|

|

Forum Index : Electronics : PV Hot Water System

| Page 1 of 3 |

|||||

| Author | Message | ||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

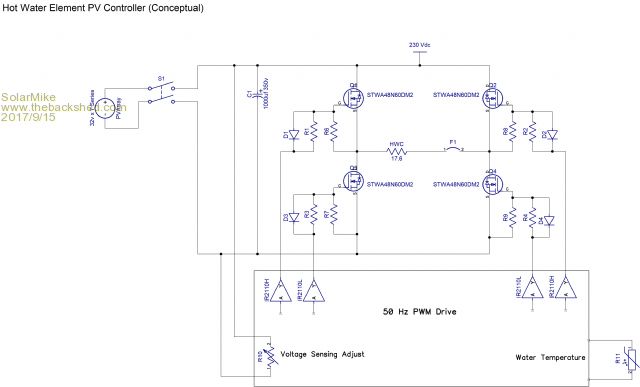

Been thinking about this for a while, I have a future requirement to install solar hot water systems at two locations, one an off grid house and the other a garden centre that wants hot water way out in a shed a hundred meters or so away from the main buildings. Having built my own solar hot water panels over 10 years ago that supply 95% of our household hot water, its a lot of work, welding copper pipe and soldering to sheet copper foil, building the alloy cases, then the control systems, pumps, etc. Commercial panels costs 1000's here in NZ, so not really an option. So ten years on, with the cost of PV having dropped dramatically, my thoughts now are to use a PV array of 7 x 32volt 9 amp series panels to produce approx 2KW of DC power at 230 volts DC. If the hot water cylinder has a 3kw element fitted approx 17.6 ohms then this will draw 13 amps, not a good match to the PV array, but if a low esr high ripple rated capacitor is charged up from the PV supply voltage then discharged into the heater element, this will allow matching and good power transfer. PV power makes everything simpler, no anti-frost system required, no pumps to wear out or leak, less expensive; only downside I can see is the array takes up more area, not an issue here, they will be ground mounted on wooden poles. My proposal is a simple H-Bridge with variable pulse width modulation to adjust the load on the PV array and allow alternating the polarity of the dc voltage across the element to prevent electrolysis. The 50 HZ square wave pulse width is adjusted by the controller monitoring the voltage across the capacitor, as the element resistance load is fixed, short duration pulses will discharge the capacitor a lesser amount in lower light conditions, longer duration for full sun. The standard thermostat can be used as it's seeing square wave AC, NZ reqs require a direct thermostat switch in series with the element for temperature regulation, relays or electronic switches are not allowed. The drawing shows the concept, the 7 panel PV array has a voltage that varies between 224 - 273, with 224 being the mppt value; H-Bridge configuration is standard but using 600v 40amp mosfets, 0.065R on resistance, so power loss is minimal. The controller will use IR2110 drivers with bootstrap cap for HH bias volts, small 14 pin PIC CPU, thermistor or DS18B20 for primary temperature control, the standard thermostat acts as backup. Isolated controller supply voltage will use one of those postage stamp sized 12 volt supplies. I really don't think I need a full mppt switch mode voltage down converter here that senses current and voltage to calculate a mppt point, the mppt voltage of the panels is known and doesnt change that much; an extra series panel could be added easily for extra power at minimal cost. Please all comments welcome, I would rather not go down the wrong track before I start...  Cheers Mike |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Someone I know is using 6 250W panels and a 48V 1500W element that can be bought on Aliexpress. It is controlled by using the original thermostat connected to a DC SSR. Obviously, this does meet your regulations or the over come electrolysis. but may be of interest to DIY people. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Some pretty lateral thinking there Mike. I really like it ! I think I would fit a small non saturating RF choke in series with the heating element to soften the turn on. That will reduce switching loss and reduce possible EMI problems. It all looks splendid, and I can see no real way of adding to your very well thought through plans. Well done Mike. Cheers, Tony. |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

That is interesting, I would have assumed that the only legal requirement was to retain the high limit Energy Cut off (ECO) in series with the element. Perhaps it is because they are built in to a lot of thermostats. I'm confused, no wait... maybe I'm not... |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

It has to be a mechanical thermo-cutoff switch in series with the power to the element; one cannot use an external relay connected to an electronic sensor as the primary cutoff. Guess they dont want the risk of electronic or solid state switches failing and never turning off. see Exploding HWC |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

The thermo cutoff switch is the bit with the reset button with the fixed temperature trigger, its not the thermostat, you can still regulate the temperature below that point how you see fit, at least you can in Oz. It is possible to buy them as an individual item, I have retrofitted some to old HWS. The biggest problem I have with hot water is judging how much the client needs and when they need it. Water used first thing in the morning after a cold night is the hardest to cater for. On some systems we have fitted a preheat tank to stop cold water mixing in the evening on others we have installed instant gas and used bottled LPG because their use pattern is not regular. I think the idea has merit for the remote building but for the offgrid house I wonder if something that adds to the AC capacity might give you some extra flexibility. I'm confused, no wait... maybe I'm not... |

||||

| hotwater Senior Member Joined: 29/08/2017 Location: United StatesPosts: 120 |

I have been heating water for years with excess PV. I have only 36V PV array feeding a capacitor bank. For some this can be considered a low voltage system. The secret is using inexpensive 120V 2,000W heater elements too bad for those in 240V land. I have two small tanks in series so one is pretty easy to heat up quickly. As said before, I use a fixed voltage set point as it is mostly used in a single season. In a dedicated system you can occasionally shut off and use a % of the open circuit voltage as determined by experience. The programming is simple enough for a 15 year old to do it. The UNO/NANO have six PWM outputs that drive each heating element. The A/D converter reads the voltage and either increments or decrements a counter. Only one heating element is PWMed at one time, the others are fully on or off. This greatly reduced the capacitor bank size by limiting the pulse current. I do pure pulsed DC. Mechanical switches do not like DC over 30V. 50V is a little iffy, but it should only open in an emergency as temperature control is electronic. I use 122Hz and use a simple opto isolator driver for the FET. Optos are slow and you just don't get switching noise. In software I prevent short pulses and the slow speed causes no FET heating. This also allows the controller to be many feet away from the tank. Again, my system only operates on PV power that would be wasted. Typically that is about 2,500WH a day from my 900W array after providing refrigeration and everything else. Only have about 5 days a season when I have to forgo hot water. I noticed a while back there was an AU company that appeared to offer a chopper system for hot water. I asked some detailed questions and the sales person told me a bunch of bogus stuff and then stopped responding. Everything I've read says that the price point between PV and evacuated tubes is about $1.50US a watt. That is way in the rear view mirror now. All I can say is I love the system and easily have 120F water by 10am. |

||||

| hotwater Senior Member Joined: 29/08/2017 Location: United StatesPosts: 120 |

Everyone uses hot water and is wasting energy that could be harvested/stored. You would think this would be a popular topic, but I have never seen interest in it over the years. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Solar hot water heating systems were more popular here in NZ 10 - 15 years ago but have mostly disappeared today, there used to be a plethora of manufactures building them, most have gone belly up, many were cowboys using shoddy construction methods and installation, which meant their systems didn't last and rapidly fell into a non-working state. Today those that are still in business with better quality products are very expensive, so coupled with the fact that the average Kiwi moves house every 7 years means installing a solar HWC setup isn't cost effective for the purchaser, by the time the system is breaking even the owner has moved to another property. With the rising percentage of rental properties here in NZ there is no incentive for landlords to install these as they are not a tax deductible item, so none are installed. Council fees to install can be very high, many new property sub divisions have covenants preventing their installation for aesthetic reasons, PV also included in this. So for the potential home owner wanting to do the right thing, there are too many hoops to jump through and its not worth it. Basically this means if you can DIY build your own, and to hell what the neighbours think then its cost effective. Cheers Mike |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

Solar hot water is very popular in at least the part of Australia where I live. There have been government rebates on them as well which has helped. Solar hot water is a big part of a households energy use and as we get more and more focus on climate change and renewable energy solar hot water heating will be used more and more. Recently in the news here we heard about a steelmaker converting to solar power. A certain former prime minister said you can't make steel with renewable energy. But this company is doing it purely for economic reasons, they have worked out it is cheaper to make the power themselves. Although they will still use grid power depending on the weather they will be a net exporter of power. I have a solar hot water system that works well and is also connected to my off-grid power. When the charge controller determines that there is power not being used it turns on the heater element in the HWS. Most days it comes on around 11 AM and within about 1 hour the thermostat opens. It has a 320l tank and we can go 3 days of really cloudy weather before needing to use mains power to heat the water. This only happens a few times a year. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

With our current govt, there are no rebates on anything energy related, solar, PV etc, so the take up is minimal. We have just had an election, anyone's guess however what the result will be, so I hope perhaps in vain for a change in stance from our current elected politicians .... |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

If they have signed the Paris Agreement something will have to happen. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Finally fleshed out some more detail of the circuit design. Just have to write some software on a breadboard test chip and to make sure the CPU hardware will do what I want. Have had to rethink and make some changes around the original H-Bridge HPWM switching, now am not using the inbuilt HPWM controller as it doesn't allow independent timing and pulse width of both HH and HL outputs, instead will run the chip at 32Mhz and use a timed PWM 1000Hz interrupt to allow independent timing of the upper and lower switching. Upper AHin/BHin will switch at 50 Hz or 10ms per side (less work for the bootstrap caps), the lower ALin/BLin will be switched at a independent variable rate determined by the time to charge then discharge the main 400V low esr cap, the values given will discharge in approx 1.5ms, charge 2ms so in each 10ms half cycle there will be several lower cycles. These will vary according to the amount of sun hitting the PV array; the cpu can measure the capacitor voltage to determined the limits to switch at. Using the 1-wire DS18B20 also stuffs up the internal clock frequency by switching back to 4 Mhz, so the HWC temperatue will be measured say once a minute with the Bridge turned off for 1 second. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

... yes there is an error in the cct around UI/Q1, sorry no beer for those that spot it. Cheers Mike |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

'VS' not connected to source? Klaus |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Yep, only noticed it after posting. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Have played around with various software and can confirm the Picaxe running at 32Mhz will do what I want; the upper bridge switches at 50hz whilst the bottom legs switch at an independent faster frequency determined by the time to charge and discharge the capacitor around the panel mppt voltage. Have decided to use the 20 pin variant so an LDC display, alarm outputs and some touch sensors can be added for setting up the voltage switch points. Next step is design a pcb. Cheers Mike |

||||

| Ralph2k6 Senior Member Joined: 24/09/2017 Location: AustraliaPosts: 129 |

Looks impressive mike, I've been following this with interest. Looks more complex than I would have initially expected, but worth if for the polarity reversal to prevent the electrolysis you'd mentioned earlier. Ralph |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

Attempting to keep the design as simple as possible whilst maintaining the wanted functionality isn't always easy. In fact I think really two capacitors would give better power transfer, when one was discharging the other would be charging up, but that will make things more complicated. Any suggestions for improvement are welcome... Mike |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1138 |

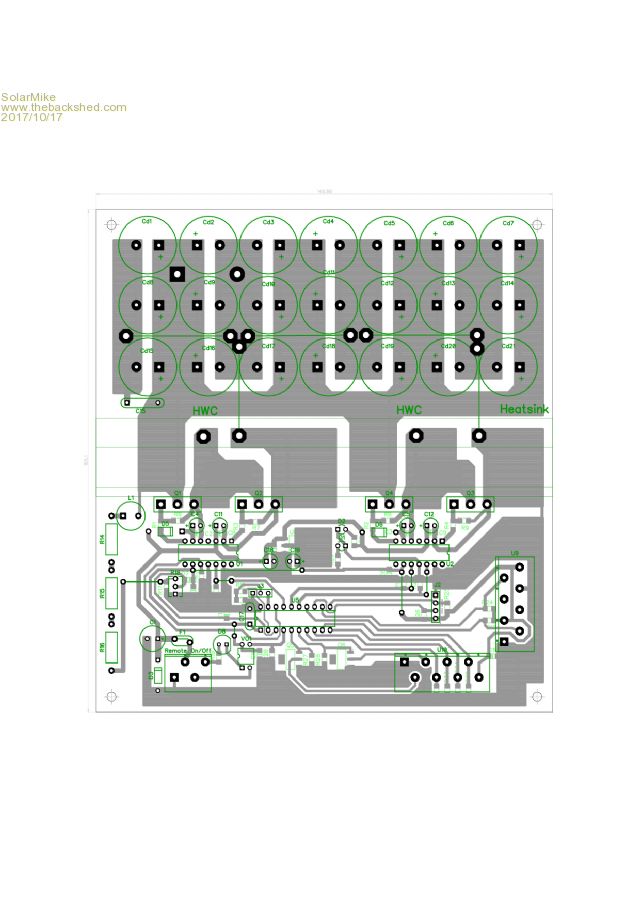

PCB designed (165mm x 150mm), have allowed for 21 x 100uf or 150uf 450 volt caps in parallel to get the required total discharge current rating. Done as a single layer PCB for testing purposes, with several heavy duty jumber wires linking the caps and a few jumpers elsewhere. Altered the bridge switching, so bottom halves now switch at 50Hz to keep the bootstrap caps charged up, top halves are modulated to switch at a rate as determind by the mppt panel voltage window on the capacitors, this varies with panel output under differing sunlight and temperature, if the panel output is weak the top half switching may be very slow, if full sunlight will be at several hundred Hz. Have to build it up and do some tests on an old elctric jug and a big power supply; will be interesting to see if the AC squarewave transitions allow the normal thermostat to work without undue arcing and contact destruction.  Cheers Mike |

||||

| Page 1 of 3 |

|||||