|

|

Forum Index : Electronics : 150V 45A MPPT - roll your own

| Author | Message | ||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1420 |

I think the LEM sensors can be installed using the "6mm2" cable I use. It has 62 fibres, 0.3mm diameter. It worked fine and because you have so many thin fibres, you can form them into nearly any shape. the 62 x 0.3mm diameter = 4.5mm2 in actual fact. This is fine for the 45A maximum current. The length is only about 45mm so the resistance is tiny. I'm home this weekend and Monday, text me beforehand? wronger than a phone book full of wrong phone numbers |

||||

| SYM-1 Regular Member Joined: 18/10/2019 Location: New ZealandPosts: 45 |

I want one of those v2 brainboards too. Grant Persistence is the key |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

Peter, I am curious, did you try different chokes for the 3 frequencies or was it all using the one choke (same uH) ? From the ripple current changes I am assuming just the one core was used. If that is the case that may help explain why there was little change to the performance ? Soon I will have a board to play with so I can stop bothering you with all these questions and try it myself. Just noticed the first measurement was 37A ripple - that seems rather high - it is almost the same as the output current. is that the peak ripple relative to zero or was it the p-p ripple ? I was expecting sub 20A p-p for the ~40A output. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1420 |

Wiseguy: all 3 tests using the same inductor. I agree the 37A ripple is big. Probably too big. At 40kHz the ripple is now acceptable. This test was to see what changes if any can be seen if I vary the pwm frequency. I can not measure current very accurately but in the 3 tests I measured things in the same way, same device, etc. It was an attempt to see switching losses. I think it also includes core losses which are a function of frequency too. Anyway, we can see going from 20 to 40kHz will cost about 50W. I wanted to have some idea of this cost since one inductor (of my present design) is not enough to contain the ripple current. I will be making my charge controller using 2 inductors in series. The losses from having 2 cores and 2 windings is much less than 50W, being that loss when we go to 40kHz. I will need to confirm that this is indeed so by experiment. Edited 2020-06-11 09:07 by poida wronger than a phone book full of wrong phone numbers |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Its unacceptably high. For a fixed load power supply such as you might find buried inside a piece of equipment, usual design figure might be around 30% peak to peak ripple maximum. A supply like that would never have to operate at anything less than full load, always flat out. And that would be fine. Now a 50 amp battery charger might need to operate down to perhaps 1 amp dc output or even less. You certainly cannot call very narrow sub microsecond 37 amp current spikes dc output. And that is all you are going to be able to get from such a small choke. It may as well not be there at all. Getting it to run at 2Kw is dead easy. Getting it to work at 20 watts is going to be a whole lot more difficult. It really needs a choke that is several hundred microhenries at least. Higher voltages need more inductance, there is no escaping that. Ferrite is not going to work, size and cost of something that is going to work rules it out, ferrite just saturates far too easily. Mollypermalloy would be the material of choice, but that will be neither small or low cost, or have very few turns either. Very low permiability powdered iron is just possible, but its much better suited to lower voltage applications. High volt/microseconds per turn are going to be a problem for you, and most common grades of powdered iron will just burn up from core losses. If you add extra turns to make the core losses lower, it just saturates earlier. Reduce the ampere turns, and the core bursts into flames. Powdered iron would be perfect for a 20 volt 50 amp choke. A 150 volt 50 amp choke is really pushing the limits of most powdered iron materials. Cheers, Tony. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

Only have a few minutes to write before I have to go out. If having to buy parts I would urge members to buy the FOD3182 over the TLP152. Of course if you have TLP152's or similar in your parts bin by all means try them out. The Gate resistors should probably then be between 2R2 & 4R7 ohms at 40/80kHz I suspect. When running at 40kHz the inductor volume can be halved and less turns are required. When running at 80kHz the inductor volume can be halved again and less turns required. This assumes the same p-p ripple for each case, a bit more inductance and the ripple further reduces. But now we are in the realm of EE55/65 cores which are a lot cheaper. 32-150-44 EE55/F44 $3.98 each + GST 32-240-48 EE65/F48 $5.55 each + GST I think some more work needs to be done to get the magnetics right re cost & performance - this will probably not affect the software created to date at all. Ferrites may be suitable but they should not be run too close to saturation maybe ~70% at full performance might be ok - there is always laminated iron or gapped C cores to explore along with powdered iron/sendust type cores. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Only if the core losses are negligible or zero. That is about the only advantage ferrite has as far as use for dc choke applications go. Any other type of core material may be core loss limited by temperature rise. As the frequency is raised hysteresis and eddy current losses in the core increase much faster than the frequency, and its usual to significantly reduce ac flux density, with increasing frequency, especially in a particularly lossy material. In this example, you could EITHER halve the turns, or halve the core cross section, not both together when doubling the frequency. Yes it can be made smaller, but not that much smaller. Dc limiting conditions still apply, no matter how high the frequency. Switching losses in your mosfets also increas directly with frequency. There ain't no free lunch in this game, unfortunately. There are two very different aspects to choke design. The dc considerations, which involve ampere turns, magnetic path length, core cross sectional area, and any air gap. The ac considerations (which are the same as for a transformer). These include ac voltage, frequency, number of turns, core cross section, and potentially core losses. The ac and dc operating conditions are quite independent of each other. If you run a choke on dc, it becomes just a big wire wound resistor ! If you plug a choke directly across the 230v mains, it might run fine, or it might explode. Voltage across a choke does matter, its not just the ampere turns and the current. You cannot just build a choke with the right inductance and dc current carrying capacity. That might work fine in your inductor tester too. But it can fail miserably in a circuit where either the ac frequency or the ac voltage is too high. A choke also needs to be operated well below its own self resonance, which is another whole can of worms at higher frequencies. Cheers, Tony. |

||||

| nickskethisniks Guru Joined: 17/10/2017 Location: BelgiumPosts: 458 |

Peter did you think about skin effect? It's possible you are heating up inductorwire and loosing efficiency because you are not using enamelled copper wire. This could be an option for eu members? T400-26D Edited 2020-06-11 23:18 by nickskethisniks |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

There would be a high pecentage of those who wanted boards that would have aerosharp bits (lying around free), so would it be worth while testing the steel cores? I'll bring some if you don't have any spare, I have quite a few of the smaller ones, and just got a couple of the bigger ones. Cheers Caveman Mark Off grid eastern Melb |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

When running at 80kHz the inductor volume can be halved again and less turns required. Only if the core losses are negligible or zero. That is about the only advantage ferrite has as far as use for dc choke applications go. Any other type of core material may be core loss limited by temperature rise. As the frequency is raised hysteresis and eddy current losses in the core increase much faster than the frequency, and its usual to significantly reduce ac flux density, with increasing frequency, especially in a particularly lossy material. In this example, you could EITHER halve the turns, or halve the core cross section, not both together when doubling the frequency. Yes it can be made smaller, but not that much smaller. Dc limiting conditions still apply, no matter how high the frequency. Tony I didn't include the whole of your text as a quote. The formula I used for my comments was E= 4.44*f*N*flux So if F is doubled flux can be halved usually meaning volume can be halved too Turns could also be halved - but I do agree not both at the same time but a mix of both could be done. Also I agree that reducing flux density is a must at higher frequency but I consider 40 & 80 kHz as being almost DC  I thought this was only required in the hundreds of kHz. I thought this was only required in the hundreds of kHz.Most of my choke/energy work has been at the discontinuous and bordering into early stages of continuous mode. Clearly the very high standing currents that will flow due to using continuous modes and trying to reduce ripple currents (making the average standing current even higher) are the biggest bug bear to using ferrite. You may well be right that we may not find a suitable ferrite solution but until I actually try it and see the results I was not going to write them off totally, I had already mentioned that stacking ferrites will no doubt be part of a working solution. I have also said all along that sendust materials and the koolmu and hiflux derivations are perfect for the job and that is what I will use. Recently I have been looking at prices of ferrites and sendust cores and the lack of availability and high pricing has been a bit of an eye opener. Since I sold my business in 2011 and stopped sourcing these items it is amazing how much harder it is to buy magnetics stuff and at a reasonable prices. And yes to Mark - I already mentioned that steel is a good contender for this MPPT. Edited 2020-06-12 09:23 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

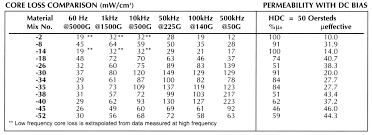

This is why T400-26D will not work. Sorry about the image quality, it is all I could find. Horizontal axis is magnetising force (ampere turns). As you wind up the current to perhaps 200 orsteads, the inductance falls off significantly, in fact -26 material, the lowest curve is the WORST possible material for a very high power design. Now look at -2 material, the highest curve. At 200 orsteads it still has about 98% of its original inductance that it had at zero current. Dash two material is also the least lossy at high frequencies.  With the T520-2 monster toroid I suggested earlier, a workable design is entirely possible, its the only powdered iron material that stands any chance at all of working in this application, and even then it needs 100 or more turns. . Edited 2020-06-12 09:42 by Warpspeed Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I have also said all along that sendust materials and the koolmu and hiflux derivations are perfect for the job and that is what I will use. Recently I have been looking at prices of ferrites and sendust cores and the lack of availability and high pricing has been a bit of an eye opener. Since I sold my business in 2011 and stopped sourcing these items it is amazing how much harder it is to buy magnetics stuff and at a reasonable prices. Stacking ferrites can certainly work, especially if you already have big free chunks of the stuff on hand. But buying brand new ferrite in sufficient size and quantity these days would be an expensive exercise. Agree with you 100% sendust cores are the best modern high tec solution for a project like this, but obtaining something suitable at a reasonable cost has become much more complicated, especially as with Chinese sourced material, you can never be quite sure of what is actually being supplied. When it all came from USA at least it was something that was fully specified, and there was reliable technical data that could be relied upon and trusted. I have been out of professional magnetics design since retirement, and the supply chain has changed rather a lot over the last few years. Its now a lot more confused than it used to be, and I am glad I am out of it ! When I looked at Peter's project I just plugged the numbers into an ancient old DOS program for Micrometals powdered iron cores. Usually it comes up with multiple solutions, where various things such as size, and cost can be compared. But in this case it came up with two possible workable cores. One was a very large toroid, the other a pair of E cores that are now very rare, obsolete, and unobtainable. Not trying to be a total pain in the bum, but I would not like to see people ordering in things with great expectations that I know are not going to work. So please forgive me for all my criticisms of other peoples suggestions, its all supposed to be well intentioned. Cheers, Tony. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Here is a clearer data sheet on that T400-26D core T400-26D-DataSheet.pdf T200 Core T400-26D-DataSheet.pdf Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Can you come up with a workable design for one or more of those cores ? 150v in 50v out 20Khz 16.7uS/33.3uS (1,667 volt/microseconds) 50 amps dc . Edited 2020-06-12 10:31 by Warpspeed Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Just had another look at that T400-26D core, and it might actually work, here is my reasoning: Assume 20Khz switching frequency (50uS) Turn on time 16.67uS with 100v across choke (solar minus battery volts) = 1,667 v/uS Turn off time 33.3uS with 50v across the choke (battery volts) = 1,667 v/uS We normalise that to 50% duty cycle 25uS on, 25uS off 1,667/25 us = 67 volts. From "red column" core loss it recommends about 90mW/Cm cubed max design core loss. From the loss curves at upper right, 90mW/Cm crosses the 25Khz line at about 350 Gauss. There is no 20Khz line, but its going to be pretty close. Now we can work out our minimum turns requirement to reach 350 Gauss at 67 volts and 20Khz. N min = 67 x 25uS divided by .035T x 685 mm squared core cross section = 69.9 turns. So we must use at least 70 turns to satisfy the ac loss requirement. For 50 amps we need 12.5mm squared wire (4mm diameter). Our toroid hole is 56mm, and theoretically 149 turns would fit with zero allowance for insulation. Seventy turns plus insulation should hopefully fit. Initial inductance at zero dc current will be 70 turns x 70 turns x Al value of 262nH/turn. Comes out to 1.283 mH. Now the dc part. Magnetising current (H) = 0.4 x 3.142 (pi) x 70 turns x 50 amps divided by 25cm core effective length = 176 Orsteads. Plotting 176 Orsteads on the magnetization curve we see about 15% of initial permeability. So we have 1.283mH at zero current, and 1.283 x 0.15 = 192uH at 50 amps. That is rather a nice result. Its going to run pretty warm. Ripple current I = 100v (turn on) x 16.67uS divided by 192 uH = 8.68 amps peak to peak (at 2.5Kw) At very low power, the inductance rises to something approaching 1.283 mH. Ripple current I = 100v x 16.67uS divided by 1,283 uH = 1.3 amps peak to peak. So with luck its going to run in continuous mode down to around 1.3 amps dc (65 watts) The figures are a bit wobbly, but should turn out fairly close. Cheers, Tony. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

I went on to the Micrometals site and used their Inductance designer. For that T400-26D core, plugged in values 20Khz, 150v in 50v out 50 amps, here are the results: Their software does all the analysis, with 25 turns we see the max,min uH in the graph at 50 amps, the other details show core losses etc. Running same at 40Khz is better: Not the best core I agree, but available, they have much better ones will little losses all about 1 to 1.5Kg and approx $15, however shipping in small numbers would be the killer here. Here are the T200-26D spec's, will also just work if you stack 3, I am using them at 64Khz 30amps (2 stacked). T200-26B-DataSheet.pdf Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

They are really pushing the core loss with only 25 turns, 33.97 watts core loss, Wow ! And that is not just flat out, that ac core loss is there even with minimal load. The data sheet recommends 90mW per Cm cubed, and the volume is 171 Cm cubed or 15.39 watts core loss with that sized core. With 25 turns instead of 70 turns, that changes things rather a lot. They start out at 277.47uH and finishes at 90.55uH at 50 amps. My design starts out at 1.23mH and ends up at 193uH at 50 amps, and runs cooler too, but at anything over 50 amps, its going to be in real trouble with sudden death saturation. They really pushed the ac side of things to the limit. I went more for max dc and inductance. But it shows how a different design approach with different trade offs can produce totally different results. And yes, 25 turns at 40 Khz makes much more sense. Mosfet switching losses are going to be double at 40 Khz though. At 20Khz, I would still prefer less heat in both the mosfets and the core with more turns and a much lower minimum current where it finally goes discontinuous. Anyhow, some ideas for Peter to kick around. Just came back from about a three mile walk to the ATM and back. Thinking about all this, how about stacking a T400-26D with a T400-2D ?? The higher permeability -26 would give a very high inductance at low current. The -2 core would insure the combination would never be saturated, even if the -26 went to zero. The best of both worlds. It would be like having two very different chokes in series. For something that has to work over a very wide load range, that might be an interesting thing to try  Edited 2020-06-12 14:57 by Warpspeed Cheers, Tony. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1156 |

Mike if you stack two of those cores & play with the turns and inductance a bit, does the core loss reduce to less than the ~30W as before. Gut feel tells me maybe half or even more but I dont know and I wont have time to feed the numbers in myself until later on in the weekend. Also any idea of the cost of the cores ? If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If you stack two cores, flux density halves (twice the cross sectional area), and so does core loss per core. Core loss is measured in watts per pound (Kg?). Half the loss, but now twice the core mass = no change in total loss, but it will run a lot cooler because of the increased surface area. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

This whole saga is rather reminiscent of the historic oZ inverter toroid history. The original oZ inverter design was a huge step forward for mankind, but the original toroid designs were basically reverse engineered from commercial inverter toroids. Idling powers were in the 50 watt to 80 watt range for a stacked toroid 5Kw+ oZ inverter design. I had a very long hard battle trying to convince people that by adding turns and reducing flux density, idling power can be significantly reduced. Today, its possible to build a stacked toroid 5Kw pwm inverter with around 20 watts of idling power. And the whole concept has now gradually been accepted. I had a similar up hill struggle trying to convince people to fit a series choke to their pwm inverters. Many people argued (and abused me) saying their oZ inverter has no choke and its been working fine for years. Again I tried to convince people that the mysterious inverter output waveform wobbles could be fixed by tuning the toroid to x1.5 the inverter operating frequency. I struck a lot of opposition there as well. But anyone that has tried that particular demon tweak, along with a good series choke, has had success at getting a nice clean pwm sine wave. Now I put on my armor, gird my loins, and draw my BIG sword and commence the great solar controller inductor battle. Bring it on !!!!!!!!!!! Edited 2020-06-12 16:51 by Warpspeed Cheers, Tony. |

||||