|

|

Forum Index : Solar : Deciding if I should build this solar heater

| Author | Message | ||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1022 |

Aluminium welding. We used to use an argon helium mix for welding boats, fuel tanks and various other bits, needed to weld hulls fast and without any bubbles in the welds, would do a 5 meter run, pull the trigger and walk the full distance don't stop. The 3 phase mig had plenty of power and the 1.2mm aluminium welding wire was no trouble at all to push through 2 meters of liner to the hand piece. AC Tig with a HF start was ideal for Tig welding, We avoided scratch start Tig's, sharp clean Zirconiated tungsten electrodes I think it was. Auto darkening helmet was a must in the workshop as it saved time when tacking and or holding things. The best practice for someone how has done done steel welding is.....to forget what you now about welding steel and start fresh with the aluminium and learn from there, follow the puddle. Worth learning if your going to be doing plenty of aluminium welding, if not, just stick to what works for you. My $1 worth. Edited 2021-07-14 18:05 by Revlac Cheers Aaron Off The Grid |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

At our Bunnings the gas bottles are in locked cages outside the building ... and the oxygen and acteylene are in seperate cages some meters apart. I haven't noticed argon there but have seen a handful of other bottles. I bought an auto darkening helmet with the welder but even on the darkest and most sensitive settings it is too slow for me ... I get a flash everytime I strike an arc and it is really annoying as well as being dangerous. I've gone back to an old arc welding helmet, but that is really inconvenient and a bit too dark. I watched a few youtube videos and went and had another go last night with the TIG ... and had a better run than before ... but still nowhere near good enough to attempt welding useful things. The aluminium brazing rods arrived yesterday, surprisingly quick ... and I had a go with them last night too. Still needs a lot of heat to make them work but at least these are the ones I was after. I need to find a way to spread the heat out from my oxy because I still ended up melting the tubing when I didn't move it around enough ... too busy concentrating on moving the rod over the join. Perhaps if I put on the biggest tip and experiment with that ... or jam some copper tube over the end and drill a few holes in the side so I have a wide flame front. I can see why a propane torch could work more easily. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Haha, I have the exact same thoughts when I build something with scrap or secondhand parts ... when I've used this where will the next lot come from. I am definitely going to give it a go ... and hopefully I'll have some of my own to experiment with ... but if not, we are in the middle of a market gardening area, so no shortage of potential suppliers. My brother has been quite successful using aquaponics, but seeing we've got hundreds of square meters of glasshouse area, I might as well use some of it. Thanks for that, I'll ask more questions when the time comes around. My problem may be that there might be too much heat ... and I'll have to work out a way to add ambient air to keep it down. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Awesome. I'd just love to be able to do 5cm without collapsing my tubing or sticking the electrode in the puddle and wrecking the whole thing.  I do wonder just how good a result I can expect from my elcheapo machine ... at least on TIG. My welder friend had a play with the MIG side of it when I first bought it and he was impressed with it ... but he never tried the TIG. Anyway, whats the saying ... "a poor worker blames his tools" ... so I'm not going down that track. I need some training and practice. Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Oxy is a bit too fierce for brazing. You will do a lot better with propane with a really big head or tip or whatever its called. Oxy can also very easily oxidise the aluminium which the brazing rod will not flow over. Yes, the heat really conducts away quickly in aluminium, especially with thicker sections, which makes the whole process rather slow. But you really need an even heat so the brazing rod will flow right into the joint. Its not like fusion welding where very intense heat produces only a small molten pool. Very best results will be had by carefully "tinning" both parts so you can see that the whole surface has a thin covering layer of brazing material, scrubbing with a stainless steel wire brush while it hot helps the brazing material to cover. When both surfaces are tinned, assemble the joint, reheat and the joint will be perfectly sound. Its just like lead/tin soldering really...... Bunnings Argon: https://www.bunnings.com.au/search/products?q=argon%20gas&sort=BoostOrder&page=1 Cheers, Tony. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1022 |

The auto darkening helmets, some were really good, had replaceable batteries, the cheaper ones had built in batteries and still did a good job, after a while the battery was not upto the job first off, easy fix was to put the helmet out in the sunlight for 10min's before work, don't know the quality of the units these days. Also aluminium has a great dislike to stick to itself (another piece) that you are attempting to weld together, steel and SS totally opposite, they will stick easily. What type (brand) of welder you have? I have not seen a mig welder with Tig option that will do AC of Pulsed DC for aluminium. A Tig welder for aluminium AC or DC pules generally don't come with a mig as well, and they will not be as cheap as a DC mig tig or stick welder. Perhaps they have changed since I last looked. I have never used those aluminium brazing rods, I have some around somewhere. Cheers Aaron Off The Grid |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The biggest hurdle with welding aluminium by any method is oxidation. That is the goes grey and won't stick to itself problem. That is why all aluminium fusion welding requires a shield gas, usually helium or argon, or some mixture of the two. Argon is very cheap, helium less so... The worst possible thing to use is oxy acetylene, even a tiny excess of oxygen, and the extreme temperature guarantees grey oxidised aluminium, and total failure for the metal to flow and join up. There is pure oxygen roaring out of the nozzle before it even burns, and oxidation and failure to weld is absolutely guaranteed. Propane is better for two reasons, a lower temperature flame and if you use the right part of the flame there will be minimal free oxygen. The flame itself keeps most of the air out, and the low melting point of the brazing ally helps a lot too. Its not really fusion welding at all, but more like a soldering process. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I got a CIG brand auto darkening helmet when I bought my last welder. Its very sensitive so much so that if I start grinding in bright sunlight ( or otherwise) the darkening will kick in making the thing blink. It's certainly fast enough to react, never got anything like a flash from it but it is dark even on the supposed lightest setting. Other gripe is the thing does not fit my melon head properly. I have tried every adjustment and strewed the thing so tight It hurt but soon as I bend over or look directly down, bastard falls off. I was thinking maybe I need an elastic chin strap on the thing. When storing these helmets I have read and agree it's best to store them where they get some light, IE on a hook on the wall rather than in a dark Cupboard. Dads one was in a Cupboard and it wouldn't work. saw something on the net saying to keep them where they get a bit of light to keep the batteries or caps from collapsing. Put dad's out in the sun for a day and the thing seemed to come good. Sits on a shelf now where it gets the normal shed interior light levels and haven't had any more problems. There are of course the DIY welding mask solutions....  And the deluxe Ray-Ban version for the Hip and cool dude welders out there...  Makes you wonder how long these people have been doing it this way. Would be funny if the implications weren't so bad. By the same token, You would not belive how many people have had a go at me for showing welding on my YT Vids. Complaints because I didn't warn people so they could close their eyes or I was going to cause people to go blind from watching it. No antidote for stupid and ignorant! I forgot a welding mask once when I went to do something for a friend. Wasn't a Big job so thought I'd just close my eyes which I was careful to do. My EyeLIDs were so damn sore and sunburned that night it wasn't funny. Spose they don't normally see a lot of sun let alone intense UV from welding and they were red as. I thought it was my eyes till my wife noticed how red the lids were when I closed my eyes. Won't do that again! |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Sorry for the slow reply Aaron, I couldn't think of the name the other night and then forgot to look. It's a Mishto. I've had it at least 5 years and it is blue ... but otherwise appears the same as this I had used the MIG gasless for all this time but after trying the TIG with gas ... also used gas with MIG. I learned that you have to swap the polarity to do that ... and there is an easy changeover link inside the wire spool cavity. As far as whether it's AC or DC for TIG I have no idea ... the manual was totally useless and in fact, the images of the controls don't even match the machine I have. When you go to start the TIG there is a nice feathery splay arc until it fires ... so kinda looks high frequency or something ... but what the welding waveform is I don't know. I'll have to stick my helmet in the sun to see if it improves. It came with a nice thick black bag to protect it ... and then I also have kept that in its box ... so no chance of any light. Cheers, Roger |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1022 |

No worries about been late, always other things happening, priorities and such. Yeah, I had to change the polarity in the 3 phase mig for gasless wire, had to rewire it inside, was welding with some 1.6mm flux core steel mig wire, that was fun.  looked at those welders some time ago, handy little unit, now I doubt it will do AC Tig for aluminium. Easy to figure out, if it will do AC tig you would here a 50Hz buzz while welding, some more expensive machine will have a variable frequency, DC pulse, square wave and many other settings. If the machine is just a DC Tig the arc will smooth and quiet, sounds like gas flowing out the tig torch, if this is the case... You wont be welding aluminium with it...it wont work. Will be great for steal or SSteal. Found an example seems to do aluminium ok according to the reviews AC Tig many others around but you can see it has a few variable settings, and notice the FOOT PEDDLE, very handy, start with some heat and turn it back as the object (been welded) heats up. Hope your welding mask is better than those above....  Edited 2021-07-16 17:52 by Revlac Cheers Aaron Off The Grid |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 648 |

Thanks for that tip, I did not know that. My helmet is stored in the box it came in  |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

My first Mig Of how ever many years ago, 20? was a Cheaper brand. Thought I'd get something I could afford and then upgrade in the not so distant Future. I guess for what I did with it I can't complain but it did teach me things I wanted to look out for next time. Still works but I think the torch is a bit past it's use by date and unlike the new ones which are interchangeable, This one is fixed as it were and of course Unobtainable. Still works for heavy stuff but turned down the wire feed is cactus and the liner is probably buggered as well. I have a real good one up the back that was Dads. The wire feed control went on it and the replacement board is of course stupid expensive. The feed motor is just a 24V windscreen wiper motor which is still good so when I get round to it, I'm just going to use a 24V PWM on the thing which I can't see why it won't work. It's a Massive transformer type and I think gas only. I offered to fix it for Dad but he had seen the smaller HF types and had his heart set on another new toy so I managed to find him a great deal on a New old stock Unimig which is a very nice machine as well. I tried setting that up on gasless wire but now thinking about it reminded with this conversation, I can't recall if I did reverse the polarity? It did not like the gasless wire at all so maybe that was why? I knew about this but in the excitement of setting it up, Who knows? Got a middle size spool of regular wire which will last him a long time so all good. I didn't even look at the no names when I bought my last welder, I wanted to buy a decent if not a fantastic machine because I realise the difference they can make. It's easy NOT to blame your tools but sometimes, They can be a big part of the problem. I wanted to eliminate that so there was only one thing to look at. The CIG I got is made in Chynaah bit it is miles ahead of the other one. I spose 20 years technology and development does not hurt either. A mate has a Rossi branded TIG/ MIG/ plasma and I have used that and found it a very good machine. The only problem I did find was when using the plasma, Running the compressor and the Machine was waay too much power draw and would pop breakers with ease. At my old place it wasn't hard to run one on one circuit and one on another but he like most people didn't have that advantage and the length of lead to the next circuit wasn't much help. I got a large car gas tank and welded a plate and a valve on that so he can run the compressor, store the air then run the plasma without the Compressor running. Yeah, a little fiddly switching from one to the other but there is enough air to get a decent run and then not hard to find something that needs going while the compressor pumps up again. Also a lot better than the things cutting out mid cut as always happened. I have Unimig with a Built in Compressor which is handy. Still will pop a circuit if you turn it up but I don't have much trouble. I have a solar inverter tied into the power circuit where I run my main tools from so the Inverter takes much of the load off the Main circuit. I put a sub board up there for thing like that so I didn't have to hike all the way back down the house but if the sun is out a reasonable amount, don't have any trouble at all.... and the wire hasn't fried yet so even better! :0) I did see on Dads machine a Prominent tag and warning in the manual that Filing down the earth pin to plug the machine into a 10 A Circuit would Void warranty as weould fitting a 10A plug. No Biggie, just went and got a 15A outlet and replaced the 10A one. :0) I have his solar on the shed circuit as well so No problem with the Voltage drop there either. Even if the solar is only making a Kilo, it's still a big load reduction on the circuit. I have see a few reviews on the Chyneese " Cut 80" I think they are commonly called Plasma's. They seem to be universally thought of as Junk. I am surprised how few people seem to have plasma's these days. I would be lost without mine completely. There are some VERY skilled people using angle Grinders out there in YT land though. One of the few things I don't have in battery Version but I think I have 5 in corded including one 9" muther of a thing that I hold onto like it's the Jaws of a Full grown Crock I'm in a bathtub with. That will go though anything and lets you know you are alive or may soon not be if you don't give it full concentration. Bit of a Fuse Vaporiser too back when Places still had them. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Thanks for the tips on keeping the helmet in the light. I've had it in the house for the last few days and then I decided to check it all out again and err ... ummm ... discovered that the batteries were flat ... 2 x 2032 coin batteries. After replacing them, it worked ok. It was the first thing I checked when I had trouble with it years ago and yet it had always been slow at blocking that first flash. I must have gone through the sequence of adjusting the three seperate settings dozens of times thinking I had them set wrong somehow. Anyway, I'll keep it out in the light from now on. I finished welding up the base frame ... it's pretty big ... and if I stand on my tippy toes I can just touch the top ... though not as heavy as I first thought it was going to be. I reckon I should be able to drag it up on the roof if I lay a protective mat over the gutter first ... and have someone down below to help lift. I tried a dry assembly to see if everything fits where it's supposed to and thankfully no surprises so far. Will drill all the assembly holes and weld a few captive nuts in place so it can be reassembled easily on the roof ... then start chasing the sheet metal that I'll need. I still haven't sorted out my aluminium welding or brazing ... and have spent a few hours experimenting with propane and the supposed low temp rods .. as well as with the TIG again. Couldn't work out why my results were so bad, until I realised that when I swapped over from the MIG, I hadn't transferred the gas hose over to the TIG inlet!!! I actually could manage some reasonably controlled welds with the TIG ... but of course I ran out of proper filler wire. Once I get some more, I might have another go. Here's some photos to show the progress.     Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That is a truly amazing piece of fabrication work there Roger. Did your Chinese differential temperature controller ever arrive ? Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

Wow! That puts things in Perspective as to the size of this setup.... and your Shed! Mancave jealousy there for sure! I agree with Tony, that's a great and substantial bit of Fabricobbling and very professional looking as well. Wish I had some Skills and was clever. Looks like it's going to kick out a lot more heat than the calculations suggest. I can see this ending up in self sufficiency type magazines and websites. Make sure you comb your hair and polish your shoes when they come round for the interviews! Won't be hard picking your home on google earth that's for sure. I was up the back yesterday looking at that Gal channel. The stuff I have is the same profile and looks similar Gauge but the holes are much larger and further apart so I doubt would have been any help. Probably more a frustration of the near miss. Very impressive work Roger! I wouldn't worry about how the welds look too much, people are going to be far too blown away with the look and size of the thing to even notice or be worried about a detail like that. Might be a lot of work but I am certain the satisfaction and independence you and the family get out of it will be worth it 100X over. Being passive it will also save you endless work in the future with the wood cutting. Your son will probably be doing projects on it at school and he or you going up there and talking about it. I got asked to do that a few times with the veg oil thing and this is way more interesting and up to date. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

Thanks Tony, it's certainly turned out big ... and I am happy with the way it's going, apart from being all too slow. The controller turned up during the week, but I really haven't been able to work out yet how to make use of it. Have to decypher the instructions somehow. Haha, thanks Dave. I do keep thinking I may have overdone it a tad ... but if I'm gunna build something, it has to have a good chance of performing well. Thank you. Very pleased to have found this place with sheds already attached ... big house but even bigger sheds ... and wife loves the place. I need to learn to throw stuff away though, or sell it ... would give me twice as much room to work in. Thanks mate, I've been a bit surprised myself at how it's turning out ... very happy. And don't cut yourself short, I've seen enough of your youtube videos to know you have some pretty decent skills yourself ... between coming up with ideas and then proving or disproving them ... and then improving on the good ones. My biggest problem, as we've discussed before ... is I have to have every little detail worked out in my head before I lift a spanner ... otherwise I won't risk starting a project. Means I do a lot of thinking and very little of anything else. Haha, my cynical self doubts they'd even be interested, but maybe there would be some interest. Hope it works then ... or I'll look really silly. I did wonder how close it might be, but was bound to be something that would make it unsuitable. Luckily I shouldn't have to do that part again ... and I can't see myself making another one in a hurry. It certainly didn't need to be that heavy a gauge ... but I couldn't find anything lighter weight to substitute. The other thing is the aluminium tubing ... mine has 2mm thick walls, where .5 or 1mm would be plenty stong enough ... but finding something cheap there has been difficult. Yeah, just thankful I have an angle grinder to tidy up some of the worst ones. And you're right about the long term value ... there's no reason this couldn't run for 50 years. May need a new fan motor one day ... but nothing to wear out ... just free heat whenever the sun is out. Perhaps the electronics ... that'd probably be the weakest link. I'm afraid he probably thinks it's pretty ho-hum ... but maybe if others get excited about it, he may see some value. I'm pretty sure some stuff is rubbing off on him though ... will have to wait and see. I'm pleased to hear that there were others interested in your veg oil exploits ... it's good to know that at least some people want to see waste reduced or alternatives explored. Cheers, Roger |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

Don't worry about it, he's pretty young yet and he's also used to seeing you playing around with it. My Kids were the same. The veg thing was a whopping great bore UNTIL other kids saw it and thought how cool it was and THEN things changed. I used to Volunteer to take the kids to different places for school when there was only small groups. I'd have a line of kids wanting to come with the Fish and chip car and my kids were happy to go in something built in the same decade. Was the same with a few other things. Was all boring and annoying until some other kid thought it was cool then they were real happy to bask in the attention and tell everyone what they knew about it. Once he starts learning about it in High school things will change. Same will be when you do the solar setup. Give him a panel, a battery and controller and some sort of ( fun) load like a little electric go kart or bike he could learn about charging and he'll be plenty interested. Would not be a bad thing at all for a young fella to get an interest and grounding in such a thing. I can see it being something with plenty of opportunities in the future for well paid work. By the look of that shed, you are going to have plenty of room for a very decent solar array as well. All it will need then is a Veg burner in the corner keeping the place a Toasty 30oC and You'll be warm wherever you are around the place. Another burner for the Pool for mid winters swims and all will be great! |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

BTW, I really think you should take LOTS of pics of the construction of this as you go and some Video explanations wouldn't hurt either. You may not ever want to use them for anything but if you do, now is the one and only chance you will have to get them. I think you sell yourself way short and there would be a LOT of people far more interested in this than you think. Worst comes to worse, something to show The grand kids and remind yourself of the great work you are doing. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I believe that controller will make a VERY big difference to your results. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 852 |

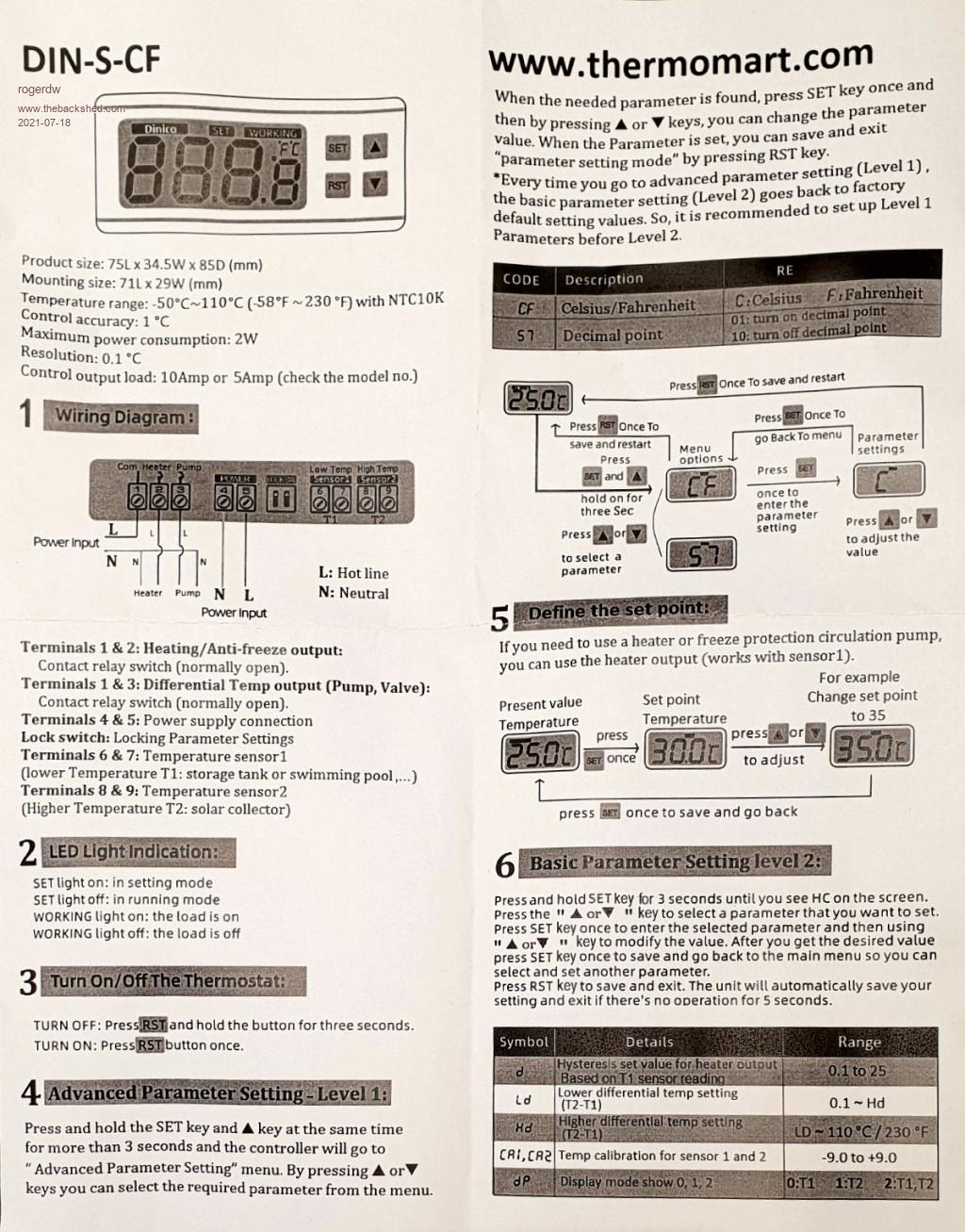

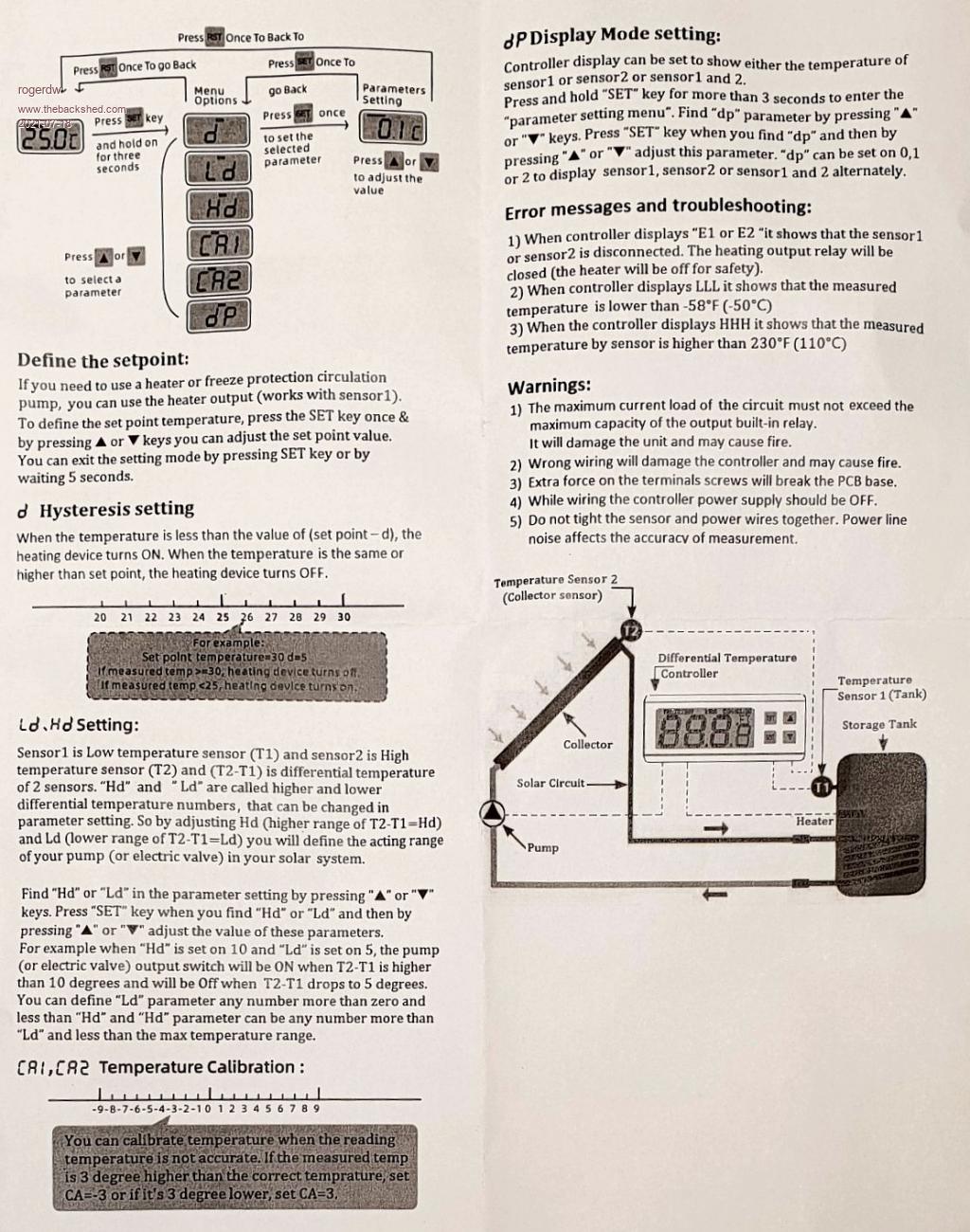

Yes it should, if I can ever work out how to apply it. It seems to work backwards for what I need. What I would like to do is have it off until one sensor (inside the tubes) reaches say 40 degrees ... then turn on the fan. As long as the second sensor can reach (quickly) and then stay above say 25 degrees ... then the fan can stay on ... but as soon as it drops below that ... the fan should go off. I'm feeling a bit thick ... does it look like this can do that, or do I need to add some extra logic?   Cheers, Roger |

||||