|

|

Forum Index : Electronics : building an Inverter from scratch

| Author | Message | ||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Warpspeed, your neat terminal blocks would not have prevented any burn marks caused by the exploding mosfet, if the terminal was mounted on a PCB. If you look closely at the picture, the mosfet legs go through the 3 holes and are terminated on the track side which has no damage whatsoever. I too do not like to unsolder 3 legs to remove busted mosfets and I don't have to with my termination method. Only the gate lead is soldered to a PCB track. The drain & source leads are bent over to lay flat against their tracks. They are terminated there by clamping with the 1.5mm copper strip I mentioned elsewhere. Klaus |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Clockman, you possibly never worked as an electrician. I have and every high current connection I came across was bolted, swaged or clamped. There is little chance you ever see people joining power cables wielding a soldering iron. Solder is actually a poor conductor in itself, check the conductivity of lead or tin if you use standard solder. Solder should also 'never' be relied on to carry any load at the connecting point. It can get brittle with micro cracks if there is a repeated mechanical or thermal stress on the connection. If you do not believe me check the high current connections the maker of your car uses and tell me where you found one that was soldered. Klaus |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Screw terminal blocks and crimp terminations are a very well established method, if enough pressure is applied during assembly, the metal actually flows into any voids, there are no peaks and troughs as you suggest if termination is carried out properly. As for "high power" the cross sectional area through any part of those screw connector blocks will be much greater than through the legs of the mosfet. A really badly burning mosfet can certainly discolour or melt some of the plastic in the terminal block, but that can be replaced as easily as unsoldering a mosfet. But a disaster of that magnitude only happens rarely. Usually a mosfet just goes pop and fractures, or craters in the middle. The main issue is to preserve at all costs the integrity of the actual circuit board and its tracks in the case of a very violent blow up. Even an expert will have problems after replacing the same mosfet several times, the tracks and pads just lift off the fiberglass, then you are in real trouble. Replacing one or two mosfets by unsoldering is not a big deal. Replacing twenty at a time starts to become a real pain after a while. Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

I think it depends on how you do things, and the board design. I can see where Clockman is coming from, and his boards can withstand any amount of fet replacement IF you do it similar to me. 1. do not even contemplate removing the fet in one piece. 2. snip the legs off so you only have to remove three bits of wire. This takes any stress off the board, the pads, and the bloke doing the unsoldering. It reduces to seconds the removal process... faster than undoing a screw even 3. Once the legs removed individually, simply solder sucker the pad holes, heating from the largest lands side if double sided...once again, only a few seconds 4. replace fet... it is very fast and simple even for 24 fets at a time.... I know this very very well When it first happened it was a saga, trying to remove the fets, but when you simply use the bead cutters instead, and only need to remove a little stub of wire ... well it. takes longer to unscrew the fets from the heat sink, than removing it almost. On the clockmans boards, the lands are so massive, that I figure lots of changes is within reach for these boards. He has made the holes big, the lands big, and the thickness of the copper makes for a very robust environment.... and I have tested this out quite a few times.... there is no discernible degradation to the board. With a 60 watt iron, I still need a heat gun to supplement the energy needed to work on these boards. If you just use the iron full blast, you will probably over heat locally, and that s when the pads suffer loss of adhesion. They seem to suffer the solder temperature just fine, but when you try to heat up everything in sight with just a hot tip.... at the pad of course, as there is no mask there, you tend to overdo the tip temp, and cook the pad glue. My boards I got commissioned for the power board, has slightly less meat on the lands, but seems to suffer replacement well.... big holes and double thickness help, but chopping the legs off is the key to not damaging the board, regardless of manufacture. I can see the sense in the screw type for testing, but for long term, I will feel better doing it the way the manufacturers use. So snipping the legs makes it far less painful is the key.... and a heat gun to spread the heat helps immeasurably too with solid boards like the clockman. I know clockman says use big irons on his boards, as the big copper lands soak up the heak very very fast, but smaller ( 40-60w) and a heatgun to get the board up a few hundred degrees first seems a better system to me and the boards. ..........oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes, I use the cut all the legs off method all the time when replacing large logic chips and microprocessors, then fit a good quality machined contact socket for "next time". But what if you have a dozen mosfets in parallel and only one has shorted ? Do you trash the other eleven as well just to remove them all quickly ? I would much prefer to remove all of them without any damage, and individually test each, along with the gate series resistor, and driver chip. If you don't do a really thorough job, it will very likely go bang again and blow another set of mosfets. After a lifetime of designing commercial power electronics and repairing same myself, It is always good to make the job of the poor service tech just a little bit easier if something can be done slightly differently. And if some snotty company bean counter start nagging me about cost savings, I grab them painfully by the ear and let the service guys loose on him. A a dose of reality about hourly labor costs (and the morale) of skilled tech people usually convinces them. I suppose for a hobby it does not rally matter. Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

No Warp I don't mess about. With fets so cheap, and it being so easy to replace one or all.. I replace all. I am not smart enough to know how to test them well enough to know if the silicon has had a shock that will hobble it at high power... so just replace the lot on each leg... if one has gone, then that leg is replaced... usually for 6 dollars or less per leg total... the bigger HY4008 is probably closer to $8/leg if six fets..... close enough to free really... wouldn't even buy lunch. It takes me longer to extricate the board from the bowels of the chassis, than to replace the fets I think. The gate drive resistors are usually ok, the drivers are plug and play, the fets are easy to replace..... the thick battery cables are a pain, as are the transformer cables... thats the worst part, all the other stuff just unplugs. However, to each his own. ........oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Where do you get HY 4008 for $1.20 ? Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

https://www.aliexpress.com/af/hy4008.html?ltype=wholesale&d=y&origin=n&isViewCP=y&catId=0&initiative_id=AS_2016122202291 2&SearchText=hy4008&blanktest=0 They are more expensive than when I bought the first lot of 24 for $22aud But there are still some for .64usd which if ordered in any quantity comes in at less than $1.3 aud.... seem to be getting more expensive every day .....oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

A lot of this stuff comes from China which is priced in US dollars, and the US dollar is pretty strong right now, especially compared to the Aussie dollar. They still look like a really good deal though. Will definitely buy a bunch of them after Christmas. Cheers, Tony. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

A Happy New Year to all who read this apparently never ending saga... Yes, I started it last year in April and had thought I would have that inverter building thing sorted out long ago. Now I discovered another, unexpected, pitfall for someone trying to build an inverter from scratch, using economical parts sourced from ebay. I was firing up the big inverter after having checked everything numerous times. I do that by monitoring the DC rail voltage as the big capacitors charge up through the test resistor. Nothing was switched on BTW, just charging up the caps. The voltage climbed slowly towards the batteries (54.7V) but somewhere before 50V there was a soft 'plop', the voltage stopped increasing and then started to reduce. I disconnected the cables and then investigated to find out what had happened. A few HY4008W had shorted but why? All the electronics were switched off. It appears I bought a dud patch of HY4008's. I extracted a few that were not shorted (easy to do with my assembly) and proceeded to bench test them up to their rated 80V. I use a bench top power supply (up to 35V) end extend its output voltage with a neat box that I described here in another thread some time ago. Shorting the gate to the source, I connected the positive lead to the drain (neg to source) and increased the voltage slowly while measuring the current - there should be zero. Around 75V there was a 'plop' and it shorted out. There was a series resistor in circuit to protect my milli Amp meter. So it seems they drop dead below their spec voltage. Some of the others did so too while some stood up to 80V. I would suggest to include this test when measuring the mosfet's to match their on resistance, it could save some later hassles. Now its another wait until some replacement HY4008's turn up, I also ordered 20 IRFP4110PbF (100V/120A/3.7mOhm) to try. Klaus |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I am waiting on HY4008's due to dodgy IRFP4110PbF's I have found all the ones I have are 10 times higher RDSon than they should be. The HY4008's I have ordered from 2 different suppliers from Aliexpress have not arrived yet due to silly season, perhaps Tuesday they will turn up. Other really cheap items I ordered after them have already arrived, their shipping times are all over the place. Next time I think I will just bite the bullet and buy from a more reputable source would be cheaper in the long run. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Have you got anybody in mind for your reputable source? Klaus |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Someone like RS or similar where you know you should not get seconds. I had Diodes on order from Aliexpress and got impatient and ordered the same from RS. Ended up getting the ones from Ali and they were exactly the same except at about 1/10th the price. Maybe someone else has a suggestion where you can buy quality at reasonable prices. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

You can buy from people like RS, Farnell, Moser, Element 14, Digikey, over the internet, but you will be paying full price for genuine articles. They make their money buy bulk buying, and selling one at a time for a very high mark up. Even better might be to buy direct from the manufacturer, it will be cheaper per item, but there will always be a minimum order quantity, usually a full tube which might be fifty devices. That can easily run to several hundred dollars which really puts it beyond our reach. A Forum organized bulk buy might be a possibility, but it might be a more trouble than its worth. I really do not know. A great deal of the really cheap electronic parts flooding out of China appears to originate from a variety of different sources. One interesting source are bulk container loads of dead electronics that the local garbage recyclers send back over to China, where all the smashed circuit boards are picked through and second hand parts reclaimed. These parts can actually sometimes be of very high quality, but old. I have bought old EPROM memory chips and high end European made electrolytics from Chinese sources that have been excellent value. The second source of cheap Chinese are reject out of specification parts that have failed a manufacturers final test. The parts almost always work but have some problem such as voltage regulators with out of spec output voltages, or quartz crystals and filters way off the marked frequency. As Tinker has discovered, some components may start to avalanche destructively below the rated voltage, or may have very low gain, or very high "on" resistance way worse than specified. These parts still work, and may be useful, unless you really need to push it to one of its design limits. In that case you may have a problem. Third source of cheap Chinese are just total outright fraud. Parts that are total duds, that have never worked. Probably found in bulk on the tip, and are perfectly genuine parts but totally useless. You sometimes see adds on E -bay for things like "component type xxxx". we do not know what these parts are for, and have no way of testing them, sold as is. No returns. Very cheap buy fifty for a dollar. Good luck with that ! Fourth are deliberate counterfeit parts made with zero quality control up an alley somewhere, and stamped with the logo of some large reputable company. These are usually total garbage, but you will never know that until the parts fail to work, or work very poorly, or just stop working after a very short time. So really you get what you pay for. But if you are very careful there are definitely bargains to be had. But you will get taken sooner or later. I use a lot of cheap Chinese, but NEVER in a critical location where failure is likely to cause a lot of expensive difficult to repair damage. Cheers, Tony. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Thanks for the insight comments Tony, they make a lot of sense to me. Since this is just a hobby for me I probably persevere with the ebay parts. I did price them at RS, over $5.00 each at 25 pieces/lot. Perhaps last resort if the ordered parts also turn out to be crap. Klaus |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Cheap Chinese can still be a bargain, but it might be worth individually testing every individual part before soldering it in. Its a hobby for me too, and my time is not worth much these days. Cheers, Tony. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

there is a fifth source, that is where a big manufacturer finishes a project or it fails to get to market and they auction/sell their surplus stock of parts. the parts can be resold "as is" which is fine but they are also cleaned of markings and reprinted or reskinned to resemble similar components that are in short supply or more expensive. This is the hardest to detect, it looks like a genuine brand cos it is but it can be a different rating. I'm confused, no wait... maybe I'm not... |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

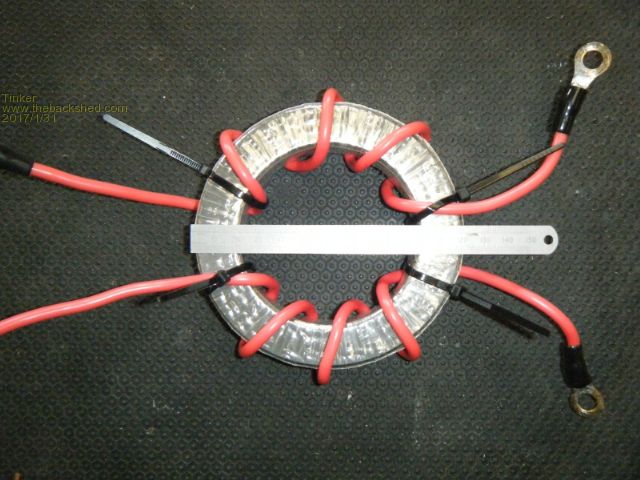

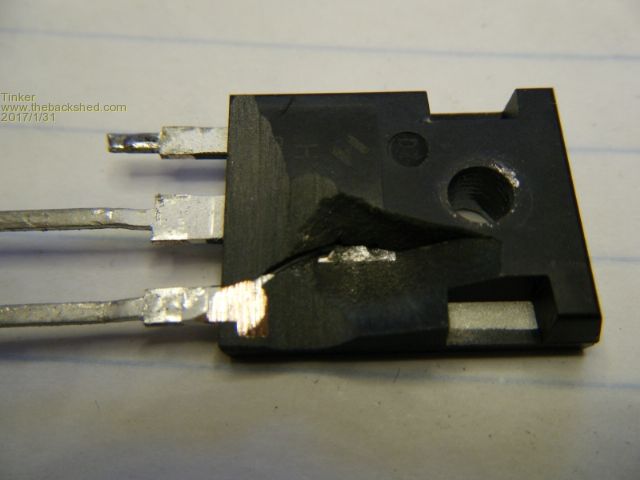

So its been a while since my last post here, there was only a little progress on my monster inverter since. Madness posted a picture of his ring core ferrite choke recently, the one I'd ordered (its bigger)ferrite ring core has arrived and I tested it on my 4 Mosfet test inverter. Well, its certainly quiet, none of that annoying buzz one gets from the E-core chokes. And there is heaps more room for the cable to wrap around, 8 turns are doable. So I wrapped 8 turns (of 6mm sq) on and started testing. The trace on the scope looks good, just a small wiggle at the zero crossing line with a 1200W load (all my test toroid can handle with its 4 x HY4008 Mosfets). Next I replaced the 8 turns with 2 x 4 turns like this:  The idle current is exactly the same as with 8 straight turns, the CRO trace the same too. So this is the way I'm going to wind my ring core choke, using 4 x 20mm sq cable in parallel for each 4 turn wind. Doing it this way is easier with my placement of the stacked core toroid and the Mosfets on the big heat sink. I can use the individual connections of the chokes to replace extra heavy cable links I had to use before. Something I found out about these chokes: more turns = < idle current (there is a practical limit here). Also: bigger core cross section = < idle current. To test the latter I had the E-core everybody uses which is 540mm sq. and a larger E core with 850mm sq and The new ring core with 418mm sq. The larger E core with 4 turns still had a lower idle current than the ring core with 8 turns - 146.5 versus 172.5mA. So, if one wishes to push the envelope here I would suggest a double stack ferrite ring core. This would cost almost the same as the 540mm sq E core but be a lot easier to wind on. On another matter, I think I found one reason why I managed to blow so many HY4008 chips. The last 'accident' was a gentle affair, just the top of the chip popped off rather than the usual violent explosion.  One can make out the place where one of the two tiny wires that connect the source leg to the substrate was. These 2 wires were no more than 0.5mm in diameter and they are about 5mm long each. Passing 200A through this is a big ask, even if they were silver wires. So I think that 200A rating is perhaps with an infinite size water cooled heat sink  . . My problem was the Mosfets had to be insulated from the heat sink, I used those silicon pads with heat sink compound. When running my test inverter for a while on its max load I measured a temperature difference of almost 10 degrees between the black Mosfet back and the heat sink. So I now think that sudden extra loads create more heat that can be moved quickly through the silicon washer, the chip overheats and - pop. What I will do to get around this - I still prefer an outside, non 'life' heatsink - is to mount the Mosfets onto my sub heatsinks straight on. As there are 4 sub heat sinks there is electrically no problem as long as each of the sub heat sinks is insulated from the main heat sink. The heat transfer area is now about 10 times bigger so the insulator should transfer it better too. I'm using that thin double sided sticky tape, as used to stick heat sinks onto CPU chips. That tape comes in many sizes and thicknesses, I picked the thinnest tape I could find which is 0.06mm. Its quite economical even in the 50m roll it comes. Best of all, it easily withstood my 90V DC test and its rated to 120 degrees C. Time will tell if its a success. Klaus |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

I think your turn count is incorrect as i only get 3.5 turns per side on the core. Maybe that will change the calculations slightly? Sometimes it just works |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I beg to differ Pete. According to our toroid expert here (oztules), there are *no* half turns with toroid cores. A turn is counted each time the wire passes through the center hole. Klaus |

||||