|

|

Forum Index : Windmills : My new mill

| Author | Message | ||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Bob, I think you are providing apples and oranges data for windspeed and power. You have provided some maximum numbers from power measurements, but seem to be only giving low averages for the windspeeds. My owm measurements show that the wind gusts can be 2-2.5X the average. What you are presenting are peak results with averages. The peak windspeeds associated with the 3m/s could be as high as 8m/s. This could explain the numbers that you have quoted above. This is misleading and does little to show the power to be expected in particular winds. Windmill power data is usually presented at a constant windspeed, and not the peak power for an average windspeed. It is difficult to get constant windspeed in the real world, so the best we can get is measure at a reasonably fast sampling rate, windspeed, current and voltage etc, and use mathematical techniques to correlate the data and estimate performance. I await your logging data results. Accumulated daily kWh data comparisons will probably be the only way to really compare the windmill performance in lieu of some logged data. I am presently evaluating a PowerJack 1200W GTI. Initial testing has revealed that they do not MPPtrack a windmill. They seem to work OK on solar panels across a wide voltage range though. I will present some testing data elsewhere. Gordon. PS the dark sky looks ominous. become more energy aware |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Gordon The results where observations off the amp and volt meters and the wind speed was measured with a hand held anemometer on the roof close to the mill and it didn't go to 3Ms while I was watching it as I said there where gusts that went higher but I was in the shed watching the meters. I haven't hooked up the rpm multimeter to check the rpm yet as its on the other mill at the moment. The whole thing is just haywired together at the moment, I just hooked it up so the mill couldn't be up there unloaded. In saying that the output was much higher than I expected for the given wind speed indicating that the blade profile is working far better than I predicted using Alton calculation site. The only way to be sure is to get the logger going and show it as it is. Your comments on the logger in the other post got me thinking that I may have a earth loop problem as the laptop hasn't got a battery it is running on the power all the time. Next time the wind is up I will take a photo of the meters with the weather station wind speed going. Not really definitive but the best I can do at the moment until the logger is up and running. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

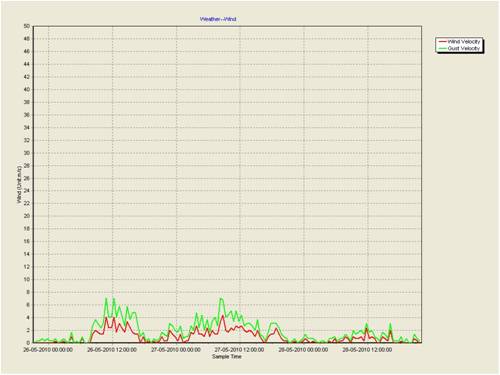

Hi Gordon Yes the gusts can be mutch higher, but without a instantanious reading ASI its difficult to get it accurate even the weather station has it limitation for responding to gusts

This is a graph of the type of wind experienced but not at the time I was talking about as I have to replace the battery in the roof top sender, got a battery yesterday but haven't fitted it yet. The wind speed here is higher than experienced when got those readings I think the last half of the graph is more representative of what I had when I took those readings. I have found the same thing with the GTI and partly overcome the problem by fitting a large capacitor bank across the input, on the 300 watt one I have a 330,000 uf 85 volt cap, and that makes it more stable but it needs to be larger capacity, on the 1200 watt one I plan to use a 3 farad cap out of a car woofer amp power supply. Without the caps they seem to go into a oscillation with the landing control. Without the caps the voltage can rise quicker than the inverter can synchronize as it is unloaded, it then goes into a overload and shuts down, then repeats the process, once it locks on to mains frequency it is better but gusts can cause it to over voltage and drop out. I think some of these new super caps would be ideal but their voltage rating isn't high enough yet. The MPPT circuit seems to have a power time constant more suited to Solar Panels. When using them on the batteries I have found that they need a bleed resistor to slowly charge the internal caps otherwise the inrush current destabilizes them and can blow the fuses. 470K 1 watt seems to work, not calculated, just tried it and it worked. Next time I go to Brisbane I will pick up a few big caps my friend has salvaged from s some old servers, not sure what size in capacity but they are very large. All the best Bob Foolin Around |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Bob, I think you will find a problem with your own measurements, rather than with Alton's calculator. Sorry, but The graph above is pretty hard to read! I have found the DAVIS anemometer responds well. I have the same unit on my weather station as my computer logger, and the units correlate well. Apples and apples. I will not elaborate any more on this thread, as it is detracting from your description of your windmill. <<Another place and time>> PS 10000uF65V caps are not to expensive, but sounds like the number will push the price into not viable. Too much capacitance and the windmill response will be impeded. The windmill has to be able to respond quickly to the windspeed changes to extract optimum power from it. I have much better results with an inductor, a mosfet, a diode, and a micro controller for a MPPTracker. Gordon. become more energy aware |

||||

| scoraigwind Newbie Joined: 23/09/2009 Location: United KingdomPosts: 21 |

I don't want to be rude, you guys but is this what you call a site for a wind turbine? Maybe go a bit higher above the tree tops? Hugh Piggott |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Hugh In Bob's defense, I think it boils down to working within one's means. You think Bob's site choice is silly, take a look at all the silly crap I've come up with! (click on my profile) For many of us here, the 4m is just a gathering place for show-'n-tell. I for one, would love to be as seriously into this endeavor as are you, but for me, as many, it's merely a passionate curiosity. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Hugh I am the first to agree it isn't ideal position from the east where the trees are, but it is convenient to work on, and later on I plan to make an extending tower that will take it 20 ft higher. From the south where the main winds come from it has a clear way to the dividing range also to the north, so its not ideal but usable. The trees to the east are going to be trimmed as they are leaning and at risk of falling over due to the wet weather and saturated ground. I realize that it doesn't look the part but it is 25 ft above the ground and when I get the logger to work I will post some accurate figures on its performance, as I have gone for bigger diameter blade to catch low winds where it is, I would have to go for smaller blades if mounted higher. As my signature suggests I am just Fooling Around for the fun of it,As Mack said this is our hobby not a serious venture, as if I want to do that I would mount a 10KW on a 100 ft tower in the clear portion of the block, however pension limitations along with health problems do limit my hobby somewhat. By the way, thanks for your work and research into wind power as that has been an inspiration to all of us. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Hugh Just to give you an idea of the clear passages for wind, this picture is looking south with the rand of hills in the distance is th part of the great dividing range on the New South Wales Queensland border.

This is the primary wind direction for fronts moving west to east. The next picture is to the north where the main heavy summer winds come from, mainly the north west from tropical storms and remains of cyclones.

The band of trees to the east is a pest but thats a work in progress. All the best Bob Foolin Around |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Man thats a lot of grass! Nice. Bet you dont use a push mower for that. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glen It sure keeps me out of mischief, there is 25 acres to mow, most times I do it with the rider mower, which I find relaxing, apart from the blisters on the bum from bouncing along on the plastic seat. I have an old tractor and slasher but spend more time fixing it than using it, not relaxing. All the best Bob Foolin Around |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Bob Get a goat to eat the grass and buy a small plane! That looks like it'd make a dandy runway.

. . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Mack Had a goat once but gave up on them as it liked camping on the roof of the car away from the wild dogs, bit hard on the roof and the paint, tried cows but they preferred my fruit trees to the grass so back to the mower. Got a few kangaroos and wallabies rabbits and hares but they don't eat much. I have several small planes and a big one belonging to a friend parked here too, it was done as a runway twenty years ago as we had a pilots training school here, but my friend who was the chief flying instructor had a heart attack so that was the end of that. All the best Bob Foolin Around |

||||

| isaiah Guru Joined: 25/12/2009 Location: United StatesPosts: 303 |

Bob Nice looking country but mowing 25 aches? That would seem a real pain . Do I understand right what you did was extend the blades to a larger swept area and did not make the blades any longer? The tail vane you might try making it taller and shorter but still use the same % square foot area. Would these mills be available in the USA or would the fright be out of reason? Maybe you could fly one over for us to try and give those planes something to do. How much room do you need to land? the neighbor has an airstrip for a small plane. well I'm drifting off subject so good job Bob URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Isaiah The original blades where moved further out on their spigot shaft, as its only the outer 30% or thereabouts that makes the power, the center is there to hold them on. In light wind this morning it was spinning up to cutin while the other mill was barely turning. it was showing 12 volts DC and the other mill wasn't over 2 volts. Its survival in high will be the big issue to contend with. Both mills are on a GTI for initial loading, until they get to 27 volts, then they kick in to charge the batteries. It did that for a short time last week on wind surges so I know it will work well once there is some decent wind, over 6 ms. My friend gave me an old laptop today so I hope I can get Gordon and Peters logger working on it, just have to change the hard drive, and reload windows. There is an agent in the States for these mills, do a search on OEM windturbine. I think its a bit far to fly over to wee you with my ultralight, as I can't swim to good, might get over there next year to Chicago on the flying bus once they get their engines sorted out, my wifes sister lives in Rockford and she is wanting to go and see her, wants me to go as well, but last time I was there I nearly froze my arse off. My airstrip is 880 yards long but he plane only needs around 200 yards. Your friends strip sounds good but couldn't afford the petrol to fly there, the airbus is definitely cheaper way to travel. I agree on the larger vertical tale but wanted to leave it as standard as possible. Might give it a try later on. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

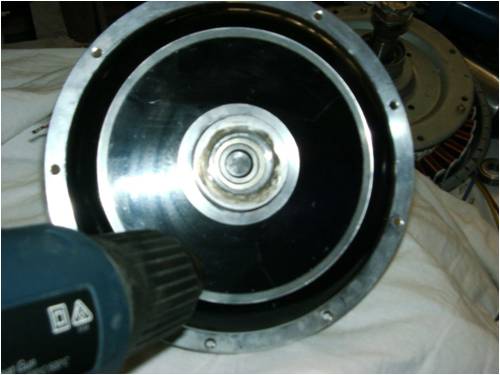

Hi All This is a neat little mill with potential way beyond its humble looks, however like all turbines I have seen from china the basic concept is good but the engineering in construction and assembly and wiring is a bit suspect, so before putting it up Phill recommends a blueprinting of the unit along with a few minor modifications for long term reliability, so I have put together a few photos to show what I did to the alternator, I got a bit carried away but in the long term I think it will make for a better and more versatile unit. The alternator needs to be fully dismantled to carry out this work.

The fitting of all the bearings is press fit in the housings front and rear and is very tight to dismantle so I used a heat gun to expand the housings so it could be dismantled without damaging the housings. The bearings where also a press fit on the main shaft.

The bearings where so tight on the shaft that it slightly expanded the inner race and caused the bearing to bind internally, causing the rotor to be harder to turn, not a good thing with a wind turbine as everything needs to be as free as possible to allow easy starting of the blades. The solution. To linnish the bearing seats down till the bearing can be a firm push fit on the shaft.

This photo is the final polishing of the bearing seat and is needed to get a smooth but firm sliding fit of the bearing, however the bearing seat was so far oversize and as hard as the hobbs of hell I had to get a bit tough with it.

This is a diamond lap used for sharpening carbide tipped saw blades readily available at hardware stores, I tried a file and it just slid over the surface without cutting the metal was so hard. Looks complex but in fact only took a few minutes. The front bearing.

The front of the shaft was was also oversize and a little mushroomed from the pressing the shaft into the center boss on the stator so more of the same treatment. Front and rear covers.

The idea is to just polish the machine marks out of the housing to make the cover a smooth sliding fit on the bearing, this is done on both covers. The front cover is important to have as a removable fit as the wiring is behind this cover and that allows a switch from star to delta or visa versa should that be require down the track. More on that later. I did these modifications in the lathe as it was convenient but it all could have done by hand in a vice with soft jaws to prevent damage to the shaft.

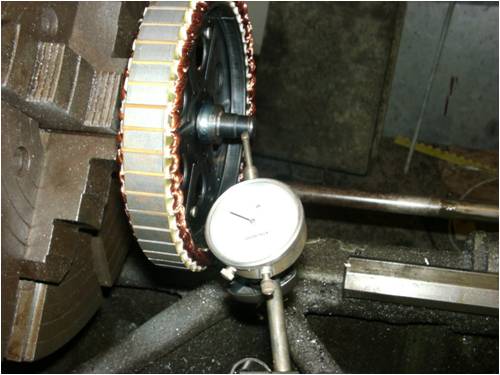

It is important to get a good Finnish on the shaft to allow a nice smooth sliding fit without clearance, its called a size on size fit in the trade, and is used where parts need to be dismantled with ease, not like a press fit that is more permanent but harder to work with down the track. When setting up in the lathe a dial gauge is used to set for zero run out in a four jaw chuck, I use the four jaw chuck because it can be set for zero runout whereas a three jaw self centering chuck is always a bit of center, unless you have access to a very high quality one, most of us are using what we have and isn't always ideal

Thats enough for one night,more bit following over the next few days. All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All I have posted a blade comparison on you tube:- Turbine blades comparison at 1.4 MS I cant get the link to work but if you do a search it comes up on this. The wind was steady at 1.4 MS this morning and my old mill was just moving while the new mill was coming to cut in at 12 volts DC. Just to give you a comparison on the slow speed startup on the new blades. Hope you can find it as this is my first attempt to post a video. All the best Bob Foolin Around |

||||

| isaiah Guru Joined: 25/12/2009 Location: United StatesPosts: 303 |

Hi Bob Did You get the Pictures I sent to you via email ? I have a terrible time sending pictures. It looks like you got your mill coming your way. The ECM motor on my mill is wired Jerry. URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All Another try to get the hype link to blades. http://www.youtube.com/watch?v=jaKdrkDKkD4http://www.youtube.com/watch?v=jaKdrkDKkD4 Amazing it worked (I think) All the best Bob Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Charlie I did get your emails but had trouble downloading the pictures, If I may make a suggestion, get a yahoo account and you can put then all on one email. From what I could see on the thumbnail prints it looks good. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Bob, Nice work with all your mods, I noted you were asking about experimenting with smaller blades, I do have heaps of the extrusion available and as I have talked to you about the 2.8m and the problems that can arise with delta and the larger blades. The biggest problem is the tubing that they use , the closest is 25.4 Hydraulic Tube with a 2.5mm wall (from memory) which may have to be machined down a bit on the spigot. The good point is that it is cold drawn the bad is it is quite expensive @$70+ for 6m . Look Forward to further updates with what you have done . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||