|

|

Forum Index : Electronics : OzInverter OzCntrl PCB rev12 Sept2017

| Author | Message | ||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Mark, you will get more sore muscles when you straighten your wire. Look up other inverter builder's posts to see how they solved the straightening. You want to manipulate that wire as little as possible. Ideally you have a stretch of ground ~30m long. Hook one end to something firm and unwind the wire from the shuttle to the ground. I first slid a plastic nozzle (as from chaulking cartridges) over the wire and carefully pulled it along the wire to pre straighten the kinks and stopped to open any loops (loops are *very bad*). Then I used my patented  wire straightener. wire straightener.After this I carefully wound the wire around a plastic bowl (a short bucket would do also) to form a coil about 250mm diameter. Just the right size to load your winding gizmo (I used a cut hand casting fishing reel). It helps if the corners of the toroid are rounded a bit more. The hard way to do that is using a grinder  the easy way is to cut 2off 6mm plywood disks, round the edges on one side and epoxy them to the core. the easy way is to cut 2off 6mm plywood disks, round the edges on one side and epoxy them to the core.BTW how were the original windings arranged? on my latest aerosharp 3KW toroid the 230V winding was innermost, consisting of 3 in hand 1.8mm windings, 195 turns. I just wound another 30 turns (3 in hand) evenly around the toroid and had a finished secondary. Much less work than winding the lot (225 turns) but I did my first toroid the same way as you  . .Now, clockman gives you somewhat different numbers than I used. Oztules worked out a ratio of 9:1 turn works well for these inverters. I found that a 225 turn secondary gives a nice low magnetising current of 45ma @ 230V and the curve of which is fairly flat until past 250V, happy with that. My primary is 225:9 = 25 turns 3 in hand of 1.8mm wire is 7.5mm sq. Your primary should be 7.5 x 9 = 67.5mm sq. Try to get close to this. Have fun and do some experimenting. Whether you wind your secondary 'hands' individually or simultaneously (there's a challenge!) you should test each 'hand' for short circuit turns before connecting all up. A shorted turn will increase the expected magnetising current substantially and, after a while, things get hot. Do take the precautions about connecting 230V AC to large toroid windings unless you have a variac and can start from zero Volt up. Klaus |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Its not obvious, but the only part of the wire that actually does anything is the bit that is within the ferrite slot. Or in the case of a toroid, the very short section of wire that passes through the hole. The other three quarters of the length wrapped around the outside is just there so it can make another pass through the hole. You will have noticed that clamp testers and current transformers often just go around a single wire very loosely and they work fine. So don't fret about trying to wrap a really fat cable around a ferrite with very sharp corners, it really is not necessary. Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Tinker, I'm afraid you have just confused me. What I pulled apart was a mess, very fiddly, the last section below the copper tape was three wires wound around together, unfortunately, they crisscrossed a lot, so I had to use three different bits of wood to unwind the bastard. I wasn't counting jack crap at that point, just cursing it. Winds going back on? Hmmm I am totally confused by that too, there have been so many different numbers, I was going to cross that bridge when I came to it. Warpspeed, that makes it a lot more simple than having to make a tight coil, thanks mate. Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

I like the idea of ply ends, I'll probably use MDF unless there is a reason for ply. Cheers Caveman Mark Off grid eastern Melb |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Ply is what I had, you have MDF, same job... Put epoxy over the outer surface, its a bit soft where sanded otherwise. Klaus |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Don't get hung up on the turns you took off. I did not count them, you just need to calculate the number of turns based on the cross section of you toroid (or the 2 of them stacked together). I used a grinder to take off the corners and then smoothed it off with a cylindrical flap thing in the drill, there was nothing hard about that. Also you don't need to go out and spend a few hundred dollars on a Variac, you can connect a 240V bulb in series to handle the sudden inrush of current when your first apply power. Oztules has posted very clear instructions on how to do straighten the wire and wind the toroid here. Only the primary you need is a 9:1 ratio not 8:1, 8:1 is for PowerJack boards, only other difference I would suggest is reusing he enamel wire rather than welding wire as per the link I posted previously. There are lots of different ways to go about it, do what feels best for you. PS To wind the Toroid takes a lot of pulling and bending, Your arms and fingers will get a workout. I would suggest doing it short sessions and work on other parts of the project in between. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Confused you, I'm good at that  I unwound the three in hand (outer 250V winding) as one and then laid all three along the ground and unravelled them that way. Using three shuttles at once would be a real challenge, congratulations for mastering that feat. You need not count anything by way of turns when unwinding. That is why you wound a ten turn test winding around the thing while it was still whole. The voltage from these ten turns gives you the volt per turn ratio. From that you can calculate how many turns your original winding had. Provided, of course, you took precise measurements with the 10 turn and original winding mains voltage. If your core measures 203mm OD, 100mm ID and 70mm high you could use my suggested numbers (225 turns of 3 x 1.8mm)secondary, 25 turns primary. While warpspeeds comments are true with the toroid, you should try to wind as tight as possible to avoid vibrations in the turns. That is also why we epoxy each layer and wrap that clear tape back on. You will never get the new windings back on as tight as the original machine wound ones were. With my original 195 turns and added 30 the hole had shrunk 75mm. I put that electrostatic tape back on which shrunk it a bit more. After my rectangular enamelled primary winding was on the hole had shrunk to 55 mm. You will get a lot less than that using round bundled wire. Just leave enough for the 12mm mounting bolt. Calculate the space required for your primary wire bundle first, before you put that static tape back on. If it looks very tight with space leave the static tape off and gain a few mm that way. This tape prevents static coupled primary to secondary interference. Klaus |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Mark is doing a double stack Tinker. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Here's a picture of my winding table:  Its safer than trying to wind the thing while its on end and ready to roll off the table. Klaus |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

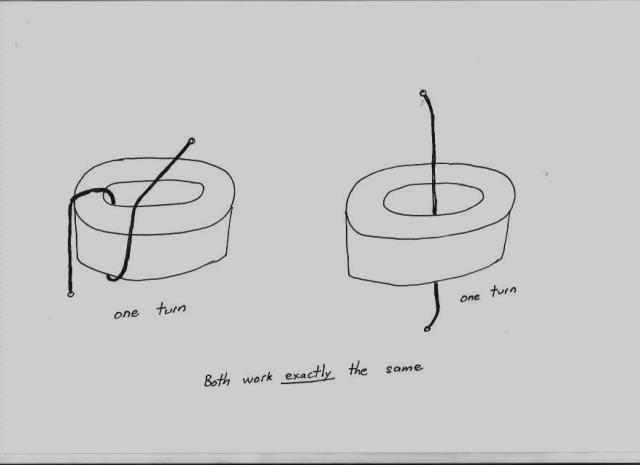

[quote]While warpspeeds comments are true with the toroid, you should try to wind as tight as possible to avoid vibrations in the turns. That is also why we epoxy each layer and wrap that clear tape back on.[/quote] Yes a good neat tight solid winding is definitely the way to go for the final effort. But for quick and dirty initial testing, for example a ten turn experimental winding as previously suggested, just ten loose sloppy turns of any old pvc wire will work exactly the same for measuring turns per volt, or magnetizing current. With all these things, one pass through the hole counts as one full turn, regardless of where the wire is located in the hole, or how it gets back around the outside of the magnetic core to the other side.  Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Thanks guys, yeah I'm doing a double stack 6kw version. So the next one has to be pulled apart now. Still have another 2 NIB 3kw to make a second one as a backup, or split them across the house. They sound so reliable and with a std small home and 1 child, prob 1 will be totally fine for the house. I have Clockmans book which mostly covers the PJ boards, but it has the testing technique with the bulb. As Madness suggested I've been bookmarking all of Oz's relevant pages on the net. I saw how Oz straitened his with the bearings and was going to copy that, I'm concerned about scratching the enamel off though, I was thinking of using the plastic rollers on the bottom of sliding doors, they have a nice rounded concave shape and a bearing in the centre, was thinking about some silicone spray but that won't be good for when it needs to be glued, maybe the garden hose set on mist spraying at the area? (might be over thinking it there) Ha, when I first looked at it I was thinking maybe a week to build, now it's clear it will be a couple of months at least. Thanks again for the help. Cheers Mark Cheers Caveman Mark Off grid eastern Melb |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

It does not take long to build once you have done one..... it figures. Laziness now.... I just stretch the wire straight, as someone else suggested. I expect it makes micro cracks in the enamel, but who cares.... it is all insulated by the mylar, and the epoxy fills the cracks that may be there. I make sure there is never any overlapping of enamel wire, which is more than I can say for the commercial stuff. Of all the ones I have built, none have failed or shown any sign of fatigue.... and I fully expect that to continue. The epoxy covers a lot of sins. .........oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There is only going to be a couple of volts at the most between adjacent turns. so the insulation is not going to be very highly stressed. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

How many have you got running now Oz if that is not a rude question? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

So when you start the unit up do you hold the reset button when you turn the DC supply on, then release the button? Cheers Caveman Mark Off grid eastern Melb |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

No. When you put the 48v batts on, it will probably start if you splat the terminals, but if you use a say 30r resistor to alleviate the splat, it will hang... then press the reset, and it will start normally from this time on. ........oztules Village idiot...or... just another hack out of his depth |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Thanks Oz, I've been printing out all these tips and keeping it in a folder for when it's needed. Cheers Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

OK thanks Oz, just to clarify it, you "prime" the system using the resistor, once charged up, then the resistor is removed and dc power input permanently connected. Cheers Caveman Mark Off grid eastern Melb |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

yep Village idiot...or... just another hack out of his depth |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

This is the way I turn mine on too. But the resistor is connected across the DC C/B permanently. With the breaker open the caps charge up via the 33r resistor (use a big one, 10+Watt rating, in case there is a problem). I have a zener diode controlled battery voltage sensor which turns a LED on when the caps are charged up. When that happens the DC C/B is closed manually, shorting out the 33R resistor. That battery voltage sensor also doubles as a low voltage shut down. This is done by tripping the over current thyristor. You can see how that's done in one of the circuits I posted a while ago (building an inverter from scratch). Klaus |

||||