|

|

Forum Index : Windmills : Help with my first windmill

| Page 1 of 2 |

|||||

| Author | Message | ||||

| weaver Newbie Joined: 21/06/2016 Location: United StatesPosts: 7 |

Hello, i recently took the time to build my first small windmill and have been having lots of trouble with it. To start off I built a pvc frame that i would upgrade if i got it working right. And I bought 20 magnets that are 20 by 20 by 25mm and they are n52s. Then I made coils to hold my copper on about 1 inch diameter and .800 wide. So 20 of them accounted for about 2 1/2 pounds of 26 gauge copper.But not i can not get it working properly. I tried wiring it in 3 phase star but it only made about 3 volts so i just tried a parallel connection and got 1 volt??? Hoping you guys could give me some help on what im doing wrong. Also those voltages are taken after the ac to dc rectifier. Could it be that the copper gauge is to small? |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Welcome, A bit more info like - How many magnets to how many coils and how have you mounted them as well as a picture will give people info to better advise you. Ahh your pics just loaded, you can not have 20 magnets and 20 coils , they need to be in correct ratios like 12 magnets to 9 coils or 16 /12 and so on also the magnets need to be mounted on a steel plate to complete the Flux Path. Then it seems you are trying to build an Axial Flux you will need another set of magnets on the opposite side with the coils in the middle so then your magnets required ar 24 / 9. Then you need to make a test coil to establish Volts to Rpm before you go ahead and wind all your coils only to find out its all wrong. When you get to that stage there is a formula or set it p with a rectifier and capacitor. I would strongly suggest searching on the net to see how others have done it this is a link to my last AX FX AX320 and it might give you an overall picture. when you get it up and running would turn the blades around the other way with the small end out and pit a slight curve in them. Looks like you are pretty handy so there is nothing to hard just have to do a bit more info gathering before you leap back into it .... PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Can you measure just one coil, by itself. Let us know what voltage you get. The design of your windmill is not a good one, but it will teach you a great deal. Use this one as a learning tool, dont invest too much time and money into it. The magnets are good and can be used for a better design later on. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| weaver Newbie Joined: 21/06/2016 Location: United StatesPosts: 7 |

thanks for the answers and yes i am making it axial flux. just another thought what is more efficient an axial flux or a regular type. Also I had no idea about the magnets to coil ratio so thanks for that. Out of 1 coil I am getting 3.5 volts ac. which is kinda weird because thats the highest i have ever seen it. Also I`m not sure if this helps but when i test the ohms of one coil it is about 3.0. update the weirdest thing just happened i just tested it with 17 of the coils connected and i am getting 6 volts dc. I have no idea why it is doing this?? |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

OK, if one coil makes 3.5vac, then try connecting 2 coils side by side in series. You should see 7vac. If not, swap the wires on one coil. 20 coils in series will make 70vac. Be careful, this can be fatal, at least give you a nasty shock. Because you have a same number of magnets and coils, your alternator can only make single phase power. It will never make 3 phase, and can not be wired in star or delta. What is your target voltage? Battery voltage? Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

you can make a dual rotor axial flux alternator with ten poles per rotor . you will need two iron/steel rotors for the magnets to sit on these metal rotors will contain and concentrate the magnetic flux. your magnets look to be cylindrical 20mm in dia. by 25mm thick . Yes? if so, 10 mags x 20mm dia. + 20 mm space between mags = a circle of mags 400mm in circumference . 400mm /3.14= 127mm dia. circle add 20mm for the width of your mags,you will need two steel disks about 6" in dia. your mags are small in dia but thick and powerful so you will need the mag rotors thick enough to contain the flux. 1/4"steel should do it . you can use all your mags on one larger metal rotor but you will need another steel rotor to rotate in sync with the mag rotor . your trying to make an area between the rotors of very strong magnetic flux with your copper in between. |

||||

| weaver Newbie Joined: 21/06/2016 Location: United StatesPosts: 7 |

Thanks for all the replys and yes my target voltage is 14 volts dc to charge a battery. So if I have 3.5 volts ac out of each coil how could I get 14 vdc? And for this one I would like to stay with this if workable. |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

You will have to scrap this one ... Sorry but that is learning. As I did say and ED1 has pointed out, first you have to concentrate the flux lines and put the magnets on 2 steel plates with the magnet forces trying to pull them together. you then need to separate the plates the width of your coils + air gap. they must also be configured N,S,N,S 1/4 plates will do for mucking around but I doubt that will contain all the flux on 20mm NE52s and would be more like 16mm . The easiest way to check is put a steel pin on the back of the steel plate and if it drops off then there is no magnet flux radiating and you have contained it. If you do this then you wont have the problem of the magnets popping out as you have now. You will need to devise a way of lowering the 2 plates together and keeping them apart with the coils which are usually encapsulated in resin in 100% of axial flux designs. If you want to make good power to charge your batts this is how it must be done, with the emphasis on Good and Must. Sorry but its not going to happen with plastic. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| weaver Newbie Joined: 21/06/2016 Location: United StatesPosts: 7 |

thanks for all the replys so far im learning a lot from all from this! So i will try to wire this one with 4 coils in series and see if i get around 14 volts. if i do i could wire 5 sets in parallel and maybe get a decent wattage out of it. And as of the design I thought an axial flux design, you could not have the magnets in contact with each other(on a steel plate) or is that not axial flux? I could connect them all together if you think that will help. I do like your idea fillm but in something like that if i used magnets around the size of mine would it be more beneficial or using a bigger copper such as 14 or 16 gauge? |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

I cannot see from the photo as its too small, but are all your coils wound the same way and placed in the same direction, because if one coil is opersite to the other it will cancel out the power produced. This can be a easy mistake to make by putting a coil upside down to the one next to it. All coils and windings MUST go in the same direction. Sometimes it just works |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

without causing a dispute, if he has 20 mags and 20 coils it's got to be single phase . so every second coil must be reversed. |

||||

| weaver Newbie Joined: 21/06/2016 Location: United StatesPosts: 7 |

Ok so I made some progress on it. I wired 4 coils in series and got 16 volts at about 300 rpm so if I would wire 5 coils together it might be useable since it would work at a lower rpm and I will have to double check to make sure all of my coils are in the same direction. |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

in single phase each coil is in series and each coil is reversed. in three phase each coil in each phase is wired in series. no coils are reversed. in three phase you require a ratio of 3 coils for every 4 mags so with 20 mags you can only have 15 coils. each phase will contain 5 coils. |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Re think that one .... the magnets are normally placed N - S - N so the coils all run in one direction. Weaver- You might be getting a bit excited over OCV but when it comes down to primary thing as a battery charger, if the flux is not concentrated as with normal AXFX Alts then I predict that as soon as it gets to charge voltage the Flux will be dissipated and you will see no meaningful current. You could liken it to a slipping clutch in a car, as soon as a load is applied it goes no where. Also I would think you would have 100s+ of turns on those spools with (26AWG = .13mm˛) and just the wiff of magnetic flux would give VOC.I have hairs in certain parts that thick. What is the resistance in Ω on each coil? Even if you concentrate the flux in this project the 26AWG wire is not going to get hot rather than give amps . Look at this as a good learning project. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

well mr. film you can wind the coils in one direction but if you were to wire them that way; nose to tail, to nose to tail, you are going to be disappointed. you re think it |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

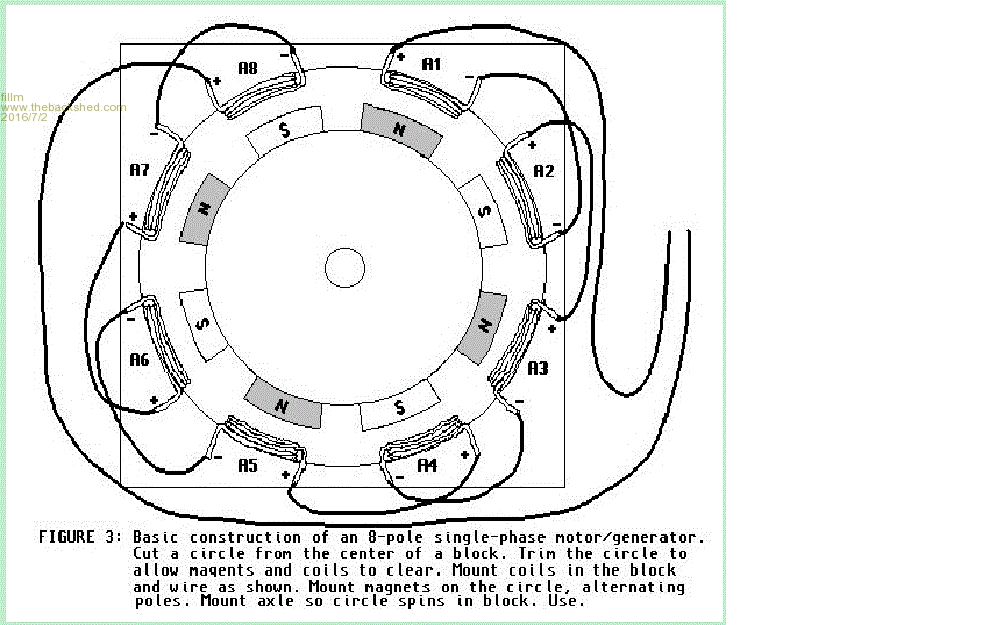

Do you mean like this, is the nose to tail mean n-s ? Please explain a bit more on reversing the second coil and your theroy on single phase set ups . If i were to build a single phase generator I would keep all the coils wound the same way and orientated the same way depending on how many you want in series then they would be connected across a rectifier and the magnets in a N-S-N configuration as shown. I can not see the benefit of having all your magnets the same way and reversing the 2nd coil. Maybe I am missing something between the lines but if the magnets are all the same way would that also play hell with the flux.

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

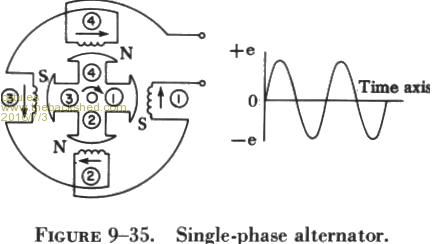

The picture above is wired exactly as Electrondaddy has explained. The plus and minus signs are confusing, and are a representation of the orientation of the coils, not of the output polarity at any time in the sequence. (In fact with the magnets in that rotation position, all coils have no EMF, as the change of flux is in a static point as far as the coils are concerned.) We want a cumulative effect from the coils, like the batteries in a long torch ie + - + - etc until we get the voltage we are after. So if we have alternating magnets and we don't reverse the connection to each successive coil, they will cancel.... so we reverse every second coil. The diagram is misleading as you are likely to think the + and- means emf.... and it does no such thing. If you have the orientation of all the coils as the same, but the magnets are NSNS... then the potential of every second coil is the reverse of the next coil...they cancel.... so we need to change the wiring going to each second coil as they have done...... The proof is that four of the coils are the same orientation when say the N pole is passing them.... and yes they are adding, so it makes sense that the four south pole ones engender an opposite effect and so needs reversing by the wiring, then they all add up. So that alternator circuit works, but the + and - is not the output of the coils, as thats not what they are getting at with the + and -..... they should have used A and B perhaps, the plus and minus is confusing the issue. I guess if you mentally change the + and the - in that picture of each second coil, you will have the additive effect we are after. If we were to use the magnets in all the same polarity, then we would have effectively doubled the pole count of the magnets.... because we can't have a unipolar rotor... So it will create a phantom south pole between the N pole magnets... we use this to advantage particularly in three phase 1400rpm motors. In this case it would require a major rethink on the coil and magnet spacing. From avstop.com .... a simpler version, so easier to see perhaps

Note the arrows, and what has been done to make them all apparently have the same orientation... we reverse the wires of each second one.... call the head end of the 4 arrows positive for example.... Note also the sine wave graph. Thats for a single rotation (360 degrees), and note also the wave ends in zero when the magnets are under the coils exactly.... It may be maximum flux density at that point, but from the frame of reference of the coil, there is no change of flux that can generate EMF in the coil/s ( actually from internal cancellation within the coil windings itself.... one side of the coil cancels the other side at that point in the cycle... so no terminal output to see on any coil. ) The real reason is that the terminal voltage is a vector addition of all the wires in the coil, and they all see the field slightly differently. As the magnet comes towards the coil, the emf will be one polarity, but as it gets to top dead center, both sides of the coil are now seeing the magnet as equally coming towards the windings or leaving the windings ( it's in the middle )... which will stimulate a different polaritys in each side of the winding, and at that point as many wires see the magnet coming towards them as leaving them... so no emf at the terminals. This is the same for both pictures, but easier to envisage with the 8 pole unit.... imagine what each side of the single coil sees as the magnets come and go. It is actually easier to envisage if we have a single point coil ( no physical size ) and see what the velocity the field will look like to it, as a magnet on a circle or linear for that matter comes towards it and then leaves it.... remembering that the force is a square function of the distance, and the emf sign is a function of a field moving towards it or leaving it. If the magnet comes and goes relative to the coil, there must be a point where it is neither coming nor going... or a stationery field so zero emf at dead center of the coil. Armed with all that drivel weaver, you will be able to design your own, and know what to expect and why. ...........oztules Village idiot...or... just another hack out of his depth |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi OZ, been a while and its good to see you kicking around. Anyway, I agree I am wrong and its been a while since I churned the grey matter around with winding coils and AXFX Alts. I will always own up and apologize that I have been wrong. Where I went wrong and it may be obvious, but not looking 3 dimensionally at the coil and the way flux passes through a winding I did not see the electrons going in the opposite way when the pole passes across giving a complete single phase sine wave . So yes in a single phase with N-S-N magnets the second coil needs to be wound and placed the same as the first but when connected in series then its Tail to Nose or End to Start. But none the less a N-N-N arrangement is messy and pointless I would think. As far as weavers project goes I will still stand by my original advise and he needs to start again with a new design with experience under the belt. As far a AXFX designs in general I think they are floored with encapsulated windings and compounded more so with my position using the GOE 222 Blade.My last AXFX is sitting on the floor in the shed and shivers every time I walk past with a GOE. I will not revisit those until I have designed a suitable Var Pitch System. These days I am more involved with the 1 & 2kw designs of EX - (OEM / Whispering Winds) after buying them out 100%. With a name like Whispering Winds is reason enough to fail, anyway I will get around to posting some info in the future but for now being Retired Early there seems to be more and more bones to chew and not enough time to digest. Sorry weaver for derailing the thread a bit PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| weaver Newbie Joined: 21/06/2016 Location: United StatesPosts: 7 |

thanks for all the great info, ive learned a lot from this forum. I will continue to play around with this one but your right about it not being able to product much usable steady power. But now i think ive got enough knowledge to eventually start a new one in the future to make usable power. Just one more question if i were to build a bigger windmill would it be more beneficial to use say 14 gauge wire, with less resistance if you wanted to make say a 500 watt one? |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

It is best to get your design sorted first and concentrate the Magnetic Fields " Flux " with the neos on steel plates and as a 3 phase set up. As has been suggested before. I suggest you research plans and info out there on the net, and its not to hard to work it out if you follow the steps laid out . When you have the mags all positioned then make a test coil with your 26 gauge to see what you get with volts per turn for a given RPM, the result remains the same for thick or thin wire. When you know that then you can start to determine the wire size and if its all going to fit. Get the biggest copper wire that you can handle or you can wind with 2 o 3 smaller wires that makes it easier to handle, its called 2 in hand and so on. The other important thing is blades and the diameter, 500W is easy to make in roaring gale but if that's all it can do then the point of a wind turbine is virtually useless. As a newbie and to build something worth while then go with something that has been already proven, to date I have not seen one made from 1" PVC pipe. Although there is always a first and have not bothered to google it. Sometimes for your first it can be easier to use washing machine motors like F&P or LG. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Page 1 of 2 |

|||||