|

|

Forum Index : Windmills : Disassembly of F&P washing machine?

| Page 1 of 2 |

|||||

| Author | Message | ||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

OK, I finally found a machine! Electronics are dud but thats fine - I want the motor, damnit! I must say, in pulling this thing apart, I have to take my hat off to the F&P engineering people. They've done some really smart stuff. Things like water cooled heatsink for the electronics, and the myriad of bits held in with a twist or one screw and a couple of clips. Sounds cheap, probably is cheap to make, but I can see no indication of "nasty" in the final result. Having gutted the thing, I now have the motor itself (complete) solidly attached to the large, outer plastic "shell". The agitator came off easily, as did the bowl itself. I can see the bearing and seal that holds the shaft to the shell, but I can't see an easy way of getting it off/out. Is there a trick? I can't see any clips, screws or bolts. Cutting it sounds just way too butcherous given the way everything else obviously went together and came apart. I'm reluctant to give the shaft a whack with anything too substantial lest I damage it, and I don't recall who I lent my slide hammer to (15 years odd ago!). I don't have a hydraulic press, and even if I did, I doubt I'd fit this great big thing in it. Surely there's an easy way. The pump motor came out with just a half-turn (but of course, it doesn't have the main seal to contend with either) Hoping someone can give me a pointer, or better still, a step-by-step instruction site, with pics :) TIA, RossW |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

On the end of the shaft the hub and stator cam off, there is a big nut. With the machine up side down, after you have removed the hub ( undo the plastic nut ) and the stator ( 4 bolts ), you should have the shaft looking at you. There is a large nut on the shaft that needs to be aken off. They can be tight, you need to grab the shaft with a pair of multigrips and use a large shifter on the nut. Once off, then tap the shaft down and it should fall throught. There are no reverse threads to worry about. Yeah they are well made, hats off to F&P. Glenn. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Just came back in to say "I went back with the mindset that it HAD to be simple" and found just that! Was about to post some pics! |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

For anyone else whos in the same boat (and I suppose, for historical reference)... Looking at the complete assembly from underneath. The transport locking ring (pale thing on the end of the shaft) can be turned anticlockwise while holding the motor rotor steady. As you turn it, the rotor comes off the shaft, exposing more of the coils. Eventually it is fully undone and can be lifted off. The 4 bolts can be undone (I used a 3/8" socket, but it's probably some mongrel metric size!) (Can anyone identify if this is a 60, 80 or 100 from the closeup of the windings?) With the bolts undone and the coil assembly removed, the shaft and bearing housing are visible. Hold the shaft with multigrips or vicegrips (use some brass or copper shim or similar to avoid damaging the shaft) and undo the large nut with a large shifter. Don't smack your knuckles into the spanner like I did when it finally lets go). Then ease the shaft down, through and out. I'm still trying to work out how to get the bearing and its bits out. Looks like it's going to require brute force. Something I was trying to avoid! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

To remove the bearings I just use a drift ( or a long old bolt ) and tap the bearing out from the other side. There's also a spacer sleeve in there. They are good photos there Ross. Could I use them on the web site with your description? Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Yeah, I came to that conclusion. Haven't done it yet! Thanks, and after that flattery, how could I say no? :) |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Ross I wonder if the washing machine is brand new nor near new after l look at your web site as look at the part is very  clean like new clean like new |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thats a 80 series Ross, a good all rounder

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

All done. I put the details on the Info and Projects page ( was called Windmill Projects, but there's so much stuff in there I thought I would rename it. ) Near the bottom, just above the PicLog. http://www.thebackshed.com/Windmill/AssemblyA.asp Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

It was one of the earlier ones by the look of it, a model 701 smartdrive I think. It was out for the local council "hard waste" collection so I asked the owner if I could nab it. The bowl and the rest of it was pretty grubby, so no, she certainly wasn't new or near-new. |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

HI Ross That is strange Why is so many near new F&P. Smart drive washing end up at lifeline or the dump some of then was near one years old and got approx 30 of them and the stainless steel washing bowl went to the chook shed where chook lay eggs

Anyway l am going to built Batteries shed near my workshop and it too dangerous have batteries in my workshop as I do grinding and welding as last time the worker did some grinding on steel work with the electric grinder approx 4 metres away battery blew up lucky no one was hurt and when l was young l did some stupid thing by put the spanner by tapping the terminals to check battery and blew up on my faces and eyes and to run and flush tap water on my face so l would like to know what is best way building batteries shed in Besser block or timber size shed is 2metres long x 1.5metres wide and 2 metres high and need some kind of insulation to keep the temperate more stable where can l find information about how to store batteries in the shed ??? Dwyer the bushman |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Wow, I'd like to have that many to choose from! I'm looking at this one and thinking do I make an incinerator/firebox from it, or use it for a small compost-tumbler? Bad karma! Yes, I've seen some very large batteries explode (I used to do some thermographic analysis work in power stations, and some of them have *HUGE* battery rooms! (or is that "rooms of HUGE batteries?")) My battery room is underground, 2m x 5m roughly. The north, west and east walls are concrete-filled besser blocks, the remaining wall is just standard besser block. The floor is a 150mm thick slab, and the roof is a 200mm thick slab. I have the batteries sitting on a "plinth" made from yet more besser blocks, 2 deep to make a 400mm deep shelf for the batteries to sit on. I'll try to find some photos. Ahh yes, here we go: During construction: Original batteries, 2 banks, each 24 x 2V/300AH cells. Me, wiring up the inverter (bolted on the wall)

And before someone says "those cables are too small", they were not the battery cables, I made these up: (Left: the cable I wanted to use, right: the cable I did use) |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 574 |

Hi Ross Bloody Hell I nearly fall off my chair when l saw your large batteries room and this it the first time in my life that is so many batteries for your home nor anywhere else Gee  and what about the windmill gen? Still enough to keep up the charge up and what voltage?? 48 volt and what sort the inverter (bolted on the wall) you use pure sine or modify square sine and max output?. Well done Ross. The last time l was in Perth couple years ago l went to see the Submarine Museum and did have tour to go inside the sub is quite interesting and also outside on the ground saw one large battery same size as home refrigerator weight approx 2 tons as l think 40 of these batteries are inside the Submarine. and what about the windmill gen? Still enough to keep up the charge up and what voltage?? 48 volt and what sort the inverter (bolted on the wall) you use pure sine or modify square sine and max output?. Well done Ross. The last time l was in Perth couple years ago l went to see the Submarine Museum and did have tour to go inside the sub is quite interesting and also outside on the ground saw one large battery same size as home refrigerator weight approx 2 tons as l think 40 of these batteries are inside the Submarine.

Dwyer the bushman |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

I'll take that as an "I'm impressed" response, shall I? :) The windmill (and the solar panels) are really just a help along the way. I'm FAR from self-sufficient unfortunately. I have way too many computers running, and all our water pressure is from pressure pumps, and my teenage daughter can't live without her TV being on most of the time etc. We're getting by on a meagre 15 KWH/day during summer (but a bucketload more in winter). I have a moderately large home-made genset (based on a 4-cylinder automotive engine, converted to LPG) with computer control to do all the start/throttle-control/stop, warmup, cooldown, air/fuel control etc. It can make about 15KW of output, but I rarely take more than about 8KW for charging batteries and running peak loads. The genset also provides the hot water for domestic hot water (kitchen, laundry, bathrooms) and heating (hydronic floor heating). It's a 5KW continuous, 10KW peak pure sinewave job. That said, it's 5KW *INVERTER OUTPUT* - when the genset is running, it synchronises itself to the same frequency, phase and voltage, then hooks the load, genset and inverter together, so it can quite happily provide loads of 5KW *MORE* than the genset is capable of. When there's surplus power (ie, the load is less than the genset can supply) the inverter will take "what's left" and use it to charge the batteries. It's a very clever beasty. It also took two of us to lift it into position, while a third put the nuts on all the dynabolts! Danke! Yeah, they're *IMPRESSIVE*. I'd love to have a bank of them, but I couldn't use 'em! One day, I hope to have enough money to find a decent set of "traction batteries" from a large forklift or something. Ideally, with recombination caps. Something in the 1000 to 2000 amphour per cell (2V) would be great. I've been fooling around with the idea of using water in tanks as a "storage" system. I have two 105,000 litre tanks - one at the house, and one about 50 metres (vertically) down the hill. I reckon a turbine could get me a constant 500W at 1 litre/second with that head. Problem is getting the water back! |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

[quote]Problem is getting the water back! [/quote] I am not sure what you are considering here Ross, I gather you want to store energy by pumping water into the higher tank? Surely that is a job for a wind mill pump? In fact where anyone has the suitable ground contours two water tanks could take the place of the battery banks, almost. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Yes, the idea was to allow water to flow from the higher tank, through a micro-hydro turbine, into the lower tank to cover my "base load" and virtually eliminate the need for batteries apart from high-current, short-duration transients (like when the heatpump kicks in etc). Sadly, the bottom tank is right down in the valley and gets little wind - otherwise, I'd stick a windgen there! The problem is, I'd want a near continuous flow of water for my base load, but it'll take a LOT more than that to get water back up, and the tank only holds about half a days worth of energy (I have to leave enough for domestic water and firefighting) |

||||

| Saaremaa Newbie Joined: 10/12/2005 Location: AustraliaPosts: 13 |

Hi Rossw I think your idea of " Things like water cooled heatsink for the electronics," might be only part of the sory. I've looked at that unit - and recall thinking it was where hot and cold water could mix. I haven't got one handy at the moment but a closer inspection might reveal a temperature sensor chip attached to that tube somewhere. This is logically how it could sense water temp for a warm wash. Is your battery room used solely for batteries - I was thinking it could do double duty and make a great wine cellar. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Yes, there is for sure. It probably serves several purposes: they can measure temperature of the water to make "warm" water. I think (in hindsight) I remember also reading somewhere that its primary purpose is to measure the heatsink temperature, and if its been working too hard while agitating or spinning, can let some more water through to cool down the switching devices quickly and stay within safe limits. That was just one example of their cunning though. The machine is riddled with it when you pull it apart and appreciate how much it's been built for speed of assembly and ease of replacment parts. Well, it serves several purposes. (a) it was originally conceived as a safe evacuation route in the event of fire etc, as the service way runs right across the back of the house (55 metres) with entry or egress from 4 points. (b) it provides access to the generator room (c) it is a good, cool, dry and constant temperature room for the batteries and inverter We built a "wine cellar" in the "kitchen cupboard". (Granted, our "kitchen cupboard" is bigger than some peoples kitchens - it's 3m x 5m with floor-to-ceiling shelving around all the walls, and a largish island workbench in the middle (2.5 x 1 metre) which has a double-sided wine rack under it that holds about 15 dozen bottles - and being in the middle of the house, underground, the temperature remains very stable year round in there. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

[quote]Problem is getting the water back![/quote] This could call for what my friend calls a "HBS", hare brained scheme, the idea is to think of silly ideas on the chance that there may be something practical among them! No wind at the bottom tank but with that lift the pump must be there. Possibilities include an electric pump powered by a wind generator at the top of the hill, maybe use transformers to raise the voltage and reduce transmission losses. I think that is the most conventional way of doing it. Now for the HBSs, what happens if two F&Ps are connected and one is spun? Does the other turn too? Maybe the wind turbine turns one F&P then three wires go down the hill to another F&P that drives the pump, I cant imagine this would be a very big pump though.

The wind turbine pumps a small amount of water down the hill at considerable pressure where it drives a hydraulic motor to turn the pump. Hmmm, I think the friction losses would be rather high unless the water pressure was really, really high in which case the cost of the tube gets to be a bit discouraging. Make an Archemedies syphon, at least I think thats what it is called, stand a pipe in the tank of water and pump air into the bottom of the pipe, bubbles rise up the pipe filling the pipe with a mixture of water and air. This mixture is lighter than water and rises higher than the level of the tank. Repeat as necessary to get to the top of the hill. Unfortunately I think you would need about 20 stages to get the height you need. Make an Archemedies Screw, I assume there is considerable slope in this 50 metres? Make a helical contraption of pipe wrapped in big loops around a shaft that extends from one location to the other. Windmill turns the shaft and as the helix rotates water in the bottom of each loop is raised to the top, well I did say these are hare brained schemes! Windmill operated bucket chain?

Hmmmm.... I think the wind gennie at the top of the hill driving a pump at the bottom is quite attractive considering the few alternatives that come to mind. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

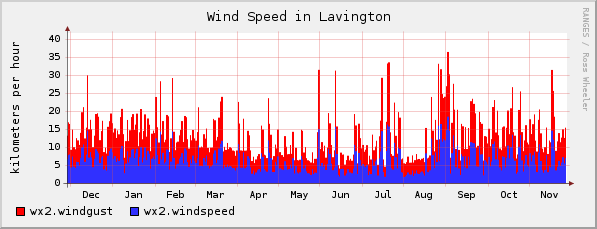

Hey, there's nothing wrong with HBS as brainstorming concepts. I do it all the time :) Surprising how often a germ of an idea sprouts from something silly beyond compare! Yes, I currently have a positive-displacement 24V submersible pump there. It takes about 4 amps but with 50m head, only manages about 60 litres/hour. I also have a vertical multistage pump that takes 2.2KW at 240V AC and can move about 3000 litres/Hr with 50m head, that I can put down the bottom if required. I already have cables from up top to down bottom, and some 40mm thickwall poly. Yes, but given it takes me 6 times more power to move a litre of water up the hill than I get from it going down the hill, it still doesn't make any sense to do it this way. If there was wind at the top, I'd be better off just sticking that power into batteries. At least they're about 90% efficient, not 15%! Yes, back-to-back steppers will track, but from my days as an electrical fitter, I seem to recall that the end-to-end efficiency of a rotary power input to generator then to a motor and back to rotary power output taking all losses into consideration is a maximum of about 70%. The wind turbine doesn't need to push water down the hill, gravity will do that. With 50m head, there's a fair pressure. I calculated that a micro-hydro turbine with suitable jets would consume about 1 litre/second to give me 500W output, but that's 3600 litres/hour, so at most I'd get a day from a tank full of water (but I still need to keep a minimum of 25,000 litres for firefighting (legal requirement) plus something for domestic consumption) - so I'm bargaining on at most 12 hours flow. Air-lift pumps are not new, and can lift water quite significant distances. No moving parts is a bonus too, but the problem is getting sufficient volumes of compressed air. Again, more energy in than I get back out. The slope is fairly substantial. The bottom tank is about 200 metres away horizontally, and 50 metres odd vertically. Its not a linear slope though, so the screw wouldn't quite work. OK, *NOW* we're getting to the HBI :) IF I had constant wind it'd be fine. But if I had constant wind, I wouldn't need the hydro either! Wind is very fickle here, sadly. Here's the last 6 months odd worth from this site:

I probably just need a decent VAWT that works even in very light breezes and turbulent airflows. |

||||

| Page 1 of 2 |

|||||