|

|

Forum Index : Windmills : Chinese WindTurbine - Downwind conversion

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

I am the proud owner of a new Chinese FD - 300 Turbine!! Initial testing proved it to be as stable into the wind as Chinese Politics - the tail design is all wrong. Rather than modify the tail I have converted it to run downwind - stability is vastly improved however it does not produce power running backwards. Theory tells me it should produce power in either direction. Question - Is the controller designed to prevent it producing power when it spins the wrong way or am I missing something. Any help greatly appreciated Regards Rodin Murphy was an Optimist |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Hi Robin Did you turn the blades around? Turbines are designed to face the wind. If the wind is coming from the other side, the turbines performance is way down. The alternator and controller will be happy either way. Would be good to see a photo, I'm courious now. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

Hi Glenn Yeah I turned the blades around, it runs very nicely, just no power. I am using a Victron Battery monitor on a 400 A/H battery bank, it will measure down to 0.01 amps at 12 volts & not a flicker of power yet. I was getting over 10 amps in moderate winds with the original configuration but it would swing offwind every time it started producing usable power I can post a pic if I can work out how to post them on this forum David Murphy was an Optimist |

||||

| Smart Drives Senior Member Joined: 06/07/2009 Location: AustraliaPosts: 115 |

Sounds like the one i bought (but 24v), also it spins anti-clockwise which use to look stupid next to my other turbines. So i am presuming the chinese STUFFED the motor wiring and had to make blades that spin the opposite direction for some reason ? It drove me nutty. As soon as we got big winds it swung all over the place and it looks like there is no furling device as the motor is centred over the pole. I have trimmed the top of the tail (which had a slight curl) and after 6 months of procrastinating it will be going up in the next couple of weeks. My wife calls it the little whale! I will post a pic if it works. Cameron. All smart drive parts sold Custom built turbine parts on Multicam flatbed CNC Router |

||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

Here's a couple of pics to show what I am trying to do

The Turbine as it came out of the box As it spent most of its time swinging offwind or recovering from it I researched both tail modifications & running it as a downwind turbine. Taking a High Tech approach I decided downwind was a more interesting option & potentially more stable. The tail was removed & a coke bottle sawed in half. The coke bottle cap was carefully torqued down to 5 ft/lbs & the bottle taped onto the body in place of the tail - the blades were then removed & reversed. Voila!! job done It is now much more stable - I would go as far as to say perfect except it produces no power!!

David Murphy was an Optimist |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

The tail of that turbine in its original upwind configuration looks smallish and the tailboom looks to be short. Would've been interesting to see how it would have responded to (temporarily) increasing the tail surface area by bolting-on a larger sheet of plywood. Might have made all the difference. Also, the yawing pivot point seems to be pretty much to the rear, with the blades sticking out much in front of the pivot point. This increases the moment that tries to turn it out of the wind, and reduces the moment of the forces on the tail to steer it back into the wind. The downside of downwind turbines is that the blades pass through the wake of the mast where wind is more turbulent and less strong. This causes cyclic variable loading of the blades, possibly leading to problems (fatigue) in the long run. And higher load on the bearings. I assume this is the main reason that we don't see many downwind turbines, as they certainly do have benefits (no yawing mechanism needed, for one). I hope the torquewrench was recently calibrated so you can be absolutely sure that the bottlecap was actually tightened at 5 ft.lb? Peter. PS: As far as it not producing power, you need to follow a systematic approach to faultfinding. Temporarily disconnect the generator from the rest of the system (battery bank) and measure output (AC or DC?) directly. Spin by hand and see what voltage you get. Add a small lightbulb (bicycle lamp, 6V/3W) over the output and see if you can get that to light. Try bigger lights (12V/10W) if you can get the small one to light. If you can't get a lightbulb to light, not even a little, something is likely wrong with either the generator, the wiring inside it, or the controller or rectifier (if one is present within the windturbine). Just some quick things you could try out. |

||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

Hi Peter Your comments mirror my research exactly. I am also working on a tail extension. I will compare the results & run with the system that works best A point of interest - the downwind configuration actually vibrates less in high winds than the upwind one. I am guessing that the tail is so badly designed that it is contributing to the vibrations. The torque wrench was recently calibrated by hitting my ex wife on the foot with it with a force of 5 lbs, the results were most gratifying David Murphy was an Optimist |

||||

Beanman Newbie Joined: 12/09/2009 Location: AustraliaPosts: 1 |

Hi guys I have been playing around with one of these units for a few weeks, I also noticed i was producing 6-10 amps in moderate to heavy wind then it would sort of peek then amps would drop off and the cycle would start agin to a varying dagree, I noticed the turbing also seemd to be self governing, followed buy the unit constantly furling or spining around, the turbine also made a vibrating noise as it peeked on about 8 amps, Well turns out in my haste and excitment of wanting to get this new toy up in the air I just used a couple of old extension leads (about 1.2mm dia conductors) with a run of about 20 meters for the hook up leads back to the batter and that was a BIG mistake on my part, the instructions are very basic and even the specifications have no mention of auto brake etc in this turbine but low and behold this unit has an auto brake built in to the controler when the unit detects 14.1v (at the turbine head not the battery) the turbine will stop charging and seems to short the windings some how causing the unit to goven and slow down but not stop completly. Long story short I replaced the cable with 4AWG 5mm Heavy battery cable and instantly now I get 20+ amps at the battery and the unit sits very stable unless the wind goes over 15 m/s or the voltage reaches 14.1 volts I had a huge voltage drop on the cables and the turbine thought the battery was fully charged I am only new to this guys but thought Id share my experiance as i can see these units getting condemed with out good cause. Mine is running great now. Here is the info I used WIRE SIZE LINK Also found more detailed info check out the Features regarding auto brake left out from the manual must be somthing to do with the conversion to CHINGLISH hope this helps. WFD2.5-300 12v turbine |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

The controller in these windmills sounds like ones provided with some of the 24V, 500W chinese windmills. I have one of these. The early models needed the regulator to be placed right at the battery, for reliable operation. Sounds like the new models have overcome the warranty problems. The older units could fail if the battery was disconnected. Gordon. become more energy aware |

||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

Final Results - Thanks to all who provided Help/Feedback These Turbines Will definitely benefit from modification to a downwind configuration. Stability is vastly improved & there is no apparent increase in vibration from the blades passing through the wind shadow from the mast. Tracking into the wind is excellent though furling may need to be examined at some point. At the moment the internal electromagnetic brake seems fine but if it fails I can see major probs resulting during high wind events. A small fin mounted close to the blades & downwind of the pivot point may be the solution The lack of power is from the internal electronics & it spinning backwards in downwind configuration. I will publish results on that when I determine exactly what the problem & fix is. Conclusion These units have a lot of potential as a cheap ready to run turbine BUT there are some major aerodynamic design flaws. 1/- The tail design is about as bad as it can get, it should be thrown away & a longer heavier vane type tail fitted 2/- The centre of gravity is too far forward of pivot point magnifying the probs from the bad tail design. 3/- The electromagnetic brake may be causing probs too. When it activates the turbine swings violently offwind, probably from sudden torque reaction & the bad centre of gravity helping. 3/- Chinese electronics are ALWAYS suspect, trust me on this - I have a Chinese 5.5 kva deisel generator that has been scrapped after 40 hours running due to a computer problem that no-one in Australia can fix at a price less than the cost of a new generator. I am reverting to the original upwind configuration & fitting a new tail. If I can build a new controller I will definitely try the downwind config again, but I think the point has been proven that a downwind config will work if the electronics can be reconfigured - this may vary from model to model - there is no consistency from batch to batch with products coming out of China. On a positive note, the Chinese at last seem to have got the blade design right from a noise point of view, we have had no noise issues whatsoever. I will continue to monitor this thread for any additional info but will start a new one for the next stage of testing Thanks again David Murphy was an Optimist |

||||

| tomasp Newbie Joined: 20/10/2006 Location: New ZealandPosts: 28 |

I got one of these turbines as well. The yaw bearing is screetching after a few good storms, no surprise there. As Rodin mentioned, the tail is a joke. I will take it down to replace bearings and will have a look at the controller to see if it can be changed to run in downwind config. Anyone else with these turbines, could you post some pictures of the new tail you fitted in place of that ridiculous thing that looks like it is made of recycled plastic bags? |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All I have a number of these things in my shed all new and all duds, however they have potential to make something useful. The ones I pulled apart are full of metal chips from machining as they where not cleaned out before assembly, one was so bad it damaged the windings and refused to turn. Also the housings required re machining as they where causing binding. Repair to the regulator is high velocity over the left shoulder and then fit a bridge regulator and park switch and dump load regulator. Once they are going the generator is a good solid unit with lots of potential. The rest is best recycled back into plastic bags. The plastic housings are rubbish and stress crack around the pivot bearings, if you get a decent blow they will part company and be a 17 KG missile with a meat chopper on the end. The blades are to small for useful power until they get over 12 ms. I can see why they call Chinese boats Junks. All the best Bob Foolin Around |

||||

| tomasp Newbie Joined: 20/10/2006 Location: New ZealandPosts: 28 |

Thanks Bob, Mine must be the "v2" version, it is full aluminum housing, cast aluminum hub and fibreglass blades. Only the tail is plastic. This turbine survived a few big storms (the storms here are BIG, roaring 40's) with no issues, apart from wandering in the wind and the bearings became noisy. I believe with a proper tail or converted to downwind (probably better) it would be a decent machine. This was meant to be an Air X clone for marine applications....probably why they put Alu body on it. Anyway I might take some pics when I take it apart. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Tomasp After the trouble they had with the plastic body I could well understand they went to Alloy, The bearings supplied in the Chinese mills are generally substandard from my experience, and a few i have popped the seals on had no grease just a light coat of oil so it is no wonder they die quickly. It may also be that they went for plastic as a corrosion prevention as Alloy still can corrode in the marine environment, all the bolts and cap screws in the ones i have are stainless steel with the exception of the main shaft, so they have tried to get it right. I may set one up as a downwind machine to try it as I believe the GE-222 blades would be ideal in this application,third project in line. All the best Bob Foolin Around |

||||

| tomasp Newbie Joined: 20/10/2006 Location: New ZealandPosts: 28 |

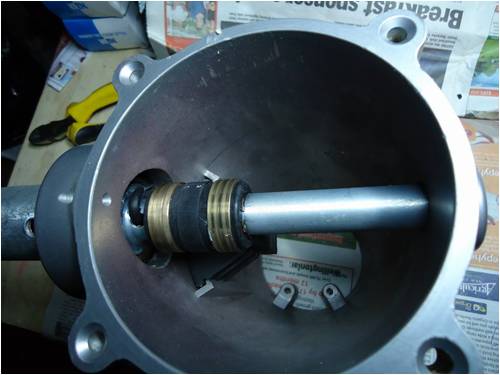

Hi Bob, Any idea how can I open up the alternator? I took the bolts out but I cannot seem to open the covers at the ends of it. For anyone interested here's my writeup on opening one of these turbines. Here's what it looks like before splitting up:

After splitting it into alternator and the "body" (housing sliprings and yaw bearings) we can see the controller bolted up to the alternator:

I suspect the same turbine is sold as 12V/24V by just using a different controller. The controller is quite small and sadly it is filled with epoxy:

Here's the slipring assembly. Note one of them has 3 narrow shiny rings on it, indicating that the brush is not making full contact with it:

The main reason I opened it up was because the main yaw bearing is nearly seized after only a few weeks in the air. Also just recently it started misbehaving, as in it would not switch on, the controller would keep it shorted all the time. Well here's what I found inside:

Looks like it was too much for this Chinese back EMF braking system and the controller burned out, the plug is deformed from heat, probably lots of amps were going through. The reason I think controller is dead because if I try to turn the shaft by hand (turbine not connected to the battery) it is being braked. If I disconnect the controller, it spins normally. I would also like to disassemble alternator to check out its insides and possibly replace bearings too (not TOO bad but a bit noisy) - but I can't seem to be able to open it... Will update here once I get the bearings out. By the way, will probably replace all hardware as all bolts are black steel or zinc plated if you are lucky and already started to rust. I plan to put rectifier into the turbine (to be able to use sliprings) and Gizmo's simple controller with diy resistor load inside the cabin. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Tom My ones have a similar regulator all potted but have 3 slip rings so I can send three phase down the pole. The generator on mine splits in the center and I think is rated at 600 watts. Your heat problem looks like a bad contact heating problem in the earth wire as the magnetic brake is in the module and connected to the alternator output wire directly. the ones I have pulled apart are the same for 12 and 24 volt but 12 volt is delta and 24 volt is star connected. It looks like the rotor is removed by pressing from the front shaft, be careful when dismantling or replacing the rotor it is best to make a jig to do it in as the magnets are very powerful and can take the end off a finger faster than you can blink. Keep us informed as to your progress. All the best Bob Foolin Around |

||||

| tomasp Newbie Joined: 20/10/2006 Location: New ZealandPosts: 28 |

Took the bearings off, here's what they look like: As Bob mentioned, this is the bearing that was hardly rotating, you can see rust inside and needless to say there was no trace of any grease in it - probably just a drop of oil: I don't have a shop press so could not open up the alternator, and I don't want to use hammer anywhere near it. The bearings are almost fine on it, I am not sure if they make any noise at all, so probably will leave them as they are... Will post further updates here, hopefully it will be useful for someone. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi tomasp You can make up a puller with some threaded rod that will do the job. Not a good idea to put up without greasing the bearings as all the ones I have are dry or slightly oiled, as per the makers assembly lubrication. The head bearings will last for years with a bit of grease even if a bit rough with rust etc. All the best Bob Foolin Around |

||||

| tomasp Newbie Joined: 20/10/2006 Location: New ZealandPosts: 28 |

Hi Bob, Thanks for your message. I opened up the alternator - actually was not so bad - I tapped the shaft onto a piece of timber on the ground and after a few times it started opening up: For some reason they did not think having seals is a good idea so now there is a gap between the shaft and body through which the moisture can creep in, and it does: So they put in a rubber gasket to seal lid to the body, but did not close the hole around the shaft...A proper way to fix this would be to machine holes in the end lids to accept one of the standard sized seals (or just dust lips), but it is beyond my abilities. I will probably glue some welt around the shaft once it is all back in one piece. Took the bearings out - and behold these ones HAVE some grease in them! I could have re-used them after re-greasing but I am replacing them with Japanese-made just to do it all properly. So I guess that concludes the mechanical part of this turbine. I will update this topic once I get electronics done and when I do the actual conversion to the downwind. Cheers |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

It looks like a good alternator inside. I have a few AC servo motors that look the same internally, I would bet thats where the alternator originally came from. Like a lot of the Chinese stuff, its a good design badly assembled. I think once you sort out all the manufacturing issues, it will be a reliable windmill. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Page 1 of 2 |

|||||