|

|

Forum Index : Windmills : Airblenda 500W VAWT

| Page 1 of 3 |

|||||

| Author | Message | ||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

I have been encouraged to share some details on my Airblenda 500W VAWT. VAWT's benefit over HAWT (your standard windmill style wind turbine) is that they work better in area's subject to turbulent wind conditions (in my case a built up urban environment). In these conditions HAWT's tend to spend most of the time trying to "search" for the best wind direction. I say this not from reading copious amounts of literature but by having a Air Breeze sitting up on my roof for 2 years. I tied in the Air Breeze into my house electricity grid by using a SWEA (WWW.SWEA.NL) grid tie inverter, it worked well but spent most of its time trying to "find the wind" and then kicked out when the wind got > 12m/s, (which it does everytime the sea breeze kicks in). Yes I live in a windy area (Fremantle in Western Australia). So I went about designing and building an Urban wind turbine that I could mount on my roof and which would generate around 500W in a 12 m/s wind, in turbulent conditions. But could handle winds greater than this and genrate more than 500W. It also needed to be smart enough to stop itself from being destroyed in a serious wind. Just to make it be useful it also had to be silent running, and not big enough to have the neighbours or govt types knocking on my door with a please explain. End result is a 1.5m * 1m VAWT mounted on a 100mm diameter steel pole (with 5mm walls). The following clip was made of the initial prototype in 5-7m/s winds AIRBLENDA in action Because its a prototype I built in a number of adjustment mechs to allow me to vary the angle of attack of the blade and other variables so I could easily figure out the optimal operating configuration prior to completing a more industrial strength grid tie unit that will mount on the side of my house and suppliment my grid tie solar unit. Lets face it I wanted a set and forget unit, not something that needed to be mothered all the time!

The unit is mounted on the outside wall of my house, in a normal suburban environment, and is on the wall adjacent to the bedroom. You would be hard pushed to hear the unit when its turning, and because of the way its mounted no vibrations are felt at all. The blades for the VAWT I sourced from Phil on this website DIY Parts whilst I am using a Ginlong PMA, but a suitable configured F&P would also work quite well. The Airblenda is designed to have interchangable Airfoils, PMA's, and also uses laser cut aluminium stays, all of which can be altered based on predominant wind speed, and desired characteristics and end purpose. i.e grid tie, or battery charge, low wind environments etc Its been a decent learning curve for me but I am close to where I want to be at with my hobby in thebackshed. The neighbours are happy, and also want one, I'm getting closer to supplimenting my electricity bill and my partner doesn't mind the time I have spent on it now that its out of the way and up on the roof :-) "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

smithy Great gob! This has to be the first VAWT I've seen that actually makes sense and WORKS! I've built plenty, just because they "look cool" when they run and they don't need a tail. None of the ones I've ever concocted ever got going fast enough to create any worries about flying apart, so from that standpoint, I was happy. On the other hand, the rule for me at least has been they don't have enough power to whip up a batch of eggs, so I usually build HAWTs. Like I said, great job and a great presentation; short, simple and the best part is: IT WORKS! . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Smithy, I was at a pause when I saw the picture,,,I built a test model less than 1/2 the size of you'rs, I had my wings set up differenty, crounded to the outside and tilted in by 8 degrees of the circumferance plain. I did some testing with the wings flipped like you have you'rs, but had slightly better test runs with them the other direction. Might be in the size differance, or it might be that you'r machine is made out of aluminum, or something else entirely, such as the generator and electric loading. Makes me nervous because I've made my wings to fly with the crown to the outside. I have also determined that if you need more speed all you need to do is add another wing or two, or narrow the radius a little, but you loose power by makeing it narrower. Loose speed by makeing it fatter too, but you can get the speed back by adding another wing. Strange animals to figure out these vawts. Thanks for posting, and keep us informed with how it progresses. "Interested", thats putting it mildly, yes I am interested. .....Mac46 I'm just a farmer |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Smithy Very nice machine and looks good in the urban environment, I will be very interested to see output figures when you get to that. All the best Bob Foolin Around |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Smithy, I think if you are looking for alternatives with an alternator with a F&P , I would suggest trying a 80S or 60S stator on a 7 phase conversion , you will get a low rpm cuttin and should not overload it . All the details are in the projects page , even the staggered stator that Glenn was playing with might be worth a go. From memory a unmodified 60S will cut in @ 50 ~ 60 Rpm , and produce high volts . I would have to go back over my old testing data . It might be worth a go if you are going with grid tie . Off course the ultimate would be to design a small Axial Flux to suit so you would have no cogging or iorn losses giving easy start-up. Even making a AXFX from ferrite magnets could be a cheaper option and worth playing arround with , I seem to remember Windstuff Edd using microwave oven magnets. Nice touch with the blade adjustment , with all the ones I have seen built with the ALU GOE222 Blades to date , every one that is working well has the blade convex facing out. How to actually caculate the best Dia and angle of attack for a VWAT using these blades is a bit out of my league, my solution would be to make it all adjustable and strong . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Smithy, I'd be interested with torque and or (moment) data of a single wing profile in stages of rotation around the axis. .....Max46 I'm just a farmer |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

Mac46, You might find the following link what you are after re torque. Its shows the results of 2D airflow modelling on a VAWT, configured with various different foils, and mounting configurations. I managed to get them to run the GOE-222 (They called it a GEO-222 but hey its the same one). You get an idea of what works and what doesn't. Link to VAWT 2D fluid modelling Smithy "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Smithy, Thank you for posting the link, (vawt 2D fluid modelling), very interesting. You'r doing some good work. I'd like to add...study the effects of hilicopter blades as they counter-rotate during an unpowered emergincy landing, this will help you realize the 3-D effects and motion of air under and over the wings. I've never experianced this first hand, Thank God for that, nice work. .....Mac46 I'm just a farmer |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

I have had low wind speeds the last week and the AirBlenda has thought about moving then stops again. So I got up on the roof and found that the wind speed between the top of the VAWT was different to the bottom of the VAWT (by about 1.5 m/s on average). This is most likely due to the proximity to the roof line. I have 2 main options I can look to address this. Raise the VAWT up a bit more to get a more uniform airflow across the wind swept area of the VAWT or Add some more airfoils to increase the start up torque (this will however decrease the top RPM, and the top power generated). To be honest I will probably try both and see what works out best. "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Well done Smithy It looks simple and easly ajustable. i think 1.5 meter blades on a on a one meter diameter is a good size. I havnt had a look at your vidio yet as the computer at work wont let me acces it but i will have a look at home when i can. Its good to see anouther VAWT up and running on the back shed. All the best Dean. |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

Well, I'm onto the next phase of the project and that is to link it upto a grid tie inverter, and hook it into the local grid. Sounds easy when you say it fast, but the local bureaucrat's are making it like extracting teeth. Aim is as follows Airblenda (3 phase output) going through 3 phase bridge rectifier into Grid Tie Inverter. Where the output from the 3 phase bridge rectifier in DCVolts = 1.414 * ACVolts coming out of the AirBlenda. The Input into the Grid Tie Inverter is DC Volts. The size of my grid tie inverter (2KW) means that I can add on more Airblenda's, and have them in series after the 3 phase bridge rectifier. Which then increases the voltage into the GTI. Smithy "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

No real feedback from my local power company for linking it in with the grid, so I have done a bit of tinkering. Firstly I pushed it up 1/2 a meter extra just to see if it gets any more wind... answer mmmm possibly. Next step is to increase the length of the airfoils from 1m to 2m. This effectively doubles the wind swept area, and hence the power available to the VAWT. The PMA that is currently hooked up is the Ginlong 500A which a low voltage PMA and I use it to charge batteries currently. Works quite well for 12V batteries. Phil, expect another request for 2m length aluminium blades this time :-) Latest AirBlenda Vid Smithy "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| vawtwindy Newbie Joined: 23/10/2010 Location: IndiaPosts: 31 |

nice work mate. keep it up, ginlong 500A,? at 150-250 rpm it is less than 100Watt? max 450RPM = 500Watt? i guess you are extracting too low work from it? have you tried your own turbines? |

||||

mac46 Guru Joined: 07/02/2008 Location: United StatesPosts: 412 |

Smithy, I suspect that the air turbulance is the cause of most of "our" problems with the vawts...just like hawts, we need clean air flow. Increaseing wing length also adds weight but each location is unlike all others so like myself, one must experiment to find out what works the best. Keep up the good work...I am following you'r project with interest. with kind regards...Mac46 I'm just a farmer |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi Smithy Hopfully we are on the right track going up to 2m wings. I think to push a decent size alt up to speed 1m wings are far to small. It sounds as if you have come to the same conclusion as me so I will be interested to see how your project pans out. It is all a good learning experience and one thing I have learnt, to make good power you need lots of RPMs with grunt. All the best Dean |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

The Ginlong 500A alt is really just for test work, the main Alt is the high voltage Ginlong 1000, which I am trying to get the local power company to OK the link in with the Ginlong Grid tie inverter, This combination is a good combination, and at 300RPM will push out around 600W (the idea is to have 2 Airblenda's feeding the grid tie inverter) . My current task is working on the best blade angle and length to give me the best RPM return. The more RPM the better, but I don't want the VAWT to fall apart so I have probably over engineered it and possibly made it a bit heavy (its around 10-12 kg minus the Alt). Having said that It gets very windy here and I don't want to blow it apart. By increasing the height I will double the wind swept area without increasing the diameter of the unit, so the extra power should be pushed straight through to creating more RPM which is what I want. "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| vawtwindy Newbie Joined: 23/10/2010 Location: IndiaPosts: 31 |

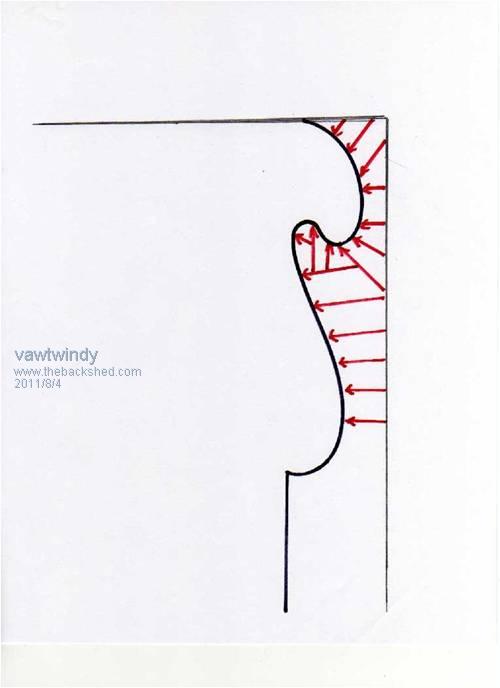

as you mentioned in youtube, @Airblenda since it is swirling wind (is that a right term?) why can't you think of having small curves in place? like this

, by doing this will the torque shoot up? might be a difficult task, but i felt it might help you? |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Smithy, how fast will it rotate unloaded in it's current configuration.In other words is it the swept area and power limiting it's speed or the aerodynamics or both. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| smithy Regular Member Joined: 30/01/2011 Location: AustraliaPosts: 52 |

When the battery is not well charged it requires quite a good wind to get the turbine going, whilst when its fully charged it fly's in a similar fashion to when it is isolated from the battery load. I think the weight of the wing assembly is a big factor, and it needs a reasonable torque to keep it moving. If it was lighter but with the same wing profile it would spin a lot easier. Having said that its heavy as its got a lot of aluminium (6mm plate alumin for wing supports) for a reason and thats strength. Another option for increasing torque is to add more foils rather than just have the three, but this then affects the upper RPM. Given enough time, resources and access to a decent wind tunnel then all the options could be tested and then I would know definatively. I like Phil's airfoils as I don't have to create any of my own, but I do recognise that better ones exist, but getting them made up using extruded alumin would be very very expensive and beyond the scope of my hobby. Smithy "The answer my friend is blowing in the wind, the answer is blowing in the wind" Bob Dylan |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi Smithy With your wing profile I would be tempted to go with a 5 wing set up, an unsymetrical wing will only produce good lift with the wind in the prefered side of the profile so with a 3 wing set up you will only have 1 wing in the powering leg of the rotation at the one time. But with 5 wings you would have 2 on the power leg of the rotation, so the maths sugests a 5 wing set up is a better option for a wing that is not symetrical. I have gone for a symetrical profile so that wing will be powering through more of the rotation. Your profile will give you beter lift than my symetricl wing will but for less of the rotation. So by adding 2 more wings you could double your mills lift but only increase the drag by 1/3. All the best Dean. |

||||

| Page 1 of 3 |

|||||