|

|

Forum Index : Electronics : GEC reel-to-reel tape deck motor problems...

| Page 1 of 2 |

|||||

| Author | Message | ||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

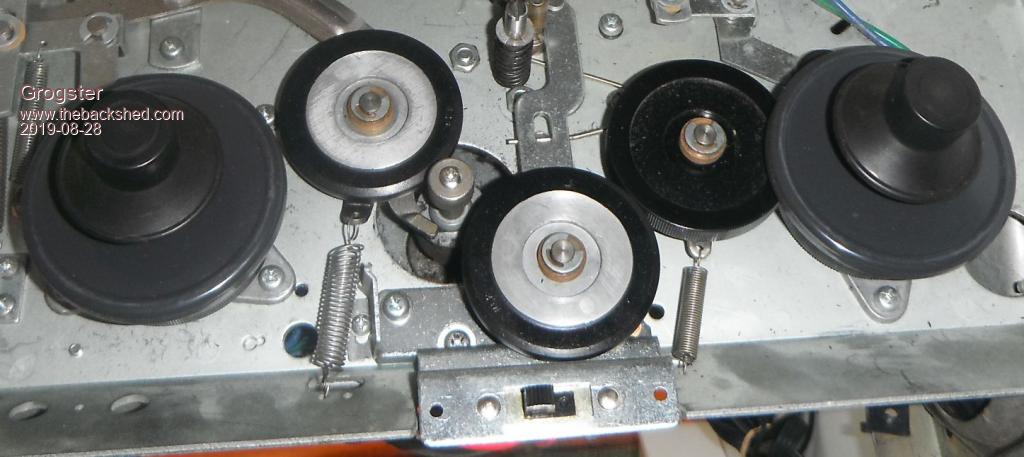

Hello all.  I am more an electronics guy then a single-phase motor guy, but I expect that others here will know what the problem is. The unit I have, the motor often won't start, but it will go if I flick the spindle manually - then it spins-up. Once spinning, it lacks torque, and trying to play a tape slows the motor right down till it stalls again.  The same applies if I try to FF or REW a tape - the motor just slows down till it stalls. The same applies if I try to FF or REW a tape - the motor just slows down till it stalls.Some photos.... Inside the guts at the rear, showing the motor:  Other side of motor showing rubber drive wheels etc:  I note that there seems to be TWO start-caps on this motor, as the little slide-switch is a tape-speed switch, which changes the speed of the motor when it is running. If I power-up the unit, the motor does not start and I have to flick the spindle(between the two rubber drive wheels), then it spins-up, but it is slow to spin up even then. As I say, as soon as you put any load on it, it just slows down to a crawl and if you keep the load on, it stalls completely. If I let go of the motor at that point, it DOES NOT spin-up again. If I flick it manually, it does. I don't really know the ins and outs of induction motors, so this is why I am hopeful someone here can at least tell me if I am going in the correct direction towards a fix for it. I suspect the start and/or run caps. My plan at this stage, is to replace BOTH the caps on this motor, in the hope that this will restore correct operation as far as starting of a stopped motor is concerned, but another question I have is: 'Does the start cap have anything to do with the torque of the motor once it is running?' It could also be that the motor needs to be pulled out, disassembled, cleaned, lubed and replaced kind of thing. If you have a crook run cap, will the motor still run but lack torque? With the power off, the motor seems to spin reasonably freely if I just flick the fan at the back of it. It does not seem sticky or anything like that. Anyone in the know with single-phase induction motors, I would appreciate your comments. Smoke makes things work. When the smoke gets out, it stops! |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

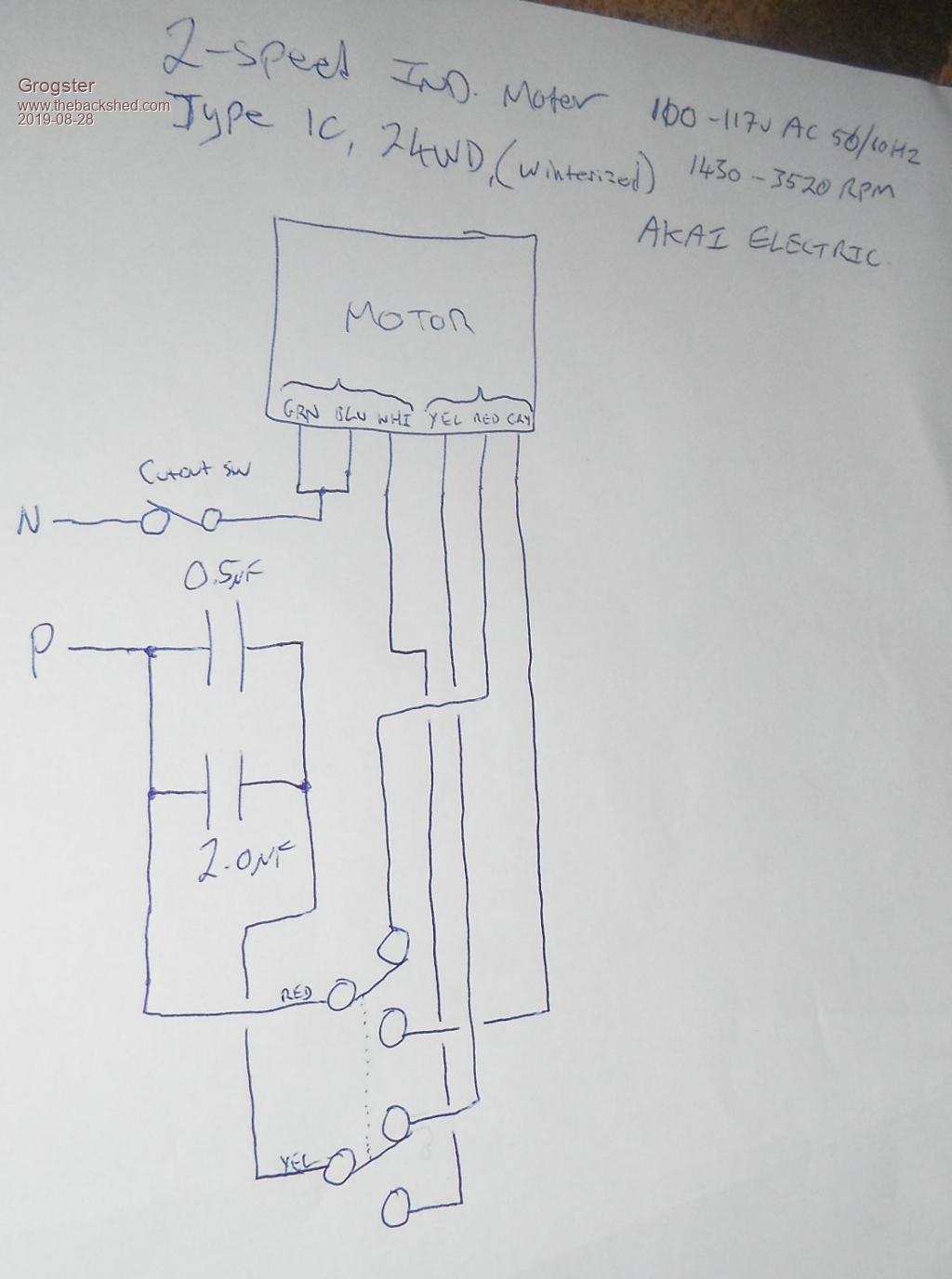

ADDITIONAL: Here is a hand-drawn diagram showing how the motor is wired up:  Both caps are dated 1965, so I expect their dielectric has totally dried up and they probably aren't caps anymore.  This is where I plan to start, but some reassurance from those who know more then me about induction motors would be nice.  The 'Cutout sw' is a micro-switch that is activated by the tape-tensioner arm on the take-up spool side of things. If the tape goes tight, this arm is pulled upwards by the tension, and trips this switch, which stops the motor. I don't like switches in the neutral, but this is how it was built, so.... EDIT: At this stage, I am planning to replace BOTH those caps with one single 2.5uF cap such as this one. Thoughts? Edited 2019-08-28 11:34 by Grogster Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

The caps will work fine, but what's the model number on your tape deck? |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

Would it be this one? http://www.tzsupplies.com/2-speed-hysteresis-synchronous-hc-24d-i5021631/ https://www.sekaimon.com/itemdetail/223640313394?country=US Also might be helpful: http://www.tapeheads.net/showthread.php?t=60495 Edited 2019-08-28 13:23 by SimpleSafeName |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Yes, it is exactly that motor which you can see better in the 2nd link you put up. 1st link the photos are too small to see any details. Tape recorder is GEC/AKAI 1700 series. Here is a photo of the front of one - my one is currently in bits.  Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

Okay, thanks! I also came across this: http://www.tapeheads.net/showthread.php?t=60495 I edited my previous post, but it might get lost in the clutter. The long and short of it is, by all means change the caps. :) |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

Here's the original eBay (US) link: https://www.ebay.com/itm/AKAI-M8-Roberts-770X-M-8-Reel-to-Reel-Motor/223640313394?hash=item3412005e32:g:GwcAAOSwrfRcDVc0 |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

And I believe that this is the schematic of the motor: https://parts-ring.com/akai-m8-schematic-just-a-simple-tube-amp/ |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Service manual download is here. I have printed this so I can examine things in more detail, but definitely will be doing the caps. Manual suggests that you replace the motor if it is lacking torque. That could be tricky, as the ones that you can get on eBay etc, could have the same issue.... Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

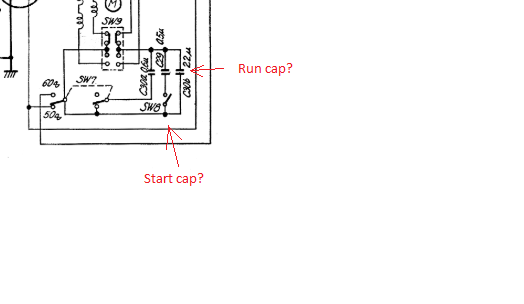

Because an AC motor has to have some phase shift component to provide torque, the capacitors are absolutely essential. Start there. And if you don't smell burnt enamel, and the motor spins freely, then it's probably your caps. And switch #8 looks like it might be a centrifugal switch that brings in C29 while the motor is coming up to speed before dropping out. Check both the cap and the switch since the switches are known to go bad as well. And I found that manual (or one like it), but I really don't want to sign up for another service for a one-off download. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Thank you for your posts.  I will replace the caps first, and see what happens. While I have it apart, I am tempted to re-electrolytic-ify the rest of it.  IE: Replace the electrolytics in the amp, as they will be 1965 vintage too, but I will do the motor caps first, and see if it operates normally. If it does, I will probably leave it at that point. This deck does not get a whole heap of use, but I do want to make it work again. Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

You're more than welcome, and I think that changing them out is going to get you going again. :) |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Thank you.  I have ordered a new 2.5uF cap. The label on the motor says: "2.0uF - 2.5uF, 60Hz - 50Hz" I interpret that to mean that you should use 2uF at 60Hz(USA mains frequency) and 2.5uF at 50Hz(me) In any event, the two caps that are in place now, are in parallel, and add-up to 2.5uF, so I think I should be OK replacing both the old ones, with one new 2.5uF one. I will post back here with the results, as soon as the new cap arrives and I can fit it. Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

You're welcome! :) Are you sure that they get wired in parallel? The schematic suggests that C29 is a Start cap and drops out after the motor is up to speed (otherwise, why is there a switch?) But in any case getting comparable values as replacements should do the trick. Just be sure that switch SW8 is functional.  |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Yes, I was wondering that myself, but MY unit is NOT wired up like the schematic. I have tested the caps connections using my meter, and they both are definitely connected in parallel. The 0.5uF cap does not go through any switch. That does make me scratch my head, as this does NOT match the schematic. I note that in the schematic, they also show SW7 as changing things for 50Hz/60Hz, but on my one, there is NO SWITCH AT ALL on the frequency change thing. It mechanically moves the main drive belt to the capstan flywheel between two different steps on the motor pully and the flywheel. SW8 would appear to be the cut-out microswitch connected to the tape-tension arm, but this switch is in series with the neutral return from the motor. Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

Odd. Maybe a mid-run engineering change. I'd say that you should be good then. :) |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

I knew an old machinist ages ago who had a saw that had its start cap switch go bad. He would start his saw using a lawnmower pull cord. Whatever works... :) |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

HAHAHA!!!!   As you say - "Whatever works" Although, I have to say - I think that is a brilliant solution.  I know you are new on the forums, but I am rather enjoying this thread and all of your posts. Please do not leave any time soon.   I know electronics, MCU's and circuit-board layouts, but mains-rated induction motors are not me!  The tape-deck is strange in that respect. As mentioned above, but on the front the unit: branding by the tape-path-through-the-heads is 'g.e.c' in grand lower-case-letters, but on the back of the unit, it says "AKAI 1700"... Smoke makes things work. When the smoke gets out, it stops! |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 319 |

You would have had to have known Vince, his shop was a "National Cleanup Site" (I once had to dig down through several inches of debris to put out a fire that I started while grinding), he couldn't see worth a darn due to type 1 diabetes, and he was "only" cranky on a good day. But the machines that he built were incredible! He was a self-taught carpenter turned machinist (complete with a couple missing fingers, like any self-respecting carpenter). Thanks! I'm enjoying my stay, and I've got no plans on going anywhere. :) I went through the electrician's apprenticeship back in the 70's, and got my Colorado Journeyman's and Master's licenses. I like to think that I know something about AC motors, but all that I really know is that there is a lot more out there than I ever imagined. But I only play at being an electrician these days, through a quirk of fate I ended up working as a Controls engineer for Saturn and General Motors (one night I hacked into a GE Series Six PLC and fixed a part of the program for the engineers at Goodyear in Lincoln, Nebraska. After they got done chewing my butt out for doing that, they gave me the job. I went on at Goodyear to do much of their programming for the GE S6. When I left Goodyear, I figured that I would never see a S6 again, but along came Saturn and that was nearly the only PLC that they used. Our company installed thirteen systems in General Assembly for Saturn, and a couple of years later I hired on as a Controls engineer there). So I can claim mediocrity in two fields. :) Electronics has always been a hobby for me, and I'm no threat to a real EE. But lately I do a lot of embedded development for work, something that I would never have expected to be doing. :) And I'm not the only one here at the house: https://www.youtube.com/watch?v=-Q29C5nc-9k Stephanie was eight when she built her Spectrum (she's also built a CMM, a transistor tester, a Micromite Companion, and an AM radio - and helped me fix her parent's TV). So it looks like it was a model made for G.E.C. by Akai. That explains it. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9308 |

Your daughter, correct? If so, keep on encouraging her(like you need me to say!). Women make great technicians, if they are only given the chance. I know a couple, and they are really good techs, so it is not just a man's thing anymore.  Smoke makes things work. When the smoke gets out, it stops! |

||||

| Page 1 of 2 |

|||||