|

|

Forum Index : Windmills : Started on the axial flux

| Page 1 of 4 |

|||||

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Well after a conversation with one of the long time forum members, I've decided to get my act together and start work on the Axial Flux windmill I mentioned in a previous post. The big hold up has been location, I'm still living in a rental till my place is sold and very limited in what I can do. But Trev is going to help out with a location for testing, and his fiberglass skills in making the stator. This is the new windmill so far, impressive isn't it.

OK ok, not much to look at yet. Now that I have the hub I can finish the design work on the PC and get the magnet plates and stator supports lasercut. Its going to be a 24 magnet 9 coil axial, magnet spacings and coil winding based on the Other Power and Hugh Piggott designs, but using a different construction. While a wheel bearing is not the most energy efficient bearing I could use, it is by far the easiest. The turbine will be 4 meters in diameter, and the blades built using Oz's chain saw technique. This will be the prototype, to iron out all the bugs. We'll then build a second and put the plans on paper ( the web site ). I'll update this thread as it come together. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Gizmo Good on you mate and I look forward to the outworking of the project. Keep up the good work and I hope you get your windy city in the near future. All the best Bob Foolin Around |

||||

| shawn Senior Member Joined: 30/03/2010 Location: New ZealandPosts: 210 |

Great stuff I also will be building one of these and I need all the help I can get so it will be great to follow the leaders

|

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Glen Based on information from a couple other 4m members, I've decided to use a shaft on bearings separated by several inches instead of the Timpkin tapered roller bearings used in automobile hubs. "My" reasoning is different from most, as I build only small stuff and the internal friction of a tapered roller bearing (especially a new one with no run-in time) is too great for my small blades. Chris Olson has said he doesn't use the hub bearings either, because they are too difficult to adjust, especially when they're 80 feet up in the air. Another reason for my choice is I have gone to using multiple rotors in an attempt to garner more current from a small-diameter alternator. I don't know how much weight you can cantelever on a single tapered bearing before it starts to wear excessively, but adding more rotors would do just that. My small toys have sealed ball bearings at each end and can support any load I throw at them. Just some stuff to think about while you're in the planning stages. . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

True, but roller bearings dont take sideways thrust very well compared to a taper bearing. I know there is drawbacks with taper bearings but i do like the "off the shelf" approach for a base model. Then a 4m prop should have a good torque range to boot. Pete. Sometimes it just works |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

off the shelf ..(or out off the scrap heap...  .) can often ...(circumstances) be the easiest route .) can often ...(circumstances) be the easiest route

the bearing in here is out of something big and ugly from a nearby agricultural scrapyard .. it cost 20 euros (about 28 Aus dollars)..the whole machine is built around it the bearings and shells were replaced before the mills final assembly .. i think (...and its just a thought.) with thrust bearings like this, running with as big an air gap as the mill is comfortable with is the balance ...air gap (including play tolerance due to wear and tear ) seems the deciding (..builders choice..) factor ps...the welder in the pic is called Sean... very nice welder too niall |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

In my 2hp motor conversion it has tiny roller bearings so I put a 5206 in the rear end which is a dual roller bearing. With a 3 metre prop hanging off the end of a 25mm OD shaft it's still going strong today and has survived several 100K+ wind storms. If I can get some spare time at work (next joke) I'll make my own hub assembly and use a matched pair of tapered rollers at the back and a full complement bearing at the front and have the hub oil filled. With lips seals at both ends with the seal journal machined down so only a light crush to help prevent resistance and labyrinth seals on both ends. At setup of that nature will last for years even with a 4 metre prop hanging off the shaft. Cheers Bryan |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Gimzo I have just thinking about your hubs and bearing and as l am not too sure if you or anyone have try turn both taper bearing other way around before assembly as i will have look tomorrow morning to see if is possible that can be done. just a throught

Dwyer |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Bryan i didnt know that you could get a dual roller bearing...i,ve learned something new today ....  ...i know zip about bearings and always worry a bit about mine ...i know zip about bearings and always worry a bit about mine

i,ve had to replace them once and this time i tried cv grease with better quality (i hope) taper bearings to see how things last..... Dwyer sorry about coming in after your post ...i like wondering about bearings too ps...should have added before that i gratefully gate crashed the axial build concerning that bearing i posted about earlier ...  ...i thought as the thread was about hub bearing choices it might be ok ...i thought as the thread was about hub bearing choices it might be ok niall |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

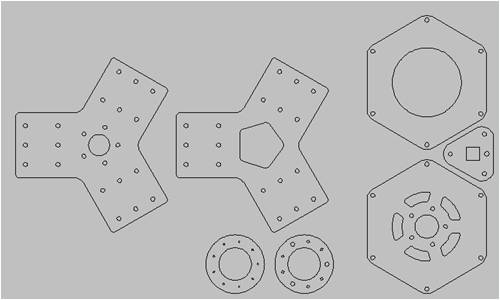

I've finished the cad for the steel magnet plates, stator supports and blade mounts. I'll send these off to get a couple of quotes from the local laser and waterjet cutters. I also need to cad up the mould, and get that cut from MDF. All these bits could be cut by hand, but I'm lazy. Besides, its a new design and there are bound to be little changes needed along the way, so I'm going to make it as easy as I can for myself. Magnet PCD is 270mm. I wont go into what the individual bits are.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

AMACK Senior Member Joined: 31/05/2009 Location: AustraliaPosts: 184 |

Hi All. I know bugger all about axial flux gens, But if I was to want to build a gen out of 101.6 x 25.4mm Disc Rare Earth Mags with a pull of 262 kg what power would you get out of it, and what effect does mag strengh have on the out come. From what I have read I can gather that the stronger the Mag the more out put. What windings would I need for a 262 kg pull mag? I think the number of mags would come into it too. I would like to make a Axiial flux down the line but I am going to do my home work first. If I was to make one I would like to make a big sucker not a minny one. AMACK *Note to self 1. Make it thick 2.Make it heavy. 3.Make it stronger than it should be. 4. Don't rush the first job as the second job will cost more and take mor |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Boom and that AMACK is where all the people on otherpower regularly go spectacularly wrong, run into furling problems, burnt up stators etc etc. best to start with a prooven design unless you are OZ, Phill or Gordon and go from there to bigger things. Luck favours the well prepared |

||||

AMACK Senior Member Joined: 31/05/2009 Location: AustraliaPosts: 184 |

Hi Karl, I dont mean a mega watt thing just something bigger then the mini one that MacGyver built. I have seen a few on posts and spoken to Phill about the ones he has made. The costs involved are quite high from what I can gather to get all the gear. I just want some thing around 2500-3000 watts. I think phill has a 5000 watt one but that a bit out of my reach. The mags that I mention were the biggest one listed and I was just trying to find out what power you could get out of them. MacGyver no disrespect to you turbine.. AMACK *Note to self 1. Make it thick 2.Make it heavy. 3.Make it stronger than it should be. 4. Don't rush the first job as the second job will cost more and take mor |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

BTW most of the otherpower type mills are flat out making 1.5KW, increase the blade diameter from 10' to 12' melted stator

need to be very careful, employ OZ for a week to build it perhaps! Luck favours the well prepared |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Have a few quotes back from a couple of local metal engineering firms. The laser cutting came in cheapest, but I was expecting that. For cutting mild steel, plasma cutting is the cheapest, but the least accurate. A cnc plasma cutter would struggle to cut a nice a 13mm hole in 10mm plate. You could get away with plasma cutting the outside shape, and then mark and drill the holes yourself, but I dont have my workshop set up for that sort of work, I wanted all holes cut out for me. A waterjet will cut out the holes easily enough, but waterjets cut mild steel much much slower than plasma or laser, so even though the process is cheap enough, the extra time taken to cut mild steel makes it a more expensive option. However, waterjets cut aluminium much faster than a laser cutter, so if you ever need to cut aluminium, take it to a waterjet cutter instead of a laser cutter. Lasercutting is by far the cheapest way to cut mild or stainless steel, especially if you want some accuracy. As a rule, in mild steel a laser can cut a hole as small as the material is thick, so if its 10mm thick plate, the laser can cut a 10mm hole with reasonable quality. I need 13mm holes in my 10mm plate, so they will cut out fine. To cut out the two magnet plates and stator bracket from 10mm mild steel, and the two stator sandwich plates and two blade mounting plates from 3mm mild steel, will cost approx $230, including material. Here in Mackay we pay about 30% more than other regional centers, so I would expect it to be less than $200 everywhere else. I've placed an order and should have them by the weekend. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| ChrisOlson Regular Member Joined: 19/01/2010 Location: United StatesPosts: 60 |

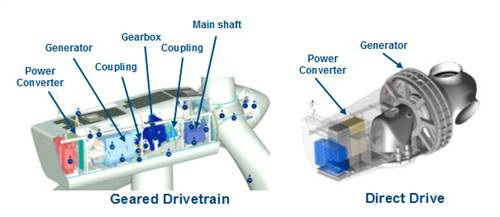

FYI, a pair of 207 block self-aligning ball bearings will handle 2.1x the axial thrust loads of the little boat trailer spindle tapered roller bearings that most people use in homebrew axial turbines. On a wind turbine application only one bearing handles the thrust with a tapered roller bearing set. The other one just keeps stuff from flopping around. With two self-aligning ball bearings on a mainshaft, both bearings absorb thrust loads and more evenly distribute the load over the yaw deck/turbine head structure. They don't build utility-scale turbines by hanging a generator and set of blades on a Kenworth steer axle spindle and hub. They build them with mainshafts riding on self-aligning bearings of various designs, and either drive the generator and hydraulic systems with a gearbox or direct-drive PTO. The same concept can be applied to homebrew turbines. I've built lots of them such as this one with a PTO-driven, direct-drive, rear mount generator:

-- Chris off-grid in Northern Wisconsin, USA |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

True but they are starting to design big turbines like that. Recent trends in the industry are leaning towards direct drive PMA turbines. They actually have a 'truck looking' spindle the size of a Volkswagen that the generator hangs off the front of. It's funny because I always thought small wind would start to emulate big wind. I see more of the opposite happening. Perry

|

||||

| ChrisOlson Regular Member Joined: 19/01/2010 Location: United StatesPosts: 60 |

Some are permanent magnet, but they're incredibly expensive to build. Enercon in Germany has long favored wound-rotor generator technology in their direct-drive designs, although permanent magnet technology is now the choice of most manufacturers of direct drive units under 90 kW. A direct drive generator, with a wound field rotor is more complex, requiring excitation power to be passed to the rotor, but it benefits from additional controllability that you don't get with PM rotors. Without that controllability it requires expensive (and usually inefficient) onboard converters to sync the machine with the grid. -- Chris off-grid in Northern Wisconsin, USA |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

The laser cutter (http://www.lrsmky.com.au/) phoned to say my parts were ready, so I dropped round to pick them up this afternoon. While I was out I bought some 12mm and 5/16 threaded rod. I picked 12mm (M12) over 1/2 inch because it has a higher thread count, so should make jacking the plates apart easier. If I find the 12mm it just to small a thread, I can drill out the holes to take a 16mm thread, there's enough clearance in the design.

I'm pretty happy with the cut quality. This is the 10mm

and 3mm

Below is a close up of the 10mm edge. You'll see a thin layer of dark scale flaking off to show the clean steel underneath. Whenever you get steel lasercut, hit the edges with a wire brush to remove this scale. If you dont, and you paint the edge, the scale will eventually fall off, with paint, to expose bare metal that will rust. Also worth noting, the laser cut edge is hardened steel, if you intend to tap a thread into a laser cut hole, its better to laser cut a smaller hole, then drill it to suit the tap. That way you remove the hardened layer and wont wear out your thread tap.

Next step is a trial assembly. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

top stuff gizmo Luck favours the well prepared |

||||

| Page 1 of 4 |

|||||