|

|

Forum Index : Windmills : The Mannly Smart Drive hits the 1150Watt

| Page 1 of 4 |

|||||

| Author | Message | ||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

I took some heat here on my Mann Smart Drive and the power output I posted. I made this VID to put all of that it can not be done to bed. And for all of those that helped in the design it worked out just great Thank You. There is alot more to be pulled from this motor the GTI still needs to be programed for this motor as Steve has commented that the voltage reading is low. http://youtu.be/phbF1uGRmpY The Brigeport motor is 1.5 HP we were max out for speed I think we can say it is the most powerful low cost Smart Drive in the World. I now it is a big claim but this one is under the $500 US marker that is ready to go just add wing. If you can back up nother motor with the same test at the same price point I will eat these words on a VID for you. I know most do not like the in the face claims but your F&P is a true work horse it just needed some USA over hauling. Bob Mann |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Bob Congratulations mate good results from your machine, the documentation should show the critics that it works well and that high voltage is the way to go for grid tie. How about some specs such as stator type and is it your dual stator or a single stator. It will make a fine HAWT at reduced rpm in the 700 to 800 watt range with reserve capacity. The design looks nearly bullet proof and should do years of reliable service. Is it star or delta connected, as I found the 60 stator tended to overheat at high power levels when connected in star. Keep up the good work All the best Bob Foolin Around |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

May have to eat my own words. All our experience has shown a uppler limit of about 500 watts for a F&P. But maybe that limit was due to the way we were using them, with a bridge rectifier and loaded to 12/24/48 volts, either into batteries or a grid tie. What you are doing Bob is something different, running the F&P at its natural voltage, instead of clamping it down. The grid tie inverter your using is designed to use the wild voltages from a wind turbine, and maybe thats the key. 1kw would mean a 3 meter turbine or larger, so 600rpm is a little high, but quite possible with a good turbine. A 4 meter turbine geared up would be a better match I think, it really depends on your local wind conditions. Good work Bob Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Yes Bob, I also have to congratulate you on your performance. It looks like there is something to a high voltage GTI machine. This isn't an 'in your face' claim. Actual data never is. Good job. Perry |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Bob ..the alt seems to be working well i,d worry a bit about ..... "just add wing"...thats the big question ..matching the load putting alts on lathes dosent really relate to actual wind conditions ....but then thats just me being the eternal skeptic ....

that ginlong looks interesting...  niall |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Hello it was a single 60 Delta wired stator with larger air gap and cogging was in the 11 inch pounds. I think it will be up to some one eles to build the best wings to power it there are far smarter people out here on that. I did build a HAWT hub mount for this Bad boy that supports 3,6,9,12 rapter like blades or three auminum ones from Phiel Down Under with a tail mount all auminum. Thank you. Bob Mann |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

BobMann Hey Bob! one and a half horsepower is = to 1119 watts plus the losses of the motor.? How can you run two machines on one and a half horsepower and generate one point fifty four horsepower as an output??? I watched your movie on U tube and was very surprised at the performance shown here. Just pulling your chain a little, I realize a motor rating and what it can do for a limited time are quite different. Nice looking work and a Job well done. I must admit I had some reservations about the numbers in some of your posts. --------Cheers and may Fortune follow you!. Roe Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

some one had posted this on the YouTube. Nice video and great power. One question, I am guessing you are running the mill from the grid? If that's the case, then the smart drive is also supplying power to drive the mill and the excess is being dumped to the grid. That means it's actually making more the 1150 watts. It would be interesting if you drove the mill with an external power source (gas generator), switch off all loads in your house and then see how much power is pumped to the grid.... When I get some time I will retest with watt meters on the Brigeport to do a cross check. |

||||

| Xmaswiz Regular Member Joined: 14/04/2011 Location: United StatesPosts: 69 |

What model GTI are you using? Santa Maria, CA. Noel |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

ginlong 2 K unit Bob Mann |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

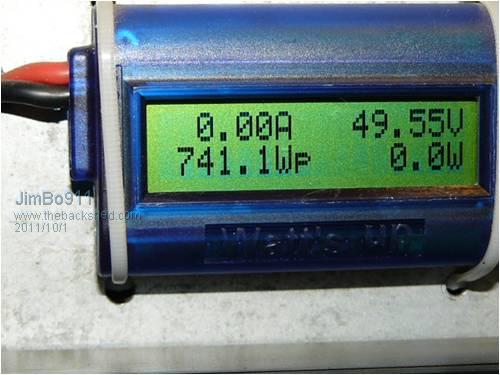

Mr. Bob I must say job well done. I guess were just gona have to put some of the AxFx machines to sleep for a short time. The tried and trued F&P rises again. After all the fuss about lets see some real numbers I though that i might add some numbers of my own. After crashing and burning and couple of times my 60, delta, neo set up is been flying some sweet numbers as well. 2 meter blade set with some ALU Geo blades. My doc wattson meter tells the story. 741 Wp and 11.73Ap At full furl she pushing out about 640 watts. I could crack it up a bit but we all know what happens when we sass mother nature

Been designing a duel stator mill but it may take awhile I am really happy with a mill that keeps putting out the KWH. Jim |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

BobMann Just for kicks, I plugged some numbers into Alton's Calculator and worked this backwards to see how big a mill you'd need to turn this and get the same results. The funny thing is, on Altons, using a 4 meter (diameter) blade and not changing any of the other variables, in about 18 MPH wind it's turning 268 rpm and kicking out 1183 watts. Yours was kicking out just a tad more, but you were at 550 rpm. I'm thinking that's a pretty big difference and I'm wondering why. To the best of my knowledge, Alton's is based purely on math (although I'm no mathematition) and there seems to be quite a discrepency between what Alton's Calculator predicts to what you have shown in your video. I'm still learning all this too (read that: clueless), but I thought I'd toss it out for your consideration. . . . . . mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Mac The altons calculator has several variables such as CL, TSR, and airfoil efficiency and to work it backwards you need to take into account that his blades are a different section and all these things vary, On the GEP222 blades I am using they are much more efficient at lower RPM below 500 rpm, than the carved blades he is using as a standard, but more at the low end range of RPM,below 300rpm, his blades perform better at higher revs a crossover at about 800 RPM from my checking as I have two mills up with the two types of blades and can compare their relative output. Also the Alton calculation doesn't take into account multi blade sets of high speed blades as the have a higher TSR and more blades to collect energy swept area density. The figures that Bob used I think are direct drive from a Bridgeport mill and would not reflect a set of blades as such that has yet to come I believe, I believe a set of GEO 222 blades would be ideal for his machine as I checked them against my own calculations with my generator and a set of 3 meter ones will push past 1500 watts at 10 MS.

These are the blades that are close to Alton calculations on start and power out and RPM in wind speed relationship. By the way the mater eagle landed yesterday. Thank You. All the best Bob Foolin Around |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

I am looking for some help on one of the water tower projects. We now run my 3 modified Lenx wings 4 feet high at a three ft round VAWT I need to stay with a VAWT for now at this site.. If I stack 2 sets in line making one solid 8 ft high set x3 what outside raid es should I shoot for?? What RPM range = Wind speed will you think we will be running. We will be a 200 ft high supper clean wind. Or what other solution in wing design ?? Bob Mann I do have a data logger on a site at the same 210 ft marker close by it is running at 10 to 30 MPH most of the time. I would like to pull high as I can go on RPM say 200 RPM+. See I can build my Lenx blades to 8 ft long and all TIG to gather with one sheet piece of 8 ft=21inch aluminum wrap. what would work for a arm length. Bob Mann |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi Bob I dont think that increasing the size of your Lenx wings will give you any more rpms but it will increase the torque. I beleive that in going to a high speed set of wings you will increase rpms but lose torque and the cogging and loading of your alternator will not allow it to get up to the speed you need. My findings are that a set of full lift wings dont produce much torque at all, no where near as much as a hawt of the same size. I think the best thing you could do is build your big lenx wings and then gear it to get to the rpms you need. Good luck Dean. |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Thank you all for you input. I do not wish to add any gearing it. It is dricte drive unit. Bob Mann |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Mann Smart Drive needs help on wings?? Reply Quote ------------------------------------------------------------ -------------------- Here are the results of my program. The program matches the Lenz2 turbine to the Mann Smart drive to predict the output into the load. The power curve of the Lenz, the curve of the Alt, the variable resistance of the alt, and the MPPT are all taken into account. Each chart is for a different height of turbine. Each line on the chart is for a different diameter of turbine. The x axis is the wind speed in MPH. The Y axis is the power to the MPPT in watts. This isn't really what I expected to see. The diameter of the turbine does not scale to power output, probably because the bigger it is the slower it spins. The height also does not scale to power. Also notice that the optimal diameter for a given wind speed changes with the turbine height. I can't guarantee the program is bug free since I wrote it in a few hours, but I have looked over the individial routines and I think it's working. I've included the perl source for anyone who is interested. Here is the link to the ploting I will paste pic later for all. http://www.vawts.net/t45294520/mann-smart-drive-needs-help-o n-wings/ - Edited by sjh7132 on Monday 3rd of October 2011 04:36:23 AM Attachments LenzMatch.pl (4.0 kb) |

||||

| Xmaswiz Regular Member Joined: 14/04/2011 Location: United StatesPosts: 69 |

Congratulations mate good results from your machine, the documentation should show the critics that it works well and that high voltage is the way to go for grid tie. How about some specs such as stator type and is it your dual stator or a single stator. It will make a fine HAWT at reduced rpm in the 700 to 800 watt range with reserve capacity. The design looks nearly bullet proof and should do years of reliable service. Is it star or delta connected, as I found the 60 stator tended to overheat at high power levels when connected in star. Keep up the good work All the best Bob What model GTI are you using? ginlong 2 K unit Bob Mann is this model specif for USA? I tried looking up the unit on their site, and only saw single phase 230VAC units. Do you mind if I ask how you ordered it, and cost? appreciate any info! thanks Noel Santa Maria, CA. Noel |

||||

| turnymf Regular Member Joined: 04/10/2008 Location: AustraliaPosts: 84 |

It's only single phase output with dc input. Apparently, from a quick read of the manual, you can program a power curve that matches the turbine. I would guess it tracks the dc applied to it and the sucks out the current proportionaly as per the power curve installed |

||||

| BobMann Senior Member Joined: 30/06/2011 Location: United StatesPosts: 134 |

Bob What model GTI are you using? ginlong 2 K unit Bob Mann is this model specif for USA? I tried looking up the unit on their site, and only saw single phase 230VAC units. Do you mind if I ask how you ordered it, and cost? appreciate any info! thanks Noel I ship them in from China and they are 220 Volt $1800 you will still need some kind of switch and dump set up. they do sell one but the cost is a bit high. If you view the MMPT post this my be a solotion too. Bob Mann |

||||

| Page 1 of 4 |

|||||