|

|

Forum Index : PCB Manufacturing : PCB making in China

| Author | Message | ||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2916 |

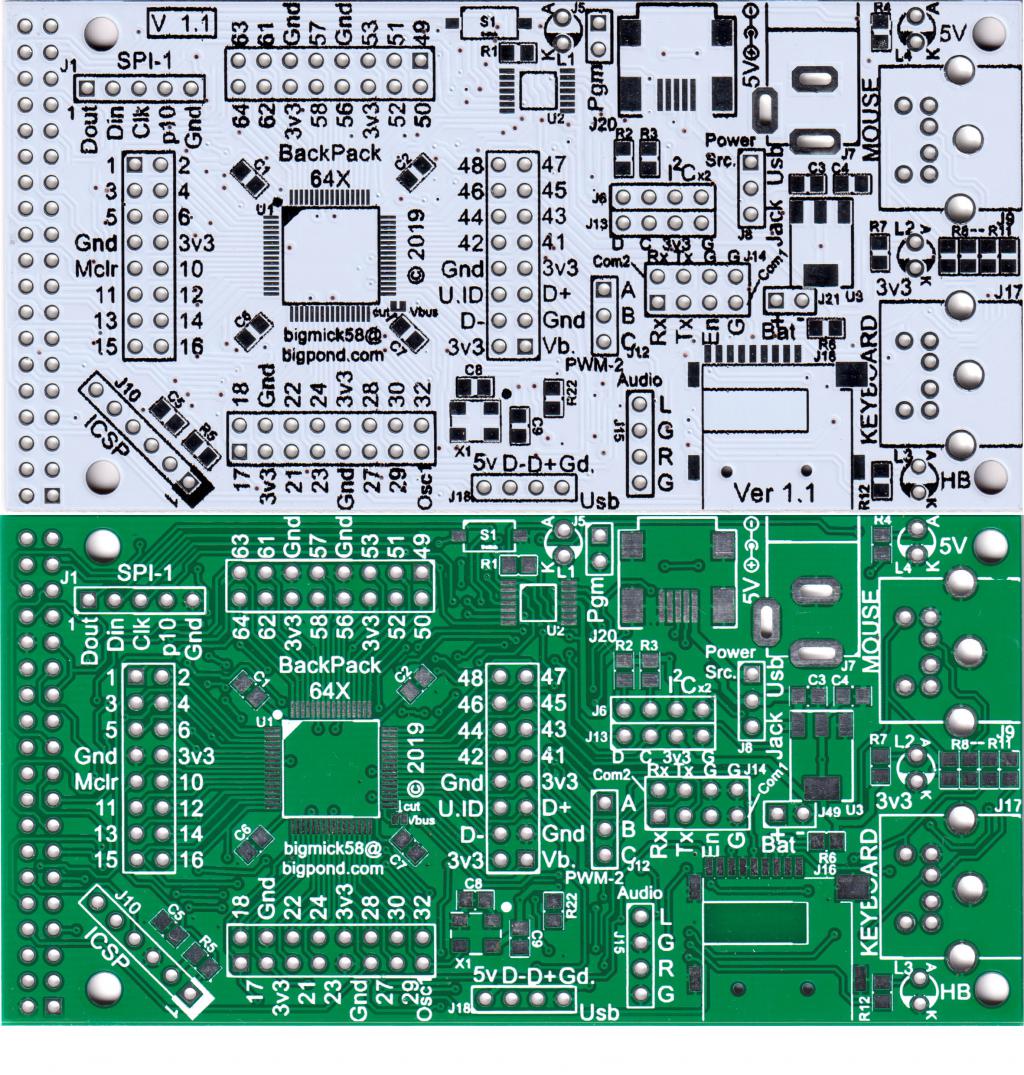

Hi Mustard, I have been using jlcpcb.com recently and am very happy with their service. I am receiving my boards typically 10 days after i email the Gerbers off to them.. Their prices are pretty good (start at $2US for 5 pcs 100x100mm or $5US for 10pcs) Their postage (DHL) is a bit dearer than Shenzhen2U who I have been using but considering I am getting the boards in about the time it has been taking SHenzhen2U to produce the things I am very happy. I ran your boards through their quote system and for 5 pieces double sided standard options they will produce them for $12.04 AU (around $8US). I would expect shipping to be around $15-18AU for that QTY.. My last order was 2 lots of 10 100x100 plus 2 lots of 5 100x100 and shipping was $31AU it increases slightly with each extra board added to the order. Anyway their quality is great although I got some WHITE Pcbs with Black text and they had some blurring issues but their white on Green is as good as i have ever seen. Here is a scan of two boards (Green is BackPac-64X version 1.0, white is 1.1 and I have 1.2 in being produced now) note that the white on green is very clear in comparison to the black on white, I suspect this is due to the fact the white soldermask is very thick and glossy so the black ink tends to not adhere as well as the thinner more matte green.  Kind Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| PeterB Guru Joined: 05/02/2015 Location: AustraliaPosts: 651 |

G'Day All I started with FREEPCB to layout single sided boards which I then engraved using my CNC machine. It was good fun and much better than VERO. Then I plucked up the courage to do a proper job. I can order a board from PCBGOGO on Monday and it will arrive on Friday. The people there are very tolerant, patient etc. A one off board is expensive because of postage but 50 boards is cheap. The hard part was working up the courage to do it. When I worked for a living I could give my circuit to a bloke and some time later a beautiful board would turn up by magic. Peter |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The Chinese do business all around the world in every time zone, so they work in shifts 24 hours, seven days a week. They also have no break over Christmas/new year. The only time everything seriously shuts down in China is Chinese new year (first new moon in February). I am reliably informed everyone stays drunk for at least a fortnight and absolutely nothing gets done. So you can order your boards at 3am on a Sunday and very likely get order confirmation an hour or so later by e-mail. DHL also work seven days/24 hours. I have received late Sunday afternoon deliveries from DHL. As Peter says, its about four to five day delivery here from time of order, and weekends or public holidays make no difference. Cheers, Tony. |

||||

| PeterB Guru Joined: 05/02/2015 Location: AustraliaPosts: 651 |

B & A on the subject of getting boards loaded in China. I looked into that and you need to specify each component in detail and that's as far as I went. A lot of things were happening in my life at that time and I used it as an excuse to do nothing. PCBGOGO sent me a sample component list, that's how good / keen they are. Getting boards loaded in Chins is the next logical step but does involve a bit of work. Peter |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The point is, if you only want one board, its far better to spend an hour loading it yourself, than ten hours of work to prepare all of the necessary error free documentation to get someone else to buy in all of the components and get someone else to load it for you. If you need a hundred boards made, or a thousand boards made, then ten hours work by you to set it all up for someone else to organize the work might be a good deal. But what if you get your boards made by someone else and none of them work because you put a decimal point in the wrong place? Cheers, Tony. |

||||

| PeterB Guru Joined: 05/02/2015 Location: AustraliaPosts: 651 |

I have no argument with that, so, at what point does it become economical to have them design and load the boards? I have had this worry in the back of my mind for some time. We have designed a system and built quite a few examples but what happens if there is a big demand for them? I am 82, the ABS tells me I will die in 8 years and I don't want to spend them loading boards. I may even get hit by a truck or shot by a jealous husband, who knows? But what a wonderful problem to have. Peter |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Difficult to say exactly Peter. In your case it sounds like you might be better off employing someone part time to load your boards, if its not all that many. Plenty of people out of work, or retirees looking for a few extra cash dollars. If its a serious quantity, you may have to go full scale commercial production. How many attempts does it take to get one absolutely perfect final board, and its producing the computer files and documentation that is usually the problem. Assuming the circuit works, all the hole sizes are correct, all the component values and designators are correct, everything fits, nothing gets too hot, there are no noise, power supply, or grounding problems. Components can have an extreme mix if tolerances. All of the component part numbers and suppliers are specified, along with alternatives. Every screw and washer has a specified part number and assembly drawing. Every part needs to arrive packaged in a form that can be loaded into their fully automated production machinery. And one other thing. If there are 200 individual parts involved, and only 199 are currently available, you are screwed. Too bad that the one vital missing widget is on seven month back order. It might take several attempts to get everything exactly right, and each attempt will come with a significant setup charge. It might be rather expensive getting to that stage depending on the complexity of the board and your level of design experience. But once there, you should be able to get a pretty good price for producing a very large quantity of identical boards. Its all a lot easier if you are part of a friendly capable team working withing the same company. A really good drawing office, purchasing officer, and production staff can be a real help. That is how I have always done it. Trying to do it all over the internet by myself with people in China I do not know, might be far more troublesome, I really do not know. But its definitely a real thrill seeing something you have designed from scratch go into mass production and prove to be long term reliable and a commercial success. Edited 2019-12-15 06:54 by Warpspeed Cheers, Tony. |

||||

| zeitfest Guru Joined: 31/07/2019 Location: AustraliaPosts: 484 |

I would wait for the demand to be actual tangible orders before making many plans. To load some pcbs, typically a pcb house will need a file with the component id's and x,y positions (accurately), and also sourcing info for the components - will you supply them and/or will the pcb house use their sources ?? They will probably only accept a minimum order based on say 50 or so, or at least a serious set-up fee each job. The board stuffing machines have to be set up with components in tapes etc so it is not trivial. There is often extra cost for non-smd components as well. For a pcb with a small number of components the cost per unit was around a dozen dollars as well as the components and pcb, and that would still require you to hand-finish for some stuff like connectors etc. Most pcb software has an export facility where the components and their positions can be listed to a file, which you then adjust to give to the pcb house. Getting that data right is critical. I would do that, and check it exhaustively, before getting the $$ involved. (Ed - Warpspeed beat me to it !! Good advice too.) Edited 2019-12-15 06:49 by zeitfest |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The business side of things is another whole different can of worms. Its difficult to sell things that have very extended delivery times, most people expect it to be delivered right now. Your best bet might be to employ someone part time, at least to begin with. Cheers, Tony. |

||||

| zeitfest Guru Joined: 31/07/2019 Location: AustraliaPosts: 484 |

mustardman said If you are after hassle-free, OSHPark is not bad, the deal is you get three very high quality trimmed pcbs with very easy soldering and free shipping for the price. For prototypes it is good, use it for one-off trials etc. The shipping is not express though. The price was $5 / design square inch some time ago, haven't checked in a while. Otherwise PCBway was good, good quality and inexpensive for a standard 100cm max square batch of ten, more production-run oriented. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Handy hint for cutting up say 100mm x 100mm boards up into smaller units; get them made 1mm thickness rather than standard 1.6, use a large set of straight metal tin-snips to cut, its like a hot knife though butter, no problem, no mess and no dust. I make up quite a few modular pcb components that are perhaps 2cm x 3cm, just space them 1mm apart in the 10cm footprint with a printed silk screen line for cutting against. Cheers Mike |

||||