|

|

Forum Index : Windmills : Windmill Project

| Author | Message | ||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

No need to take your ball and go home Mac. That wasn't a flame at all. Electrocution by AC or DC is like being hit by a car or attacked by a bear. They'll both kill you. Perry |

||||

| arklan Newbie Joined: 18/08/2010 Location: AustraliaPosts: 29 |

http://www.thebackshed.com/Windmill/assemblyMini1.asp this can be as complicated or as simple as u choose |

||||

| wind-pirate Senior Member Joined: 01/02/2007 Location: CanadaPosts: 101 |

Hi Guys Remember Mikes servoes? search this board for 97fishmt. Lots of info on his project. Ron THE Pirate. stealing wind & solar energy is fun |

||||

| isaiah Guru Joined: 25/12/2009 Location: United StatesPosts: 303 |

Look and see if the school has any old Copier's or those old large Typewriters, Printers not in use any more ?The motors May be small as 1.5 square or up to 3.5 inches. They could have permanent magnet motors in them which are dandy for mini mills . The pivot and tail can be very simple for these. We take the motor rpm and divide it by the volts of the motor then take this answer and multiply it by 15 and that will give you the rpm the motor has to turn to make 12 vdc charging rate. 2000 rpm divided by 200 volts= 10 x 15 =150 rpm for charging rate. If the tag is gone or not legible take a multi meter and check out the combinations.! If the school has a lathe you can make up a hub and blades can be made from pvc pipe of old spray cans. The spray cans can be a bit touchy as they are very sharp . I have one right now flying with blades 14.5 inches cut out of a piece of 10" pvc drain pipe. for a mini mill 4" and up should work. I cut mine out with a hand jig saw and file and sand them until they are the same weight.I use the balance type baby scales to get them the same.these mini mills do not require the strength of tower of the bigger turbines.If you want to be more creative you can take the solar panels out of old solar calculators and wire them up until you achieve charging voltage and tie this in with your mini mill to a battery bank. URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

||||

| daveames Newbie Joined: 19/09/2009 Location: United StatesPosts: 30 |

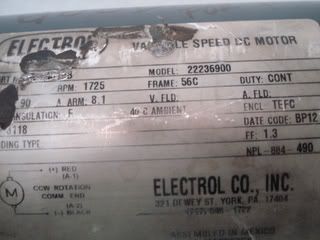

hi tech ed, sounds like you were hoping someone might point fingers and name names for something that might be usable for a working demo mill? took a quick look at some of the fleabay offerings for something that would fit the bill as a little 4 footer (1.3 meters) and ~100 watts? i'm always after a bargin and this one caught my eye. http://cgi.ebay.com/Electrol-22236900-Variable-speed-DC-Moto r-/350391934357?pt=LH_DefaultDomain_0&hash=item5194fc9d95

we see this one is rated 1725 rpm @ 90vdc from this we can get an idea of what it might do as a generator by finding the volts per revolution 90/1725=.052volt per rev we need 15 or so volts to start charging. so 15/.052=288 rpm of the mill..let's give ourselves a fudge factor of 10% and say we need to spin a little over 300rpm to reach "cut in" voltage. lots of guys around here can calculate a blade with a pencil..not me

we can cheat and use a nice online program by alton moore III. http://www.alton-moore.net/wind_calculations_english.php we see a four foot prop with a tsr of 5 (typical diy pvc blade) will reach a cut in speed of ~300rpm in about 8-10mph wind..just about right! here is a nice ac motor that is a ready made three phase alternator (it's like an inside out f&p motor) http://cgi.ebay.com/GE-ECM-X13-Motor-1-HP-230-VAC-7-6-Amps-L 013A9061314-New-/330470341964?pt=LH_DefaultDomain_0&hash =item4cf1913d4c&x=17&y=3 won't take too much reworking to run this as a 12v charging mill. bet it might even do ok stock with series caps. have you looked at some of the f&p mills the guys here have shared? you can get one here in the states from randys workshop. http://www.watchtv.net/~rburmeister/products.html if randy is out of stock, i have a new f&p kit here to buy or borrow. i live only minutes from you in southington. cheers, dave |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

It would seem Tech-Ed has not commented for some time so wonder if he is as keen as he first implied, and even still reading the forum? Pete. Sometimes it just works |

||||