|

|

Forum Index : Other Stuff : Diesel engine muffler?

| Page 1 of 3 |

|||||

| Author | Message | ||||

| Ironmaiden Regular Member Joined: 09/07/2019 Location: United StatesPosts: 53 |

Hi Guys, I am hoping someone can tell me where I can get a muffler like the one on this Lister CS 6/1 in South Africa? https://i.ytimg.com/vi/nxSdXS8P6S8/hqdefault.jpg Robert |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

One very effective way to silence a stationary engine is with a LARGE expansion chamber filled with fibreglass wool. You need something with very thick heavy steel walls, say 6mm thick. Something that works really well is an old compressed air tank/receiver. These are incredibly heavy and usually have a removable inspection cover. Stuff as much fibreglass wool as you can into the tank. Fill it right up ! The pop-pop-pop of the exhaust gets muffled really well, and the thick steel walls prevent the direct sound from escaping. A restricted outlet, say a short length of three quarter inch water pipe, will just hiss, without any sound escaping at all. There will be a drain outlet at the lowest point to allow condensed water to drain. If you are patient, something suitable and pretty cheap will show up on e-bay.  Cheers, Tony. |

||||

| Ironmaiden Regular Member Joined: 09/07/2019 Location: United StatesPosts: 53 |

Tony, That is complete overkill borderline nuts for a Lister engine. Part of the fun in having a Lister is in the sounds it makes. I just wanted to find the muffler because it looks good on the Lister. The muffler on the Lister is a Donaldson product. After many hours of research, I finally found a catalog from Donaldson with a similar muffler. Robert Edited 2019-08-10 12:52 by Ironmaiden |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I suppose it all depends if you have very close neighbors.    Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

The muffler in the picture looks like any standard run of the mill tractor Muffler. Shouldn't be hard to find on fleabay or a tractor/ ag machinery place. There are several different universal types and sizes. Listers are easy to quiet the exhaust on, what most people overlook is the racket the INDUCTION makes. I just got a couple of Kubota single cyl 12 HP engines. They have an oil bath air cleaner but the racket out of the intake like all of those diesels, the China models especially, is far more than the exhaust which generally isn't bad at all. It's easy to test by getting some rag and putting it over the exhaust for a few seconds. You'll hear the tone change but the noise levels are no different. Easy to check these days with an app on your tablet with a logging feature. I got a towel and wrapped it around the air cleaner and the noise difference there was chalk and cheeses illustrating what was really making the racket. I'm going to put a Muffler in the INTAKE side of the kubota's and the air filter on the end of that. Car air boxes can be good too especially if they have a snorkel. Many these days have little chambers and offshoots for resonance tuning and silencing of the engine they came off. They can be sliced off and taped over. The other thing that can be a significant noise maker particularly with aircooleds is just mechanical clatter. Having a water jacket round things makes a big difference. Also allows the engine to be much more enclosed with just the air in and the exhaust out than an air-cooled will allow without a Lot of trouble. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes you are right about the clatter from air cooled engines. I have a 12Hp single pot Wisconsin, and the exhaust noise is now just about zero, but the mechanical noise is terrible, and its just been rebuilt to spec, so there is nothing wrong with it. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I just did a 16 Hp wisconsin for my mates trench digger a few months ago. It was about 30 YO but pretty much like anything from that era, rough and basic! :0) I think the newer China engines are a lot better than any of the older stuff especially from the US. I wouldn't touch a side valve briggs with a 40 Ft pole no matter how much people rave about the POS. I have pulled down brand new unstarted brigs and the workmanship in them was pathetic. Many parts were out of spec before the thing was run and the price of spares... I remember my mate who ran a mower shop showing me the invoice for a set of pistons for his sprint car was cheaper than a piston, rod and rings for a briggs and he got them wholesale! I have acquired a bunch of China petrol engines over the last couple of years on Tillers, pressure washer, a mower, chippers and other things and am pretty impressed. They are pretty quite ( although the mufflers have atrocious gas flows and I have modded most of them with little noise but plenty of performance and consumption difference) and I never fail to be amazed at the ease with which they start. So far the biggest problems have been a kinked throttle cable on one and the other day the fuel hose which is universally crap on china engines, split. I usually keep some of that and have replaced it on most of the engines but used it all up. Is diesel expensive or hard to get where you are Tony? Not many people run Petrol generators which I assume this is. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

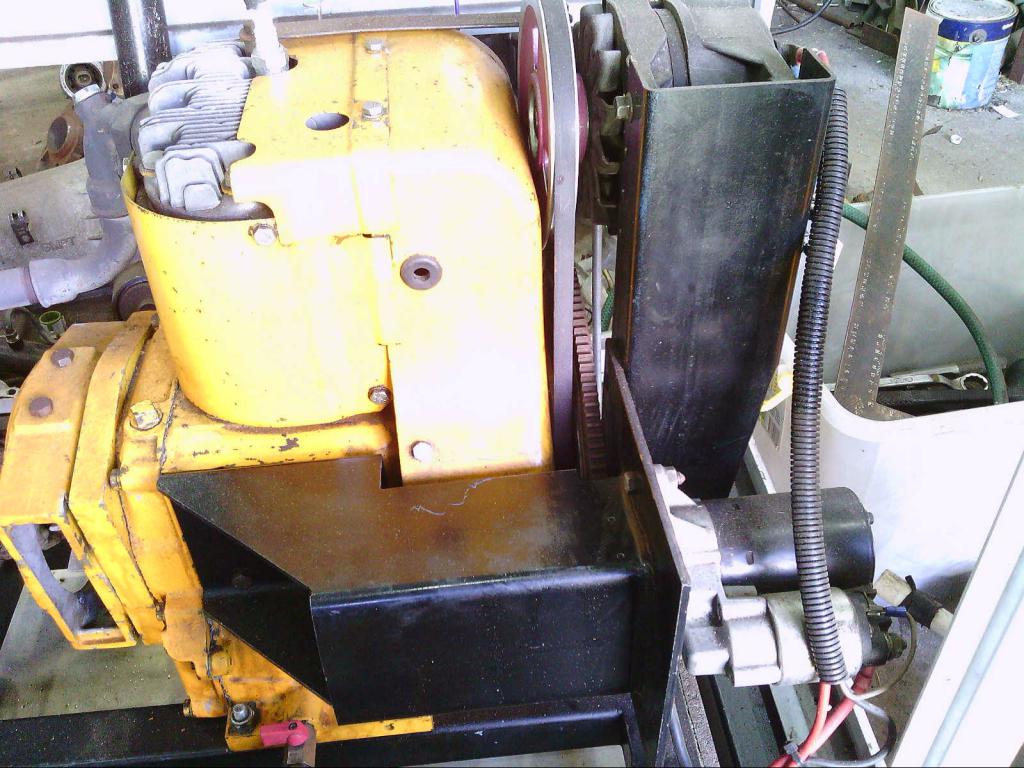

I bought this for fifty bux on e-bay, 12Hp Wisconsin with a 240v generator, not working because of a missing carburetor but otherwise complete. So I pulled it to bits, found it had been completely rebuilt, still had the cross hatch hone marks in the bore, but had an oversized piston fitted with standard sized rings so the ring gaps were gigantic. It was terribly hard to start because of the ultra low compression. Anyhow, fitted an ignition coil and Bosch igniter, tachometer, electric start and a 12v alternator to it and raised the compression ratio. Also a massive steel compressed air tank as a muffler. I planned to eventually run it from natural gas. But its rather noisy and no simple way to fix that as its air cooled. Its now quite a nice machine, starts first push of the button and runs well. Diesel would be better, but as natural gas is so cheap and comes in an unlimited quantity and requires no refueling, that has to be best of all. Next attempt might be a small water cooled diesel converter to spark ignition and natural gas. What do you think ? Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I have seen a few examples of gas conversions of Diesels on the net. The biggest problem is metering the gas on a single Cylinder engine. A guy I know did it and used an Impco brand carb I think it was. He'd been through a lot trying to get that sorted but the one he got which he put on a Lister cleared up all his problems in one go and has been working successfully some years now as his main power source. He runs LPG but no difference. I don't know anything about gas injection but I believe late model Fords ran LPG direct through the petrol Injectors. I am not savvy enough on the subject to know why you couldn't run gas through a normal car injector other than that the pressures for LPG are around 100PSI and petrol Injection systems are around 40-60 PSI. If you wanted some injectors to play with I could send you some. All one would need to do would be have some load/speed sensors to widen the pulse width of the injector and keep the thing running at the required RPM The ignition part would be a snap for someone like yourself. Conversions remove the injector and fit a spark plug in it's place. Other than that, depending on the engine you got, You may have to reduce the compression. Gas will run higher than petrol and some of the lower end compression diesels would be OK stock on gas. Others would need a decompression plate. There are Diesel Conversions out there on an industrial Level. I know CAT does them for one thing and have seen a 3 engine setup at a Data Centre they use for backup. Myself I would look for an over size engine that would develop the power you want well down the rev range and gear it up on the pulleys. That way you could have an engine doing 1200 revs or less ( much less if it were a lister type) which would keep it quiet and give it very long life. You could easy convert a car engine for this which would be ideal. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The ignition part was easy, the Wisconsin originally used a magneto with fixed timing. I just used the original points to drive a Bosch igniter module, no problems at all with that. A carby I bought on e-bay gave perfect air fuel ratio mixtures straight out of the box. I was planning to use a model servo actuator for the carburetor and a microcontroller as a more accurate rpm governor. Only ever finished the mechanical actuator part of that. Anyhow, if I removed the diesel injector and fitted a spark plug, it should be easier to start and eliminates all the injector/pump problems. You are right about the heavy induction pulsing being a problem, but the same problem exists with carburetors. Its just a matter of fuel calibration. There are complete natural gas conversion kits available, Impco being the most well known. I would probably start out with something like that. I have no practical personal experience of small water cooled diesel engines so am not sure which way to go with this. A big bore very low rpm Lister might be the quietest, and I can rig up a 12v dc system for starting, charging and ignition just as I did with my Wisconsin.Its a bit of work, but pretty straightforward.  A car engine run at very low rpm would require a larger heavier flywheel, but would have a lot of advantages. I believe the Japanese Kia class minicars usually have 650cc three cylinder EFI engines. They are probably not worth that much, but would come with a starter, alternator and water pump. Edited 2019-08-11 13:13 by Warpspeed Cheers, Tony. |

||||

| Ironmaiden Regular Member Joined: 09/07/2019 Location: United StatesPosts: 53 |

I hate neighbors! I have one now that annoys me to no end. My next toy is going to be a gas turbine engine. Maybe they will get the message to leave. Something like this would work well. https://www.youtube.com/watch?v=P97LHc44TTo  Robert |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

That's a great looking setup you have there Tony, I see electronics is not your only Talent. To clarify, are you looking to drive an alt for battery charging, a 240V gen head or Both? My father has an old Tiny Subaru 3 Cyl whatever they call those micro cars on his property. I think the distributor is stuffed as was a common problem on them and spares have long since disappeared. They are a little 900Cc engine I think it is. I was going to ask him if he wants to get rid of it and I was going to do an engine transplant with one of my 6 HP China Diesels. I'd gear it down a fair bit as I don't need the thing to do over about 10 KMH round the yard but I would like a bit of grunt for pulling things around and I'd Probably make a small plough and scarifier for it. Just put a 12" pulley on the gearbox and a centrifugal clutch on the motor with a 2" Pulley and that's it. The engine would be easy to convert to a stationary engine as one could do away with the dizzy all together and just use a magnetic pickup off the flywheel. they are the size of a sewing machine and I'll bit I'd have no trouble picking one up unlike any decent size Diesel. If you had to beef up the flywheel on an engine, Which I'm not sure you would have to, that wouldn't be hard. I have a couple of old flywheels I have picked up from scrap bins as they are often thrown out particularly on trucks when the face gets too worn and aren't worth machining. I moved one the other day, must be 40Kg at least! Then again, the ones on my 6Hp lister are about 80Kg... EACH! I don't think one would need to be too fussed on getting a really small engine, the load is going to determine the fuel consumption more than the size... to a point anyway. If you are going to drive a few KW + of gen head I think you could go for a 12-1300 engine which I think would be easier to get than smaller ones. If you just want to drive an alternator then anything is overkill. I think listers can be very over priced...and usualy hard to get. If you get a listeroid ( Indian lister copy) they all need tearing down and setting up correctly as the Pizz poor engineering and setup on ALL of those is well known. The most common faults are about 300g of casting sand left in the sump and often thinly pained over just waiting to erupt, Lifters that don't turn, binding throttle linkages, Out of balance flywheels and terribly aligned camshaft gears that cause them to break in a couple of hundred hours... or much less. Leaking base gaskets are also a popular accessory from the skilled Technicians at Rajakot because the bottom of the Cylinder is a 1mm or more out of square and on the top end the head gasket won't seal because the liner is 3mm High or 2mm too low. And that's the main problems. The one I have is so out of balance it will snap 1/2 Bolts with ease holding it to the concrete, or trying to and I can't drive stakes into the ground far enough to stop it vibrating them loose and walking itself down the yard. I once foolishly mounted the thing on a trolley with car tyres. It's quite an exciting thing to watch a half ton of engine, Motor and trolley bouncing right off the ground completely and figuring out how the Fk you are going to get close enough to shut the thing off before it goes through a fence, shed our your house. As the things are counterbalanced on the flywheels not the crank, balancing the bastards is not easy. Diesels, particularly water cooled models are not easy to come across and exy as hell usually when you do. Funny enough they don't sell well around Sydney and I have picked up a few bargains over the years when people advertised them for many months and got no takers. There is a 25Hp twin Cyl aircooled Lombardini I have been watching since jan near me but the seller is one of those people that thinks the price he conjured up is fair and anything less is ripping him off. Probably one of those morons that says stupid things like " I rather take it to the tip than sell it for that". Come across a few of them in my time and if there is one thing I love with buying stuff off Gumtree is being told where to shove your offer then 3 Months later getting a message "are you still interested xxxx..." Many times I then play hardball or say I bought one cheaper than I offered so it would only be worth ( less) to me now but thanks for getting back to me. Then you get a message if you want it for that, come get it. So I do! :0) Owning a few air cooled Italians, You would NOT want one where noise was a consideration, unless it was making the most noise possible that is. I'm on acreage and they are really too loud to use for anything long term and I'm not even concerned about the Neighbours, just me! Car engines can be very quiet and you only have to run them fast enough to make the power you want and gear them from there. The beauty of a car engine is it can make 10 HP at a fast idle so if you gear the 1000 RPM it's doing up to 1500 to drive a small genny, you are laughing. The other thing with water cooled's is you can co gen them. Instead of wasting the heat in winter, you can run it to the house, a garage or a greenhouse. Honda actually made a co gen unit set up for this very thing. Ran off gas, made power for the home and the heat could be used for the home or heating a water supply. Looking on fleabay there are a few potntial candidates for your project" Polo engine golf Barina Got an idea they are similar or the same as the Geo engines favoured for such projects in the states. Honda In looking at those, I must have passed over about 9, 6 Cyl ford engines. If you had the ability to pump about 500A into your battery bank, might be a contender. For the couple of hundred bux any number of them seem to be available for, Might even be worth seeing how they went if the alternatives where you are are a lot more exy. If you want any 12V 80A enclosed fan alternators, let me know. I'll send you some if you pay postage. I love the enclosed fan type, they are unbreakable. I have a couple on My lister. I have run them hours with no battery which is supposed to kill them and it won't. I have actually done about all I can to kill them less run them less run them dead shorted for long periods and I can't find what will bring them undone. Couple of months ago the one in my ute was playing up, I pulled it apart, cleaned the commutator, brushes were OK and put it back together. seemed to work fine. I was at my fathers and left after dinner as usual to drive the 4 hours home. an hour down the road the thing popped and I was worrying about getting home. I stopped at the 1/3rd mark and saw the alt was very hot but the car started easy. I should have worked it out but I didn't think it through properly. I got to the end of the freeway and thought if it dies now, mrs can come get me, no big deal. I got home fine but coming up the driveway I could see steam coming from under the bonnet and knew what happened the 100A alt was charging flat out. Sure enough the battery was boiled dry and ruined. The alt was sizzling hot when I applied the standard spit test. Fired it up the next day with a Jumper pack and sure enough, alt was cranking the full 100A. They are tough those things. New regulator was $95, new alt with 3 year Guarantee, $125. Went for the shiny one. the enclosed alts have a fan at the front for the coils and a fan at the back for the Diodes and reg. They are way harder to kill, if you can than the old Bosch/ Lucas etc exposed fan models. Apart from that they are a lot harder to stick your finger in the fan when you are running a 12V gen setup and split the bone in your finger in 2 Places. I can personally guarantee you that!  Anyway, If you want some I have a plentiful source and happy to send you as many as you want. They are Mitsubishi's. Have a serpentine belt drive but easy to put on a v belt if you want or I can send you some short Multi v's as well. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That 12v alternator is just to recharge the starting battery, and it turns pretty slowly. There is a 240v two pole alternator on the other end, possibly 20 amps. After much thought I think I will run the thing at half speed, 25Hz and 120 volts. The noise is much less at 1500 rpm, and it will still put 20 amps into my 100v battery which is plenty. I can then run the whole thing as an inverter generator, using my main inverter to generate 230v, so I can throttle the Wisconsin right down and still get useful dc power from it. That is probably the direction I will eventually go, with some kind of car engine run at much reduced speed and on natural gas. That is all still a fair way off in the future as I still have a bunch of other unfinished projects to complete. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

2 Poles being 3000 RPM are never favoured for quiet or longevity. The 4 poles running 1500 RPM are the preferred choice. The 2 Poles also tend to be the single bearing type which hangs off the end of the tapered crankshaft of an engine and are often cheaply built as possible throughout including using aluminium windings. I have been toying with the idea for a while of brining in some Gen heads from china. I'd probably go for the STC's what are the 3 phase variants and widely reported to be much better made than the single phase ST models. Looking at the Prices, something around the 17/18 KW output would be what I'd want. That would allow one to get an easy and under stressed 5 Kw out of each phase. There is literaly a few $$ price difference between one output and the next one up so may as well go that bit bigger. Besides, the bigger the head the better the reactive power and stability. I could get 5 KW 3 phase for the better build quality but that would give crappy output per phase or they would have to be re configured to single phase output. 5 Kw is where the main market would probably be though. Probably better to go for the Stanford type which are more exy but a better unit again. Finding suppliers isn't hard, what I need to do the homework on is Customs agents and the associated fees which I have a bad feeling could be very steep on a small volume import. I found an old single phase motor up the back today. I took it off a friends pool pump when the plumbing had been leaking so long the bottom of the alloy pump casing has corroded away and you could see the windings exposed. That would be good to turn the rotor down and put magnets on it to learn about permanent magnet generators and their proclivities in that layout. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes its 2 pole 3,000 rpm and air cooled, which is about the nosiest possible combination. Sill for fifty dollars it was worth a try  This has the usual long Wisconsin crank taper, but with a rear ball bearing on the alternator, so the armature is very well supported. Windings are all copper. I probably will not get back onto this project until after Christmas. If I do go the car engine route, I would much prefer a three phase alternator, as the rectified dc from that would be much nicer. A quite different approach to this, might be adapting an old dc fork lift motor. These are usually series wound, the armature and brushes should work as they are, but the field windings will need to be rewound with a much larger number of turns of very thin wire for the voltage regulator. That should be pretty straightforward. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

Have you seen many forklift motors around where You are Tony? I see a lot of things on YT that seem to be easy as pie to get in the US but either impossible or impossibly expensive here. Can be very frustrating. I would be interested in a forklift motor for an EV yard kart but all I have ever found and the controls make it way too expensive to even contemplate. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There must be thousands of electric fork lifts around, and they must all eventually go somewhere to die. Don't really know, I have not yet started looking around for one. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1578 |

I had a look at some Chinese generators this afternoon. $20 More for a 3 Phase 20 KW over a 15 Kw. For that I'll definitely take a 20! I then got to thinking that maybe I was going overboard and a 5 KW would do. More than half the price of a 20! Given the similar proportion of higher shipping charges which really add cost of even a 5 kilo, I'll go for the 20. Least that way if the power does go out I can run everything I want without thinking about it and throw a lead over the fence for the neighbour. A 3rd thought came to mind ( 3 all in the one day!) and that was I could also hook the solar into the generator and take the load off the Motor which might be the Limiting factor with a gen that large. I have my 12 HP Kubotas which are water cooled, a 30 Hp Ruggerini twin which is an air-cooled ( but relatively quiet) and the Mercedes engine which could do 80 HP now if needed. Probably need to bite the bullet and decide which way I am going to go with the gen head. Do I keep going with the IMAG or drop a grand on an STC head and hook that up? If I got that, I Might go back to the merc engine. All I'd need for that would be an electronic controller. I was thinking about the cost but if I had that setup, I wouldn't need anything else and I could get rid of a LOT of my other engines as I would have no need for them and be well and truly in front. Mrs approves ANYTHING that means a reduction in my engine collection. With the 10MM Cable I'm looking at putting up the shed in 3 phase, I could run any and everything from the genny to the house. Only reservation is the room all this would take but another thought again is one I have been tossing around of putting another shed up behind the other one. If I had that, then there would be plenty of space and it would be in the farthest corner from myself and the neighbours and I could get some cool room panel and make a separate room for the the genset to make it silent if need be. Cheap and easy then just to extend the cable from the main shed to the second one. All I'd have to do then would be hope there were a lot of blackouts to be able to put it all to use. :0) |

||||

| Ironmaiden Regular Member Joined: 09/07/2019 Location: United StatesPosts: 53 |

Davo99, I am wondering what sort of setup are using the Imag for? Which connection method are using on the Imag? I have found C-2C to be somewhat temperamental in my experiments. Over here C-2C doesn't give optima performance because of our split phase system. I prefer having a star connected motor and wiring the capacitors in delta across the windings. Cap between L1, L2, & L2, L3, & L3, L1. I have also noticed that capacitors of 50uf seem to be the right value from 4KW up to a 20hp or 15kw generator. I don't know why 50uf seems to be the right value most of the time? The math suggests this should not be the case. But 50uf X3 caps in delta certainly works well for my generator. There does exist a sort of C-2C method of connection for a star connected machine. The problem as I see it has to do with taking the load between L1 and the star point of the capacitor set. This would result in distortion of the waveform I would think? See, C-2C Star Winding For our split phase system, I am thinking the above method is actually better with the windings of our 9 lead electric motors connected for low star. We should be able to get twice the current vs reconnecting in high series delta to achieve the normal delta C-2C connection method. Our 9 lead motors are wound 2 in hand. I could open up this motor and fetch the ends of wires 10, 11, 12 and then be able to reconnect in either low delta, 120v only. Or high series delta for 120/240 for C-2C delta. It's alot of work to separate the ends and attach lead wires though for what seems like an unfavorable connection vs star connected C-2C as in the paper above. There is also the novel C2R-R connection scheme. In short what this scheme entails is connecting one capacitor across the ends of L3 and taking the power between L1 and L2. In some of the documents I've seen suggest this connection is more stable than C-2C. I have to wonder about balance issues with the windings? PDF is free to download to read. https://www.researchgate.net/publication/268390678_Novel_C2R-R_Configuration_for_Micro-Hydro_Plants_Used_in_Islanded_Systems Robert |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Robert, you might like to look into the "Scott Tee" transformer. I don't know if it will help, but its a way of combining three phases to produce two balanced 90 degree phases, or single phase with unequal loading on the three phase supply. Edited 2019-08-19 08:07 by Warpspeed Cheers, Tony. |

||||

| Page 1 of 3 |

|||||