|

|

Forum Index : Electronics : 8 KW Inverter Build

| Author | Message | ||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Thinking about it a bit more, that 50uF does seem very large, which means the transformer inductance must be particularly low. The 1.5 Kw inspire grid tie inverters use 5uF and resonate at about 82 Hz which makes the secondary inductance about 753mH. Now a much larger transformer will have fewer turns, and I would expect the inductance to be lower. Inductance increases proportional to turns squared, so as turns are reduced the inductance falls very rapidly. I really have no intuitive feel for this, I have not wound or tested any of these large stacked toroids so I have no experience from which to judge what is reasonable. If a few people that have built these monsters can measure the inductance, or better still check the resonant frequency with a known capacitor it would give us all a bit more of an idea where we are with this. There is no particular problem with 50uF, its not really shunting power from across the 240v, but resonant reactive power is circulating back and forth between the transformer and capacitor, it is not power being constantly drawn directly from the bridge. My only concern is that a transformer with abnormally low inductance is probably running at a very high flux density which is bad for two reasons. It would increase the magnetising current and hence increase no load idling power, and there is a much greater danger of core saturation at inverter start up causing a massive and potentially destructive current surge for several cycles. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I have been thinking about this...  Those discontinuities just after the zero crossings, might be caused by a reactive load, where the current is slightly out of phase with the voltage. Its only speculation, but PWM can have problems with providing a current path back through the inverter around the zero crossing points, depending on the actual PWM switching pattern used. If all four mosfets are off at the zero crossing, then the only current path will be back through the inverse diodes which could cause a voltage discontinuity. Try it with a fairly large completely resistive load like an electric room heater and see if the discontinuity goes away. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Hi Warp, That wave is the result of a fan heater 9A @ 230V, so only a small motor for the fan and the rest is a resistive load, however, the elements in those heaters are tight coils stretched out a little. I have ordered a meter that measures inductance, I will till it arrives to look at what my transformers are doing. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes you are quite right. But the transformer secondary itself is a pretty big inductive load right across the output. By tuning the output closer to 50 Hz, that excess inductance can be reduced. Another way of looking at all this is power factor correction. I would not worry too much about it. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

One trap with inductance meters, they assume only a pure inductor is connected to it. Some of these clever microprocessor based inductance meters take measurements at quite high frequencies, especially on the lower inductance ranges. A tuned circuit will measure inductive way below resonance, and measure as a capacitance way above the self resonant frequency. This is the fundamental problem with our big transformer. Its definitely inductive at 50Hz, but probably highly capacitive at 20 Khz. If we try to measure the inductance of this transformer at several Khz, close to its self resonant frequency, the results may be highly inaccurate. A much safer way is to fit some large capacitor to it, say at least several microfarads, measure the resonant frequency using an audio oscillator and oscilloscope, right down in the range we are working at, and then calculate the inductance. Klaus's inductance meter may be telling him lies. Best to use the resonance method, there is far less that can go wrong. In fact all you really need is to know is how much extra capacitance is needed to pull it down to roughly 75 Hz. The closest commonly available capacitor value to that will be close enough. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The Aero-sharp GTI's have a big inductor across the secondary has anybody played with them across the secondary of a OGI? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Check it is not a common mode choke. ........oztules Village idiot...or... just another hack out of his depth |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

OK this is the inductance meter I got:meter Also keep in mind that I have wound the secondary with 4 in hand of 2.5mm sq each. I will try that oscilloscope method, there is a basic audio oscillator on my shelf somewhere. But what I would like is some confirmation of how to go about it. So I connect a know capacitor (I can check it with the above meter) across the secondary. I connect my oscilloscope across that and then my audio oscillator. Adjusting the frequency on the oscillator, what I am looking for on the oscilloscope? Klaus |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Klaus, I have a very similar inductance meter myself, and it works great. Its just that while thinking about all this, the thought occurred to me that there is the possibility of quite a large measurement error if the inductance is being measured at a frequency fairly close to the self resonant frequency of the transformer. Connect the capacitor, transformer secondary and oscilloscope all in parallel as you have already done. Then connect the audio oscillator to that combination through a resistor. The resistor isolates the tuned circuit from the low output impedance of the audio oscillator. You should see a definite, and fairly sharp peak in the voltage across the tuned circuit at the resonant frequency. Try different resistor values like 1K, 10k, and 100K. If the resistor is made too small you won't get a really sharp peak. If its made too large there may be only millivolts of signal across the tuned circuit and it becomes more difficult to see. Experiment with a few different resistors, and you will get a very sharp unmistakable peak that fills the screen at one specific frequency. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

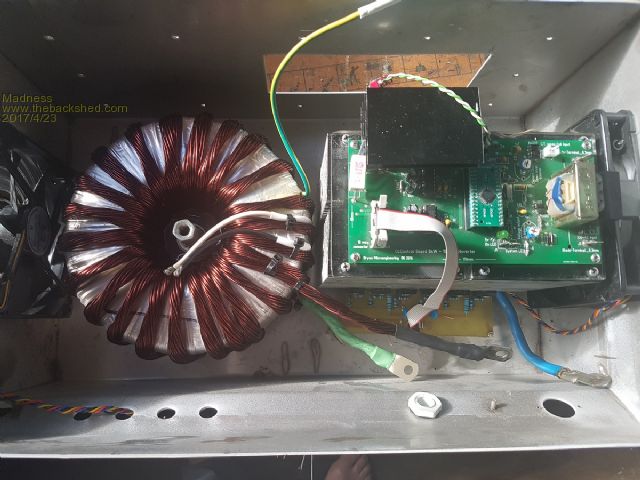

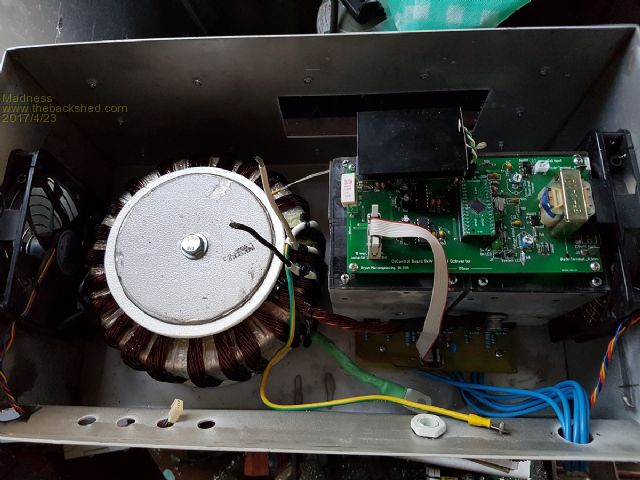

Here is the smaller Inverter I am building with the repurposed wire from the Toroid used as a new primary. This Toroid had a 250 Volt secondary and a 230 primary on the inside, I left the 230 to be the new secondary and reused the 2mm square wire X 19 with 24 turns as the secondary. With 230V on the secondary, I get 1.1V per turn.  I was also able to reuse the piece I cut out for one of the fans to hold the Toroid in place with a piece of perspex under it for insulation.  I thinking it should comfortably run 3 - 4KW continuos, FETs are 4110's I will see how the go but might change them for 4008's There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Damn impressive winding effort there. Should make a nice little unit... I'm a bit iffy about the enamel wires touching as they have been worked a bit by now, it may have been possible to put them in a 6 meter x 25mm heatshrink tube for extra insulation too, but then again they may be just fine. I like it a lot. ...........oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There is only about one volt per turn, so the electrical stress between turns will be very low. But I agree, its a really nice job ! Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

It has had a coat of epoxy all over the primary so there should be no movement or exposed wire. The wire was also very flexible, this toroid is different to any of the other Aero-sharp ones I have seen. The 1KW SMA toroid (not the one in the photo's) that I scrapped had tape on every wire where they went through the core on it's primary so that each turn had an extra layer of insulation between each turn, the tape was very similar to Kapton tape. I had thought insulating it more but this way it is going to cool better, another thing that is really nice about doing it this way is it did not take a lot of time and a whole it cheaper than welding wire. The heatsink from the old SMA 1KW worked out well, I never measured it, just cut it in half and then half again for the low side, there is less than 10mm to spare end to end. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The end result was 8mm diameter so 12 or 15mm is probably big enough heat shrink and you would need at least 7 metres. It was quite easy to bend around the corners too, what I found helped a lot too is to wind it through the core into about a 600mm diameter coil and tie the turns together leaving the first couple turns free, then rotate it through as you go. It took less than 2 hours to cut the wire, twist it and wind the primary. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

"It took less than 2 hours to cut the wire, twist it and wind the primary." .......... you do realise I have to try this now..... dammmit  .......oztules Village idiot...or... just another hack out of his depth |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

What you could try, if you wanted extra insulation, is to wind spiral loom wrap around it. Wound with a gap between the turns there would still be cooling but the bundled wire turns could never touch when passing through at the toroid hole. I should imagine trying to sleeve 7m of heatshrink over it would not be easy, also, if its shrunk it would stiffen the bundle a lot. Klaus |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

No Tinker, it will be easy, as you can just do 1 meter at a time.... it does not need to be contiguous.... or waterproof, the segments need not even catch onto each other. If he had used 24 120mm bits, then you could wind and only have the shrink on the inner core of the wires, leaving the outer naked. I am only concerned with where the wires pass over each other. Tape could be used too, but look poor. There is a lot of weight in a dual or triple core, and I would feel better with insulator between turns where they cross. True the inter-winding is only 1 v between turns here, but a lacquer fracture would yield a welder. He has used epoxy to hold the turns, which alleviate most of my concerns.... but you only have to do this once.... fiddly but there forever.... even every second turn would do. .......oztules Village idiot...or... just another hack out of his depth |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

If you search for "heat shrink tube 8m" on Aliexpress there are lots of options that come up. Once the cable is twisted it would be quite manageable to slip it on. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

It is a credit to you Mad.... I started on this path a few years ago... but gave up early into it, as the 1.8 diam wire was just too stiff to contemplate.... but you have the mettle to prove that I gave up too early. I wound a dual core yesterday .... now I might undo it, and try your style.... mutter mutter mutter....... ..........oztules Village idiot...or... just another hack out of his depth |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Sorry Oz, (actually I am not sorry at all  ) )You must have a big pile of unused wire with all the rewinds you have done, at least this way you reuse most of it and save $100. With the wire twisted it will allow it to bend more easily, a tool like Gizmo made to do his might be useful to do the heavier windings. Also I would like to thank you for your encouragement to use the GTI, the 1.5 KW bank of panels I have connected are always showing more power out than 50% of each 3KW banks I have connected to the 2 Midnite charge controllers. At least that is what the Aero-sharp is telling me, plus the fact that a portion of this power is not going back through the OGI there is increased efficiency there also. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||