|

|

Forum Index : Electronics : petrol gen wiring

| Page 1 of 4 |

|||||

| Author | Message | ||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

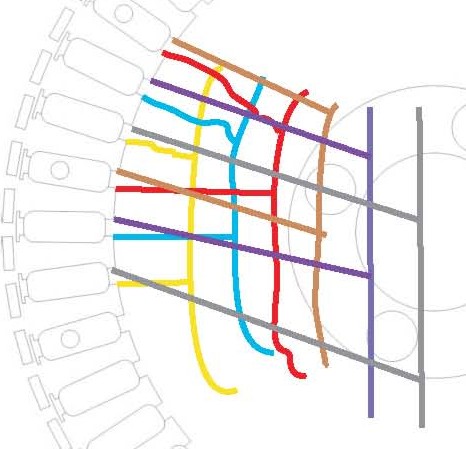

Again I'm uncertain of what I think is right, so I'm asking for help again. Is this how to wire a 1 pole 3 phase delta?

If so is this the right choice for a petrol gen using a 3.5 hp motor?

I would love to use a 100 but I only have 80 stators. Central Victorian highlands |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

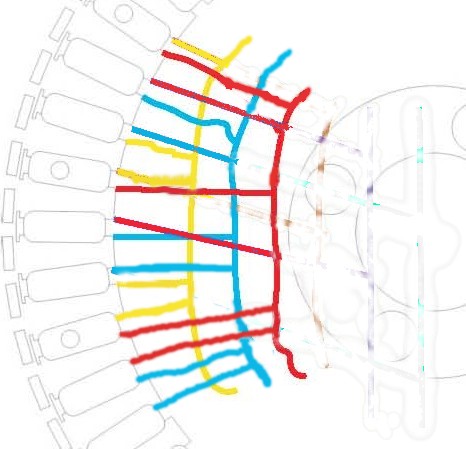

Well yes, you could do it that way if you connected the yellow bus with the pink bus, the red with the voilot, and the blue with the grey. Your arrangment could also be changed to star by connecting pink voilot and grey buss together. More versitile yet more wires. A simpler dedicated Delta could look like this:  . .

As to the motor, I'm not sure what your trying to do. If it's to turn the 3phase_single pole_delta, I guess it's ok, adjusting your gearing up til you run out of power. I've no experience here to know what ratio suits. Sorry I can't help more. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Pt w/field Matt Senior Member Joined: 24/02/2006 Location: AustraliaPosts: 105 |

hi highlander try the gearing you have and if to tall back space the rotor with washers to get the motor in its power band,you can also use this method to adjust output amps matt down south |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Well, bugger me. Thanks Gill for saving me the extra wiring.  Bloody legend. Bloody legend.

It works a treat. The ammeter I put on there goes to 50 amps and at half throttle it went off the scale. It idles at 8a, and effortlessly does 30 amps at slightly above idle. I wish the mill did that.

The volts on the batteries was a little high 16+ so I ran the inverter with a 1000 watt load and it brings it down to around 14.5-16v depending on speed of the honda. Is there any other way to keep the amps up and lower the volts? My neighbour saw my mill today, now he wants to make one. At least I can tell him what not to do.  Central Victorian highlands |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

The way I see it, your single pole Delta gives you lowest voltage with highest current. The only other thing is, to do that with a series100 stator. Is this genny for your monthly equalization charge? My battery manufacturer suggests 7% of the amp hour rating for 3 hours after reaching full charge (temp allowing). So for me that's 70amps, and where do you get a 70amp battery charger cheep? I had a couple of 150amp diodes in the junk box so rewired the secondry of an arc welder. Works like a charm with variable amp output too. Trouble is i'm a bit slack and skip the monthly equalization so my battery is sulphating. Here's a thought, battery desulphation occurs with a 1k/sec hi Volt pulse. I recon the smartdrive could be set to run at that pulse frequency [motor driven], and with the appropiate voltage, so the only other thing to do is to control the pulse width. OK you electronic hobbiests, any takers? was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Gill, monthly equalization ? huh, I wasn't aware of this. By your statement I assume it reduces sulphation. I already made a jaycar one for this, somewhere I read not to use them for long periods as they can blow the batteries up. Is that right? If so how long is a safe time, I put it on once or twice a week for 24 hrs. I made the gen to keep the power up when excessive loads are used ie air con. (It's set up 1km from the big house where the mains power is.) BTW the multi rpm Hz test doesn't work on this stator, but works fine on the 7 phase. The readings jump all over the place. Central Victorian highlands |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Equalisation? Well the best way to give you the drum is to copy this section direct from the battery manufacturers booklet. _____________________________________________ EQUALISING It is commonly believed that whilst a battery is being 'float charged', it will remain in a fully charged condition. This belief, however, is incorrect as stratification (the seperation of electrolite into distinct layers of difering densities) can occur, resulting in uneven current distribution between the plates of the cell. This uneven current distribution and the varing 'acid strength' can cause the gradual discharge of portions in the plates located in the low current density areas. Initially the overall cell voltage remains at the correct float level because portions of each plate , which are galvanically continuous, remain fully charged and still in acid of a high specific gravity. The partial discharge in areas of the cell plates will eventually cause sulphation, which worsens with time. The battery internal resistance is then affecterd, causing considerable variations in individual cell voltages and, more importantly, specific gravity. This is commonly known as 'out of step' condition. The only corrective action possible to rectify any 'out of step' condition is an equalising charge. The battery should be charged at a rate which is five to seven percent of the ampere hour capacity at the 10 hour rate. This charge should continue until such time as the specific gravity and voltage readings of individual cells have reached a maximun value and have ceased to rise for a period of 3 consecutive hourly readings. At this point the cells should be gassing vigorously with voltage being in the region of 2.5 to 2.75. the actual value of voltage is not so important as the fact that the voltages and specific gravities cease to rise. It is recommended that equalising charge be carried out when a cell's specific gravity drops by more than 0.015 (15 points)from it's origional level. ____________________________ There is reference to excessive temp whilst charging as being 50degC, and never to exceed. From other sources as well I understand that sulphation occurrs in batteries and has 3 crystal states. The initial crystal state is returned to solution with normal charging. Most, however, not all sulpher crystals are returned to the sulphuric acid electrolite. A periodic Overcharge (equalising charge) returnes these first stage crystals to solution and maximises battery effiency and life. Another way of returning these first stage crystals to solution is with the 1k Hz pulse of your battery desulphator. This however does not address the stratification of the solution issue of batteries in a continual 'float' condition. (I can only wish for this problem) Hz readings for RPM calcs can suffer from Harmonic circulating currents. Look at the readings you get and you may see thay are multiples of your expected reading. I have 3 multimeters and they have various levels of triggering sensitivity. The most sensitive meter may respond to the harmonics whereas another won't. I have attenuated the signal to one meter by adding a 100K resistor to each test lead and this works fine now. (actually the resietors are permanently attached, sticking out the rectifier input terminal strip and I clip onto them.) was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Chipboy Newbie Joined: 13/12/2006 Location: AustraliaPosts: 16 |

Here is something I can help on, Highlander the Jaycar kit as made will only help you and your batteries, it can be left on indefinately without damaging anything. The pulses it makes are dependent on internal impedances in the battery so (they say) as it (the battery) desulphates it will reduce in impedance and hence the pulses will reduce too. I have mine on a battery and its been there for a few months now, I will be putting another onto my 2 * 100Ah deep cycle batteries to give them a work out too. Go for it, do not delay. Matt Wind wannabe |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Chipboy, I got two more deep cycles, 120ah they're about 2 yrs old and were holding 13v I pulled them out of the bank and started to give them a zap while under charge. The first one was on overnight and the volts dropped to 11.3v when the charger was turned off. Is this because the zapper has revealed parts of the plates that were sulphated and they have sucked the power from the rest of the plates now that they are clear? Hopefully it will hold a higher charge now, if it does, my theory is right. Time will tell.  Central Victorian highlands |

||||

| Chipboy Newbie Joined: 13/12/2006 Location: AustraliaPosts: 16 |

Time will tell indeed. If they are heavily sulphated then the pulser will have drawn them down over night just by its use, but as you have said they were on charge came from a bank and were at 13 V at rest so they should be ok, leave the pulser on one or put the two batteries in parallel and charge with the pulser connected and monitor. Flooded lead acid should be equalised at 14.5V dc and check the sg too. It will not hurt at all. Use heavy cables between the batteries and whatever you do, do not reverse bias the pulser unless you bought tthe current jaycar kit at $100 which I believe has reverse polarity protection. Make sure your fluid level covers the plates this is critical and I cannot say how many times I have been found wanting on this with abtteries, it never fails to surprise. all the best, Matt Wind wannabe |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Thanks, can't check the gravity or fluid level as they are sealed l/a Central Victorian highlands |

||||

The_Professor Newbie Joined: 22/04/2007 Location: United KingdomPosts: 11 |

Hi, Real nice project

From a mechanical point of view, its best to keep the pulleys as close to the generator (and engine)as possible, otherwise you may find the drive shaft will fall off through stress. Where the pulley is currently mounted on the end of the shaft of the genny, this allows the shaft to flex (even the minute amount is eventually harmful) so will slowly fracture the shaft. Alternatively mount a bearing by the pulley. May possibly also help to have a bigger pulley on the motor than on the generator, thus gearing it up. This will avoid over revving the engine and possibly save fuel. Steve |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Steve, thanks for that. I knocked that up out of bits lying around. The end of the shaft has a star with a smaller od, which happened to fit the pulley I had. I agree placing the pulley closer to the gen would be better, but haven't got around to it yet. I think the gearing is about right, it makes 80+ amps so with that load it creates quite a strain on the motor, it's petrol not diesel so it may not have the torque if it's geared up any higher. Dunno still works well though. It looks a bit different now, the stator is on rails to adjust the tension, a work in progress.  Central Victorian highlands |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day fellas, I'm scratching my head again.

I updated the mounts, which turned out well

The problem I have is the new 1mm stator I rewired exactly the same as the .8mm has dropped away in power dramatically. I revved it way harder than before and got a max of 60 amps. The old .8mm gave me well over 80 amps with much lower revs.

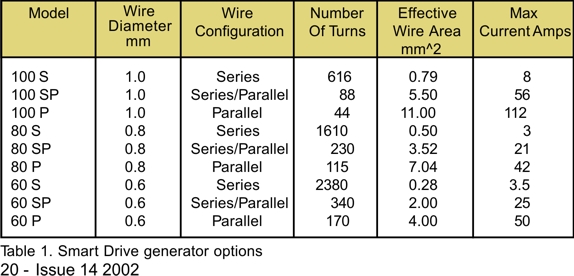

This is a table from ecoinnovation

The 100p, is that 1 pole delta?      Central Victorian highlands |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day highlander, Something seems wrong with those figures from ecoinnovation. I would have expected the current to be progressive as it dropped in wire size. The number of turns seem right. I guess you have checked for rubbing wires in your modification so got me wondering too. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Gill, Just went over it again fo 1/2 hour, looks fine. When it runs on the gen nothing is getting overly warm so that also indicates no short, also with the belt off, it spins fine. I just noticed that ecoinnovation table has the highest output of an 80, which is the 80p is listed at 42 amps. But I was getting well over 80amps. One other thing, the 1mm has much, much lower voltage. At the rev's I would normally get 10amps from the .8mm the 1mm wasn't even making 14v. The only thing I can think of is it needs to be revved way over 1000rpm. I'll just put the 80 back on.  Central Victorian highlands |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Well this really had me stumped, so I emailed ecoinn. Q: The table I got off your site shows a 100p as 112 amps is that 12 or 24v? A: "It is the maximum possible, voltage does not matter. You just have to spin it twice as fast, too fast and you kill the unit At 1500 rpm 40 amps at 24vdc or 80 amps at 12vdc is possible." End of quote. So you can theoretically get 112 amps but you have to spin it so fast, it will probably self destruct. It appears that the 80 is actually better as I was getting 80+ amps at way lower rev's. Central Victorian highlands |

||||

| ericvr Newbie Joined: 24/11/2007 Location: AustraliaPosts: 37 |

Hi all, Is it possible to use the model 80 or 100 can be used to generate 48 volt? And if so has anyone done so? What would be the number of turns required to generate 48 volt and what would the current capacity be,I realise that the size of the wire determines the current capacity, should I use Star or Delta configuration,I would be looking at approximately 30 to 40 amps to charge a 48 volt battery bank of about 480 ampere hours ((5 x 88 a/h 12 volt batteries in paralell )x 4) as in my picture on my other post. Also where can I get the Fisher and Paykel drive motors please. I am in Laverton, Victoria. Thank you for your help Eric van Rhijn (ericvr) limited greenie |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

This looks like a good idea for a backup charger. I was thinking of fitting one to one of these here I see this one used a 3.5 hp, if using a 6.5 hp you could probably do a 1 to 1 ratio and run it at fairly low revs, being mindful not to stall it. What would be the best wiring for a 48v system, I picked up an 80 series FP motor. Cheers Mark Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Perhaps get some pulleys like here So you could play around with optimal speeds etc. Cheers Caveman Mark Off grid eastern Melb |

||||

| Page 1 of 4 |

|||||