|

|

Forum Index : Microcontroller and PC projects : Anyone still wire wrap?

| Author | Message | ||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 855 |

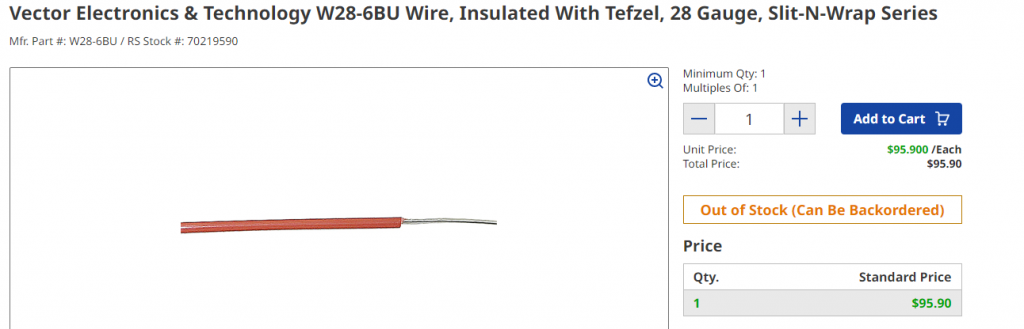

@barewires Don't think I'm keen enough to grab a Vector Slit-N-Wrap tool:   |

||||

| RendPhys Newbie Joined: 29/10/2020 Location: NetherlandsPosts: 6 |

Yes, I used it a lot over 40 years ago (with automatic tooling) and since a couple of years again sometimes, now with simple manual tools. To connect sensor-modules, PCB interconnections, etc. Easy for tests and firmware development.  |

||||

| Plasmamac Guru Joined: 31/01/2019 Location: GermanyPosts: 554 |

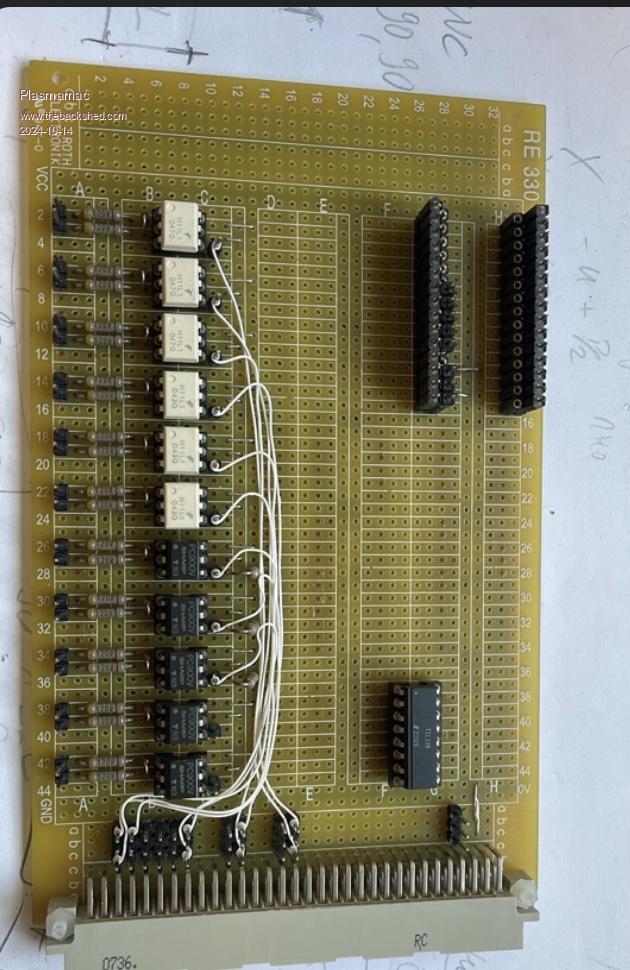

2022 cnc Signal input card Plasma |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 855 |

I'm liking this stuff; I have even wrapped wires onto IC socket pins and then soldered the socket onto the proto-board. The wires are then routed down the middle of the socket and are hidden when the socket is populated. Tidy and robust  |

||||

| v.lenzer Regular Member Joined: 04/05/2024 Location: GermanyPosts: 49 |

I've heard of wire wrap before, but never used it. Based on the forum entries, I bought the tool (the blue one from OK Industries). I'm impressed and will be using it more often in the future. Of course, I won't be building complex circuits with it, but I'll be connecting a sensor to the RP2040 quite often. Best wishes! Joachim |

||||

| EDNEDN Senior Member Joined: 18/02/2023 Location: United StatesPosts: 117 |

A quick suggestion for you: When you use the center wire stripper... always pull the wire through the device. Don't put the wire into the stripper and pull away from the device. Everybody I know that has one of those tools quickly breaks off the flat black metal wire stripper if pulled too many times away from the tool. |

||||

| astroboy Newbie Joined: 28/12/2014 Location: AustraliaPosts: 39 |

I don't understand this. Please explain if possible. Thanks John |

||||

| EDNEDN Senior Member Joined: 18/02/2023 Location: United StatesPosts: 117 |

Sure... No Problem... If you use that blue tool the way you would naturally use it, you will break off that little black wire stripper plate after 50 or 100 wires. The most natural thing to do is you cut the wire to the length you need (plus 2") and stick each end 1" into the stripper plate. You press the wire deep into to slit and you pull on it. That works fine 50 or 100 times. The problem is, eventually the wire will have a small kink or when you press the wire into the slit the metal will cut into the wire and grab it. When you pull the wire to strip the insulation off of it you will pull hard enough on the VERY BRITTLE black metal plate and it will snap off. Instead... You need to do the unnatural thing and insert the wire from the far side (or the back side) of the black metal plate, press it down into the slit, and pull it to strip the wire. If the wire gets a kink or the stripper plate bites into the wire the unsecured side of the black metal plate will be supported and the black plate won't break off. Edited 2024-10-15 12:38 by EDNEDN |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 855 |

Wasn't aware of the breakage issue but I have been doing this from the get-go  However, I have a Knipex auto-stripper that is only intended for a minimum 24AWG but with this 30AWG it puts just enough bite in the insulation that I'm able to pull it off with my thumb-nail. I like this because I know for sure that the conductor won't make contact with the blade.  Edited 2024-10-15 15:51 by PhenixRising |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 6764 |

You can probably get an auto strip & wrap tool for the price of that. ;) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| v.lenzer Regular Member Joined: 04/05/2024 Location: GermanyPosts: 49 |

Thank You! Good to know! Best wishes! Joachim |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 855 |

Yeah I hadn't discovered Aliexpress at the time  |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 6764 |

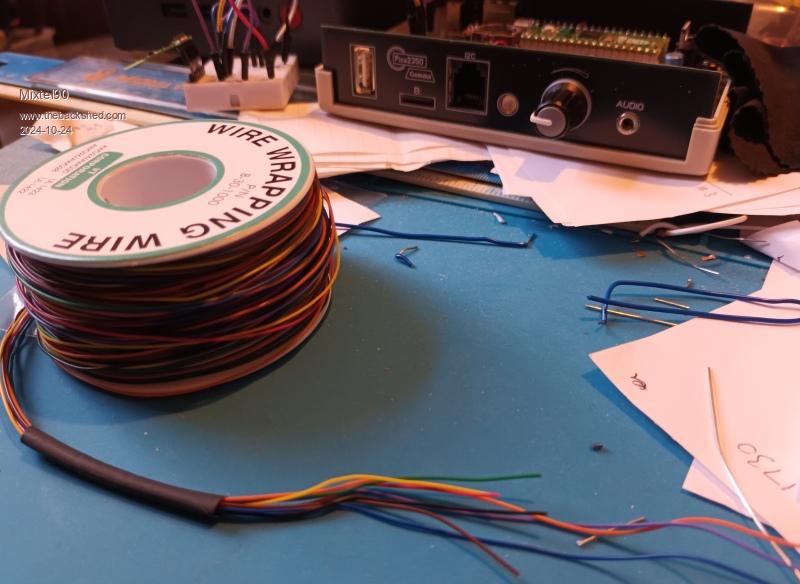

My OK wire wrap tool & wire have turned up. I've just been playing. It's impressive, isn't it? I'm not getting the "modified wrap", with turns of insulation though. Is that just me? The tool is a bit of a **** to poke the wire into, even with my strong glasses! I can see this being very useful. By the way, if you thread a piece of suitably sized sleeving over all the strands of a multi-colour spool it helps keep them under control. :) . Edited 2024-10-24 21:08 by Mixtel90 Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3150 |

I don't understand. Pic? PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 6764 |

Like this...  Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 855 |

You have to kinda let a bit of the still-insulated wire slip through your fingers as you start to twist. I ended-up doing a half-turn of the insulated bit after wrapping. The idea is to have a bit of padding at the stress point. Yes it is impressive because it seems impossible to mess-up. I have had 100% success rate. Can't believe this went out of fashion.  |

||||

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3150 |

Ah, ok, thank you. I was trying to imagine a sleeve on the entire spool, or somehow on each individual wire. Very tidy looking. PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| NPHighview Senior Member Joined: 02/09/2020 Location: United StatesPosts: 200 |

Ah, this brings back memories! I wire-wrapped a multichannel A-to-D and D-to-A converter board for a PDP-11/45 Unibus machine for Ohio State University's hexapod robot project, and wrote the driver code, for my Master's thesis in (ahem) 1978-9. The "thwACK!" of the wire-wrap gun is a sound and feeling I'll never forget. A few years later, I wire-wrapped a 256K static memory add-on board for our CPM/86-based Vector Graphic computer. I think static RAM chips were 16Kx4 at the time, so it took a few :-) My wife didn't give me a hard time about that project, as we were planning to use that computer to write and edit her dissertation. We had just bought our first home, and the cost of the computer was 10% of the cost of the house. Live in the Future. It's Just Starting Now! |

||||