|

|

Forum Index : Windmills : Star / Delta controller

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Chrismar Newbie Joined: 27/05/2015 Location: United KingdomPosts: 3 |

Hi I am in the process of building a windmill generator using a F & P smart drive, I have rewired to a 6 wire star & delta config. I now need to hook up to an automatic / programmable switch that will switch between the star & delta. I took this from the [URL=http://www.yourgreendream.com/diy_fp_rewire2.php] site that explains a bit further what I am after. Any help as to what I can used and where I can purchase? Also has anyone got any advice on a controller and how to wire / configure to drive a factory configured smartdrive as a motor (NOT GENERATOR). Any help and guidance will be appreciated Chrismar |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Switching between star / delta has been a age old debate, personally I see it a danger area, as all electronics are subject to fail at some point, and from someone who have designed and built more electronic circuits in this area than most here I would not go the path of star delta switching. The rule of thumb to any windmill control design is "fail safe" and a switching system has no way of fail safe. What ever you do and how ever you do it the mill must always be connected to a load at all times, and switching allows for a runaway mill should switching fail. really star delta switching is only required if you got the mill winding totally wrong to start with and is simply a bandaid for a poor mill design. Should you be building a VAWT, than little to add other than a very poor choice of mill and nothing will fix the low output even with fancy electronics. Pete. Sometimes it just works |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Chrismar Electronic Switching is best done with delta wiring from my experiments. The idea is to say cut a 36 pole stator into quarter or sixth depending on how much switching is required over a wide RPM range. Each delta set of winding's is terminated into it's own rectifier which can then be switched using FET's to put all outputs in series or parallel depending on RPM at the time of the switching for a given voltage output. Example; At 100 RPM with a 36 pole stator 4x delta winding's all in series would produce 50V, .62A, 31W At 200 RPM with same stator 2 sets of 2x in series put in parallel would produce 50V, 2.42A, 121W At 450 RPM with same stator all delta winding's in parallel would produce 50V, 9A, 450W Note the big jump in current range, this is due to the load better matching the stator so it's not going into saturation. The FET's need to be fast switching and very low on resistance, with a make before break switch over so stator doesn't see an open circuit condition. The switching can be done at different RPM's to produce lower or higher voltage. The 36 pole stator is the best to use with a black rotor cap as stronger magnets. Also it can be cut into more configurations 1x 12, 2x 6, 3x 4, 4x 3, 6x 2 allowing a wider range of switching points. The stator can also be used in star mode for higher output voltage but less current. Difference is 1.732 times so delta volts 200 RPM uncut 100V 1.21A vs star 173.2V 0.7A same RPM. I prefer delta wiring as better current output for Voltage I'm wanting at a given RPM. What do you think? Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Here is a table of that proves my point that the power output of these F&P stators must be managed through a switch system or DC to DC converter (advanced charge controller). The power outputs in the table is from a 36 pole Stator wired in Delta mode uncut and using a Black rotor cap into a 86 ohm load. The 1/2 cut plus 1/3 cut results in the table are scaled. I have already proven the scaling dose work from other testing just didn't want to repeat the same RPM tests another 2 times. RPM Watts Volts Amps Volts 1/2 Amps 1/2 Volts 1/3 Amps 1/3 60___12.5__33__0.38__16.5______0.76_____11.00_____1.14 100__32.2__52__0.62__26.0______1.24_____17.33_____1.86 120__46.5__62__0.75__31.0______1.50_____20.67_____2.25 150__69.9__76__0.92__38.0______1.84_____25.33_____2.76 180__94.5__90__1.05__45.0______2.10_____30.00_____3.15 200__121__100__1.21__50.0______2.42_____33.33_____3.63 250__178__123__1.45__61.5______2.90_____41.00_____4.35 300__245__144__1.70__72.0______3.40_____48.00_____5.10 350__311__162__1.92__81.0______3.84_____54.00_____5.76 400__384__183__2.10__91.5______4.20_____61.00_____6.30 450__454__200__2.27__100.0_____4.54_____66.67_____6.81 500__527__215__2.45__107.5_____4.90_____71.67_____7.35 550__585__225__2.60__112.5_____5.20_____75.00_____7.80 588__660__240__2.75__120.0_____5.50_____80.00_____8.25 800__880__275__3.20__137.5_____6.40_____91.67_____9.60 The maximum output 880W was due to me using a 1200W drill with which resulted in that being the maximum shaft power it could produce. The 86 ohm load is the optimum load for this stator uncut in delta mode. Any deviation from this load to a higher or lower resistance will result in a lower output power. You will now see why it isn't practicle to connect them directly to a battery without using a DC-DC converter or some form of switching system at cutting in at different RPM ranges. Hope this data is of use to you and others that would like to use it. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

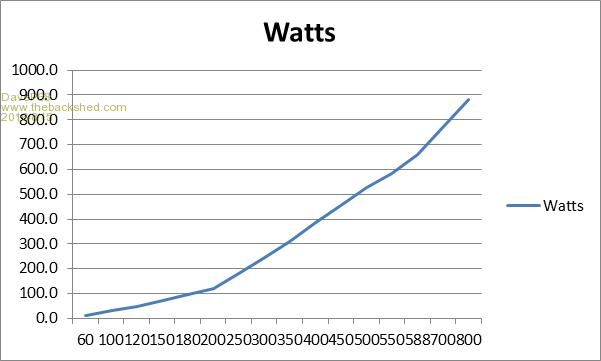

For those interested that are not sure how to interpret the table above, I've made a graph from that same data showing it's optimum operating output. As stated above I used a 36 pole stator wired in Delta mode uncut with a black rotor cap into a 86 ohm load. Horizontal axis is RPM.

The steeper the rise in operating output power vs RPM the less efficient the stator will operate. Will upload further graphs to prove my point once I created some new data tables with loads which are too low or too high resistance for the stator to remain efficient. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

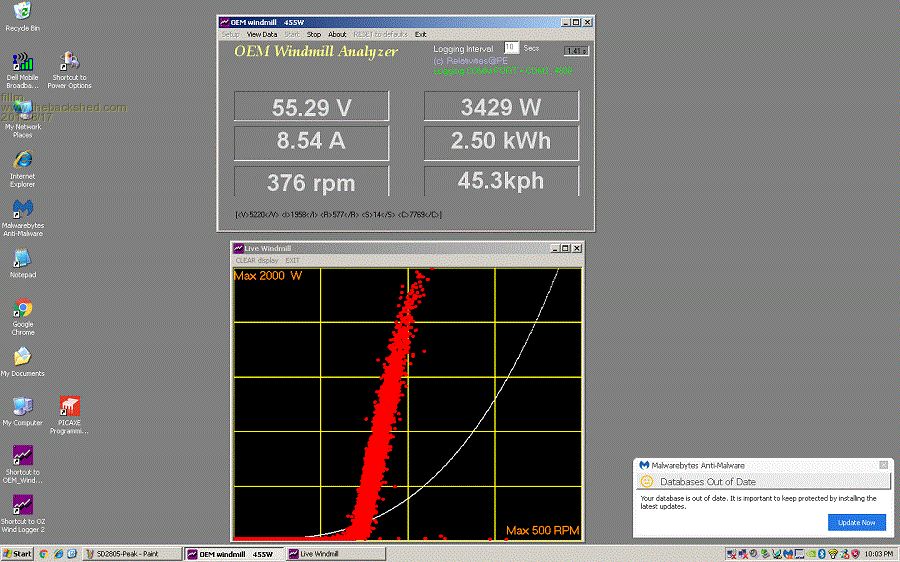

Hi Dave, I can not really see the point of giving output data into loads that do not represent anything that is useful like energy storage / battery charging or a grid tie and then secondly to get to the higher output the RPM is in a range where a wind turbine rarely operates at unless its in Antarctica. You might have some kind of controller I have not heard of to turn that data into something. The voltage range of 16 to 137.5V is such a wide range and you have not given a purpose other than 86Ohm is the best load. Testing and posting data is great but what is normally an 86 ohm load and has a purpose. Also setting up Star delta switching ect to maintain maximum output at RPMs that can only be achieved in 40+ KLM wind is messy and doomed. Dont get me wrong , I think the F&P is a great thing and is one of the few PMAs can be smashed by 100klm winds all day and not burn out and if it strong enough to take the battering. We did a lot of testing a few years back and I cut my turbine teeth on the F&P and to date have not seen or come across a black rotor. But if the windings are not .8 or 1mm then I would think the output would be limited in real world testing and if it gets over 400W I would be surprised Below is probably a bit of a plug but of no use here as 99.9% of the audience and members here are not the buy it ready to go type and more build it DIY. Also watching for new posts in the wind section here is at an all time low so please don't be discouraged Anyway what the latest 1kW - 2.5kW OZ Wind Turbines can output into a 48V / 24V battery and all at under 400Rpm with no Epoxy. The logging screen is for a 2.5kW has been collaged as only 1 peak can be shown at a time but these are absolutely one of the best Alternators. Everything is kept at very low RPMs and in control and coupled with the unbelievable torque of the GOE222 Airfoil it makes them the a very high performance turbine. In 20 - 25klm it is just ticking over at 1kW into the batteries.

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Phill I think you may have over looked some points made further back in this post. For starters I work with these Fisher & Paykel washing machines as a job and know how they work down to a component level in the motor controllers and motor operation. So understand PWM theory etc. The data you see is what I got from a single 36 pole copper stator wired in Delta using the new version Black rotor cap. See photos of test set up (instrumentation not in photos). The back rotor cap you can see in the lower photo have been used on F&P machines built in the last 7 years, so not many been scarped. This may explain why haven't seen a black rotor cap yet. My point with doing testing into an 86 ohm load (in same photo to right of black cap) is that it's the most efficient load match over a given RPM range. I'm not saying the FET switching system is a good idea under extreme conditions. If the goal is to have power storage into say a 48V battery system, a direct connection via a charge controller is why 400W is the max output for a single stator. If say a form a buck converter is used so output of the stator is allowed to operate over a wide voltage range. The converters output can thus be 56V if that is the best float voltage for the batteries. The minimum converter input voltage range being a least 3 to 1 allowing current to do it what it does best under MPPT control. A 10 to 1 being ideal which really ever achieved. If you can get 4 to or even 5 to 1 even better efficiency will be achieved. So the resistor load test was only to prove the best load conditions with max a of 275V at 3.2A DC 880W output measured into that 86 Ohm load. These 36 pole stators can be cut into more combinations than a 42 pole. I.e. 1/2, 1/3, 1/4 or 1/6 cuts, if one want to take a risky switching system on. Not advised from what you know... I'm not disputing that you chaps have done lots hard work and achieve good results over the years as I'm still new to this. Like I trying to state here is these F&P stator are only designed to see a constant load "like a resistor" to give their optimum output. Fred (flc1) who I'm in touch with on ythis site has a dual F&P stator using 2x 36 pole stators and black rotor cap producing 1.1kW output peak (DC) into a grid tie inverter. Operating voltage range into inverter is 45-90V so he's getting more than 400W per stator. He says it hasn't maxed out yet. I'm hopping to design a converter which will allow these F&P stators to connect to batteries as one day I'm move out of the city and choose to go off grid :) Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

guess it just goes to show that some people ( including myself) don't know as much about f n p performance as we thought we did. good work Dave. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Fred Thanks the feedback. I understand that you have gearing system on your F&P turbine? That will be why you are getting over 1.1kW output from it. Also I think you mentioned you used to have batteries on your F&P wind turbine and the output was not much over 400W. Just goes to show that when these F&P turbines are set up correctly using an MPPT inverter you can break past that so called 400W limit!! Personally I had the impression that this website was for DIY? That's why I'm trying to put the knowledge gained about these F&P stators to get the optimum output on here. More info to follow to fill the blanks in for the non believers... Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

thanks Dave, yea this is a free diy energy info shareing site for all to use,, not a free advertiseing, push your own product for profit site. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

I would like some form of response from you Phill conceding that the F&P 36 pole copper stators with black rotor caps out performs any 42 pole stator. All the topics I've posted over the past 6 months prove it anyway. You have gone completely silent, which can only mean one thing... There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

Personally I don't see this as a productive turn in the discussions. I've enjoyed following your work with different alternators, configurations and cap customization. Your work is impressive, well organized and well documented. Here's the but...but, it is in a controlled lab, if you will, and not exactly comparing apples to apples when put beside fillm's work IMO. The optimum output of an alternator is only one piece in a seemingly simple wind turbine. I hope you continue. And, I hope that you, or someone can take what you've learned and apply it to the real-world application in the air. Even then I hope it is a discussion with mutual respect. ~ks |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Dave , I really can not be bothered and do not have the time for your futile prodding and requests for responses... why..., because my testing does not line up with what you are spinning. You take it as some some kind of grudge match because you think a Black F&P is the most superior PMA for a wind turbine and I "must "Concede Defeat".... As I have shown , I can very easily replicate any test you say you do in real time graphed output data on a purpose built test bench. At the present I am quite busy with actual "turbine builds" plural, and have no time for constant replies and "quote" fests to your countless threads that still come down to the 1 fact, that to get the ouput you state then a specific MPPT or Cap Dblr is required. At least you have finally worked out that 10000uF caps or the 1600uf Caps is not how the cap dblr was originally intended to work  . .What you always fail to see is that a turbine does not do 350+++ Rpm with no wind and*99.99% of wind charge systems are Turbine - Charge Control - Battery or Dump load...... Simple systems that work If its just RPM then the 42 as I have been getting 1.5kW+ @ 48V from 42pole 80S Star 14 x 1 which is comparable the 36 Black give or take a few 100 Rpms Personally I do find it Ironic though that a person that has never built a single wind turbine, lived with it , repaired the failures and constantly tried to improve it is here giving out advice because he is a F&P Washing Machine Repairman. Now you have free advice thread on "How to Build" " The Ultimate F&P in the World " ..... Can you not even think of an original name or is this just another bait up for a response and constantly tainting the forum with constant implied meaning sour comments. Extensive testing with a Drill and a F&P on its Plastic drum into the Brake Resistor on the F&P Control Board and have seen that picture over and over. Is that all your design advice , Where is the advice on the Nacelle , Blade Hub , Tails , Furling , Yaw and slip rings, Balance or is Engineering not all that important ? I have got to give it to you , This one is a Gem .... Mmmmm.... I'm kind of lost for words and I hope industry as a whole does not take this approach . Who knows you might be the next Nikola Tesla of F&P Wind turbines. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| flc1 Senior Member Joined: 20/11/2011 Location: New ZealandPosts: 242 |

Gday Phill, just have to add my 2 cents worth here,As you know I DO have a wind turbine, you state that the 42 pole 80s is comparible to a 36pole with a black cap"give or take a few hundred rpm" , well that is no small diffrence,a few hundred rpm is alot over time, which is what it is all about at the end of the day,,,,,watt hours, The 36pole has almost no cogging, so it WILL start running before ANY 42 pole,which again is what its all about,because most turbines operate most of the time in low winds.So which is the better choice? ,,,,the 36pole with blackcap. It has more cut combinations avalible than a 42 ,to suit whatever voltage,and with the mppt tecnology availble now days for batterys and gridtie at a cheap price and easily accessible online, why would you use a 42pole if you can get a 36pole,and get a better output from your turbine? If we ignore all the sh*t slinging around this subject,all that Dave is saying and has proved, is that the 36pole is better than the 42 pole stator to use for a windturbine,and probably better for hydro aswell, for the simple reasons I have stated here,Even without the fancy electronics the 36 pole copper stator,with black cap will still out perform a 42 when all things are the same, simply because it has less cogging for start up, 42s in my opinion are old school, and will become hard to find soon, but its the opposite for the 36s, they are turning up in dumps etc more now. I don't touch the 42 poles ,I leave them at the dump |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi everyone here is a quote from Phill taken from his own website "A Bit of History - My trade base is a Diesel and Heavy Earth Moving Equipment Fitter." Those who read this can now come to their own conclusions about his knowledge  I at least have a back ground in Electronics Engineering & for the past 10 years been working with Smart Drive technology. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

yep and just to top it off I was introduced to some guy's who were playing around with caps and had a setup where a f&p was driven by a small motor. They did all their setups in parrallel so when I got home I decided to do something different. I put mine back to back in series. A few weeks later Gordon came up for a visit and the rest is history. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Bryan1 Getting back onto a constructive discussion. I'm really impressed with how much extra power can be gained from adding a capacitor doubler to an F&P stator. So all credit to you if you sowed the original seeds of this genius idea. Have you seen my mathematical formula for calculating capacitor values for your's and Gordon's capacitor doubler circuit? David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| kitestrings Senior Member Joined: 23/04/2014 Location: United StatesPosts: 102 |

flC1, Is your turbine fitted with a 36-pole alternator? Just curious if there were any comparative data with one in a turbine, on a tower. ~ks |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Star delta switching should be very simple with these alternators. We have the situation where shorting the windings will have no deleterious effect on the wiring due to the inductive reactance... and here it gets interesting. This shares the same characteristics with car alternators in that respect, so it is not unreasonable to find that the addition of two diode only will allow for automatic star delta switching.. totally seamless and no electronics in sight. So this can be added to any star connected mill, provided you can access the star point. The diodes will go from star point to the pos and neg rails... like in this pic from my playing with alternators story. http://www.anotherpower.com/board/index.php/topic,492.0.html Quite a few of the high power alternators use this now, it relies on the emf of the star combination falling below the delta combination. This will occur naturally, and normally you will see current limiting there, but now with the two diodes added, we will increase the current as the rpm increases until the new delta current limit is reached...... fiendishly simple, and i don;t have a unit to test it on, but if it works for car alts, it will certainly work for these long salient poled devices. ............oztules Village idiot...or... just another hack out of his depth |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi oztules That is a simple solution which I'm now keen to try out. I'm heading away for a long weekend, but on my return will try this out on a 36 pole copper stator with black cap and let you know the results. Will even try it with a capacitor doubler to get an even greater power output operating range. Lower cut in voltage at start up then higher current output at high RPM level. Good work on your part for taking the time to post this to this topic. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Page 1 of 2 |

|||||