|

|

Forum Index : Electronics : building an Inverter from scratch

| Author | Message | ||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I buy the IRFP4110s from aliexpress for $1.67 AUD each in lots of 20. They all measure around 2.1MO RDS off, my meter that measures low resistance is not resetting to zero for some reason so have not been able to measure RDS on. When the FETs switch off I see about a 5V spike from my big toroid, is your 20 volt buffer enough? Someone I know has just installed an AC and running it off a 3KW Latronics ATM, it is drawing right on the 3 KW and he has had to take the cover off and direct a big fan on it to keep it under 60. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Use a normal DVM to measure the millivolts when switched on under a known current load to calculate the Rds on.... I use a 5 amp load.... use 12v to the gate, and measure the drain source voltage in millivolts and ohms law. Any current will do, so long as you know what it is..... then millivolts/current = Rdson. The man with the 3kw expensive unit will not be pleased when he sees your unit running at 8kw and more. The other units on aliexpress that use the hy4008 seem to be ok with it in 48v units. ..........oztules Village idiot...or... just another hack out of his depth |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Thanks OZ, I should have thought of that. That fellow with the Latronics has had it for quite a few years now, he is taking the easy road and building an Inverter with Chinese ready made PCB. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

oh dear, that should read volts over current... not millivolts over current.....even though you are measuring millivolts....... or I suppose you could use millivolts/current then divide by a thousand... or ... or... think I'll just fade away about now.... ...........oztules Village idiot...or... just another hack out of his depth |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I know what you meant, I would have used the app on my phone called electroDroid. It has lots of useful calculators, colour codes and much much more. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I use a 10A current through a low R load, that way no application of Ohms law is required, just divide the drain/source milliVolt reading by 10 (move the decimal point one place to the left) and you have the D/S On resistance. It is *important* that the DVM leads that measure the millivolts are connected as close as possible to where the Mosfet leg connects to the body. One gets wrong readings if this measurement is taken from one of the 10A current carrying leads. I used the same resistor/diode arrangement as in the inverter to switch the gate on from 12V. Oztules, I have not yet fiddled with the current set potentiometer to see what happens at switch off with the SD line due sensed over current. I will try that shortly. I did test the SCR turn off point by passing some amps through the C/T to see if the flashing Led comes on - it does. Later, when powering the inverter I had to adjust the current set pot as it prevented start up due the load current being too great. Klaus |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

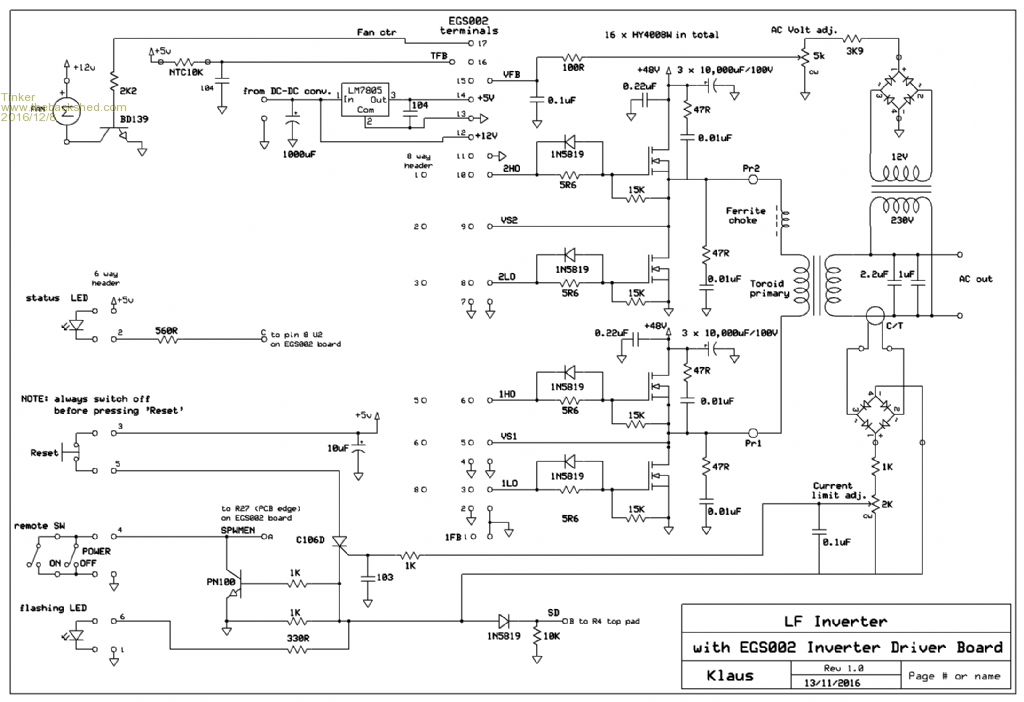

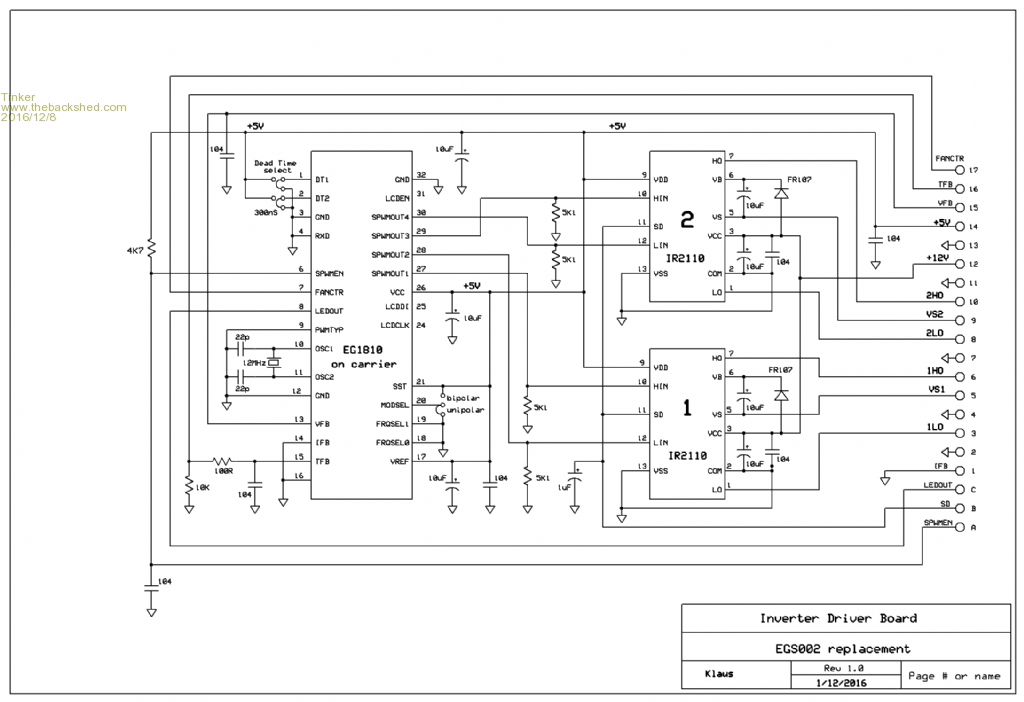

Have assembled the new layout of my EGS002 replacement board and it works! I'm happy now. Its a plug in replacement to my modified 20 pin EGS002 board (see previous page re the mods). But the big plus is the driver IC's can be easily replaced, just plug new ones into their sockets. These chips seem to go kaputt when the Mosfets fail catastrophically. So, here is what it looks like:  The board plugs into my little motherboard where the header pin connectors are located. The 300mm long gate leads from the socket did not appear to affect the running of the inverter. Here is a close up of the replacement board:  And, in case anybody is interested, here are the latest schematics:   Please note that the schematics I had posted previously have changed. I have to post updated ones as there is no way to correct what I posted some time ago. Oztules, you might be interested in the current shut off testing I did today - it works very well. I connected a 600W load to my test rig and slowly increased the current sense potentiometer until the SCR tripped. Unit shut down and flashing LED came on as expected. Reduced the current sense pot a little and, after resetting, switched on again. No start, the pot required more adjustment. When I found the setting where it reliably started with the above load every time I left the pot alone. Then I switched on an additional 100W load and the inverter shut down instantly, no hesitating at all. I could repeat that successfully many times. I did not try the short circuit test, not game enough yet  but I think it might work too as the overload shut down is very fast. but I think it might work too as the overload shut down is very fast.Klaus |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Will this work with the EGS002 as well? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

If you are referring to the lower (motherboard) then yes, it does work. You may spot a little modified EGS002 board at the top of this page running my little test inverter. The mods (described on the previous page) add 3 pins to the 17 pin EGS002 connector. These pins I labelled A, B & C on my schematic. They are required for soft start/ stop and over current shut down. Also one pin caters for the external status LED. Do read oztules reasons for modifying the EGS002 board, they are dangerous to use with our inverters as the come from ebay. Klaus |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Thanks Tinker, I have a couple of them here, I was wondering if it is worth trying them or not. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

|

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The AC I just installed can draw up to 3.55 KW, Someone I know has just installed an AC and running it off a 3KW Latronics ATM, it is drawing right on the 3 KW and he has had to take the cover off and direct a big fan on it to keep it under 60. [/quote] I know all this is quite inspiring with building ones own inverter and hats off to perseverance when blowing and throwing countless components. I do however think the topic should be about what is being done here to sort out the problems with your own builds and not have comments directly and naming and degrading what I call a Proud Australian company " Latronics ", 100% Built Wound ,PCBs cases ect Australian Designed and Built and stand behind their product with a rock solid 3 year warranty.That has continually over the years resisted moving to Chinese Production as to of our companies do. I see no reason why latronics is accused of being not correctly rated by what appears straight up to be very wise men with lots of experience. It may just be in passing comments and I think not necessary and also against forum rules if abided by. Latronics make a top quality bullet proof very high efficiency inverter and if a prospective customer is searching for reviews and gets the page where the "Someone I Know" is running a 3.5kw AC on a 3 kw Inverter with the covers of and a fan blowing into it to keep under 60 deg would probably indicate there is a lot more to the story than a sentence. I will fly the flag on their behalf as I have a very good insight into the company and employees as well the Electrical Engineers that are constantly trying to improve their products. I also know first hand what lengths they allow me to destroy their inverters so as to make them bullet proof, and intern it means a better product far less warranty work. Firstly, please don't misquote me, I never said he was running a 3.55KW AC off of a 3KW Latronics Inverter. Secondly, this person is a very reliable source and if he says his inverter is running hot at it's rated load I have no reason to doubt him. He did call Latronics and their solution was to send it back and they would repair it for a fee of $550 dollars. He has decided that he can build several Inverters for that amount of money and therefore won't be sending the Latronics back to them. I did say that he has had it quite a few years now, until this overheating issue (he has just added 5 KW of panels and never ran it harder than around 1500 watts previously) he has been very happy with it. That includes the time he had a lightning strike and he drove 3 hours to their factory and repaired it for him while he waited and then took it back home. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Fillm, please!! This is MY thread. I write about my inverter building experiences here. And when I mention a part recycled from a well known "Australian company" I do not want nor expect a lecture about what great products that company sells. Please find another tree to bark up, this one is definitely the wrong one. FYI, I do have a fully functioning inverter, sourced from your "Australian company" and it has been powering part of my house (the lights) for a few years now without any problems. I mentioned the origin of that little *recycled* toroid so others can get a picture of the size of it. This had nothing at all to do with its function in the original inverter, just the size and power rating in MY test inverter. Klaus |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Tinker - Madness, I do not want a "Bun fight at the OK-Corral", and don't want to derail a great thread. I have always applauded both of your efforts and my intensions are more about using direct company names and statements that could be seen as ..... I am sure you know what I mean. Also taking into account I suppose, what could be leveled at the owner of the site if any actual company ever takes offence. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I don't want to muddy the waters here. But after much messing about myself with building various projects over the years, and having quite a few blown mosfets from time to time (hahaha) I now build things in a way that I can replace a mosfet in less than thirty seconds without a soldering iron or the slightest risk of damaging the circuit board. The trick is to use TO247 packages as mentioned earlier, and three terminal screw blocks on the circuit board. Here I am using copper spacer blocks, simply because I already have the material. Aluminium would work just as well. If you tap holes through the spacer block a long 3mm screw can be fitted permanently up from underneath holding the spacer block in position. The mosfet then just drops over the protruding screw. Dead easy. One of Murphy's laws says something like "parts that can be very quickly and easily replaced never fail". This is an old picture of a project in progress, that illustrates the general idea. If I was building something that had a whole bunch of mosfets, I would not now consider doing it any other way. Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Phil, You can wave whatever flags you want, it does not get away from the observed facts. The Latronics 1200w ls transformer gets dangerously hot at rated power of their inverter... that is an objective assessment, not subjective as you have done. A look at the accompanying pics will give us some insight as to why, and thats the important thing... to observe facts, and then interperate the possible implications... ie is this good or bad, not make facts up. The transfromer in question has thin primary windings of what looks like 2 wires, probably 2.5mm thick, and only needs to run at an average 25amps to achieve the rating. This should have been almost within reach as 10mmsq is a fair amount of copper... so to ME looks almost reasonable.... would expect warm, not stinking hot. The next thing we look at is the distrubution of windings and here we see a departure from low leakage design, where they seem to have deliberately de-rated the transformers coupling, so that the sag of the load is more pronounced. They have only used 2/3- 3/4 of the core for the primary, and so the secondary not directly underneath the primary wires needs to get it's flux from elsewhere, rather than directly from the mmf of the primary... very loose coupling... The net result is that the transformer has been made deliberately less efficient with the use of the flux than it could have been..... this does not give your subjective argument for great efficiency much credence.... ie it looks like deliberate inefficiencies have been introduced. Next we look at the setup. Efficiency is a function of throughput in this case, and where ever there is heat there is inefficient transmission of energy. Here the electronics is running cold (with effectively a single fet driving it), and the transformer is getting dangerously hot in an open air environment, in a closed environment, there is a more than fair chance of over heating without fan assistance.... so one part is doing it cold, and one part is doing it hot... these are the facts as noted in the write up...... It does not take a genius to see where the inefficient part of the system is. So we can see the transformer as wound is hobbled..... why did they do this? The effect of non-evenly distributed windings would be to concentrate the flux in certain areas, so to get the thing to operate at high power, we need to push the flux up higher than we would have needed to if it were spread symmetrically.... this seems contra to what we would want.... why did they do that? They seem to have introduced inefficiencies at just the places we would not normally want them. I assume they are infinitely smarter than me, so they knew this, and designed for this.... they seem to have designed inefficiency into it. This extra leakage I think was introduced to the system to get the short circuit currents down. Torroids as I wind them are stiff electrically, that one is less so. I can only assume that their electronics did not cope well with the back EMF that can be produced by the torroids... up to 60 or more times their run currents. This presents problems to the inverters I build, and the PJ when it comes off charging duty... ie any change in freq will blow up the fets. It can also make the short circuit of the inverter output terminals less abrupt, and so the current control system can have a better chance of controlling the outcome of direct shorts... ie the extra leakage softens the energy of the spike. So it would seem that that transformer is not quite what Tinker expected, as it was wound with different things in mind than the ones I do. Consequently, it will use more input current to get the same output current, and thus get hotter than a differently wound one of the same wire and core. Now, thats my take on it, and I don't apologize for thinking as I do, and will not be told how to think about any given topic. I can't see how you can move forward effectively without critical examination of the facts, rather than subjective defensiveness... flying flags for anyone or anything is for the pub, and does not belong in a thread trying to unravel the mysteries of high power inverters, and the building thereof. They may have other reasons why they have designed it as they have, they are my guesses alone, and perhaps proper engineers ( Warp?)can better set me straight, but if we don't discuss it because you have a pet manufacturer... we cant learn anything. Tinker, sorry for that, but it needed to be analysed. I too bought a heap of hy4008, and will be dropping them into the clockman board... mine are not designed for 247's, just 220's. For those doing PJ boards, and do want to take advantage of the charging algorithms, then adding leakage to your torroids may be your answer, and maybe some good will have come from this. The other way to get some leakage, is to artificially space the outside windings apart from the primary further ( very loose winding, where you don't try to get it tight against the core), or wrap the outer perimeter of the torroid with some ferromagnetic material, and this will give substantially more leakage. This might help stop the short circuits that come from AC bypass back to inverter mode behavior.... that will also depend on the frequency differential too I guess. But remember, adding leakage will lower your power ratings and increase your losses, as you will have to drive the flux higher to compensate I suspect.... this may not be a problem for most power levels... but if your gonna drive it like Mad seems to be doing, it will feature prominently .............oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That sounds like a perfectly well thought out argument. We all know what sometimes happens when we suddenly apply a massive overload to an inverter. And one of the design strategies is often to deliberately add some series inductance to the system (somewhere) to limit the rate of fault current rise in the event of an "instantly" shorted output. My own preference is a separate external series choke, but as a cost saving exercise manufacturers sometimes deliberately add leakage inductance to a transformer, which is effectively doing the same thing. That in itself will reduce voltage regulation, which IMHO is a small price to pay for a more robust and fault tolerant inverter. I have absolutely zero personal experience with Latronics, never ever even seen one, so I have no dog in this fight. I am speaking only as an engineer and retired transformer designer. I would ask only one question. Does it still get hot with zero load connected ? If it does, its definitely a core related problem, either crappy reclaimed steel or an over optimistic design flux swing by some hero trying to save a dollar. If it only gets hot under actual sustained high load it can only be a copper winding loss problem, again by another hero trying to economise on copper. Cheers, Tony. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Oztules, it was I that removed some turns to reduce the primary to the required 26V. I was too lazy to space the remaining turns evenly, also did not think the effect would be so drastic. But thetoroid runs cool at idle, I will have to letit idle for much longer to confirm. I also have toroid from a 2500VA (well known aussie maker) L series, this one is 96V so its easier to take all theturns off and re wind 4 in hand (4 x 2.25mm dia) for 26V. Thatshould let me test justhow much 4 off HY4008 can handle. We'll see ifthat one gets hot too. The small toroid had 2 in hand of 2.2mm wire, I think that was more the problem. I used to be a quality control te hnician in a large overseas electronics company. Those 3 busted inverters I was given (all from the same well knownaussie maker), where I scored the toroids from would never have passed my inspection. I would begenerous to give the workmanship a 2 star rating. The other inverters I have stripped for parts (4 aerosharps) were much better made even if they apparently did not live long. Sorry about the typos, my computer is on strike and the tablet key board is something my fingers have a problem with. Klaus |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

My aerosharps ran for 6 years, and were only pulled from service after the Hydro Tasmania stuffed up the frequency of our grid over here by putting in big windmills, that threw the frequency all over the place. They spent a long while trying to solve this, and now have flywheel generators in the mix trying to get it close to the .5hz limits.... After total failure, they then allowed us to use inverters that would paper over their feeble frequency stuff ups.... now 47-54 cycles... not 49.5-50.5 so I replaced with growatt units of +-3hz Amazing these Australian standards. One minute you will kill people if the islanding is not as they say at +- .5hz, and then when they have to solve their own problems.... the govt regulator suddenly has no problem in going to a 7 hz spectrum. It was always going to over heat with 2 in hand 2.2mm wire, even fully wound..I expected thicker. Even though a longer wiring path will increase R the flux will be better distributed....so with full winding, efficiency will go up... this is a good thing efficiency wise..... But no matter how you wire it, 2.2 x2 ( sub 8mmsq) is a bit economical to run cool. It is a copper loss problem... good old resistance. I found with a 16mmsq test unit, that it could not satisfactorily support 2.3kw continuous at less than 85C with ambient 19c open on the bench and with air movement.... in a closed box it would be a serious problem. They must have expected lower duty cycle, or intermittent high power use only. Thermal mass would help too. .........oztules Village idiot...or... just another hack out of his depth |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

.........oztules Yes, that is most likely, and rely very heavily on that fan in the box. Why they put that puny heat sink (folded from 3mm alu plate) inside and populate it with Mosfets in the >12mOhm On resistance region is beyond me. I'm all for buying Australian made but it got to be well made and competitively priced. Klaus |

||||