|

|

Forum Index : Electronics : SMPS Boost inverter operational problem

| Page 1 of 4 |

|||||

| Author | Message | ||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

For about 600 Watts of PV (at full irradiance) and at Vmp of 30Volts the output voltage of a SMPS Boost inverter can be set to 70Volts into a 9 Ohm load. This SMPS That is about 540Watts (efficiency about 90%). The current clamp is set to maximum, so hopefully that is not causing any problems. The low voltage drop-out is set to about 10 Volts. While the unit is running if I try to increase the output voltage above 70Volts the unit goes into a "strange" mode. The output voltage drops, the input voltage drops and the unit starts to get real hot. I can understand that due to limited input power that the unit would not be able to supply increased power but why shut down like that? Also, while the input is removed if Vout is set back to 70Volts (panel loaded for Vmp), wait a minute or two and re-connect power it won't start. I now have to set Vout to about 65Volts, reconnect load and then I can increase Vout back to 70Volts. Possibly a temperature effect. The end result is that when the irradiance drops below 80-90% and the unit is set to 70V it goes into this "strange" shutdown mode. One observation is when the unit shuts down the Low Voltage Cutout LED comes on. My understanding is that when this happens a FET switch at the SMPS negative input is turned OFF. Maybe it is not being turned totally OFF. There is a cryptic comment in the Aliexpress ad: 2, If a switch power supply is used as input, module should be connect to power and voltage should be adjusted well before connecting to load. When connecting to load, make sure to turn off the power supply first. Ultimately, I plan to adjust Vout so that the PV panel is loaded to Vmp at all irradiance levels using microprocessor control. I was going to measure the panel short-circuit current once a second and adjust Vout to suit, hoping that the supply doesn't enter this unwanted shutdown mode. However, I thought it might be a good idea to understand what is happening here, before I go any further. The controller chip is a TL494. Appreciate any comments, Dave |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

There are several potential problems here mostly caused by this unit not being intended for use with PV. Could you provide some data on the panel/s you are using such as Voc ? It is likely you have set UVLO to low at 10V and when the panel voltage falls thus the auxiliary power supply is failing such that the TL494 is missoperating and there is insufficient gate voltage to switch the fets hence they are operating in the linear region hence heat! Your other problems may well be due to the panels Voc exceeding the 60V maximum input voltage of this device. If you have a fixed load resistance and the device tries to maintain a fixed voltage across it as irradiance falls at a constant load impedance voltage will drop, this will cause the panels to shift from mpp further reducing output power & hence voltage, you have created a positive feedback loop to zero power. What is your intended load (you mention 9 Ohms) is it a heater ? Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Dave, those 4 x 470uf 63V input caps on the PCB are too small running off a PV constant current source, try adding a 10,000uf cap to its input supply. Cheers Mike |

||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

zaphod, Are you aware of anything out of China that would be more suitable? Panel Voc 33V. The specs say the unit can operate down to 10V. The input voltage say at 50% irradiance is well above this. I will try putting UVLO back to say 20Volts where I had it originally. Just checking I have this right: If you have a fixed load resistance and the device tries to maintain a fixed voltage across it as irradiance falls the PV panel voltage will drop, this will cause the panels to shift from mpp further reducing output power & hence PV panel voltage, you have created a positive feedback loop to zero power. Yes, the load is 2 * 18 Ohm resistance wire heater elements. The next step was to adjust Vout dependent on irradiance, which seems a pretty linear relationship to Isc. Hopefully, to prevent positive feedback. But, the main think I don't know ... is this the right type of SMPS to be using. Mike, I will try the 10,000uF cap. Is the idea here that it will give me more time to adjust Vout before the PV panel voltage moves too far away from Vmp? Thanks guys, Dave |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

Hi Dave, well my experience of modules out of China is they rarely if ever perform to the written spec as usually the producer has no idea how the unit works and finds some copy of an app note somewhere then populates it with the most convenient locally sourced parts that in themselves are often fakes or below spec from the grey market so in other words the spec is largely conjecture/history! Now I have a better understanding of how you are going to make this work, using an MPU to adjust Vo and hence Po right  I am still a little confused about your panels, you say 600W but Voc is 33V & Vmp is 30V so do you have two strings in parallel as there are no cells to my knowledge capable of 20A ? As for the type of converter you definitely need one you can trust the spec of! But in any case I think if you do some modelling you might find situations where to reach mpp at lower irradiance you need to be able to increase the effective load impedance and this cannot be achieved by a boost converter alone. I myself have a 1Kw array (240 cells in series)a 12 Ohm water heater load and uses a mixed buck-boost mpp controller. Typically it switches from buck to boost somewhere around 400-500W. This is very dependent upon the match between Vmp and the load resistance & power. My controller measures panel voltage and current then uses perturb & observe to follow mpp continuously. Do you have LTspice (free) or something similar, it's invaluable for trying things out without spending money :) Zaphod Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| hotwater Senior Member Joined: 29/08/2017 Location: United StatesPosts: 120 |

I actually do this with a slightly different boost converter into a water heater. The trick is to maintain the input voltage at near power point. I sense the input voltage with a TL431. When voltage drops below 30V, it fakes the boost converters controller chip into thinking the output voltage is higher than it should be and starts driving the controller off. I have a zener that limits the TL431 to 6.3V. The voltage sense pot trip point of boost is about 2.5v and the 431 can clamp to about 2V. An LED connects the two and that voltage offset provided by the LED makes it work and provide a visual indication of it going into limit. You ain't going nowhere with what you have set up. The heater resistor can never drop below the panels voltage as it is basically a diode drop pass thru. That means a high load on the panels till you reach a panel output of 60 or more watts. |

||||

| nickskethisniks Guru Joined: 17/10/2017 Location: BelgiumPosts: 458 |

Exactly! I do something simular with an Arduino nano. Just keeping the input voltage at a constant level and the output below a certain level. You just need a mosfet driver, an inductor, mosfet and diode. I use buck mode. |

||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

Hi guys, Just got some sun to try a few things. Mike, The 10,000uF allows Vout to drop much further before the unit go into the fault mode. I can now tweak Vout manually searching for the peak. Could you explain how this small amount of capacitor storage on the input allow the inverter to operate over a wider range of input voltage drop before malfunctioning? zaphod, I have two 250Watt panels facing NE and two more facing NW. Around the middle of the day (mounted at 60 degrees) I get 30-40Amps at this time of year. Is your Sepic inverter home-made or ? I have LTSpice on another machine but only have beginner level skills in SMPS design, I am an RF engineer. hotwater, But, hopefully when I introduce Vout control with the microprocessor I will. Or, do you see a fatal flaw? Thanks everyone for your input. Dave |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Those up-converters draw very high short period input currents, the large cap 10,000uf or more will allow the circuit to pull the full required current, that otherwise wont be available from a limited current PV source. The value of caps they use on the pcb are optimistic at best, ok I guess if running off something like a battery. Once you have a cpu feedback working, should work fine. Cheers Mike |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

Hi Dave, don't worry about designing SMPS yet the first thing you wanna do in spice is model your panels so you can plot there performance, then you can try various ideas to match your loads, from there you will discover that when the panels are simply shunted by a resistive load they will never be able to reach mpp! (depending on the match). So I guess all four of your panels are in parallel, mine and most other installs I know are in series but then you have two roof spaces :) My converter is not a Sepic as I didn't like the frequency I would have to run to transfer enough power through it's series cap so instead its a boost between the panels and heater and a buck between the heater and panel return, yes all homebrew and controlled by a PIC (in realtime), quite a few yards of assembly code! Have fun :) Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

Mike, Thanks for the explanation. zaphod, Are you suggesting that you need some reactance OR that you never will get spot-on mpp, ie with common methods? I just wanted to do better than slapping the heater element across the panel. Currently, I can select 5 different Vout levels, which I hoped would improve the efficiency significantly. Vout....Power 33V.....121W 43V.....206W 53V.....311W 61V.....415W 70V.....544W so, one gets switched out depending on available PV power? Dave |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

It depends what you think common methods are, but using a boost only topology means you cannot reach mpp for insolations where p<I2R. I just wanted to do better than slapping the heater element across the panel. Currently, I can select 5 different Vout levels, which I hoped would improve the efficiency significantly. Vout....Power 33V.....121W 43V.....206W 53V.....311W 61V.....415W 70V.....544W I am concerned that the panel voltage may be forced lower than the mpp voltage by your boost converter though in principle I see the point of raising the output voltage to match your heater power to the expected panel power :) so, one gets switched out depending on available PV power? Yes exactly, the buck also operates as a very effective thermostat as switching high voltages at several amps is not good for physical contacts (arcing). I had another idea that may be of help, I seem to remember you have two 18R heaters, well you could consider switching them in series parallel to increase your options (though the arcing comment applies) or one vs two using a fet. I2R @ 30V becomes 9R = 100W, 18R = 50W & 36R = 25W. Following the insolation down to low levels may not be so important in your country of sunshine but unless I did it here in the UK I would get less than half my output, also particularly useful in winter!! Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| hotwater Senior Member Joined: 29/08/2017 Location: United StatesPosts: 120 |

But, hopefully when I introduce Vout control with the microprocessor I will. Or, do you see a fatal flaw? No you actually have to monitor Vin. Connect the panels directly to the boost converter. Add extra capacitance to the input and output to handle the pulsing current. The boost converter only draws about 50ma once the caps are charged so it can be left to free run. Monitor the input voltage and control the output pulse to heater to maintain voltage. If rate is kept under a couple hundred HZ the FET driving is pretty simple. Don't even need a micro, but I love them. |

||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

zaphod, The common methods I was referring to were: Constant Voltage method, adjusting for Vmp Open Circuit Voltage method, haven't looked into this one Short Circuit Current method, my initial method Perturb and Observe method Incremental Conductance method I am focusing on the adjusting for Vmp method for starters. for insolations where p<I2R. So, in my case for power levels less than (where Vout is set to 70V and load R = 9 Ohms or 544W) 544W are you saying that one can not reach mpp? I am ignoring the fact that Vmp drops slightly as insolation drops. My observation is reducing Vout to keep the panels at Vmp gives good efficiency at lower insolation levels. Switching elements ... the first prototype had four elements and FET switches that gave me 7 different load resistances. I could fall-back to switching the loads as you suggest and tweaking Vout. hotwater, I am measuring the panel voltage, which is Vin to the SMPS. Ah, add a big output capacitor as well ... I try that. I have several articles which use a simple boost converter, however for about NZ$20 for the unit I have it is not worth the effort to get the parts and build one :) Cheers, Dave |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

for insolations where p<I2R. So, in my case for power levels less than (where Vout is set to 70V and load R = 9 Ohms or 544W) 544W are you saying that one can not reach mpp? Hello Dave, what I am saying is even if your boost converter is doing nothing (to make the situation worse) your panels cannot reach Vmpp if the load resistance prevents it. Imagine the insolation has reduced your panels output to 75W at that power your 9 ohm load will only drop ~25 volts hence the panel is prevented from reaching Vmpp as its Vmpp is at ~30V. As the insolation reduces further the actual operating point is further and further away from Vmpp reducing the panels effective efficiency still further. There is no solution to this except increasing RL to allow the panel to remain at Vmpp. One way of increasing RL is to use a pwm (or buck) converter. BTW the use of large capacitors at the input prevents the use of P&O or similar algorithmns as the change is to slow especially again at low insolations, I use a 3.3uF capacitor on a ~120Vmpp system and that is adequate for the boost converter that switches at 125Khz. The problem with off the shelf modules is you are not in control of all the parameters! I really do suggest you try developing a solar panel model in spice, it is simply an insolation dependent current source shunted by a silicon diode (it does take some fiddling with the diode to get a good match to your panel). Good luck :) Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| hotwater Senior Member Joined: 29/08/2017 Location: United StatesPosts: 120 |

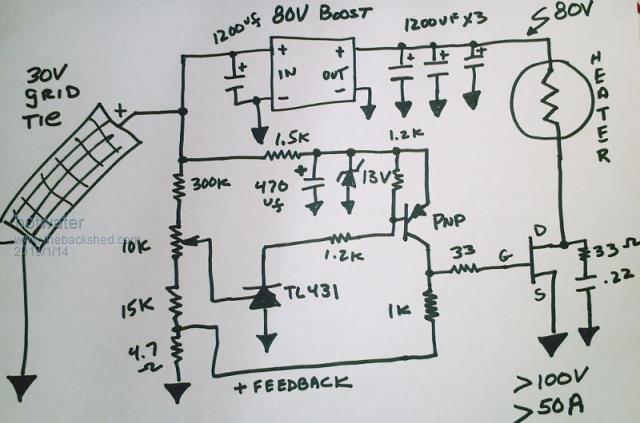

Having full MPPT tracking doesn't really matter much as this is temperature dependent. Changing the power point voltage a couple of times a year is sufficient. It also affords the opportunity to operate the system in parallel with a charge controller for harvesting wasted energy. A bust or buck converter on a solar panel alon will quickly put the panel into a death spiral. For your edification and amusement, this is something I whipped together from whatever parts were handy. t seems to work well. Needs extra capacitance on the input and a couple of FET parallel on the output. 75N75 are cheap and plentiful as are IRF540.  |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

Its fine but highly dependent on the characteristics of the boost converter, like how much insolation does it require to start up and successfully charge the output capacitance and how low can it go (all part of the OP's original problem) :) It is not true to say Vmpp is only temperature dependent as it is also insolation and therefore load dependent however as an approximation it may be good enough depending upon your requirements. Temperature itself can vary a lot between the early morning hours and midday sun at full power. Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| hotwater Senior Member Joined: 29/08/2017 Location: United StatesPosts: 120 |

Th OP's problem is that the boost converter in an effort to satisfy the output demands puts the panel into a death spiral. These boost converters will start up easily if they can e supplied with less than a couple watts from the panel. I've been testing this for years and power is fairly insensitive around a fixed power point voltage. It just doesn't matter that much in real life. It is easy for people to think that MPPT is wonderful. There is always a cost to tracking and that makes many MPPT algorithms suck. Constant voltage is very fast in responding to clouds and not wasting power. As a total system, constant voltage performs pretty well. I can't print what I think of many MPPT controllers. |

||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

zaphod, OK on what happens as I drop below about 100W on the panel. My attention was focused on all the wasted power from 100 to about 500W! One of those boost inverters will run at about 500Watts output (fan duty cycle 50/50). At 600 Watts the fan is running all the time. The final implementation will have two of these boost supplies each one feeding an 18 Ohm element. This will give me a power range of 30V * 30V / 18 Ohms = 50W to a maximum of 1000Watts. hotwater, Thanks for the schematic ... looks like it was designed for my panels and SMPS :) I have those other bits. Basically, it turns off the load at low power levels, right? The SMPS I am using has a low voltage disconnect FET in it, which I have set at 25Volts, hopefully it will perform the same function. The controller gives me 5 voltage levels, 33, 43, 53, 61 and 70Volts. The code just selects the highest voltage to keep the panel voltage above 30V. It changes one step per second ... I may need to speed that up. Now, we just need some sun! |

||||

| zaphod Regular Member Joined: 03/06/2018 Location: United KingdomPosts: 93 |

hotwater I could not agree more, solar seems to attract so much fakery its unbelievable and very annoying seeing people sucked into it. I just try to point out to people there options and what the up/downsides maybe :) davef Yup and that's exactly where I started too, then I started to realize it wasn't the whole solution, or lets say in our bloody awful UK weather the system was spending to much time at quite low insolation hence the additional complexity to deal with it. hotwaters solution is good to if you can trust the boost supply. Cheers Roger 1Kwp DIY PV + Woodburner + Rainwater scavanger :) |

||||

| Page 1 of 4 |

|||||