|

|

Forum Index : Windmills : wind direction logger

| Page 1 of 2 |

|||||

| Author | Message | ||||

RifRaf Newbie Joined: 15/10/2006 Location: AustraliaPosts: 32 |

Hi all, Am new to the windmill stuff but have made a bit of stuff over last 2 weeks. have started on a couple of the F&P willmind brackets and just made a little bike computer anemometer to start trying to pick out a site for the mill. Am wondering if someone has an idea or knows of a simple way to monitor the wind direction so that it could be read on a computer or uC. Was thinking maybe of an encoder wheel and some leds on a windvane to send a simple binary number for a microcontroller to read. Any other suggestions as the leds will need power? , maybe just a ring of reed switches and a magnet on the vane. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

In the old days this was done with a 'magslip' or 'selsyn' but for all I know the couple in my garage may be the last in existence! A simple way to read direction is with a 360 degree 'pot' and that is what a lot of the cheap weather stations use. You need to be able to read analogue values on your computer. I have a 32 position rotary switch in my junk box and if you can find the same that would probably be close enough. Your ring of reed switches is much the same of course and dear say would last longer than this switch. You would need a lot of wire though or do some encoding with diodes or something. Incidently, if you do use a rotary switch you can usually find a way to remove the ball, spring or whatever that gives the 'click' stops then the switch will turn fairly easily. Modern anemometers use ultrasonics to measure the wind in two direction and using trig derive the direction. You can use an encoder wheel but you might like to read up on 'Gray Encoding' which is a method of designing encoder wheels to avoid errors. I have thought of a way to make an anemometer that only requires two wires and will give both direction and speed. The idea uses a pickup coil mounted on your wind speed cups with the coil passing a fixed magnet every revolution, the resultant voltage pulses give you speed. The direction vane moves another magnet of opposite polarity around the same axis and the wind speed cups. So you get two pulses per revolution, one pulse and the frequency of repetition gives you wind speed and the relationship of the second pulse (identified by having reverse polarity) give the direction. I thought of making one of these and processing the output on a PC sound card. Ah, life is so short for all these projects!  |

||||

| sangeff Newbie Joined: 05/11/2005 Location: AustraliaPosts: 29 |

Im in the middle of building a weather station and the wind vein will use a home made binary coded disk, 4 photo switches from an old brother fax machine and a 74/154 4 bit binary to 1 of 16 decoder chip that is now available as an 74LS154 , (check your altronics catalogue), It wasnt dificult to come up with the parts (although I couldnt get some phototransistors to work at ttl levels and couldnt be read by the picaxe) and an old vcr head assembly will provide you with a good bearing and shaft kit, and is all housed in an upside down stainless steel drink cup. The same for the anemometer but only one photo switch. You could run the 4 bit coding through a picaxe and log it from there as was my origional plan but there isn't enough room in my head to come up with a suitable code, If anyone has writen a picaxe code for wind vain and anemometer readings I would love to talk to you. |

||||

| makourain Senior Member Joined: 19/04/2006 Location: Posts: 111 |

image the image is by now means how i would put it together but it illustrates what i am trying to say  |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Suggest VERY strongly you don't use a binary code. Binary code may have multiple transitions trying to happen simultaneously - of course, they won't, and you get all sorts of bizzare things happen. Use a "Grey Code" instead, if you want a digital output. Alternatively, my professional Davis Instruments helicoid propvane uses a 360 degree "potentiometer". Ground on one side, excitation voltage on the other, and the wiper is between 0% and 100% representing 0 to 359 degrees. In my own weather station, I simply read the analogue voltage, converted (ratiometric conversion) to degrees, and then added a constant for calibration and modulo 360 for the result. (Why do this? Well, it's a DAMN site easier to point the thing in a known direction, read the position indicated and apply a correction that then works across the board, than trying to climb up and down the tower tweeking the thing!) 4-bit code for the anemometer? Why not simply measure either time-between rotations OR rotations in a given time. (single interruption per revolution). time between pulses is more accurate for low speeds, pulses per unit time is generally more suitable for higher speeds. At the end of the day, if you're just doing "site surveys" for your wind turbine, arguably the most important consideration is your "Wind Run". Wind speed and direction gives you velocity, you need to "do stuff" to work out some idea of how much wind you get in a day, whereas wind run is measured in miles (or kilometers) and is directly useful by itself. It "accounts for" the average speed, and variation in direction. Usually, its no more than a cup type anemometer and either a small mechanical counter or little electronic pulse counter. Some read directly in miles/feet or km/m, others have a "revolution" counter and you need to look at a table, or calculate the answer. They're generally small, cheap and can be scattered across an area to find the best individual situation over time. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

An aussie chap some years ago developed a nice instrument that looked like a normal cup-type anemometer, but did speed and direction. When I looked at it, I couldn't see how he could possibly get direction! His method was simplicity itself - although a little more complex in implementation. One of the cups was slightly larger than the other two, thus the thing went faster when the big cup was going downwind, and slower when the big cup was going upwind. His code (in the embedded PIC) detected this "wobble" and was able to provide not only speed (from the average rotational speed), but wind vector by a little bit of math. I don't know if anyone is making or selling them now, he used to have a kit, but I see it's out of production now. |

||||

RifRaf Newbie Joined: 15/10/2006 Location: AustraliaPosts: 32 |

thanks for replies, good to find out some new ways i had not thought of, am gonna go with the 8 reed switches and an atmega8 for now. if i can get the magnet to trigger at least 1 reed switch and 2 when between then should be able to have 16 directions i figure and easy serial link to pc. will post a picture when i get something working. but something like this image http://eds.dyndns.org:81/~rifraf/images/direction1.jpg using same roller as for anemometer that has a tiny chunk of hdd magnet embedded in it and a balacing bit of plain metal in other side like http://eds.dyndns.org:81/~rifraf/images/anemometer4.jpg http://eds.dyndns.org:81/~rifraf/images/anemometer5.jpg |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Don't want to "rain on your parade".... but watch out for the hysteresis of those reed switches. Also, depending on which way you mount your magnet (eg, if it's mounted with the n/s as in/out (ie, radially) then fine, but you'll have more difficulty getting it to operate two reeds at once. If you choose to mount it axially (so it's sideways between the reeds) you will probably find that as the centre of the magnet goes past the reed, the reed will drop out as the n/s null goes past. With some cleverness in your code (and a state machine) you could get additional precision out of it this way :) Oh, and depending on the size of your vane, you may find that the attraction between reed and magnet will cause linearity problems in light wind. *IF* your only concern about using LEDs and phototransistors was that you have to supply power to it - thats easily overcome. LEDs consume (relatively) low current. Certainly, if you're using a system outside, you'd want to optoisolate it from your computer, so you have some room to play with. You can power the LEDs off the same supply you use to READ the return level(s). Say you apply 12V, that's plenty to run 4 LEDs in series on as little as 5-10mA. Use photo-darlington transistors, with weighed collector resistors, you could code them as (say) 5, 10, 20 and 40mA. At the "sending" end, by simply measuring the supply current you can (a) power your LEDs and (b) determine a 4-bit position code, all over a single pair of wires! |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Yes RossW I have seen that very clever Aussie method with the off balance rotor. We even evaluated it but the client wanted something more expensive. We were happy to oblidge!

He had three cups all the same size with a little flag on one plus he used fibre optic cables down to the control box which I thought was excellent lightning protection. If I recall the builder was retired and only made a few, he offered kits for a short time only. He had some arrangement with a UK supplier of anemometers to yachting and boating etc but I never saw them advertised, maybe that is where it lies now. Ultra sonics are the ultimate way to go nowadays. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

I am working on a design for something that might be interesting, meanwhile do not toss the water level switch from your F&P washers! |

||||

RifRaf Newbie Joined: 15/10/2006 Location: AustraliaPosts: 32 |

RossW thaks for the insights into the reed switch operation. Your comments make sence and can see this working using the positive parts you mentioned. After making the first test unit am pretty sure this can work, yes will need a state machine for the avr but seems i can get about 32 combinations of output using the 8 reeds. this should give readings down to 11.5 degrees and seems rather accurate testing it over a , (can see maybe 2 or 3 switches need to be flipped to get perfect). Will mount a small though big enough arrow type vane to overcome the small magnetic attraction in the slightest breeze. This is caused by the metal mount though only and raising the reed switches and magnet further up the black roller should eliminate this. http://eds.dyndns.org:81/~rifraf/images/direction4.jpg http://eds.dyndns.org:81/~rifraf/images/direction5.jpg |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

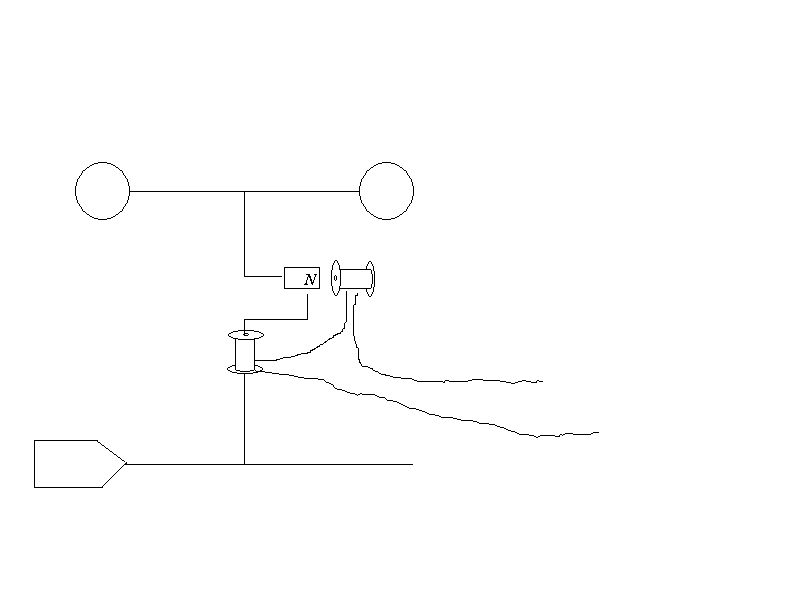

This is my scheme for an anemometer. There are wind speed cups on the top which pass a magnet over the pole of a pickup coil, every revolution gives a pulse down the line that is detected by the processor to give speed from the rate that pulses are received. There is a wind direction vane mounted underneath and with its axis directly inline with that of the wind speed cups. This direction vane has a soft iron axis with a cranked end, there is another coil mounted around this shaft but not fixed to it, i.e. the coil is fixed while the shaft turns as the wind direction changes. Every time the magnet on the wind speed spinner goes past the end of the iron rod it causes a pulse in the second coil. With the two coils in series the circuit gets two pulses for every revolution of the wind cups, one pulse from the fixed coil at the right of the picture and another pulse as the magnet passes the end of the wind direction cranked piece. The repitition rate gives the speed and the time between the first and second pulse gives the direction. Diodes, not shown in the diagram (because I forgot) fix the polarity of the pulses so that the processor can distinguish between them. Two moving parts, no slip rings or moving reeds. I hope someone finds it interesting enough to try and make one. Cheers |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

No interest? No comments? |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

ok, ok :) Yes, I think it's interesting. The missing diodes certainly caused some confusion for a while though :) I might knock something up if I get a spare hour, because it's pretty straightforward to prototype/test. RossW |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

OK, diodes go across each coil and the coils arranged so that they produce pulses of opposite polarity. Maybe I should make one myself, Lord knows we have enough wind around here to test it! |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

I can think of only one "issue" - that is when the wind is comming from the same direction as your speed coil, you will have a cancellation of signals - either your negative pulse will cancel out the positive pulse and you'll get nothing, or they will *almost* cancel and you'll end up with only a small amplitude. If the latter, you could probably detect that and still deduce the right answers but you'd significantly reduce the noise immunity in so doing. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

You could be right Ross but I find it quite unlikely that such a state of afairs would exist for more than a very short time. Also I doubt that both pulses would be anything like the same aplitude unless deliberately adjusted. I think it would be best to engineer things so that one pulse is much greater than the other to avoid confusion. Of course if noise immunity was a concern then four wires or processing at the instrument head would be options. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Yes, unlikely, but I raised it as a matter of completeness :) If we were going to process at the head end, a little PIC to do all the "work", use a 2-wire line to provide power, make the PIC output a serial stream (slow - perhaps 2400 bps) by "modulating" the supply current, which can be easily detected at the remote end. (I used to operate digital scales this way back to a DEC mainframe - 20mA current loop at 1200 baud over a pair of wires that were 1100 metres long through a factory!) |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Hiya Guy's, Below is a zipped file to an 3422 Allegro hall effect sensor that senses direction among other things.This little 5 pin chip along with some small magnets would make for a top project on an anemeter for finding out direction. By using a pic or picaxe it would be easy to not only count pulses but also direction. I only wish I incorporated it in my anemeter I made using an 1101 hall effect and a small 3x3 neo cube. I've yet to write the code for this baby but setting it up to light an led and putting in a decent wind the led basically stays lit and every pulse can be counted on a single input pin. also I made the baby formula cups 4 of them in total spin on a diameter of 100mm so it will be asy to calculate the wind speed over a given time. 2006-10-18_181121_3422_hall_effect_samples.zip Cheers Bryan  |

||||

RifRaf Newbie Joined: 15/10/2006 Location: AustraliaPosts: 32 |

Bryan, how many pulses are you getting per rotation? is it a pretty even distribution or just one pulse per rpm? after reading the datasheet can see that it could work but am unsure how you would calibrate or reset it to a known position. KiwiJohn I like the coli ideas but physically making it seems a little trickier, will be happy to make up for testing if anyone has some kind of success with the idea. Anyway the reed switch version is up in the air now, it will require 8 i/o on the uC but will give an accurate reading of 32 wind positions. Its turning in the slightest breeze but waiting for the wind to pick up still.http://eds.dyndns.org:81/~rifraf/windmill/direction6.jpg gonna modify it later to work better but the concept appears sound. will add a small compass to pick out north when mounting or actually watching it. |

||||

| Page 1 of 2 |

|||||