3 to 4 times less than inside the condenser, also the temperature is far above its boiling point at this pressure, it begins to vaporize as it stores heat from the metal evaporator which also has a fan blowing air across its fins. This evaporator is cold to the human touch because its heat has been absorbed by the expanding vapor. The compressor Gobbles up this vapor while it is still dense, (Not a Gas) and quickly compresses it back to its liquid form causing it to give up the Latent Heat to the condenser. Your Home refrigerator will be hot on its back side. The Liquid to Vapor and Vapor to Liquid is called (change of state) The Vapor state contains almost as much Latent heat * as the Gas state, but its volume is much less which allows the compressor to move a lot more refrigerant than it could if moving Gas. This is why the evaporator must have a system to control the pressure when the temperature changes (ambient air over the Fins) Or Vapor is formed when the temperature is at the boiling point for the amount of pressure acting on it. again, If the temperature is increased then the pressure must increase to a new boiling point.to preserve the conditions for creating Vapor . If the higher Temp is not compensated , some of the Vapor will flash to gas causing a loss of efficiency.(superheated) Just like a carburetor on an engine this evaporator needs adjusted continuously to produce 85% vapor 15% Gas to make sure the compressor does not receive any liquid. This 15% is called Superheat in the technical manuals. In some cases 10% may be acceptable. The trick is to Have a compressor to fit the load BTU. and a system large enough to have the required surface area of the heat exchangers and a means to adjust the amount of pressure in the evaporator. If the compressor can't remove the quantity of vapor that is being produced then the Evaporator pressure will climb to the point where no evaporation will take place. (Cannot Boil) and Liquid may enter the compressor which will quickly destroy it. If the compressor is starving for vapor it will be compressing gas instead of vapor and may overheat as well, loosing 80% of its efficiency. Note, The Vapor cools the motor winding in a sealed compressor unit as it passes through by flashing a small percentage into Gas. This makes the Compressor more efficient because its heat becomes a part of the output. The Evaporator pressure is always changing due to the daily changes in ambient air temperature. High temperature High Pressure. and vise versa. A temperature sensitive pressure valve (Expansion Valve) is a very necessary piece of hardware to make your system reliable. In the next post I will use a pressure temperature Chart to set up an example. * Latent Heat is usually expressed in BTU's per pound or kilogram of refrigerant. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi greenbelt That blew a few cobwebs out of the hair support, by the way I have used LPG quite a few times in non location critical locations, from memory it was much the same as R22. Many years ago the house next door burnt down and as I watched from a safe distance the 20 lb LPG bottle on the veranda venting with a plume of flame while the bottle in the fire had ice on it, I still have the bottle in the shed as it never blew up as I expected, then it wasn't made in Hollywood. Nice to see the little pump work so well, there is one like that on my solar HWS and they are very reliable. All the best Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

HI Bob; Thanks for the comeback. I once saw the remains of an Acetylene bottle that was is a fire, it was nearly a flat piece of sheet metal after exploding and passing through the roof of the tool shed. Heat from the fire over pressured the contents and split the Tank. It was found about 130 meters away, its passage through the roof was nearly straight up from where it sat. No tellin how high that thing went. Yes, I was fortunate the little pump can pull the grade. It can run all day and night for about 20 Cents. If all other factors preform as expected it will run about 45% of the time in winter to keep my (2) 60 gallon tanks warm, about 9 cents a day. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

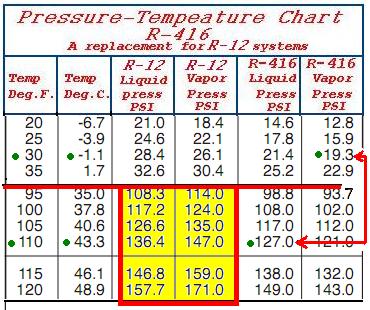

A simple Pressure/Temperature Chart. I fabricated this chart using Info from a P/T chart published by a refrigerant mfr.. Airgas Refrigerants Inc. Long island city NY.USA. (Glen, If illegal advertising, "snuff it out" Just giving credit for the Info.) I have removed the center section of values and posted only the data that I will be looking at. Note, " Blind to the Obvious" I discovered that some of the numbers in this Press-Temp chart for R-12 (Yellow Box) seem to have been put in the wrong box , (reversed) the vapor pressure should be lower than liquid pressure, makes one wonder if the any of the numbers are correct. Of the many errors in this post, this one came AS IS. ( I am not up to speed on metric pressure units, Kilograms Sq. m.. so will use pound/inch units.) . The Fat Red line with arrow points show the planned operating pressure for the evaporator and the final compressor pressure at the condenser. The big green dots mark the numbers I have chosen, Just how close I can get remains to be seen ??. This shows the Vapor pressure at -1.1 degC, 30 F. at 19.3 pounds square inch. The condenser temp will be at 43.3 degC, 110 F. the condensing pressure needed to liquefy this Vapor at this temp. with this specific Refrigerant R-416 is, 127-to 141 psi. depending on the source of the Pressure/Temp chart. The Compressor will have to increase the system pressure by (127 - 19.3) = 107.7 psi. The numbers here are important in selecting a refrigerant, the smaller the difference between the numbers the better the refrigerant is.in this respect. however some refrigerants may be easy to pump, but it may be that its ability to hold Latent heat is much less which means you must pump more for the capacity you need requiring a larger pump and bigger motor (can't Win) I selected R-416 for this example because it is listed as a retrofit for R-12 Freon systems, it is supposed to be compatible with the freon type lubricants . it has the very lowest environmental pollution index, the price is affordable and it has other desirable qualities, Non toxic, Non flammable, good stability Low condenser pressure makes it easier on the Compressor. and it is not necessary to change the R-12 system for proper operation, ASHRAE and EPA approved for domestic and auto use. No License required to purchase (must be ADULT to receive shipment ) In the U-states. There are 2 other refrigerants I have some interest in, R-401A.for one, At the heat pump condensing temperature of - 110-115 Deg.F./44C . the discharge pressure of 401 is near R-22 pressures. which is a better match for my compressor. I just don 't like its Recipe much. It would have more capacity than the 416 but not more efficient power wise. Propane has been known as R-290 forever, but some of the profiteers in the green crusade have adopted a new name ,, I suppose they are hopeful the new generation has never heard of it ?, and it is sold as ES22. no where on their Web page is the name propane spelled out [ http://www.autorefrigerants.com/22a.htm] I found out later that , R-22A is also propane/butane mix, The Warnings of combustible potential are displayed but Low Key. Propane is an excellent Refrigerant , performance is 98 % of R-22 in most all applications , best of all it does not pollute the Ozone layer or affect Global warming -------until it catches fire, Then it becomes a contributor to the green house effect by forming Carbon Dioxide. Your Dwelling may also contribute to the greenhouse Blanket. It Has been suggested that propane could be used in a remote location, Say 20 meters or so away from barns or buildings in some protected shelter, A dog House? for the equipment. Use a heat exchanger as a condenser to pass heat to a water system with insulated pipe to carry the hot water to the house where it would pass through a radiator (finned coil) with a fan to force air through the home heat ducts. doesn't sound very efficient. Enthalpy; This is an engineer hatched method to calculate the horsepower and or power requirements for the system they are designing. Its value is specified in BTU's, If a pound of refrigerant Vapor contains,X any number of BTU's. it will require a quantity of energy to compress the vapor to the condensing pressure. this is the energy you pay for when you pay the power bill. Enthalpy is different for different refrigerants because the (densities are different, Say, like petrol and motor oil ), A heavy substance may have a heavy Vapor and be capable of holding a great amount of Latent Heat. it most likely will take a high torque compressor to do this job. It may also be a bad choice refrigerant. This energy shows up as heat in the liquid refrigerant after the vapor condenses, So as a heat pump it contributes to the output. The liquid to vapor/Gas phase is powered by the low pressure in the evaporator also supplied by the compressor. BTU= British Thermal Unit, 1-btu is the heat required to raise the temperature of 1- pound of water 1 degree .Fahrenheit. Latent heat -The quantity of heat absorbed or released by a substance undergoing a change of state, such as ice changing to water or water to steam, This is going far beyond my intention when I begin this post, If we use equipment that already exists and keep the physical sizes of the components matching the original ones it should be functional enough to tune it up. More later when I get something built. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

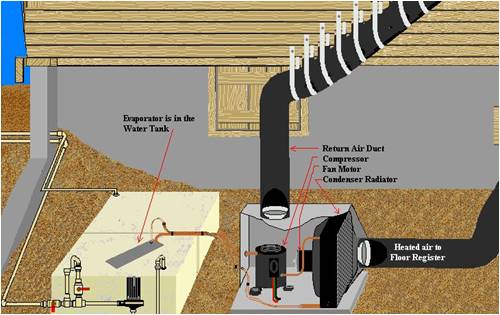

OK, Time for an Update. I have had a Month of following my old tracks,fixing things I should have done right the first time. My Well Pump Pressure Switch Give Up with burned contact points. The motor start Capacitor Had a trail of electron Blood Stain across its Terminals. The Sewage disposal pipe line plugged up, Had a very aromatic job getting it open, Thr clothes Dryer Fan wheel came off the motor shaft, Plastic Hub wallowed out. The second Day after fixing the well pump, I came home from Town to find, No Water, I took the flashlight, torch,? It was coming Dark, went to check it out. Two Days the pump worked fine with one wire not connected to the pressure switch. I first checked all the Screws to make sure I had tightened them, all were tight, I checked to see if a wire had pulled out of its terminal, when I moved the wire with my screw driver the whole thing, terminal and all came out of hiding underneath the connector Bar. It had only been touching. Eyes getting Bad. I have worked some on the project, got the Tanks connected and located in the crawl space, Have the water pipes passing through the Foundation Wall 2 feet under ground. Ran the pump for 2 hours, and lost about 30 gallons of water. the Whole Pipe system holds less than 20 gallons. This Pic will show what I'm doing now. The leak is not in the lead in ditch as I had hoped it would be. O well,

I will build in an air filter( not shown )

May have to Buy new Pipe and make new Ditches, Summer's Coming soon. Cheers! Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Roe Murphy is alive and well in the USA as well. Sounds like my place spend a lot of time fixing things. All the best Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Here's what I've done between rain showers, Weatherman says 4 more days of steady sprinkles and showers. I had some ABS pipe laying around that was intended to be a part of my septic Tank system drain field (County Building Codes Require a pressure system for liquid distribution). I bought the ABS for this but County said Code specifies PVC. So now it becomes a part of my system, I realize the wall thickness will hinder the conduction of heat but it has the advantage of a large surface area. I figured the extra water (11 Gallons US.) more than the original system 91.3 pounds can store 1640 usable BTU. When the heat is turned down at night. this assumes that 18 degrees fht. of cooling is possible before freezing. My Ground Temperature is 50 Deg.fht. I have not tried to make it pretty, I'm more interested in bedding the pipe for protection from all the sharp edge rocks that will be piled on top of them. A couple of pic's to show the Mess I have made. The area to the left in the pic's is my drain field area so no digging here. I have been breaking bedrock to get the 100 feet I needed, lucky it is fractured even though I pulled several 300 pounders out, it was getting too tough to go further, I cut a little side wing to get a few more feet. Note The Pipe angled across the puddle is a support for my glue joint while it is drying, More Later...Roe

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Roe Big job mate just as well you have a back hoe, I would hate to try that by hand. Hope all is well this time. Bob Foolin Around |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Yea Bob, That would be a Samson only possibility. I doubt that a SUMO could toss one these rocks out of a five foot ditch not to mention getting it loose from the other jigsaw pieces of the bed rock.

The second pic is my work area where occupational activities have been put on hold until the structure returns to solid ground. The water is 9 inches deep and more.

Pic 3 is a vertical pipe with shut off valve to purge air from the system, this is the high point of the loop (on solid bed rock). The other high point is the holding Tank. I can purge that side by reversing the flow through the loop. when the trench is filled I will locate the valve beneath the surface in a large pipe with cover plate to prevent damage and freezing. over time this stand pipe will collect more air and will be easy to remove. This black pipe is lighter than water. and still partially floats when full. can't keep it on the ground!. The only place its under water is where it connects to the original loop pipes. I have the pump connected and system is filled, I run the pump for 2 hours, there was no water loss that I can detect, If it has a leak it is very small. Yes It's Still raining!! Cheers...Roe

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi greenbelt Looking at the composition of your soil/ rock mixture it might pay to lay the pipe in a sand bed to avoid contact with shards of rock that can wear through the plastic pipe in time due to slight movements in the pipe due to expansion and contraction with different temperatures, it is a monumental job to do again if that happens, the other thing I have used in the past is a mat thats used in landscaping to prevent weed growth, a layer of it under the pipe and over the top would help. It will reduce the thermal conductivity slightly but I don't feel it would be enough to worry. All the best Bob Foolin Around |

||||