|

|

Forum Index : Electronics : OzInverter OzCntrl PCB rev12 Sept2017

| Author | Message | ||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

As Klaus says, aluminium and copper (plus moisture) can set up a rather nasty form of ionic corrosion. As aluminium is now a lot cheaper than copper, aluminium wire is starting to become quite widely used in the electrical trade. A special conductive grease has been developed for use when bolting or crimping copper and aluminium parts together. The trade name is "Alminox". This grease keeps air and moisture out of the joint, and it also contains microscopic very sharp metal particles that are supposed to bite through the thin oxide layer that very quickly forms on exposed raw aluminium parts. This is the stuff: https://myshopngo.com.au/product/plp-dulmison-d-alm325g-alminox-jointing-paste-compound/ Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Warp would there be any benefit to using that "Alminox" under FETs where we are relying on heat and electrical conduction to the heatink? Brac I have run my inverter at 8KW for 30 minutes with 70um copper pcb and it works fine, also it has withstood much higher surges too. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Alminox is only useful for electrically joining pure untreated shiny copper to pure untreated shiny aluminium in a possibly wet (or damp) environment. Like criming a copper lug onto an aluminium wire for outdoor use. Or bolting unplated copper straps to your lithium battery in a salty marine environment. I have never used Alminox myself, I try to avoid the problem of using raw bare copper and raw bare aluminium. Both oxidize very easily and then look horrible. Heatsinks are most often anodised, and copper parts usually tinned or otherwise plated, and if the parts are kept dry and clean, severe corrosion at the joint is not usually a problem. I just thought I would mention this product, as knowing of its existence may one day come in useful. [quote]Brac I have run my inverter at 8KW for 30 minutes with 70um copper pcb and it works fine, also it has withstood much higher surges too.[/quote] The problem of very robust PCB tracks is not so much to carry the maximum operating current under normal flat out conditions. What happens if/when it does go bang, is that fault currents far higher than anything reasonable can and do flow into those exploding mosfets. If the tracks blister and curl up, or burn away completely, it becomes much more difficult to repair the board. Its scarred for life, and will never be the same again. Much better to use massive PCB construction and just consider the sacrificial legs on the mosfets to act like fuses that blow before the tracks on the board blow. So in a way those skinny mosfet legs that are supposed to be able to carry a hundred amps or more continuously according to the data sheet(hahaha) can actually be a blessing. I now reinforce all my source and drain leads on the PCB by running extra thick wires over the tracks, or using flat earth lugs to make the board indestructible BEFORE the first blow up. Fixing it, then just involves plugging in new gate driver chips and removing what is left of the mosfets from screw terminal blocks. Apart from smoke stains the board itself survives completely undamaged. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The HY4008 TO247 Mosfets I am using don't have those long skinny legs, the failure I just had has burnt the fibreglass in that board so it is junk now. The legs on these MOSFETs only give up after a major fight. The copper tracks seem to be virtually unaffected! I am changing to a different breaker to hopefully avoid this happening again. However PCB's don't cost that much so it is not the end of the world if a PCB is damaged. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I had that alminox stuff on my shelf for many years now, its very economical  . Does not seem to go off either though the plastic tube looks a bit grubby by now. . Does not seem to go off either though the plastic tube looks a bit grubby by now.It was originally bought for my antenna's when I was into ham radio. There is a thin smear of it along the inverter heatsink edge, where it screws against the PCB tinned track. The alminox is mainly used there to prevent the alu heatsink from oxydising. I also have a thin film under the lugs connecting the cables to the heat sink. Be very careful, anybody thinking of using alminox close to the Mosfet legs. Its !conductive! and you do not want excess squeezing out and shorting those legs. Klaus |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

I know Alminox paste, have something similar in my workshop, but I would like to keep PCB & heat sinks clean and dry. Don't like to have such conducting paste close to the Mosfets. My copper foil will be tinned latter, so I do not have to worry about joints corrosion.  It is much easier to be soldered to the PCB first (because of higher temperatures needed) and after tinned surface above. It is much easier to be soldered to the PCB first (because of higher temperatures needed) and after tinned surface above.Waiting now on thick copper wire to arrive. In the moment have to finish some other projects (home automation - never ending story, and to repair some faulty Morningstar MPPT controllers, etc.)... OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

| brac321 Regular Member Joined: 30/11/2016 Location: SloveniaPosts: 54 |

Omg, what a wire they have ... VIDEO (at 8:45 min)  OffGrid 24/7: 250w black mono solar panels 6.4kWp, 1x Midnite Classic 150, 1x MorningStar MPPT 60, battery bank 840 Ah @ 48v, modified LF-8K inverter, DC/DC, hot water harvesting, etc. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Hey guys the parts list has bt169 scr thyristor But I can only find these Is the 169d ok? Clockmans boards came today PS looks like a daunting build, I'll need a bit of help at times. Cheers Caveman Mark Off grid eastern Melb |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I suppose it is if oztules selected it. I prefer a TO126 version of this SCR, like that one which Altronics sell. Maybe quicker than ebay, especially if there is a store near you. Klaus |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Those are available with several different voltage ratings between 200v and 600v. The D version is 400v In this low voltage low power application it does not matter. There are various packages too, surface mount and some through hole versions with the leads bent in various ways. Any of those should work too, but stay clear of the W version which is surface mount. So the answer is almost any BT169 will work fine, except for the W version. Cheers, Tony. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Hi, Something like this ...... http://www.ebay.co.uk/itm/5-x-BT169D-Thyristors-logic-level-Philips-TO-92-5pcs-/162800121133?hash=item25e7a4b52d Just gently plod along, and follow the information. As I have said before I might in the near future do a kit of parts for the ozInverter. I keep an eye on most of the World wide forums so I can support OzInverter builders. The torroid calculations for your cross section of the core to get the correct secondary and primary windings are on page 18, 19 and 20. Firstly…… "We want the primary to be about 30 to 32v for the PJ style processors, and 28-30 for the 8010 chips for a nominal 48v system." The cores on the BIG OzInverter are 230mm outside diameter, 100mm diameter centre hole and each at 70mm high, stacked together that gives me a rectangle section of the core 65mm x 140mm high. Oztules comments …… “Lemme see...... I make that as about 9100mmsq cross section... so ... and here I can only go rule of thumb....9000/2800=3.25 So I figure about 3.25 volts per turn. So the secondary will be about 73 turns, and the primary will be about 9 turns. How that would be worked out mathematically I can only postulate, but the in the real world measurements I have done, it would seem to indicate that roughly 2800mmsq of cross section at 50hz will yield about 1turn/volt.... so 9000mmsq would be about 3.25 volts/turn. If we wind for a few more volts than we want, our saturation is further away... so say 240 or 260v for a 220v system gives us leeway and lower magnetising current ... from there about 1:8 primary : secondary.. and we have a workable start point.... at least that how I would tackle it. Provide you have a crane close handy to hold the thing for you, it will be easy to wind.. big hole and plenty of room. It will be important to map out the wire sectors in advance.. or it will all end upon one side……oztules”. Provide you have a crane close handy to hold the thing for you, it will be easy to wind.. big hole and plenty of room. It will be important to map out the wire sectors in advance.. or it will all end upon one side……oztules”. So for the BIG OzInverter we have 80 turns on the secondary and 10 on the primary and see what we get when the secondary is tested. Components for the boards, .... Use reasonable quality. .....testing has revealed the values as listed, please do not scrimpwith the power board big capacitors etc. NOTE, I recently noticed that some cheap Chinese caps at our ratings were now a third less in actual physical size. These cheapo's were tested and did not reach the values as printed on their cases.! Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Thanks guys, yeah a kit would be a great idea, a lot of the parts I have had to order more than what I'll use, but it's all fairly cheap so far. Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

BTW would jaycar have a lot of these bits? I got a $100 gift card for xmas, was going to buy a soldering iron there till Mad showed me his one. Cheers Caveman Mark Off grid eastern Melb |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I just plugged those large toroid numbers into the flux calculator program: https://www.electricaltechnology.org/2014/02/maximum-flux-density-bmax-calculator.html 230v .000 05Mhz 73 turns 91cm squared It spits out 1.56 Teslas for flux density. That is getting rather high, the sort of figure commercial transformers run. I small decrease will make a hugely disproportionate improvement in zero load idling power. You can do that by increasing the turns on both primary and the secondary, keeping the ratio the same. 1.2 Teslas would be about as high as you might want to go. If you can get down to 1.0 Teslas and fit all that extra wire through the hole, you will be very glad you did. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I just put in the numbers from my double toroid 230V 0.00005 MHZ 98 Turns 70 Sq CM I got 1.51 Teslas increasing the turns to 125 brought it down to 1.18. I have 4 in hand on the secondary where Oztules normally has 3. I reckon there is enough room to add another 2 in hand so a total of 6, therefore adding 30% more turns @ 4 in hand should be very doable. My primary is 11 turns ATM, another 3 or 4 turns would fit in there also. Very soon I will be building a second 8KW Inverter so I could give it try with those extra turns. Tony how much power saving do you think could be achieved, the previous one I have built is just under 50W total at idle? Also at what point does it become a trade-off with the extra resistance? Mark have a look here at how I reused the wire you have to pull off to make the primary winding, it will save you a hundred bucks by not having to buy welding wire. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

Using Tony's 'Warpspeed' Teslas calculations. My 6kW Ozinverters cross section of core 6000mmsq, 118 turns secondary has a Tesla 1.4633. Idle power use is is 35w - 40w. Ferrite choke as in the book. My Big Ozinverters cross section of core 9100mmsq, 80 turns secondary has a tesla of 1.4236 . Idle power use is about 45w -55w. Ferrite choke is doubled up size. All work very well. Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

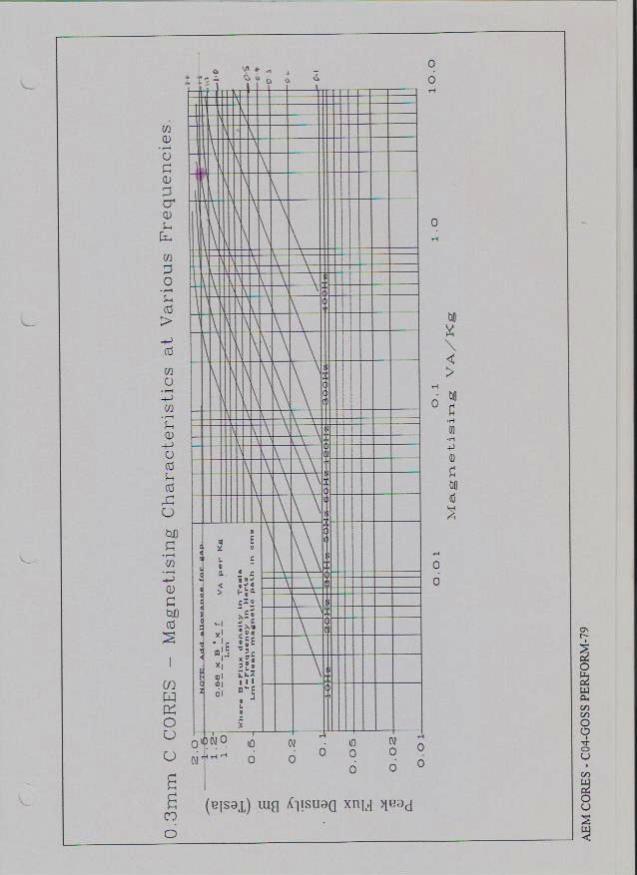

I have some very small faint and difficult to read curves for the Australian (AEM) silicon steel cores, which hopefully might come fairly close to the unknown Chinese silicon steel toroid material. At least hopefully it can give us a rough guide. The fuzzy pink dot is on the 50Hz curve at 1.5 Teslas.  Anyhow, by eyeballing these curves the closest round figures I can come up with for magnetizing core loss are: 3.2 watts per Kg at 1.5 Teslas 1.7 watts per Kg at 1.2 Teslas 1.0 watts per Kg at 1.0 Teslas So if you end up at around 1.5 Teslas you can figure on an idling power of about 17 watts for a 10Kg sized core and 51 watts for a 30Kg sized core, very roughly. There may also be other significant idling power losses beside just the magnetising current of the transformer itself. If the mosfets are switching directly into a highly capacitive load, there are going to be some huge not very productive current spikes. The capacitance comes from physical proximity between turns and the steel core, and more significantly from any deliberate capacitance connected across the secondary. This capacitance has to be charged and discharged EVERY pwm cycle at 20Khz, and the power to do that can be quite significant. That can be all but totally eliminated by connecting a suitable series choke between the mosfet bridge and the transformer primary, as you would normally expect to see in a buck regulator circuit. Many here have experimented with chokes of various types, and it is generally recognized that there can be large gains in idling efficiency to be made by fitting a suitable series choke feeding the primary. If you are only interested in reducing idling power, a ferrite choke will do that. But ferrite saturates at about 0.35 Teslas, steel at maybe 1.8 Teslas. So for a dc choke with very little ripple current, ferrite is far from ideal. The transformer magnetising current is very important, but its not the whole story regarding reducing idling power losses. Get the transformer magnetising current down as low as you possibly can by stuffing as many turns as will possibly fit onto that core. Go lower than 1 Tesla if you possibly can, although it does start to become rather impractical and uses up a lot of wire ! That is half the battle. The other half is building a non saturating primary choke. That will not only reduce idling losses, it will increase efficiency at high power output if the choke can keep working at high power output levels without saturating. Its not so much the gain in overall efficiency at higher power output, as the reduction of mosfet and heat sink temperature rises, and the potential improvement in reliability. If its running happily supplying several Kw output into the load, an extra hundred watts of input power is not that much of an issue, unless its all going into heating up the mosfet junctions and the heatsink. The more efficient you can make it, the better it will be. Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Thanks mate, that's thinking outside the box. Cheers Caveman Mark Off grid eastern Melb |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Oops, I should never post until after my second cup of coffee in the morning. That should read: If you end up at around 1.5 Teslas you can figure on an idling power of about 32 watts for a 10Kg sized core and 96 watts for a 30Kg sized core. Thats getting up rather high. At 1.2 Teslas it would be more like 17 watts for 10Kg and 51 watts for 30Kg. A 20% drop in flux drops the no load losses by 53%. The improvement is pretty dramatic, and it gets even better if you go even lower. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

My core is at least 30KG and total idle power is under 50 watts, so is expecting less just chasing my tail? There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||